Content Menu

● Understanding Rubber Extrusion Equipment

● The Compelling Case for Used Rubber Extrusion Equipment

>> Cost Savings and Enhanced Financial Flexibility

>> Avoiding Steep Depreciation

>> Immediate Availability and Reduced Lead Times

>> Proven Reliability and Performance Data

>> Sustainability and Environmental Responsibility

>> Lower Insurance and Operating Costs

>> Wider Selection and Flexibility

● Key Considerations When Buying Used Rubber Extrusion Equipment

>> Thorough Inspection and Evaluation

>> Reviewing Maintenance and Service History

>> Assessing Compatibility and Technology

>> Availability of Spare Parts and Support

>> Evaluating Seller Reputation

● Best Practices for Purchasing Used Rubber Extrusion Equipment

● Common Pitfalls to Avoid

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of buying used rubber extrusion equipment for sale?

>> 2. How can I ensure the used rubber extrusion equipment is in good condition?

>> 3. Are there risks associated with buying used rubber extrusion equipment for sale?

>> 4. How do I find reputable sellers of used rubber extrusion equipment for sale?

>> 5. Can used rubber extrusion equipment be upgraded or refurbished?

In today's highly competitive manufacturing landscape, every investment decision can have a lasting impact on your business's efficiency, profitability, and growth potential. When it comes to expanding your production capabilities or replacing aging machinery, the choice between purchasing new equipment or seeking used rubber extrusion equipment for sale is a crucial one. While the allure of brand-new machines with the latest features is understandable, there are compelling reasons why many manufacturers choose used rubber extrusion equipment instead. This comprehensive article explores the advantages, key considerations, and best practices for buying used rubber extrusion equipment, empowering you to make the right choice for your production line.

Understanding Rubber Extrusion Equipment

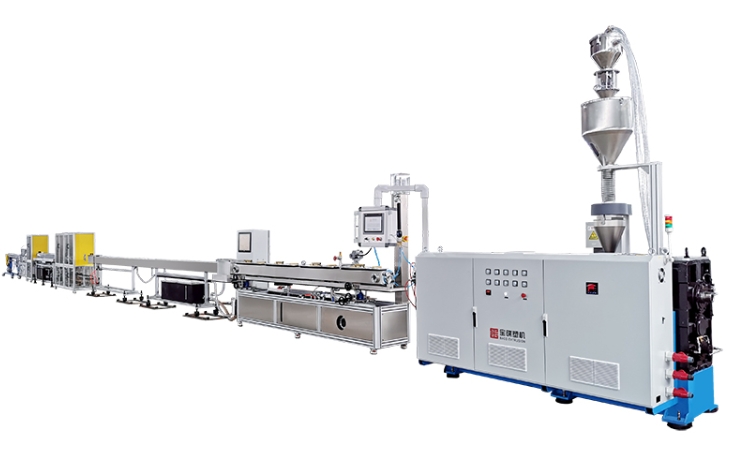

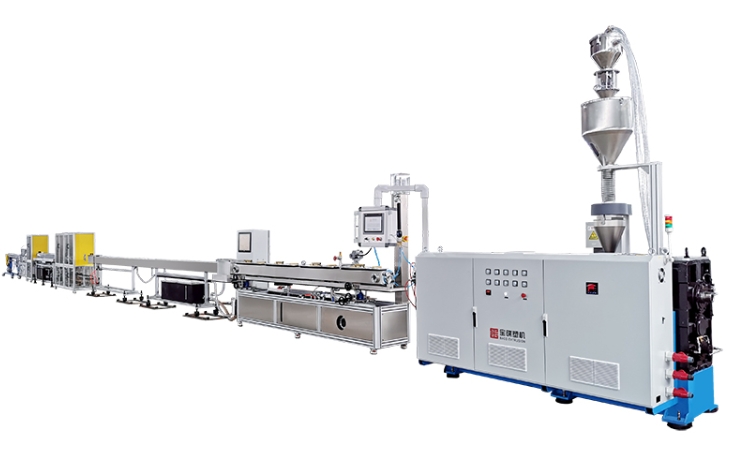

Rubber extrusion equipment is at the heart of many manufacturing operations, shaping raw rubber materials into continuous profiles such as seals, hoses, tubing, and gaskets. These machines work by forcing rubber compounds through a die, resulting in products with consistent cross-sectional shapes. The performance, reliability, and efficiency of your extrusion equipment directly influence your output, product quality, and overall operational costs.

The Compelling Case for Used Rubber Extrusion Equipment

Cost Savings and Enhanced Financial Flexibility

One of the most significant advantages of choosing used rubber extrusion equipment for sale is the considerable reduction in upfront costs. New extrusion machines often come with a hefty price tag, which can strain capital budgets, particularly for small and mid-sized manufacturers. By opting for used equipment, businesses can acquire the machinery they need at a fraction of the cost, freeing up capital for other critical investments such as raw materials, skilled labor, or facility improvements.

Lower acquisition costs also mean reduced financial risk. If a project's requirements change or if the equipment does not meet expectations, the financial impact is far less severe than with a new purchase. This flexibility can be invaluable, especially in industries where market conditions can shift rapidly.

Avoiding Steep Depreciation

All industrial equipment depreciates over time, but the most significant drop in value typically occurs within the first few years of ownership. When you purchase used rubber extrusion equipment for sale, you avoid the steepest part of the depreciation curve. This not only helps preserve your company's asset value but also means that, should you decide to resell the equipment later, you're more likely to recover a larger portion of your investment.

