Content Menu

● Understanding Aluminium Extrusion and Its Equipment

● The Startup Dilemma: New vs. Used Aluminium Extrusion Equipment

● Advantages of Investing in Used Aluminium Extrusion Equipment

>> Cost Efficiency

>> Faster Time to Production

>> Environmental Sustainability

>> Proven Reliability

>> Lower Depreciation

● Risks and Challenges of Used Aluminium Extrusion Equipment

>> Technical Obsolescence

>> Maintenance and Repair Costs

>> Safety and Compliance

>> Limited Manufacturer Support

>> Integration with Modern Systems

● Strategic Considerations for Startups

>> Thorough Inspection and Evaluation

>> Source from Reputable Sellers

>> Compatibility with Production Needs

>> Budget for Upgrades and Maintenance

>> Plan for Spare Parts and Technical Support

● Common Pitfalls and How to Avoid Them

● The Market for Used Aluminium Extrusion Equipment

● Real-World Success Stories

● Maintenance and Longevity: Maximizing Your Investment

● The Role of Technology in Upgrading Used Equipment

● Environmental and Economic Impact

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the key factors to consider when buying used aluminium extrusion equipment?

>> 2. How can startups ensure the safety of used aluminium extrusion equipment?

>> 3. What are the benefits of buying used aluminium extrusion equipment for startups?

>> 4. What are common mistakes to avoid when purchasing used aluminium extrusion equipment?

>> 5. Where can startups find quality used aluminium extrusion equipment?

The aluminum extrusion industry is a cornerstone for many modern sectors, powering advancements in construction, transportation, electronics, and consumer goods. For startups, breaking into this field can be both exciting and daunting, especially when it comes to making decisions about capital investments. One of the most pivotal choices is whether to purchase new or used aluminium extrusion equipment. This article provides a comprehensive exploration of the benefits, challenges, and strategic considerations involved in investing in used aluminium extrusion equipment, guiding startups toward a confident and informed decision.

Understanding Aluminium Extrusion and Its Equipment

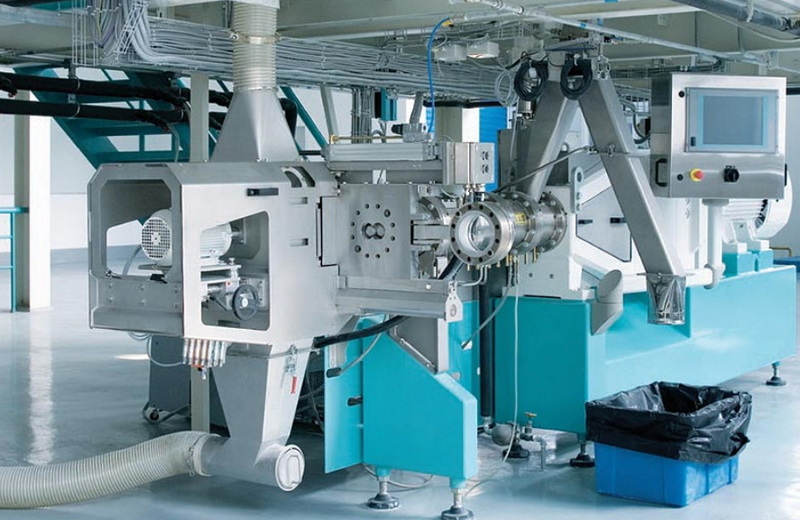

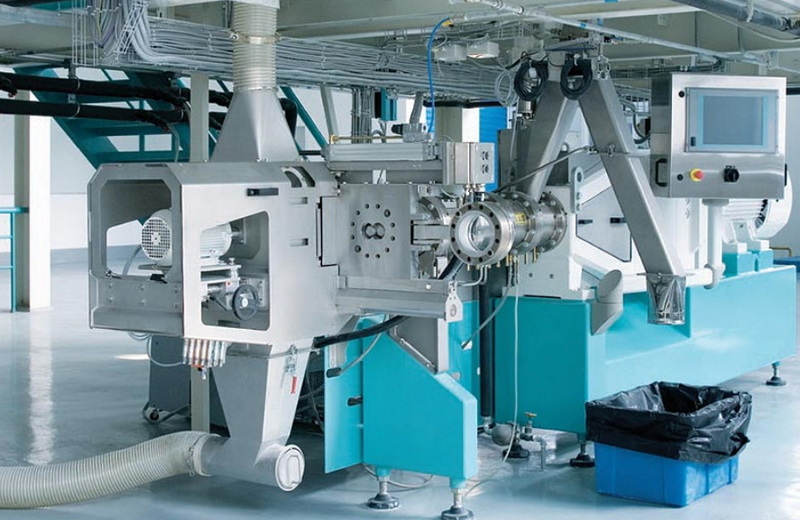

Aluminium extrusion is a manufacturing process that transforms aluminum billets into profiles with specific cross-sectional shapes by forcing the metal through a die. This process is prized for its versatility, strength-to-weight ratio, and ability to create complex shapes. The equipment required includes extrusion presses, dies, handling systems, cooling tables, pullers, stretchers, saws, and finishing machinery. The efficiency, reliability, and quality of these machines are crucial for a startup's success in the industry.

