Content Menu

● Understanding Extrusion Equipment and Its Role in Industry

● The Canadian Used Extrusion Equipment Market: An Overview

>> Key Features of the Canadian Market

● Top Reasons to Buy Used Extrusion Equipment in Canada

>> 1. Significant Cost Savings

>> 2. Immediate Availability and Reduced Lead Times

>> 3. Proven Reliability and Performance

>> 4. Sustainability and Environmental Responsibility

>> 5. Access to a Wide Range of Equipment and Brands

>> 6. Strong Regulatory Compliance and Safety Standards

>> 7. Robust Support Infrastructure

● The Buying Process: Best Practices in Canada

>> 1. Source from Reputable Dealers

>> 2. Conduct Thorough Inspections

>> 3. Verify Compliance and Compatibility

>> 4. Negotiate Clear Terms

● Advantages of Using Extrusions in Canadian Industries

● Common Challenges and How to Overcome Them

● Future Trends: Innovation and Sustainability

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main benefits of buying used extrusion equipment Canada?

>> 2. How can I ensure the quality of used extrusion equipment Canada?

>> 3. Are there risks associated with buying used extrusion equipment Canada?

>> 4. What types of extrusion equipment are commonly available in Canada?

>> 5. Why is sustainability a key factor when purchasing used extrusion equipment Canada?

The manufacturing world is constantly evolving, with companies seeking efficient, reliable, and cost-effective solutions to stay ahead of the competition. Among the most crucial assets in industries such as plastics, metals, and construction is extrusion equipment. As the costs of new machinery rise and production timelines tighten, more businesses are turning to the used equipment market to fulfill their needs without compromising on quality. In this context, Canada has emerged as a leading destination for sourcing used extrusion equipment. But what makes Canada stand out in this global marketplace? This comprehensive article explores the many reasons why purchasing used extrusion equipment Canada is a strategic move for manufacturers worldwide.

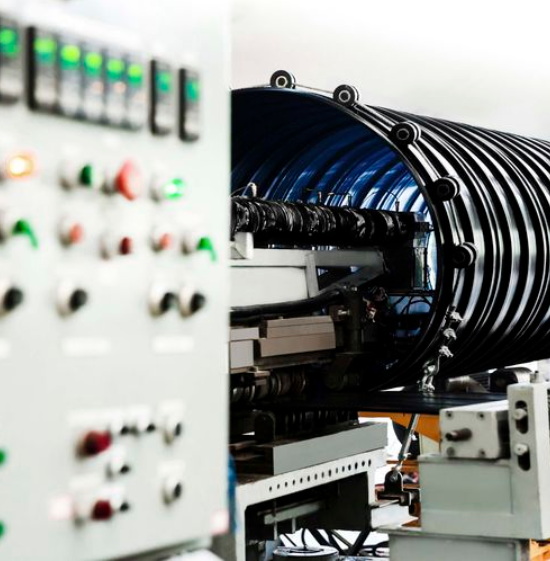

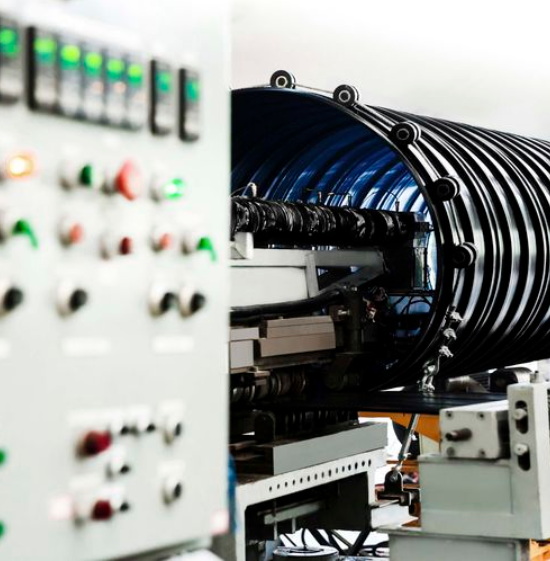

Understanding Extrusion Equipment and Its Role in Industry

Extrusion equipment is the backbone of many manufacturing processes. It enables the continuous shaping of raw materials-such as plastics, metals, or composites-into products with consistent cross-sectional profiles. These products range from pipes and window frames to sheets, films, and custom profiles used in construction, automotive, packaging, and more.

