Content Menu

● Introduction

● Advantages of T-Slot Aluminum Extrusions

>> Versatility

>> Lightweight and Durable

>> Cost-Effectiveness

● Applications of T-Slot Aluminum Extrusions

>> Industrial Automation

>> Custom Workstations

>> Safety Guarding Solutions

● Best Practices for Designing with T-Slot Aluminum Extrusions

>> Planning Your Design

>> Assembly Techniques

>> Maintenance and Upgrades

● Conclusion

● Related Questions

>> 1. What materials are commonly used in T-slot aluminum extrusions?

>> 2. Can T-slot aluminum extrusions be used outdoors?

>> 3. How do I determine the load capacity of my T-slot aluminum structure?

>> 4. Are there any specific safety considerations when assembling T-slot aluminum structures?

>> 5. How can I customize my T-slot aluminum structure?

Introduction

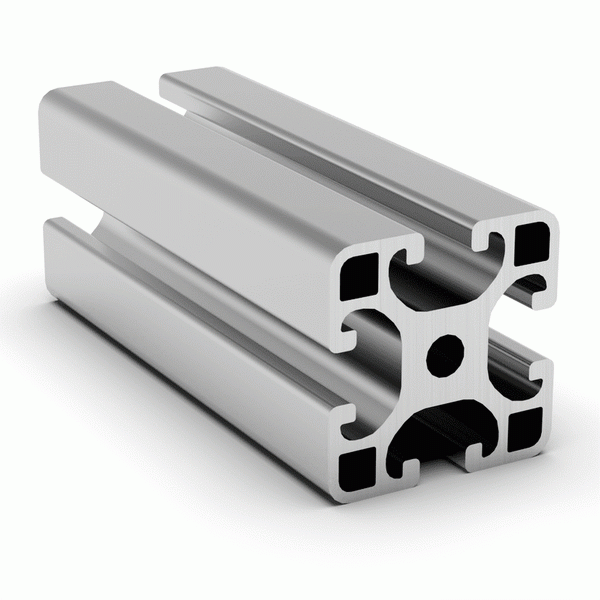

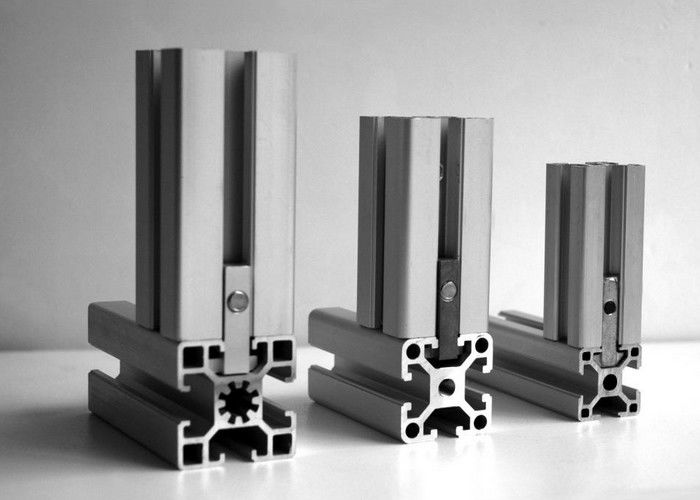

T-slot aluminum extrusions have revolutionized the way we design and build structures across various industries. Their modular nature allows for flexibility and adaptability, making them ideal for a wide range of applications, from industrial automation to custom workstations. This article will explore the best practices for assembling T-slot aluminum structures, ensuring that you can maximize the benefits of this versatile material.

Advantages of T-Slot Aluminum Extrusions

Versatility

One of the most significant advantages of T-slot aluminum extrusions is their versatility. The modular design allows for easy customization, enabling users to create structures that meet specific needs. Whether you are building a simple frame or a complex assembly, T-slot extrusions can be configured in countless ways. This adaptability is particularly beneficial in environments where requirements may change frequently.

Lightweight and Durable

Aluminum is known for its lightweight properties, which makes T-slot aluminum extrusions easy to handle and transport. Despite their lightness, aluminum structures are incredibly durable and resistant to corrosion, ensuring a long lifespan. This combination of lightweight and strength makes T-slot aluminum extrusions an excellent choice for various applications, including those that require frequent relocation or reconfiguration.

