Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Factors Influencing Minimum Wall Thickness

● Minimum Wall Thickness Guidelines

● Detailed Analysis of Common Aluminum Alloys

>> Alloy 3003

>> Alloy 6063

>> Alloy 6061

>> Alloy 6082

● Design Considerations for Minimum Wall Thickness

● Challenges with Thin Walls

● Testing Minimum Wall Thickness

● Applications Requiring Minimum Wall Thickness Considerations

● Conclusion

● FAQ

>> 1. What is the thinnest wall that can be extruded?

>> 2. How does profile shape affect minimum wall thickness?

>> 3. Can I specify different wall thicknesses within a single profile?

>> 4. What are common applications for thin-walled aluminum extrusions?

>> 5. How does temperature affect the extrusion process?

Aluminum extrusion is a widely used manufacturing process that allows for the creation of complex shapes and profiles from aluminum alloys. One of the critical considerations in designing aluminum extrusions is determining the minimum wall thickness required for structural integrity and functionality. This article will explore the factors influencing minimum wall thickness, provide guidelines based on different aluminum alloys, and discuss best practices in extrusion design.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum billets through a die to create a continuous profile with a specific cross-section. The process is akin to squeezing toothpaste from a tube, where the die shape defines the final product. The versatility of aluminum extrusion allows manufacturers to create various shapes, including solid, hollow, and semi-hollow profiles.

The Aluminum Extrusion Process

The extrusion process begins with heating aluminum billets to a specific temperature, usually between 400°F and 900°F (204°C to 482°C), depending on the alloy being used. Once heated, the billet is placed in an extrusion press, where it is forced through a die by a hydraulic ram. As the aluminum flows through the die, it takes on the shape of the opening, creating a continuous length of extruded material.

After extrusion, the profiles are typically cooled using air or water quenching methods. This cooling process helps set the material's properties and can influence its final strength and hardness. Following cooling, extruded profiles may undergo additional processes such as cutting, machining, or surface treatment to meet specific application requirements.

Factors Influencing Minimum Wall Thickness

Several factors determine the minimum wall thickness in aluminum extrusion:

- Alloy Type: Different aluminum alloys have varying mechanical properties and flow characteristics during extrusion. For instance, some alloys are more ductile and can be extruded into thinner walls without compromising strength.

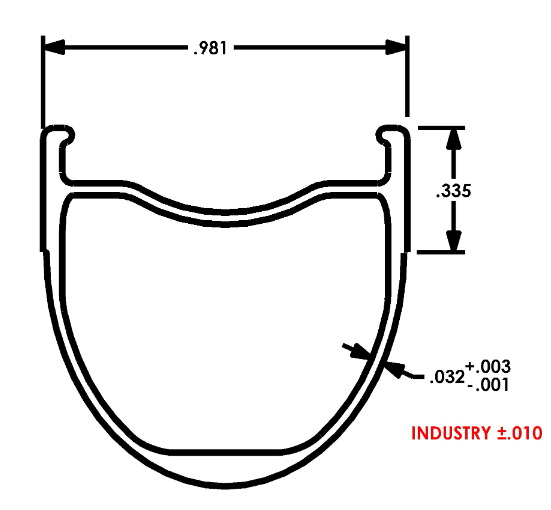

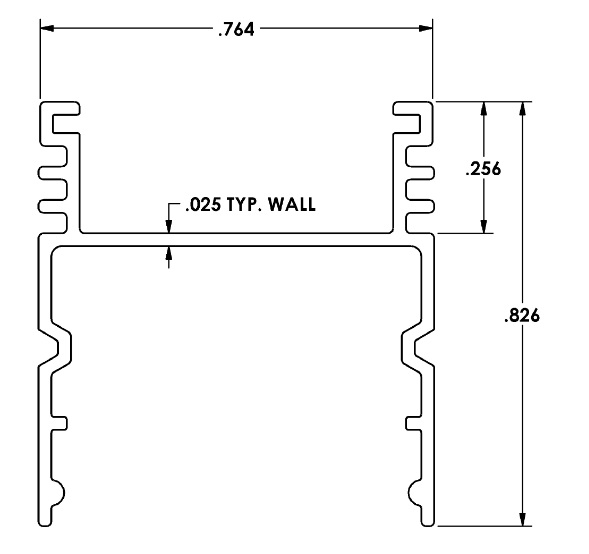

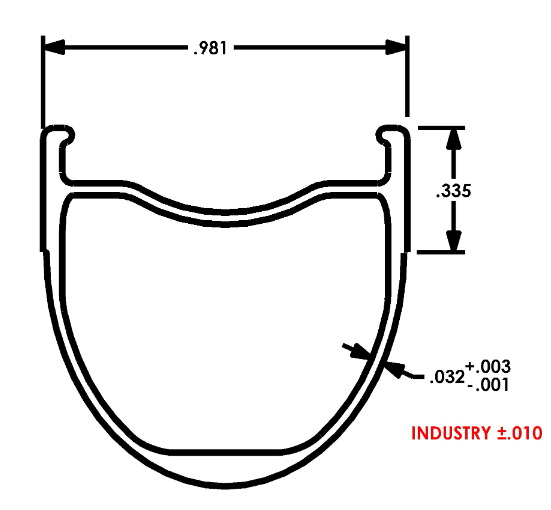

- Profile Shape: The complexity and symmetry of the profile significantly impact the ability to extrude thin walls. More intricate designs may require thicker walls to maintain structural integrity.