The extrusion process is prized for its efficiency, versatility, and ability to produce complex shapes with high precision. In Canada, extrusion technology is particularly significant due to the country's robust construction, automotive, and manufacturing sectors, all of which depend on high-quality extruded products to meet stringent performance and safety standards.

The Canadian Used Extrusion Equipment Market: An Overview

Canada's industrial landscape has fostered a thriving market for both new and used extrusion machinery. The nation's ongoing urbanization, population growth, and dynamic construction sector have driven demand for extruded products, which in turn fuels a vibrant secondary market for used extrusion equipment Canada. Companies frequently upgrade their production lines or adapt to changing project requirements, making a wide variety of reliable, well-maintained used machines available.

Key Features of the Canadian Market

- Diverse Industrial Applications: Canadian industries-from infrastructure and construction to packaging and automotive-require a broad spectrum of extrusion solutions.

- Stringent Quality Standards: Canadian regulations enforce high standards for safety, energy efficiency, and product performance, ensuring that even used equipment meets rigorous benchmarks.

- Emphasis on Technological Advancement: Canadian manufacturers are quick to adopt innovations, which means used extrusion equipment Canada is often equipped with advanced features or has been well-maintained to stay current.

Top Reasons to Buy Used Extrusion Equipment in Canada

1. Significant Cost Savings

One of the most compelling reasons to purchase used extrusion equipment Canada is the considerable cost advantage. Used machines are available at a fraction of the price of new units, allowing businesses to conserve capital or invest in other critical areas such as research and development or workforce training. Lower acquisition costs also translate to reduced sales tax and insurance premiums, further improving the total cost of ownership.

2. Immediate Availability and Reduced Lead Times

New extrusion equipment often comes with lengthy lead times due to manufacturing schedules, shipping, and installation. In contrast, used extrusion equipment Canada is typically available for immediate purchase and deployment. This minimizes downtime and enables companies to respond quickly to market opportunities or urgent production needs, which is especially valuable in industries with tight project timelines or unexpected equipment failures.

3. Proven Reliability and Performance

Used extrusion machines in Canada have usually been tested in real-world production environments, providing a proven track record of reliability and output quality. Buyers can access performance data, maintenance histories, and user feedback, allowing for informed decisions based on actual operational experience. This transparency reduces the risk associated with equipment purchases and increases confidence in the machine's capabilities.

4. Sustainability and Environmental Responsibility

Sustainability is an increasingly important consideration for modern manufacturers. Purchasing used extrusion equipment Canada supports the principles of a circular economy by extending the lifecycle of machinery, reducing waste, and minimizing the demand for raw materials and energy required to produce new equipment. This approach not only aligns with corporate social responsibility goals but also appeals to environmentally conscious customers and partners.

5. Access to a Wide Range of Equipment and Brands

Canada's mature used equipment market offers a broad selection, including leading global brands and specialized machinery for unique applications. Buyers can find everything from single-screw and twin-screw extruders to complete extrusion lines and downstream equipment. This diversity ensures that companies can source machines tailored to their specific production requirements, whether they are processing plastics, metals, or composites.

6. Strong Regulatory Compliance and Safety Standards

Canadian regulations mandate high safety and quality standards for industrial equipment, including used extrusion machines. As a result, used extrusion equipment Canada is more likely to comply with current safety codes and performance requirements. This reduces the risk of non-compliance penalties or operational hazards. Buyers also benefit from the expertise of Canadian dealers, who are familiar with local regulations and can provide guidance on equipment certification and installation.

7. Robust Support Infrastructure

Canada boasts a well-developed network of equipment dealers, service providers, and technical experts specializing in extrusion technology. This support ecosystem simplifies the process of inspecting, purchasing, transporting, and commissioning used machinery. Reputable dealers often offer warranties, maintenance services, and spare parts, further reducing operational risks and ensuring long-term value from the investment.

The Buying Process: Best Practices in Canada

1. Source from Reputable Dealers

Working with established dealers or brokers is essential to ensure the authenticity and quality of used extrusion equipment Canada. Trusted sellers provide detailed documentation, maintenance records, and references, giving buyers confidence in their purchase.

2. Conduct Thorough Inspections

Physical inspection of the machinery is crucial. Buyers should assess the condition of critical components such as screws, barrels, and control systems, looking for signs of wear, corrosion, or outdated technology. If an in-person visit is not feasible, reputable dealers can facilitate virtual inspections or provide comprehensive photo and video documentation.