Cost-Effectiveness

Using T-slot aluminum extrusions can lead to significant cost savings. The ease of assembly reduces labor costs, as fewer specialized skills are required to put together the structures. Additionally, the ability to customize designs means that you can create solutions that are tailored to your specific needs, avoiding unnecessary expenses associated with over-engineered systems.

Applications of T-Slot Aluminum Extrusions

Industrial Automation

T-slot aluminum extrusions are widely used in industrial automation. They provide a robust framework for robotic systems, conveyor belts, and other automated processes. The modular nature of T-slot systems allows for quick adjustments and modifications, which is essential in fast-paced manufacturing environments.

Custom Workstations

Another popular application for T-slot aluminum extrusions is the creation of custom workstations. These workstations can be designed to enhance ergonomics and efficiency, tailored to the specific tasks performed by workers. By utilizing T-slot systems, companies can create flexible work environments that can be easily reconfigured as needs change.

Safety Guarding Solutions

Safety is a top priority in any industrial setting, and T-slot aluminum extrusions can be used to create effective safety guarding solutions. These structures can be designed to protect workers from moving machinery or hazardous areas, ensuring compliance with safety regulations while maintaining visibility and accessibility.

Best Practices for Designing with T-Slot Aluminum Extrusions

Planning Your Design

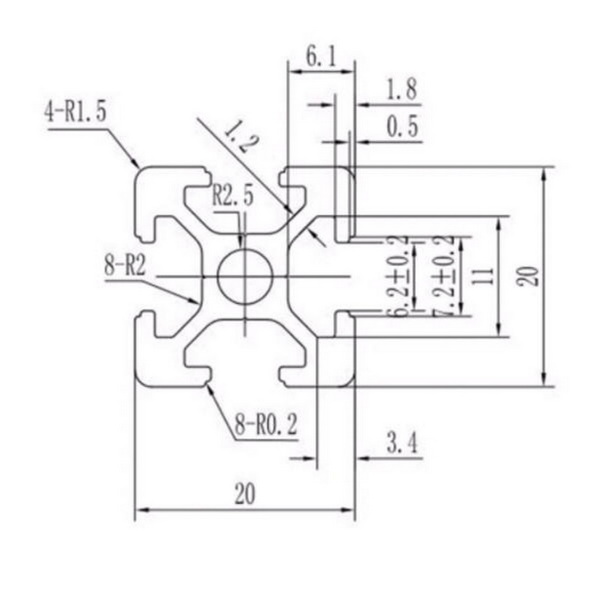

Before beginning any assembly, it is crucial to plan your design thoroughly. Consider the specific requirements of your project, including dimensions, load capacities, and intended use. Sketching out your design can help visualize the final product and identify any potential issues before assembly begins.

Assembly Techniques

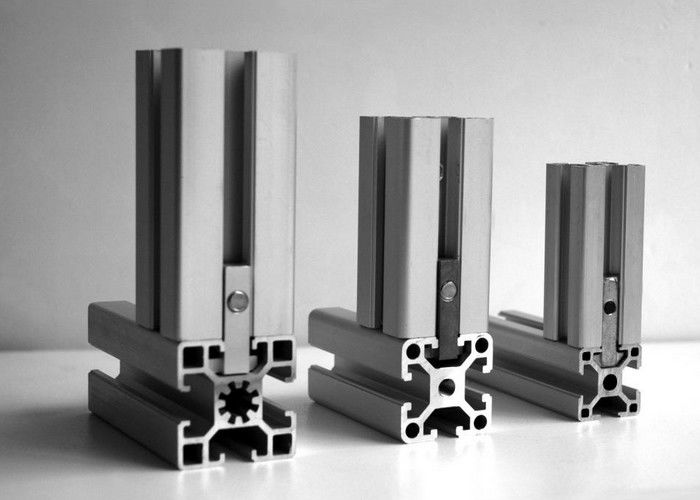

When it comes to assembling T-slot aluminum structures, there are several techniques that can enhance the process:

- Use the Right Tools: Ensure you have the appropriate tools for assembly, including T-slot nuts, bolts, and a torque wrench. Using the right tools will make the assembly process smoother and more efficient.

