Content Menu

● Introduction to Extrusion

● NPTEL's Classification of Extrusion Processes

>> Classification by Direction of Material Flow

>>> Direct (Forward) Extrusion

>>> Indirect (Backward) Extrusion

>> Classification by Temperature of Operation

>>> Hot Extrusion

>>> Cold Extrusion

>> Classification by Pressure Application and Medium

>>> Hydrostatic Extrusion

>>> Impact Extrusion

● Types of Extrusion and Extrusion Equipment NPTELNPTEL

>> Direct Extrusion Equipment

>> Indirect Extrusion Equipment

>> Hydrostatic Extrusion Equipment

>> Impact Extrusion Equipment

● Detailed Exploration of Each Extrusion Process

>> Direct Extrusion in Practice

>> Indirect Extrusion in Practice

>> Hydrostatic Extrusion in Practice

>> Impact Extrusion in Practice

● Advantages and Limitations of Different Extrusion Types

● Defects and Quality Control in Extrusion

● Applications of Extrusion Processes

● Recent Developments in Extrusion Technology

● Conclusion

● FAQ

>> 1. What are the main types of extrusion processes according to NPTEL?

>> 2. How does direct extrusion differ from indirect extrusion?

>> 3. What are the advantages of hydrostatic extrusion?

>> 4. Which extrusion process is best for producing thin-walled hollow products?

>> 5. What factors influence the choice of extrusion equipment?

Extrusion is a cornerstone process in modern manufacturing, enabling the creation of products with complex cross-sections and consistent quality. The National Programme on Technology Enhanced Learning (NPTEL) offers a thorough framework for understanding the classification of extrusion processes and the equipment used. This article explores in detail how NPTEL classifies various extrusion processes and equipment, focusing on their operational principles, advantages, disadvantages, and applications. Throughout, we will emphasize the concept of "types of extrusion and extrusion equipment nptelnptel" to provide a comprehensive understanding.

Introduction to Extrusion

Extrusion is a deformation process in which a block of material, known as a billet, is forced through a die to produce an elongated product with a uniform cross-section. This process is widely used for metals, polymers, ceramics, and even food products, but it is most prevalent in the metals industry due to the versatility and efficiency it offers.

The key advantages of extrusion include the ability to produce complex shapes, achieve excellent surface finishes, and manufacture products with consistent mechanical properties. The process can be adapted for various materials and production scales, making it a fundamental technique in sectors such as construction, automotive, aerospace, and consumer goods.

NPTEL's Classification of Extrusion Processes

NPTEL classifies extrusion processes based on several criteria, with the most significant being the direction of material flow relative to the ram, the temperature at which extrusion occurs, and the method of pressure application. Understanding these classifications is essential for selecting the right process for a given application.

Classification by Direction of Material Flow

Direct (Forward) Extrusion

In direct extrusion, the billet is placed in a container and a ram pushes it through a stationary die. The material flows in the same direction as the ram movement. This is the most common extrusion process and is suitable for a wide range of materials and profiles.

Key Features:

- High friction between the billet and container wall.

- Requires higher force due to friction.

- Capable of producing long, continuous sections.

Typical Applications:

- Structural profiles, rods, tubes, and complex cross-sections.

