Content Menu

● Introduction

● Understanding 20x20 Aluminum Profiles

● Benefits of Using 20x20 Aluminum Extrusions

>> Lightweight and Strong Structural Integrity

>> Corrosion Resistance and Durability

>> Versatility in Design and Application

● Common Applications of 20x20 Aluminum Extrusions

>> Use in Industrial Automation and Machine Building

>> Applications in Architectural Designs and Frameworks

>> Examples of Projects Utilizing 20x20 Aluminum Profiles

● Designing with T-Slot Aluminum Extrusions

>> Explanation of T-Slot Design and Its Advantages

>> Tips for Incorporating T-Slot Aluminum Extrusions in Projects

● Custom Aluminum Extrusions: Tailoring to Your Needs

>> Overview of the Customization Process for Aluminum Extrusions

>> Factors to Consider When Designing Custom Profiles

● Manufacturing Processes of Aluminum Extrusions

>> Step-by-Step Explanation of the Aluminum Extrusion Process

>> Quality Control Measures in Aluminum Extrusion Manufacturing

● Finding Reliable Aluminum Extrusion Suppliers

>> Tips for Selecting Suppliers and Manufacturers

>> Importance of CAD Models and Technical Support

● Conclusion

● Related Questions

>> 1. What are the main advantages of using T-slot aluminum extrusions?

>> 2. How can I customize aluminum extrusions for my project?

>> 3. What industries commonly use 20x20 aluminum extrusions?

>> 4. How do I choose the right aluminum extrusion profile for my needs?

>> 5. What is the typical manufacturing process for aluminum extrusions?

Introduction

In the world of engineering and design, flexibility is paramount. Designers and engineers are constantly seeking materials and systems that allow for adaptability and innovation. One such solution that has gained immense popularity is T-slot aluminum extrusions. These versatile components not only provide structural integrity but also offer unparalleled design flexibility. Among the various sizes available, the 20x20 aluminum extrusion stands out as a favorite for many applications. This article delves into how T-slot aluminum extrusions, particularly the 20x20 profile, can enhance design flexibility across various industries.