- Size of the Profile: Larger profiles generally necessitate thicker walls due to increased surface area and potential stresses during handling and use.

- Extrusion Conditions: Temperature, speed, and pressure during the extrusion process can affect how thin walls can be extruded without defects. Higher temperatures can allow for thinner walls but may also lead to other issues like oxidation or surface defects.

- End Use Requirements: The intended application of the extruded profile plays a significant role in determining wall thickness. Profiles used in load-bearing applications will require thicker walls compared to those used for decorative purposes.

Minimum Wall Thickness Guidelines

The following table summarizes recommended minimum wall thicknesses for various aluminum alloys based on their properties:

| Alloy | Minimum Wall Thickness (inches) |

| 3003 | 0.020 |

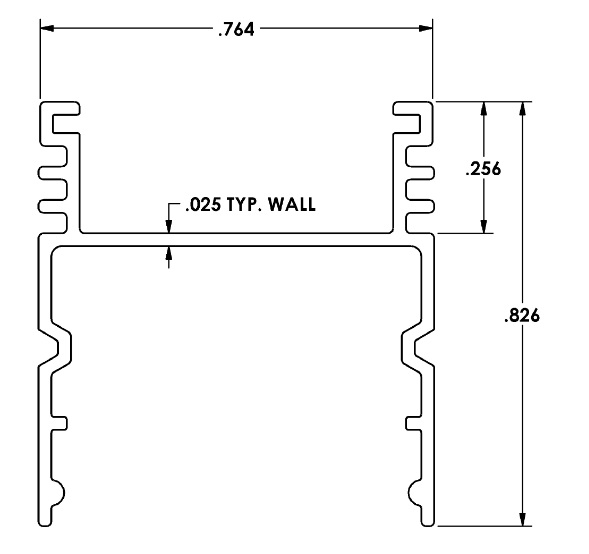

| 6063 | 0.025 |

| 6061 | 0.030 |

| 6082 | 0.200 |

These values are general guidelines and can vary based on specific design requirements and conditions.

Detailed Analysis of Common Aluminum Alloys

Alloy 3003

- Properties: Known for its excellent corrosion resistance and formability.

- Minimum Wall Thickness: As low as 0.020 inches can be extruded effectively.

- Applications: Commonly used in cooking utensils, chemical equipment, and storage tanks due to its good workability.

Alloy 6063

- Properties: Offers good extrudability and surface finish; often used in architectural applications.

- Minimum Wall Thickness: Typically starts at 0.025 inches.

- Applications: Widely used in window frames, door frames, and structural applications where aesthetic appearance is important.

Alloy 6061

- Properties: High strength and excellent corrosion resistance; more challenging to extrude than some other alloys.

- Minimum Wall Thickness: Generally requires at least 0.030 inches.

- Applications: Used in aerospace components, automotive parts, marine applications, and other industries where strength is paramount.

Alloy 6082

- Properties: Known for its high strength and good corrosion resistance.

- Minimum Wall Thickness: Minimum thickness can reach up to 0.200 inches depending on application needs.

- Applications: Ideal for structural applications requiring high strength, such as bridges or heavy machinery components.

Design Considerations for Minimum Wall Thickness

When designing an aluminum extrusion, consider the following best practices:

- Uniform Wall Thickness: Aim for uniform wall thickness throughout the profile to reduce stress on the die during production. Variations in thickness can lead to uneven cooling rates and potential warping or cracking.

