Content Menu

● Introduction to Hot Melt Extrusion

>> Hot Melt Extrusion Equipment

● Latest Innovations in Hot Melt Extrusion

>> 1. Advancements in Process Analytical Technology (PAT)

>> 2. Integration with Additive Manufacturing

>> 3. Continuous Manufacturing

>> 4. Novel Applications

>> 5. Advancements in Hot Melt Extrusion Equipment

● Conclusion

● FAQ

>> 1. What is Hot Melt Extrusion (HME)?

>> 2. What are the types of hot melt extrusion equipment?

>> 3. How does HME improve drug solubility?

>> 4. What are the advantages of continuous manufacturing in HME?

>> 5. How is HME integrated with additive manufacturing?

● Citations:

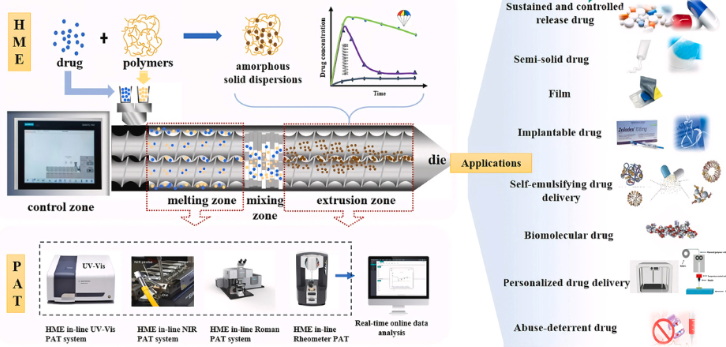

Hot melt extrusion (HME) has emerged as a pivotal technology in the pharmaceutical industry, offering a solvent-free, continuous process for producing various drug delivery systems. This technology has gained significant attention due to its ability to enhance the solubility and bioavailability of poorly soluble drugs, develop abuse-deterrent formulations, and create customized drug delivery systems. In this article, we will explore the latest innovations in hot melt extrusion technology, including advancements in equipment, applications, and process analytical technologies.

Introduction to Hot Melt Extrusion

Hot melt extrusion is a process that involves mixing drugs and polymers in a molten state and extruding them through a die to form products with specific shapes and properties. This technology is widely used for producing amorphous solid dispersions, which improve the dissolution rate and bioavailability of poorly water-soluble drugs.

Hot Melt Extrusion Equipment

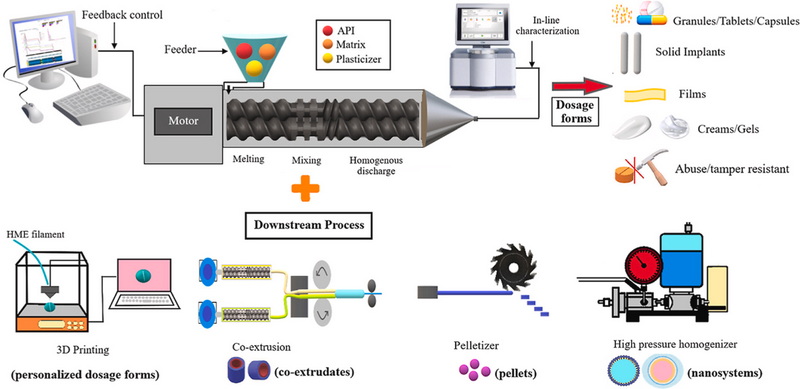

The core of HME technology lies in the extruder itself. There are primarily two types of extruders used in HME: single-screw and twin-screw extruders.

- Single-Screw Extruders: These are simpler and primarily used for melting and conveying polymers. However, they have limited mixing capabilities compared to twin-screw extruders.

- Twin-Screw Extruders: These are more complex and offer better mixing capabilities, making them ideal for pharmaceutical applications where uniform distribution of APIs is crucial. Twin-screw extruders can be co-rotating or counter-rotating, with co-rotating being more common in pharmaceutical applications due to their ability to provide consistent mixing and temperature control.