Understanding 20x20 Aluminum Profiles

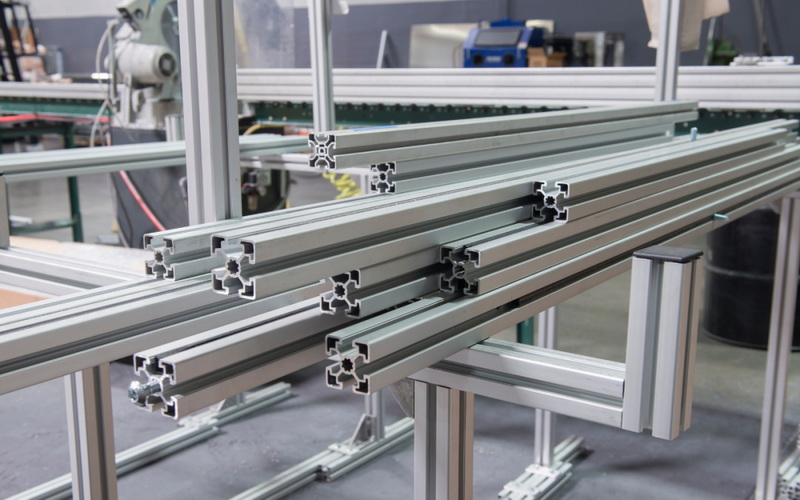

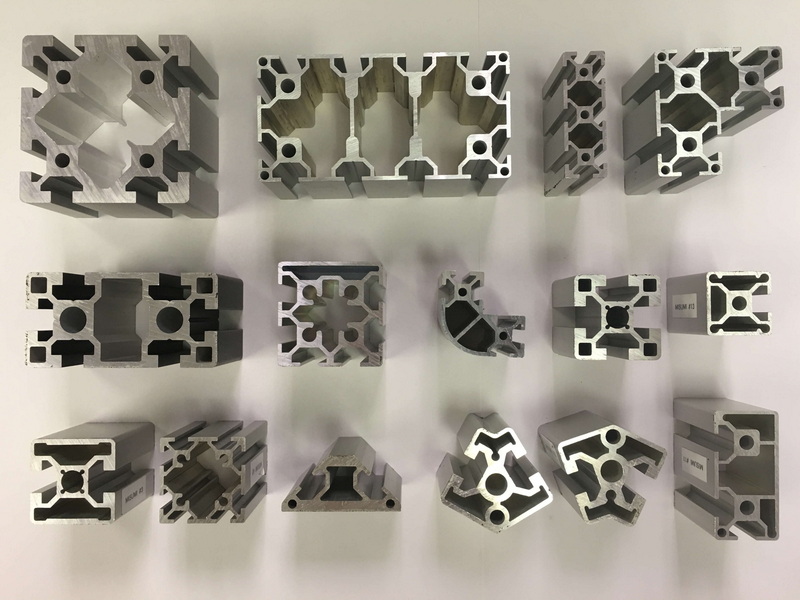

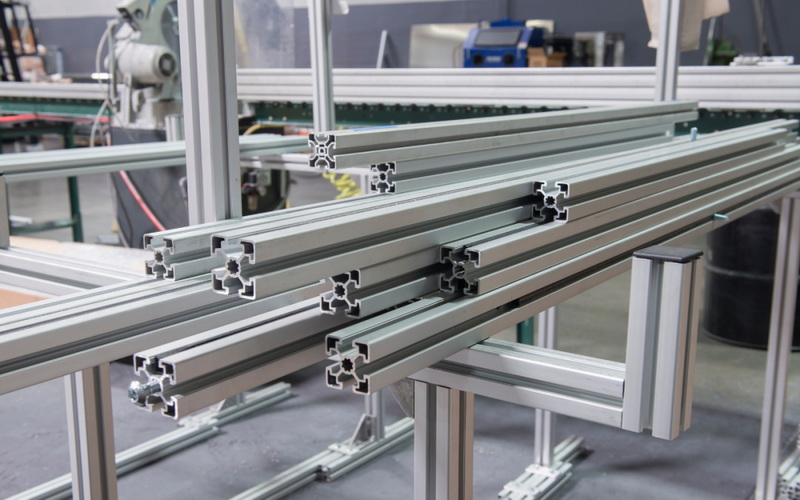

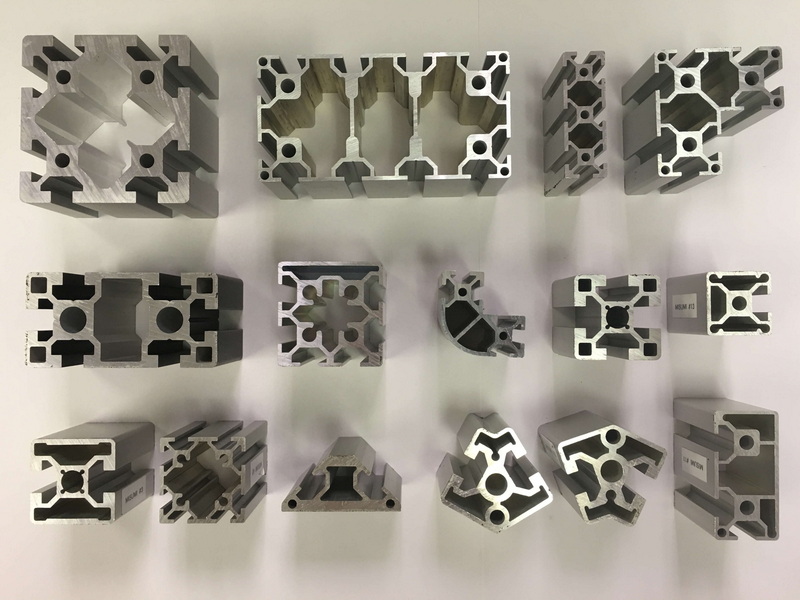

The 20x20 aluminum profile is a specific size of T-slot extrusion that measures 20mm by 20mm. This profile is characterized by its square shape and T-slot grooves on all four sides, allowing for easy attachment of other components. The design of the T-slot enables users to create complex structures without the need for welding or extensive machining. This adaptability makes the 20x20 aluminum extrusion an ideal choice for a wide range of applications, from industrial machinery to custom furniture.

Benefits of Using 20x20 Aluminum Extrusions

Lightweight and Strong Structural Integrity

One of the most significant advantages of using 20x20 aluminum extrusions is their lightweight nature combined with high strength. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal material for structures that require both durability and ease of handling. This characteristic allows designers to create robust frameworks without adding unnecessary weight, which is particularly beneficial in applications such as robotics and automation.

Corrosion Resistance and Durability

Aluminum naturally forms a protective oxide layer that makes it resistant to corrosion. This property is especially important in environments where moisture and chemicals are present. The durability of 20x20 aluminum extrusions ensures that structures remain intact and functional over time, reducing maintenance costs and extending the lifespan of the designs.

Versatility in Design and Application

The versatility of T-slot aluminum extrusions is one of their most appealing features. The 20x20 profile can be used in various applications, including:

- Industrial Automation: Creating frames for conveyor systems, workstations, and machine guards.

- Architectural Designs: Building custom displays, furniture, and partition systems.

- Robotics: Constructing lightweight and adjustable robot frames.

The ability to easily modify and reconfigure designs using 20x20 aluminum extrusions allows for rapid prototyping and iterative design processes.

Common Applications of 20x20 Aluminum Extrusions

Use in Industrial Automation and Machine Building