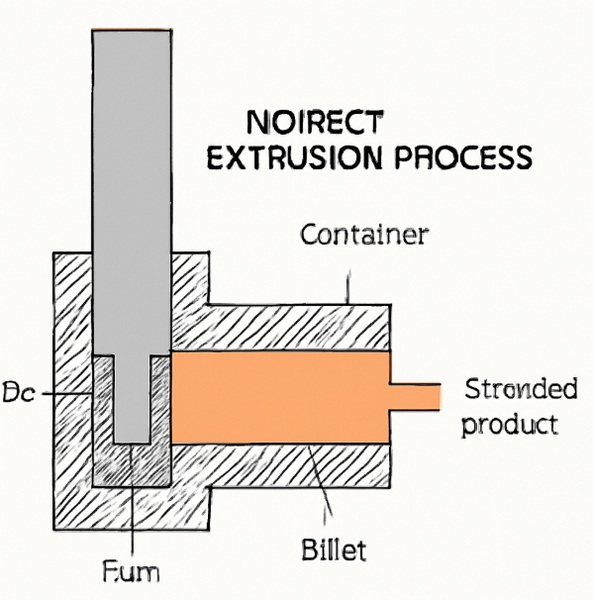

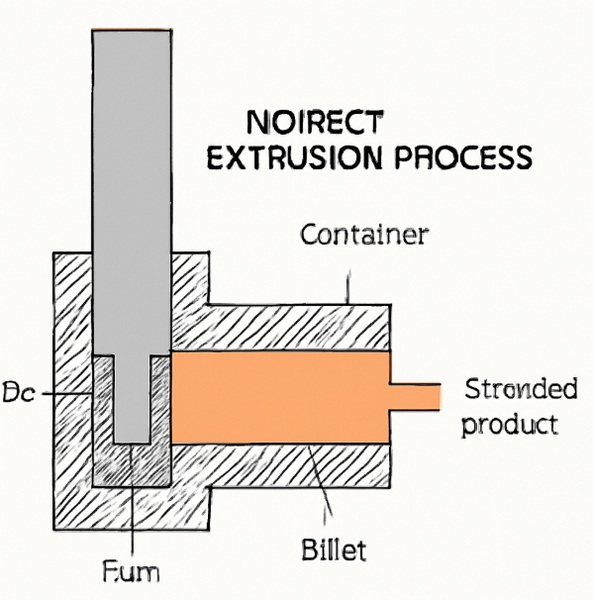

Indirect (Backward) Extrusion

In indirect extrusion, the die is mounted on the ram and moves into the stationary billet. The material flows in the opposite direction to the ram movement, which significantly reduces friction.

Key Features:

- Lower friction and extrusion force.

- Improved surface finish of extruded products.

- Limited by the complexity of supporting the hollow ram.

Typical Applications:

- Shorter extruded sections, precision parts, and applications requiring excellent surface quality.

Classification by Temperature of Operation

Hot Extrusion

Hot extrusion is performed at elevated temperatures, typically above the material's recrystallization point. This reduces the material's resistance to deformation, making it easier to extrude.

Key Features:

- Lower extrusion force required.

- Suitable for hard-to-work materials.

- Risk of oxidation and scaling.

Typical Applications:

- Aluminum, copper, magnesium, and steel products.

Cold Extrusion

Cold extrusion is conducted at or near room temperature. While it requires higher force, it offers improved mechanical properties and surface finish due to strain hardening.

Key Features:

- Enhanced surface quality.

- Improved dimensional accuracy.

- Increased strength due to work hardening.

Typical Applications:

- Fasteners, gears, and other precision components.

Classification by Pressure Application and Medium

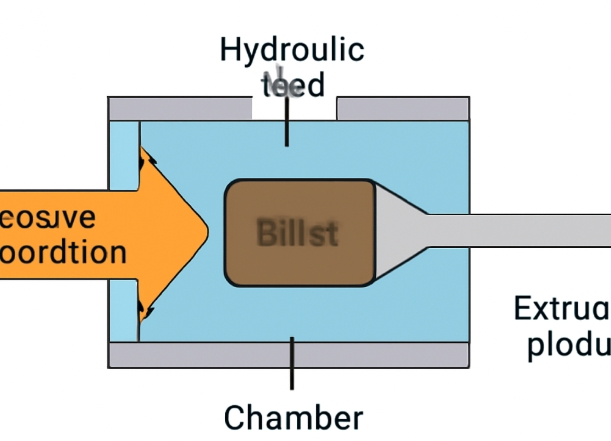

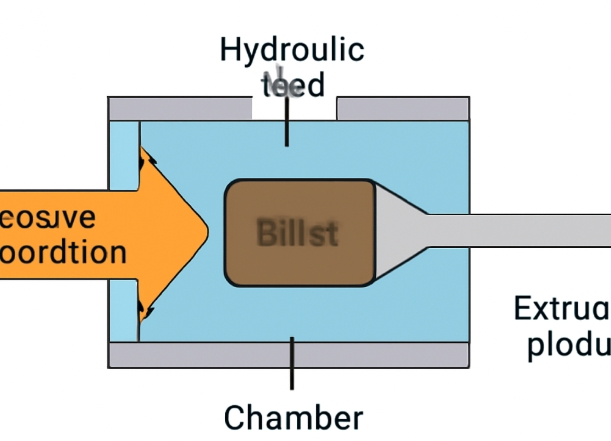

Hydrostatic Extrusion

Hydrostatic extrusion uses a fluid medium to apply pressure uniformly around the billet. This eliminates friction between the billet and the container wall, allowing for the extrusion of brittle materials.

Key Features:

- Minimal friction.

- Uniform pressure application.

- Requires specialized equipment.

Typical Applications:

- Brittle alloys, ceramics, and materials that are difficult to extrude by conventional means.