Latest Innovations in Hot Melt Extrusion

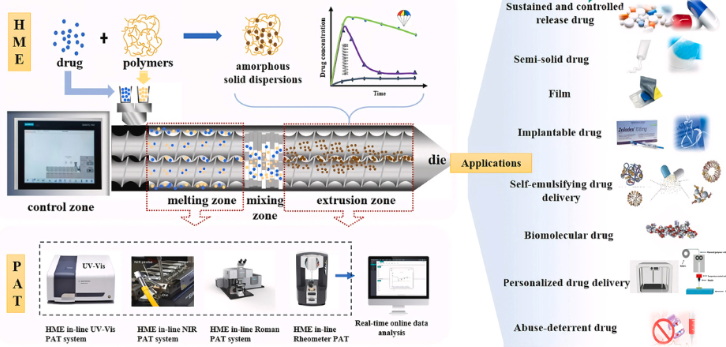

1. Advancements in Process Analytical Technology (PAT)

Process analytical technology plays a crucial role in ensuring the quality and consistency of products manufactured using HME. Recent innovations include the integration of real-time monitoring tools such as near-infrared spectroscopy (NIR), Raman spectroscopy, and UV/visible spectrophotometry. These tools enable real-time analysis and immediate process control, ensuring that the final product meets the desired specifications.

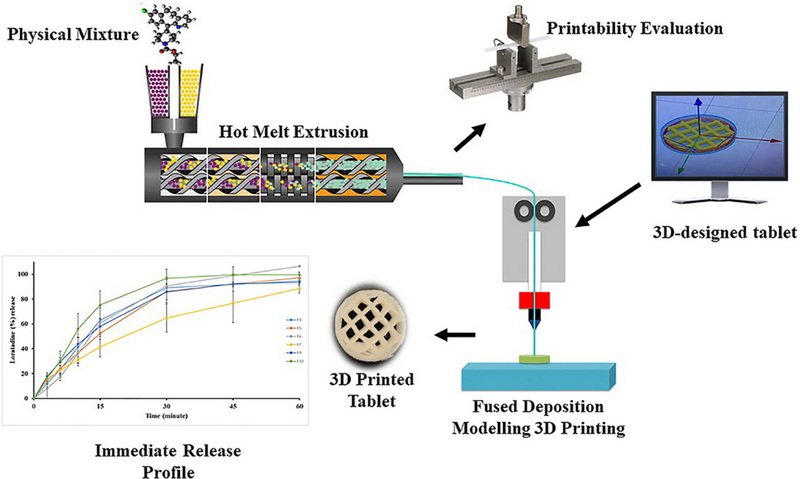

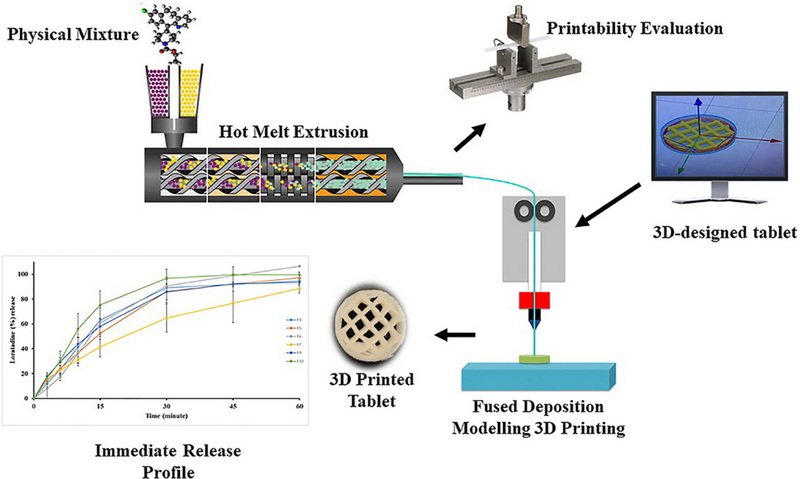

2. Integration with Additive Manufacturing

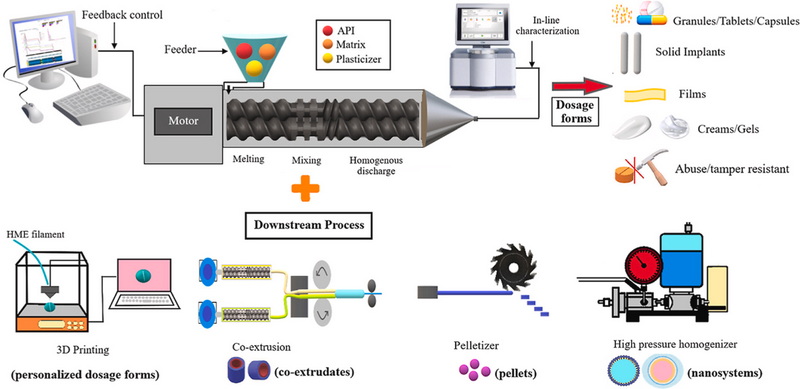

HME can be coupled with additive manufacturing techniques like 3D printing to create patient-centric dosage forms. This integration allows for the production of complex geometries and customized drug release profiles, offering personalized medicine solutions.