In industrial settings, the 20x20 aluminum extrusion is often used to construct machine frames, workstations, and safety enclosures. The T-slot design allows for easy assembly and disassembly, enabling manufacturers to adapt their setups as production needs change. This flexibility is crucial in today's fast-paced manufacturing environments, where efficiency and adaptability are key to success.

Applications in Architectural Designs and Frameworks

Architects and designers are increasingly turning to T-slot aluminum extrusions for their projects. The clean lines and modern aesthetic of the 20x20 profile make it an attractive choice for creating custom furniture, display cases, and partition walls. The ability to easily integrate lighting and other components into the design further enhances its appeal in architectural applications.

Examples of Projects Utilizing 20x20 Aluminum Profiles

Numerous projects have successfully utilized 20x20 aluminum extrusions. For instance, a company may design a modular workstation that can be easily reconfigured as team sizes change. Another example is a custom display stand for a trade show, where the lightweight nature of the aluminum allows for easy transport and setup.

Designing with T-Slot Aluminum Extrusions

Explanation of T-Slot Design and Its Advantages

The T-slot design of aluminum extrusions allows for the easy attachment of various components, such as brackets, panels, and other extrusions. This feature enables designers to create complex structures without the need for specialized tools or extensive fabrication. The ability to adjust and reposition components as needed provides a level of flexibility that is hard to achieve with traditional materials.

Tips for Incorporating T-Slot Aluminum Extrusions in Projects

When designing with T-slot aluminum extrusions, consider the following tips:

- Plan Your Design: Sketch out your design and identify where you will need to attach components. This will help you determine the number of extrusions and accessories required.

- Use CAD Software: Utilize computer-aided design (CAD) software to visualize your project and make adjustments before fabrication.

- Consider Load Requirements: Ensure that the chosen profile can support the intended load. The 20x20 aluminum extrusion is suitable for many applications, but understanding load limits is crucial.