Immediate Availability and Reduced Lead Times

Manufacturers often face long lead times when ordering new rubber extrusion equipment. Customization, shipping, and installation can delay production for months. In contrast, used rubber extrusion equipment for sale is typically available for immediate purchase and deployment. This rapid turnaround is invaluable when replacing a failed machine or ramping up production to meet sudden demand spikes.

Proven Reliability and Performance Data

Used machines have a track record. Their performance, durability, and any recurring maintenance issues are often well-documented. By reviewing service histories and user feedback, buyers can select models known for their reliability and longevity. This is a distinct advantage over new models, which may not have enough operational data to reveal potential weaknesses or maintenance challenges.

Sustainability and Environmental Responsibility

Purchasing used rubber extrusion equipment for sale supports sustainability initiatives by extending the lifecycle of industrial machinery. Reusing equipment conserves raw materials, reduces manufacturing emissions, and prevents functional machines from ending up in landfills. For companies seeking to enhance their environmental credentials, buying used is a practical and impactful step.

Lower Insurance and Operating Costs

The lower market value of used rubber extrusion equipment translates to reduced insurance premiums. Additionally, many used machines have already undergone initial “shake-out” periods, during which early defects are identified and resolved. As a result, operational costs can be more predictable, and the risk of unexpected breakdowns is often lower than with brand-new, untested equipment.

Wider Selection and Flexibility

The secondary market for used rubber extrusion equipment for sale is vast and diverse. Buyers can choose from a wide array of makes, models, and configurations to suit specific production needs. Whether you require a machine for a specialized application or a general-purpose extruder, the used market offers flexibility that can be hard to match with new equipment, which may require long waits for custom builds or modifications.

Key Considerations When Buying Used Rubber Extrusion Equipment

Thorough Inspection and Evaluation

Before finalizing a purchase, it's essential to conduct a comprehensive inspection of the equipment. Look for signs of wear, rust, or damage. Evaluate the condition of critical components such as the screw, barrel, drive system, and control panels. A well-maintained machine will typically offer better performance and fewer issues over time.

Reviewing Maintenance and Service History

Ask for detailed maintenance records. A machine with a documented history of regular servicing and repairs is more likely to provide reliable operation. This information can also reveal recurring issues or parts that may require replacement soon.

Assessing Compatibility and Technology

Ensure that the used rubber extrusion equipment for sale is compatible with your existing production lines and meets current safety standards. Consider whether the machine's technology is up to date or if upgrades will be necessary to integrate with your plant's automation and quality control systems.

Availability of Spare Parts and Support

Older machines may present challenges in sourcing replacement parts or technical support. Research the availability of critical components and determine whether the manufacturer or third-party suppliers can provide ongoing service. This will help minimize downtime and maintain consistent production.

Evaluating Seller Reputation

Purchase from reputable dealers or platforms specializing in used industrial equipment. Reliable sellers will provide accurate descriptions, allow for inspections, and offer warranties or return policies when possible. Avoid deals that seem too good to be true or sellers who are unwilling to provide documentation or access for inspection.

Best Practices for Purchasing Used Rubber Extrusion Equipment

- Define your production requirements clearly, including output capacity, product dimensions, and material compatibility.

- Set a realistic budget, factoring in not only the purchase price but also potential refurbishment, installation, and ongoing maintenance costs.

- Arrange for a qualified technician or engineer to inspect the equipment before purchase.

- Request and review all available documentation, including manuals, service records, and compliance certificates.

- Negotiate terms that protect your interests, such as warranties, trial periods, or return options.

- Plan for installation, integration, and operator training to ensure a smooth transition.

Common Pitfalls to Avoid

- Skipping the inspection process or relying solely on seller descriptions.

- Overlooking hidden costs such as transportation, installation, or necessary upgrades.

- Ignoring the machine's maintenance history or failing to verify operational status.

- Failing to check for compatibility with existing systems or compliance with safety regulations.

- Neglecting to confirm the availability of spare parts and technical support.

Conclusion

Opting for used rubber extrusion equipment for sale over new machinery offers a host of strategic advantages for manufacturers. From substantial cost savings and immediate availability to proven reliability and sustainability, the benefits are clear. However, success in the used equipment market depends on diligent evaluation, careful planning, and partnering with reputable sellers. By following best practices and considering your production needs, you can secure equipment that drives efficiency, quality, and profitability for years to come.

Frequently Asked Questions (FAQ)

1. What are the main advantages of buying used rubber extrusion equipment for sale?

The primary benefits include significant cost savings, immediate availability, reduced depreciation, proven reliability, and environmental sustainability. Used equipment allows manufacturers to acquire high-quality machinery at a fraction of the cost of new, while also supporting eco-friendly business practices.

2. How can I ensure the used rubber extrusion equipment is in good condition?

Thoroughly inspect the machine for wear, rust, or damage. Review maintenance records to verify regular servicing and repairs. If possible, have a qualified technician assess critical components and test the equipment under operating conditions before purchase.

3. Are there risks associated with buying used rubber extrusion equipment for sale?

Potential risks include outdated technology, higher maintenance costs, limited availability of spare parts, and possible safety compliance issues. These risks can be mitigated by careful inspection, purchasing from reputable sellers, and ensuring compatibility with your production needs.

4. How do I find reputable sellers of used rubber extrusion equipment for sale?

Look for established dealers, industry-specific marketplaces, and auction platforms with positive reviews and verified track records. Networking with industry professionals and attending trade shows can also help identify trustworthy sources.

5. Can used rubber extrusion equipment be upgraded or refurbished?

Yes, many used machines can be upgraded with modern controls, safety features, or refurbished components to extend their lifespan and improve performance. Assess the cost and feasibility of upgrades before making a purchase decision.