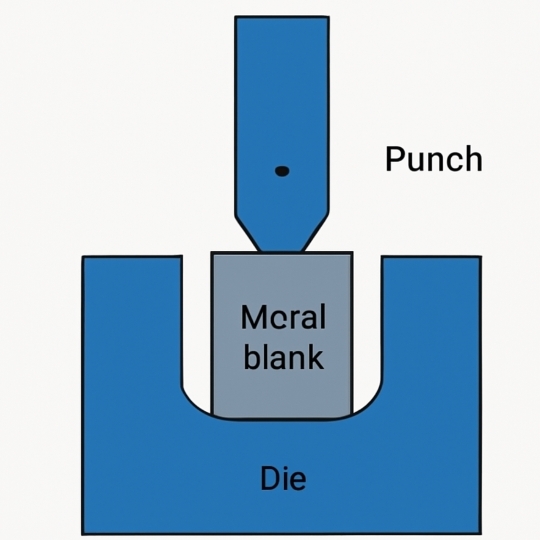

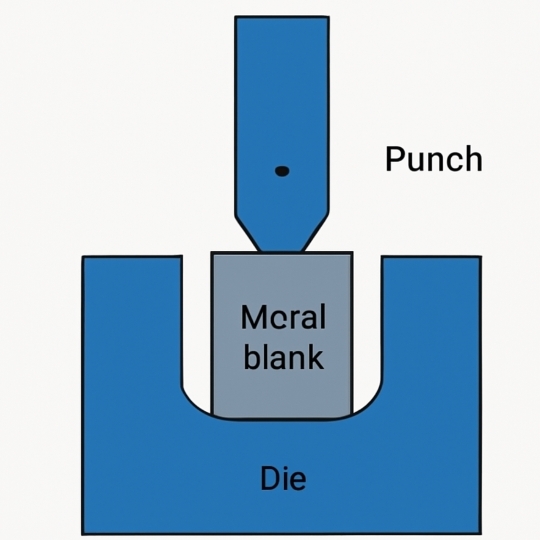

Impact Extrusion

Impact extrusion is a high-speed process where a punch strikes the billet at high velocity, forcing the material to flow rapidly into the die cavity. This process is ideal for producing thin-walled, hollow sections.

Key Features:

- High production rates.

- Suitable for soft metals.

- Limited to certain shapes and sizes.

Typical Applications:

- Collapsible tubes, cans, and lightweight containers.

Types of Extrusion and Extrusion Equipment NPTELNPTEL

NPTEL's detailed classification of extrusion processes is closely linked to the types of equipment used. Each process requires specific machinery and tooling to achieve optimal results. Here is an overview of the types of extrusion and extrusion equipment nptelnptel:

Direct Extrusion Equipment

- Extrusion Press: The main machine that applies force to the billet, typically hydraulic or mechanical.

- Container: Holds the billet during extrusion.

- Dummy Block: Placed between the billet and the ram to prevent direct contact.

- Die: Shapes the extruded product and determines its cross-section.

- Shear Blades: Used to cut off the extruded section.

Indirect Extrusion Equipment

- Hollow Ram: Allows the die to move into the stationary billet.

- Stationary Container: Holds the billet in place.

- Die Assembly: Mounted on the ram for backward movement.

- Support System: Ensures alignment and stability of the hollow ram.

Hydrostatic Extrusion Equipment

- Pressure Chamber: Contains the fluid medium and billet.

- Sealing System: Prevents fluid leakage during high-pressure operation.

- Extrusion Die: Shapes the product as the fluid pressure extrudes the billet.

- Hydraulic System: Provides the necessary pressure for extrusion.

Impact Extrusion Equipment

- High-Speed Press: Delivers rapid impact to the billet.

- Punch and Die Set: Shapes the extruded section.

- Ejector System: Removes the finished product from the die.

- Lubrication System: Reduces friction and wear during high-speed operation.

Detailed Exploration of Each Extrusion Process

Direct Extrusion in Practice

Direct extrusion is favored for its simplicity and versatility. The process typically involves heating the billet, loading it into the container, and pressing it through the die using a ram. The dummy block protects the ram from heat and wear. As the billet is forced through the die, it takes on the desired shape.

Process Steps:

1. Heating the billet (for hot extrusion).

2. Loading the billet into the container.

3. Inserting the dummy block.

4. Applying pressure via the ram.

5. Extruding the material through the die.

6. Cutting off the extruded section.

Indirect Extrusion in Practice

Indirect extrusion reduces friction by allowing the die to move into the stationary billet. This results in lower energy consumption and improved surface quality. The process is limited by the challenge of supporting the hollow ram and removing the extruded product.

Process Steps:

1. Placing the billet in the container.

2. Moving the die assembly into the billet.

3. Material flows in the opposite direction to the die movement.

4. Product is extruded and removed.

Hydrostatic Extrusion in Practice

Hydrostatic extrusion is ideal for materials that are difficult to extrude by conventional means. The fluid medium transmits pressure evenly, preventing surface defects and allowing the extrusion of brittle or hard-to-work materials.