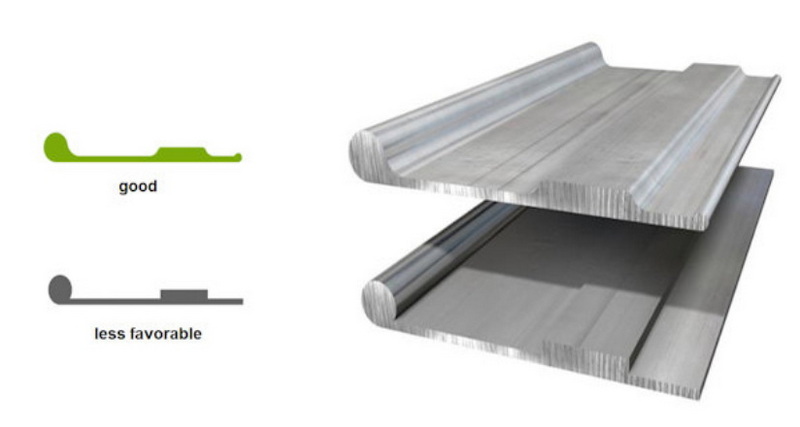

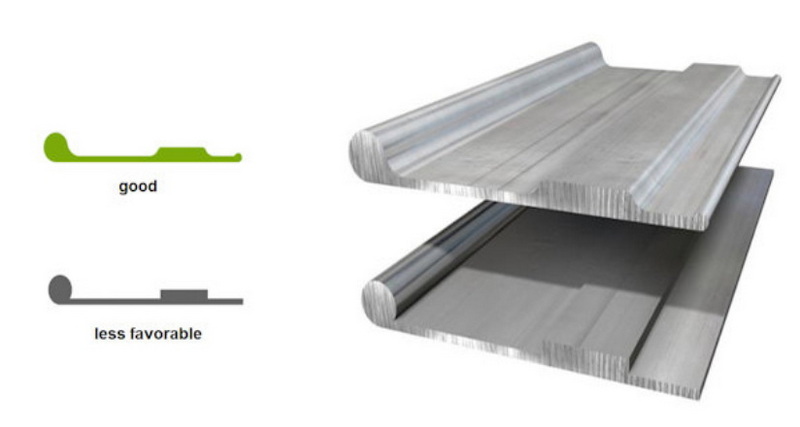

- Avoid Sharp Corners: Incorporate rounded corners instead of sharp edges to enhance flow during extrusion. Sharp corners can create stress concentrations that may lead to failure under load.

- Symmetrical Profiles: Design symmetrical shapes to ensure even material flow through the die, which helps maintain consistent wall thickness throughout the profile.

- Consider Post-Processing Needs: If additional machining or finishing processes are required after extrusion, factor these into your design to avoid compromising wall thickness during these operations.

Challenges with Thin Walls

While thinner walls can reduce material costs and weight, they also pose challenges:

- Structural Integrity: Insufficient wall thickness may lead to issues such as distortion or failure under load. Thin-walled structures must be carefully analyzed using finite element analysis (FEA) to predict performance under expected loads.

- Extrusion Defects: Thinner walls increase the risk of defects like porosity or incomplete extrusion. Maintaining proper temperature control during extrusion is crucial for achieving desired wall thickness without defects.

Testing Minimum Wall Thickness

To ensure that minimum wall thickness specifications are met during production, manufacturers often employ various testing methods:

- Ultrasonic Testing (UT): This non-destructive testing method uses high-frequency sound waves to detect flaws within materials. It is particularly useful for identifying internal defects that may compromise wall integrity.

- X-ray Inspection: X-ray imaging can reveal internal structures within extrusions and help identify inconsistencies in wall thickness that may not be visible externally.

- Dimensional Inspection: Regular dimensional checks during production help ensure that profiles meet specified tolerances for wall thickness as well as overall dimensions.

Applications Requiring Minimum Wall Thickness Considerations

Understanding minimum wall thickness is crucial across various industries:

- Aerospace Engineering: In aerospace applications, every ounce counts; thus, engineers strive for minimal weight while ensuring maximum strength through optimized wall thickness designs.

- Automotive Manufacturing: Lightweight components enhance fuel efficiency without sacrificing safety or performance; therefore, automotive parts often utilize thin-walled aluminum extrusions.

- Construction Industry: In construction applications such as window frames or structural supports, maintaining appropriate wall thickness ensures durability while meeting aesthetic requirements.

Conclusion

Determining the minimum wall thickness for aluminum extrusion is crucial for ensuring both performance and manufacturability. By considering factors such as alloy type, profile shape, size, and extrusion conditions, designers can specify appropriate wall thicknesses that balance strength requirements with production efficiency. Following best practices in design will help achieve optimal results while minimizing potential challenges associated with thin-walled extrusions.

In summary:

1. Understanding alloy properties is essential for determining appropriate minimum wall thickness.

2. Design considerations such as uniformity and corner radii significantly affect manufacturability.

3. Testing methods play a vital role in ensuring quality control throughout production processes.

4. Applications across various industries highlight the importance of optimizing wall thickness for performance and cost-effectiveness.

FAQ

1. What is the thinnest wall that can be extruded?

The thinnest wall that can be extruded varies by alloy but typically ranges from 0.020 inches for alloy 3003 to about 0.030 inches for alloy 6061.

2. How does profile shape affect minimum wall thickness?

Complex or asymmetrical shapes may require thicker walls to ensure structural integrity during use compared to simpler symmetrical profiles.

3. Can I specify different wall thicknesses within a single profile?

Yes, varying wall thicknesses within a single profile is acceptable but should be done cautiously to avoid issues during cooling and machining.

4. What are common applications for thin-walled aluminum extrusions?

Thin-walled extrusions are commonly used in lightweight structures such as frames for windows, doors, and various architectural applications where weight savings are critical.

5. How does temperature affect the extrusion process?

Temperature plays a significant role in making aluminum malleable enough for extrusion; higher temperatures typically allow for thinner walls but must be controlled to prevent defects.