- Follow a Systematic Approach: Start by assembling the base of your structure, ensuring it is level and square. This foundation is critical for the stability of the entire assembly. Once the base is secure, gradually add vertical and horizontal components, checking for alignment as you go.

- Utilize Corner Brackets: Corner brackets can provide additional support and stability to your structure. They help to reinforce joints and ensure that the assembly remains square, which is essential for maintaining structural integrity.

- Incorporate Adjustable Feet: If your structure will be placed on uneven surfaces, consider using adjustable feet. These allow for fine-tuning of the height and level of your assembly, ensuring stability regardless of the floor conditions.

Maintenance and Upgrades

Regular maintenance is essential to ensure the longevity of your T-slot aluminum structures. Inspect the assembly periodically for any signs of wear or damage, and tighten any loose connections. If your needs change, T-slot systems allow for easy upgrades and modifications. You can add new components or reconfigure existing ones without the need for extensive rework.

Conclusion

Assembling T-slot aluminum structures can be a straightforward process when following best practices. By understanding the advantages of T-slot aluminum extrusions, planning your design carefully, utilizing effective assembly techniques, and maintaining your structures, you can create robust and versatile solutions for a variety of applications. The flexibility and adaptability of T-slot systems make them an invaluable resource in modern design and construction.

Related Questions

1. What materials are commonly used in T-slot aluminum extrusions?

T-slot aluminum extrusions are primarily made from aluminum alloys, which provide a balance of strength, weight, and corrosion resistance. Some extrusions may also include additional materials for specific applications, such as plastic or rubber components for seals and gaskets.

2. Can T-slot aluminum extrusions be used outdoors?

Yes, T-slot aluminum extrusions can be used outdoors, especially if they are anodized or coated to enhance their corrosion resistance. This makes them suitable for various outdoor applications, including signage, outdoor furniture, and protective barriers.

3. How do I determine the load capacity of my T-slot aluminum structure?

The load capacity of a T-slot aluminum structure depends on several factors, including the size and thickness of the extrusions, the design of the assembly, and the type of load (static or dynamic). It is essential to consult manufacturer specifications and guidelines to ensure your design meets safety standards.

4. Are there any specific safety considerations when assembling T-slot aluminum structures?

When assembling T-slot aluminum structures, it is important to wear appropriate personal protective equipment (PPE), such as gloves and safety glasses. Additionally, ensure that the assembly area is clear of hazards and that all tools are in good working condition to prevent accidents.

5. How can I customize my T-slot aluminum structure?

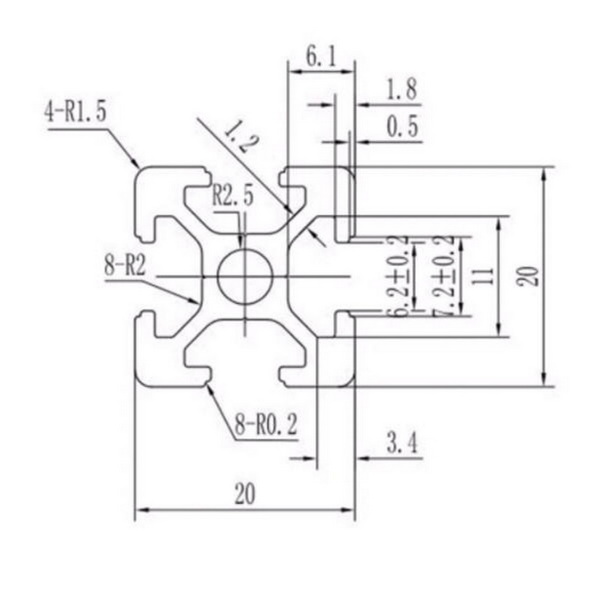

Customization of T-slot aluminum structures can be achieved by selecting different extrusion profiles, incorporating various accessories (such as brackets and connectors), and designing unique layouts that meet your specific needs. Many manufacturers offer a range of options to help you create the perfect solution for your project.