Process Steps:

1. Placing the billet in the pressure chamber.

2. Filling the chamber with fluid.

3. Applying pressure to the fluid.

4. Billet is extruded through the die.

Impact Extrusion in Practice

Impact extrusion is widely used for producing lightweight, thin-walled containers. The process is fast and efficient, making it suitable for mass production.

Process Steps:

1. Placing a slug of material in the die cavity.

2. Striking the slug with a high-speed punch.

3. Material flows around the punch to form the desired shape.

4. Ejecting the finished product.

Advantages and Limitations of Different Extrusion Types

The main types of extrusion and extrusion equipment nptelnptel each offer unique benefits and challenges:

| Extrusion Type | Key Advantages | Main Limitations | Typical Applications |

| Direct Extrusion | Versatile, simple equipment | High friction, higher force required | Rods, tubes, complex profiles |

| Indirect Extrusion | Lower force, better surface finish | Limited length, complex machinery | Short sections, precision parts |

| Hydrostatic | Minimal friction, extrudes brittle | Specialized equipment, slow setup | Brittle alloys, ceramics |

| Impact | High speed, thin-walled products | Limited shapes, soft metals only | Tubes, cans, collapsible containers |

Defects and Quality Control in Extrusion

Despite its versatility, extrusion is susceptible to certain defects:

- Surface Cracking: Caused by excessive temperature or speed, resulting in cracks on the product surface.

- Pipe Formation: Central cavity formed due to improper material flow, often seen in direct extrusion.

- Non-uniform Extrusion: Occurs due to inconsistent temperature or pressure, leading to dimensional inaccuracies.

Quality control measures include:

- Careful temperature regulation.

- Use of appropriate lubricants.

- Regular inspection and maintenance of dies and equipment.

Applications of Extrusion Processes

Extrusion is used extensively in various industries:

- Construction: Window frames, beams, and structural profiles.

- Automotive: Chassis, engine parts, and decorative trims.

- Aerospace: Lightweight structural components.

- Electronics: Heat sinks and connectors.

- Packaging: Tubes, cans, and other containers.

The choice among the types of extrusion and extrusion equipment nptelnptel depends on the material, required shape, production volume, and mechanical properties.

Recent Developments in Extrusion Technology

Modern extrusion technology is advancing rapidly, focusing on:

- Improved die materials for greater durability and performance.

- Automation and process control for higher precision and consistency.

- Enhanced lubrication systems to reduce friction and wear.

- Hybrid extrusion processes that combine features of different types for optimized results.

These innovations are expanding the capabilities of extrusion, enabling the production of more complex and high-performance products.

Conclusion

NPTEL's classification of extrusion processes and equipment provides a comprehensive framework for understanding the diverse methods available for shaping materials through extrusion. By organizing extrusion based on direction of material flow, temperature, and pressure application, NPTEL empowers engineers and manufacturers to select the most suitable process for their needs. The types of extrusion and extrusion equipment nptelnptel discussed in this article highlight the adaptability and efficiency of extrusion in producing a wide variety of industrial products. As technology continues to evolve, extrusion processes will remain at the forefront of manufacturing innovation, driving progress across multiple industries.

FAQ

1. What are the main types of extrusion processes according to NPTEL?

NPTEL classifies extrusion processes into direct extrusion, indirect extrusion, hydrostatic extrusion, and impact extrusion. Each type is distinguished by the direction of material flow, temperature of operation, and method of pressure application.

2. How does direct extrusion differ from indirect extrusion?

In direct extrusion, the billet and ram move in the same direction, resulting in higher friction and force requirements. In indirect extrusion, the die moves into the stationary billet, reducing friction and improving surface finish, although it limits the length of the extruded product.

3. What are the advantages of hydrostatic extrusion?

Hydrostatic extrusion eliminates friction between the billet and container wall by using a fluid medium to transmit pressure. This allows extrusion of brittle materials and provides uniform pressure, resulting in better product quality and fewer surface defects.

4. Which extrusion process is best for producing thin-walled hollow products?

Impact extrusion is ideal for manufacturing thin-walled, hollow products such as tubes and cans. The high-speed punch rapidly forms the material into the desired shape, making it suitable for mass production of lightweight containers.

5. What factors influence the choice of extrusion equipment?

The choice of extrusion equipment depends on the type of material, desired product shape, production volume, and required mechanical properties. Other factors such as friction, temperature, and die complexity also play a significant role in equipment selection.