The Startup Dilemma: New vs. Used Aluminium Extrusion Equipment

Startups often face a critical question: should they invest in brand-new machinery or opt for used aluminium extrusion equipment? New equipment offers the latest technology, warranties, and manufacturer support but demands a significant financial outlay. Used aluminium extrusion equipment, conversely, can provide substantial cost savings and a faster route to production, but may come with additional risks and maintenance requirements.

Advantages of Investing in Used Aluminium Extrusion Equipment

Cost Efficiency

One of the most compelling advantages for startups is the substantial reduction in capital expenditure. Used aluminium extrusion equipment is typically available at a fraction of the price of new machinery. This allows startups to conserve cash, reduce debt, or allocate more resources to other critical areas such as raw materials, skilled labor, marketing, and business development.

Faster Time to Production

Used aluminium extrusion equipment is often available for immediate purchase and installation. Unlike new machinery, which may require months of lead time for manufacturing and delivery, used equipment can be sourced, installed, and commissioned quickly. This rapid deployment enables startups to begin operations sooner, seize market opportunities, and generate revenue faster.

Environmental Sustainability

Choosing used aluminium extrusion equipment supports the principles of the circular economy. By extending the life of existing machinery, startups help reduce waste and the environmental impact associated with manufacturing new machines. This approach aligns with the growing emphasis on sustainability and responsible resource management within the industry.

Proven Reliability

Used aluminium extrusion equipment with a solid maintenance history can offer proven reliability. Machines that have been well-maintained by previous owners are often capable of delivering consistent performance for many years. Additionally, established models may have a reputation for durability and ease of maintenance, giving startups confidence in their investment.

Lower Depreciation

New equipment depreciates rapidly in the first few years of ownership. By purchasing used aluminium extrusion equipment, startups can avoid the steepest part of the depreciation curve. This can be advantageous if the business plans to upgrade or sell the equipment in the future.

Risks and Challenges of Used Aluminium Extrusion Equipment

Technical Obsolescence

One of the main challenges is the potential for technical obsolescence. Older used aluminium extrusion equipment may lack the latest automation, control systems, energy-efficient drives, or enhanced safety features. This can limit productivity, increase operational costs, and make it harder to compete with businesses using more modern machinery.

Maintenance and Repair Costs

Used aluminium extrusion equipment may require more frequent maintenance and repairs. Wear and tear on key components can lead to unexpected breakdowns, resulting in costly downtime. Additionally, sourcing spare parts for older or discontinued models can be difficult and expensive.

Safety and Compliance

Ensuring that used aluminium extrusion equipment meets current safety standards is essential. Older machines may not comply with updated regulations, necessitating upgrades or modifications to create a safe working environment. Failing to address safety issues can expose the business to regulatory penalties and increased risk of workplace accidents.

Limited Manufacturer Support

Support from original equipment manufacturers may be limited or unavailable for older models. This can make it challenging to obtain technical documentation, troubleshooting assistance, or specialized service technicians. Startups may need to rely on third-party service providers or develop in-house expertise.

Integration with Modern Systems

Integrating used aluminium extrusion equipment with newer production management, quality control, or automation systems can be complex. Compatibility issues may arise, requiring additional investment in retrofitting or custom solutions.

Strategic Considerations for Startups

Thorough Inspection and Evaluation

Before purchasing used aluminium extrusion equipment, startups should conduct a comprehensive inspection. Evaluate the machine's overall condition, maintenance history, operational hours, and performance records. Pay special attention to critical components such as the press, hydraulic systems, electrical controls, and extrusion dies.

Source from Reputable Sellers

It is crucial to buy used aluminium extrusion equipment from reputable dealers or directly from companies with a proven track record. Research the seller's reputation, request references, and verify the equipment's provenance to avoid potential legal or operational issues. Reputable sellers often provide warranties, after-sales support, and detailed documentation.

Compatibility with Production Needs

Ensure that the used aluminium extrusion equipment matches the startup's production requirements. Consider the machine's capacity, die compatibility, ability to process specific aluminum alloys, and suitability for the intended product range. Mismatched equipment can lead to inefficiencies and compromised product quality.

Budget for Upgrades and Maintenance

Set aside a portion of the budget for potential upgrades, retrofits, or initial maintenance. Investing in updated safety features, control systems, or energy-efficient components can enhance the value and longevity of used aluminium extrusion equipment. Preventive maintenance plans should be established from day one.