3. Continuous Manufacturing

HME is well-suited for continuous manufacturing, which offers advantages such as reduced production time, improved product uniformity, and easier scalability. Continuous manufacturing integrates well with PAT tools, allowing for real-time monitoring and control of the process.

4. Novel Applications

Recent innovations have expanded the applications of HME beyond traditional solid oral dosage forms. It is now used in developing novel drug delivery systems such as self-emulsifying drug delivery systems, chronotherapeutic systems, and drug-eluting implants.

5. Advancements in Hot Melt Extrusion Equipment

Modern hot melt extrusion equipment is designed to be more efficient, scalable, and user-friendly. Innovations include improved screw designs, enhanced temperature control systems, and integrated PAT tools for real-time monitoring.

Conclusion

Hot melt extrusion technology has evolved significantly over the years, offering a versatile platform for pharmaceutical manufacturing. Its ability to enhance drug solubility, bioavailability, and create customized drug delivery systems makes it a crucial tool in the pharmaceutical industry. As innovations continue to emerge, HME is poised to play an even more significant role in shaping the future of drug development and manufacturing.

FAQ

1. What is Hot Melt Extrusion (HME)?

Hot melt extrusion is a solvent-free, continuous process used to mix drugs and polymers in a molten state and extrude them into specific shapes, enhancing drug solubility and bioavailability.

2. What are the types of hot melt extrusion equipment?

The primary types of HME equipment are single-screw and twin-screw extruders. Twin-screw extruders are more commonly used in pharmaceutical applications due to their superior mixing capabilities.

3. How does HME improve drug solubility?

HME improves drug solubility by creating amorphous solid dispersions, where the drug is dispersed at a molecular level within a polymer matrix, enhancing its dissolution rate and bioavailability.

4. What are the advantages of continuous manufacturing in HME?

Continuous manufacturing in HME offers reduced production time, improved product uniformity, easier scalability, and integration with process analytical technologies for real-time monitoring and control.

5. How is HME integrated with additive manufacturing?

HME can be integrated with additive manufacturing techniques like 3D printing to produce patient-centric dosage forms with complex geometries and customized drug release profiles.

Citations:

[1] https://www.mdpi.com/journal/pharmaceutics/special_issues/W728O4A688

[2] https://pmc.ncbi.nlm.nih.gov/articles/PMC6791722/

[3] https://www.ijrti.org/papers/IJRTI2407027.pdf

[4] https://www.fitzpatrick-mpt.com/news-and-events/how-to-mill-hot-melt-extrusion-without-destroying-product-quality

[5] https://www.youtube.com/watch?v=TDIkcyNmm5U

[6] https://compoundingextruder.com/pharma-hot-melt-extruder/

[7] https://japsonline.com/admin/php/uploads/3415_pdf.pdf

[8] https://agnopharma.com/technical-briefs/hot-melt-extrusion/

[9] https://www.lonza.com/knowledge-center/smallmolecules/brief/hot-melt-extrusion-technology

[10] https://www.pharmaexcipients.com/news/hme-recent-pharmaceutical-advances/

[11] https://www.youtube.com/watch?v=6B5pb2qJhLo

[12] https://www.youtube.com/watch?v=yaLxzoPtzDQ

[13] https://ascendiacdmo.com/hot-melt-extrusion-formulation-manufacturing

[14] https://www.linkedin.com/pulse/review-article-hot-melt-extrusion-hme-pharmaceutical-mohanned-jallad-iwh1e

[15] https://www.thermofisher.com/hk/zt/home/industrial/manufacturing-processing/improving-pharmaceutical-biotech-manufacturing-processes-production-methods/technologies/hot-melt-extrusion.html

[16] https://www.bioduro.com/services-solutions/drug-product/formulation-analytical-and-process-development/hot-melt-extrusion.html

[17] https://dergipark.org.tr/en/download/article-file/1857558

[18] https://www.linkedin.com/pulse/pharmaceutical-hot-melt-extrusion-equipment-c59ee/

[19] https://www.linkedin.com/pulse/pharmaceutical-hot-melt-extrusion-equipment-qrj2e/

[20] https://www.benthamscience.com/article/111360

[21] https://www.youtube.com/watch?v=Yd8usL1VYMY

[22] https://www.youtube.com/watch?v=fb6B3xOT-tw

[23] https://www.youtube.com/watch?v=b3xFQqA48BQ

[24] https://www.azolifesciences.com/article/Hot-Melt-Extrusion-in-the-Pharmaceutical-and-Food-Industries.aspx

[25] https://www.youtube.com/watch?v=lEtZbgwtIOw

[26] https://www.youtube.com/watch?v=3ircaxO591I