Custom Aluminum Extrusions: Tailoring to Your Needs

Overview of the Customization Process for Aluminum Extrusions

One of the significant advantages of aluminum extrusions is the ability to customize profiles to meet specific project requirements. Manufacturers can create custom shapes and sizes based on the needs of the client. This process typically involves:

1. Design Consultation: Discussing the project requirements with the manufacturer.

2. Prototype Development: Creating a prototype to test the design.

3. Production: Once the prototype is approved, the manufacturer will produce the custom extrusions.

Factors to Consider When Designing Custom Profiles

When designing custom aluminum extrusions, consider the following factors:

- Material Thickness: Thicker profiles may provide additional strength but can also increase weight.

- Profile Shape: The shape of the extrusion can impact its performance and suitability for specific applications.

- Finishing Options: Consider whether you need anodizing, powder coating, or other finishes for aesthetic or functional purposes.

Manufacturing Processes of Aluminum Extrusions

Step-by-Step Explanation of the Aluminum Extrusion Process

The aluminum extrusion process involves several key steps:

1. Billet Preparation: Aluminum billets are heated to a specific temperature to make them malleable.

2. Extrusion: The heated billet is forced through a die to create the desired profile shape.

3. Cooling: The extruded aluminum is cooled to solidify its shape.

4. Cutting and Finishing: The extrusions are cut to length and may undergo additional finishing processes, such as anodizing or machining.

Quality Control Measures in Aluminum Extrusion Manufacturing

Quality control is essential in the aluminum extrusion process to ensure that the final product meets specifications. Manufacturers typically implement several measures, including:

- Dimensional Inspection: Checking the dimensions of the extrusions to ensure they meet design specifications.

- Material Testing: Conducting tests to verify the strength and durability of the aluminum.

- Surface Quality Checks: Inspecting the surface finish for defects or inconsistencies.

Finding Reliable Aluminum Extrusion Suppliers

Tips for Selecting Suppliers and Manufacturers

Choosing the right supplier for aluminum extrusions is crucial for the success of your project. Here are some tips to help you select a reliable manufacturer:

- Research Suppliers: Look for suppliers with a proven track record in the industry. Check reviews and testimonials from previous clients.

- Evaluate Capabilities: Ensure that the supplier can meet your specific requirements, including custom profiles and finishing options.

- Request Samples: Before placing a large order, request samples to assess the quality of the extrusions.

Importance of CAD Models and Technical Support

Many suppliers provide CAD models of their aluminum extrusions, which can be invaluable during the design process. These models allow designers to visualize how the extrusions will fit into their projects. Additionally, having access to technical support can help resolve any issues that arise during the design and fabrication process.

Conclusion

T-slot aluminum extrusions, particularly the 20x20 profile, offer remarkable design flexibility that can significantly enhance various projects across multiple industries. Their lightweight yet strong nature, corrosion resistance, and versatility make them an ideal choice for applications ranging from industrial automation to architectural designs. By understanding the benefits and applications of T-slot aluminum extrusions, designers and engineers can leverage this innovative material to create adaptable and efficient solutions.

Related Questions

1. What are the main advantages of using T-slot aluminum extrusions?

T-slot aluminum extrusions offer lightweight strength, corrosion resistance, and design versatility, making them ideal for various applications.

2. How can I customize aluminum extrusions for my project?

You can customize aluminum extrusions by consulting with manufacturers, creating prototypes, and specifying your design requirements.

3. What industries commonly use 20x20 aluminum extrusions?

Industries such as manufacturing, robotics, architecture, and furniture design commonly use 20x20 aluminum extrusions for their projects.

4. How do I choose the right aluminum extrusion profile for my needs?

Consider factors such as load requirements, design complexity, and the specific application when choosing an aluminum extrusion profile.

5. What is the typical manufacturing process for aluminum extrusions?

The manufacturing process for aluminum extrusions involves billet preparation, extrusion through a die, cooling, and cutting to length, followed by finishing processes.