Plan for Spare Parts and Technical Support

Investigate the availability of spare parts and technical support for the specific make and model. Establish relationships with third-party service providers or consider stocking critical spare parts to minimize downtime. Access to knowledgeable technicians is vital for troubleshooting and repairs.

Common Pitfalls and How to Avoid Them

- Skipping Inspection: Never purchase used aluminium extrusion equipment without a thorough inspection by a qualified technician. Look for signs of wear, corrosion, or hidden damage that could affect performance.

- Ignoring Machine History: Request detailed maintenance logs and operational records. A well-documented history indicates proper care and reduces the risk of unforeseen issues.

- Underestimating Operational Costs: Factor in ongoing expenses such as maintenance, energy consumption, and potential upgrades when calculating the total cost of ownership.

- Overlooking Safety Compliance: Ensure the equipment adheres to current safety regulations. Upgrading safety features can be an additional but necessary investment.

- Neglecting Training Needs: Older equipment may require specialized knowledge for operation and maintenance. Invest in training for staff to ensure safe and efficient use.

The Market for Used Aluminium Extrusion Equipment

The market for used aluminium extrusion equipment is vibrant and diverse. Machines can be sourced through online marketplaces, industry auctions, specialized dealers, trade shows, and networking within the industry. Startups can benefit from competitive pricing, a wide selection, and opportunities to negotiate favorable terms. However, due diligence is essential to ensure the quality and suitability of the equipment.

Real-World Success Stories

Many startups have successfully launched and scaled their operations using used aluminium extrusion equipment. By carefully selecting machines, investing in necessary upgrades, and implementing rigorous maintenance protocols, these companies have achieved operational efficiency and profitability while minimizing their initial capital outlay. These success stories demonstrate that with the right approach, used equipment can serve as a reliable foundation for business growth.

Maintenance and Longevity: Maximizing Your Investment

Regular maintenance is critical to extending the lifespan of used aluminium extrusion equipment. Implement a preventive maintenance schedule that includes inspections, lubrication, cleaning, and timely replacement of worn parts. Proper maintenance not only ensures consistent product quality but also reduces the risk of costly breakdowns and production delays.

The Role of Technology in Upgrading Used Equipment

Startups can enhance the performance of used aluminium extrusion equipment by integrating modern technology. Retrofitting machines with updated control systems, automation, and energy-efficient components can bridge the gap between older equipment and current industry standards. These upgrades can improve productivity, safety, and energy efficiency, making used equipment a viable long-term solution.

Environmental and Economic Impact

Investing in used aluminium extrusion equipment supports environmental sustainability by reducing demand for new machinery and minimizing waste. Economically, startups benefit from lower initial costs, faster return on investment, and the flexibility to allocate resources to other growth initiatives. This approach enables startups to compete effectively while contributing to a more sustainable industry.

Conclusion

For startups entering the aluminum extrusion industry, used aluminium extrusion equipment presents a compelling investment opportunity. The potential for significant cost savings, rapid deployment, and environmental benefits makes it an attractive option for businesses with limited capital. However, this approach requires careful evaluation of equipment condition, compatibility, and ongoing maintenance needs. By sourcing from reputable sellers, conducting thorough inspections, and budgeting for upgrades, startups can mitigate risks and maximize the value of their investment. Ultimately, used aluminium extrusion equipment can serve as a solid foundation for building a competitive and sustainable business in the aluminum extrusion sector.

Frequently Asked Questions (FAQ)

1. What are the key factors to consider when buying used aluminium extrusion equipment?

When purchasing used aluminium extrusion equipment, consider the machine's condition, maintenance history, compatibility with your production needs, availability of spare parts, and compliance with current safety standards. Always conduct a thorough inspection and verify the credibility of the seller.

2. How can startups ensure the safety of used aluminium extrusion equipment?

Startups should ensure that used aluminium extrusion equipment is regularly inspected and maintained. Upgrading outdated safety features and adhering to current safety regulations are essential steps to create a safe working environment.

3. What are the benefits of buying used aluminium extrusion equipment for startups?

The main benefits include lower upfront costs, faster setup times, environmental sustainability, and the ability to allocate resources to other critical business areas. Used equipment can also provide reliable performance if properly maintained.

4. What are common mistakes to avoid when purchasing used aluminium extrusion equipment?

Common mistakes include skipping equipment inspections, ignoring the machine's maintenance history, underestimating operational costs, and neglecting safety compliance. Avoid these pitfalls by conducting due diligence and planning for potential upgrades.

5. Where can startups find quality used aluminium extrusion equipment?

Startups can find quality used aluminium extrusion equipment through online marketplaces, industry-specific auctions, reputable machinery dealers, trade shows, and by networking with industry professionals.