3. Verify Compliance and Compatibility

It is important to confirm that the equipment meets Canadian safety and performance standards and is compatible with existing production lines. This includes checking electrical requirements, control interfaces, and integration with downstream equipment.

4. Negotiate Clear Terms

All agreements regarding price, payment, delivery, and after-sales support should be documented in writing to avoid misunderstandings. Buyers should clarify warranty terms, return policies, and the availability of technical support before finalizing the transaction.

Advantages of Using Extrusions in Canadian Industries

Extrusion technology is integral to the Canadian construction and manufacturing sectors for several reasons:

- Customization and Precision: Extrusion allows for the production of custom profiles tailored to specific project needs, ensuring optimal fit and function.

- Lightweight and Durable Materials: Materials like aluminum and PVC offer excellent strength-to-weight ratios, reducing transportation and installation costs while maintaining durability.

- Energy Efficiency: Extruded components, particularly in windows and doors, enhance building insulation and help meet stringent energy efficiency standards.

- Sustainability: Many extrusion materials are highly recyclable, supporting Canada's focus on sustainable construction practices.

- Cost-Effectiveness: Extrusions are relatively inexpensive to produce and install, making them a practical choice for a wide range of applications.

Common Challenges and How to Overcome Them

While the benefits of purchasing used extrusion equipment Canada are substantial, buyers should be aware of potential challenges:

- Technical Risks: Older machines may lack the latest technological advancements or require more frequent maintenance.

- Safety Concerns: Ensuring that used equipment complies with current safety regulations is essential to avoid operational hazards.

- Limited Support: Spare parts and manufacturer support may be harder to obtain for older models, so it is important to choose reputable brands and dealers.

By following best practices-such as thorough inspections, sourcing from trusted dealers, and verifying compliance-buyers can mitigate these risks and maximize the value of their investment.

Future Trends: Innovation and Sustainability

The Canadian extrusion equipment market is evolving alongside global trends. Innovations such as the integration of 3D printing with extrusion processes, the use of eco-friendly materials, and the development of advanced coatings are enhancing the performance, versatility, and sustainability of extruded products. As demand for sustainable construction and manufacturing grows, the market for used extrusion equipment Canada is expected to remain robust, offering continued opportunities for cost savings and operational efficiency.

Conclusion

Canada's reputation as a top choice for purchasing used extrusion equipment is well-earned. The country's dynamic industrial base, stringent quality standards, and robust support infrastructure create a favorable environment for buyers seeking reliable, cost-effective machinery. The benefits-ranging from significant cost savings and immediate availability to proven reliability and sustainability-make used extrusion equipment Canada an attractive option for manufacturers of all sizes. By following best practices and leveraging the expertise of Canadian dealers, buyers can secure high-quality equipment that meets their production needs while supporting long-term business growth.

Frequently Asked Questions (FAQ)

1. What are the main benefits of buying used extrusion equipment Canada?

Purchasing used extrusion equipment Canada offers substantial cost savings, immediate availability, proven reliability, and environmental benefits. Buyers also gain access to a wide variety of equipment types and brands, often with the added assurance of compliance with Canadian safety and quality standards.

2. How can I ensure the quality of used extrusion equipment Canada?

To ensure quality, work with reputable dealers, request maintenance records, conduct thorough inspections, and verify that the equipment meets current safety and performance standards. Physical or virtual inspections are highly recommended before finalizing any purchase.

3. Are there risks associated with buying used extrusion equipment Canada?

Potential risks include outdated technology, higher maintenance requirements, and limited manufacturer support for older models. These risks can be mitigated by choosing trusted sellers, verifying equipment history, and ensuring compatibility with your production needs.

4. What types of extrusion equipment are commonly available in Canada?

The Canadian market features a broad selection of used extrusion equipment, including single-screw and twin-screw extruders, complete extrusion lines, and downstream processing equipment for plastics, metals, and composites.

5. Why is sustainability a key factor when purchasing used extrusion equipment Canada?

Buying used extrusion equipment Canada supports sustainability by extending the lifecycle of machinery, reducing waste, and minimizing the consumption of raw materials and energy required for new equipment production. This aligns with growing environmental awareness and corporate responsibility goals.