Content Menu

● Overview of the Incident

● The Importance of Safety Measures in Aluminum Extrusion

● Key Safety Measures That Were Lacking

>> 1. Machine Guarding

>> 2. Lockout/Tagout Procedures

>> 3. Employee Training

>> 4. Personal Protective Equipment (PPE)

>> 5. Incident Reporting and Analysis

● Conclusion

● FAQ

>> 1. What are lockout/tagout (LOTO) procedures?

>> 2. Why is machine guarding important?

>> 3. What types of personal protective equipment (PPE) should be used in aluminum extrusion?

>> 4. How often should training on safety measures be conducted?

>> 5. How can companies promote a culture of safety among employees?

● Citations:

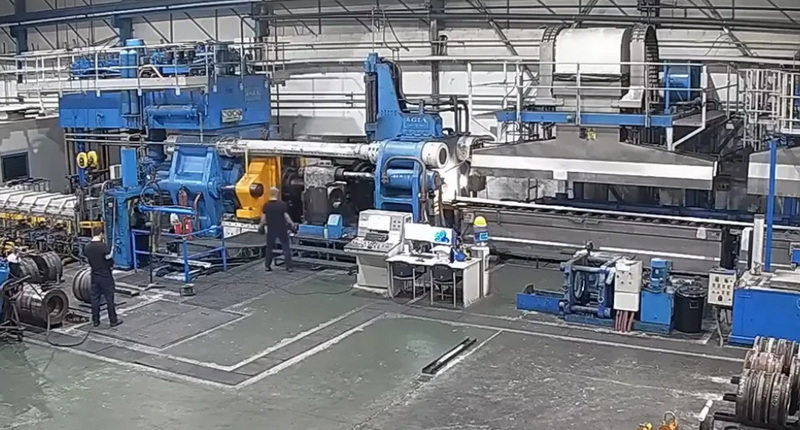

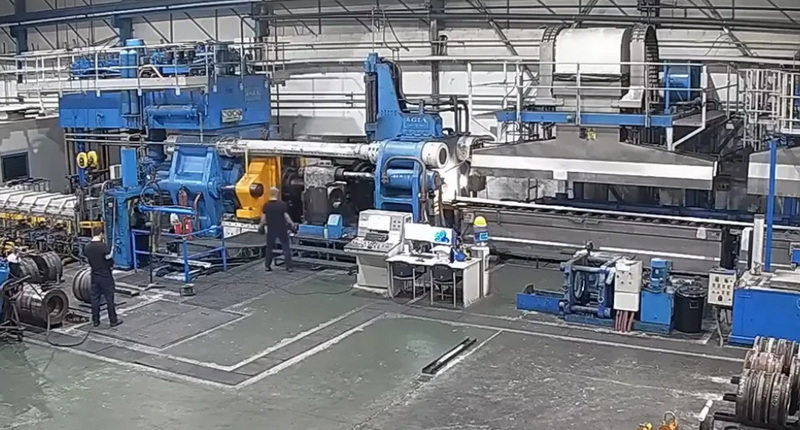

The aluminum extrusion industry plays a crucial role in manufacturing various products used across multiple sectors, including construction, automotive, and aerospace. However, the processes involved can pose significant safety risks. One of the most tragic incidents occurred in August 2014, when a worker was killed in an aluminum extrusion press accident. This article explores the safety measures that were lacking during this incident, highlighting the importance of effective safety protocols in preventing workplace accidents.

Overview of the Incident

In August 2014, a fatal accident occurred at an aluminum extrusion facility where a worker was killed while operating an extrusion press. The specifics of the incident revealed a series of safety oversights and failures that contributed to the tragic outcome. Investigations following the accident uncovered critical lapses in safety measures, particularly regarding machine guarding, lockout/tagout (LOTO) procedures, and employee training.

The Importance of Safety Measures in Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum billets through a die to create specific profiles. This process requires high pressure and involves various stages, each presenting unique hazards. The potential risks include:

- High Temperatures: The process involves heating aluminum to extreme temperatures.

- Heavy Machinery: The operation of large machines poses risks of crushing and entrapment.

- Hydraulic Systems: These systems can malfunction and lead to catastrophic failures.

- Chemical Exposure: Workers may be exposed to hazardous materials used in the process.

- Noise Pollution: Prolonged exposure can lead to hearing loss.

- Fire Risks: Aluminum is combustible under certain conditions.

To mitigate these risks, comprehensive safety measures must be implemented.

Key Safety Measures That Were Lacking

1. Machine Guarding

One of the most significant safety oversights in the August 2014 incident was inadequate machine guarding. Proper guarding is essential to prevent accidental contact with moving parts, which can lead to severe injuries or fatalities. In this case, it was found that:

- Safety Guards Were Missing: Critical guards that should have protected workers from moving components were either not installed or improperly maintained.

- Emergency Stops Were Not Accessible: Emergency stop buttons were not easily reachable, delaying response times during emergencies.

2. Lockout/Tagout Procedures

Lockout/tagout procedures are designed to ensure that machines are properly shut down and unable to be started up again until maintenance or servicing is completed. In this incident:

- Failure to Implement LOTO: There was no evidence that proper lockout/tagout procedures were followed during maintenance activities.

- Lack of Training on LOTO Protocols: Employees were not adequately trained on how to implement LOTO procedures effectively.

3. Employee Training

Training is crucial for ensuring that employees understand how to operate machinery safely and respond appropriately in emergencies. The investigation revealed:

- Inadequate Training Programs: Workers had not received comprehensive training on safe operating procedures for the extrusion press.

- Lack of Emergency Response Drills: There were no regular drills or training sessions to prepare employees for emergency situations.

4. Personal Protective Equipment (PPE)

The use of appropriate personal protective equipment is vital for protecting workers from various hazards associated with aluminum extrusion processes. However:

- Insufficient PPE Usage: Workers were not consistently wearing necessary PPE such as safety glasses, cut-resistant gloves, and heat-resistant clothing.

- PPE Training Was Lacking: Employees did not receive adequate training on the importance and proper use of PPE.

5. Incident Reporting and Analysis

A culture of safety encourages reporting near misses and incidents without fear of reprisal. Unfortunately:

- Underreporting of Incidents: Employees felt discouraged from reporting unsafe conditions or near misses due to fear of repercussions.

- Lack of Incident Analysis: The facility did not have a system in place for analyzing incidents or near misses to improve safety protocols.

Conclusion

The tragic accident at the aluminum extrusion facility in August 2014 serves as a stark reminder of the critical importance of implementing robust safety measures in high-risk environments. Key failures in machine guarding, lockout/tagout procedures, employee training, PPE usage, and incident reporting contributed significantly to the fatal outcome. To prevent similar incidents in the future, companies must prioritize safety by adopting comprehensive training programs, enforcing strict adherence to safety protocols, and fostering a culture where employees feel empowered to report hazards without fear.

By addressing these shortcomings and committing to continuous improvement in safety practices, organizations can protect their workers and enhance overall productivity within the manufacturing environment.

FAQ

1. What are lockout/tagout (LOTO) procedures?

Lockout/tagout (LOTO) procedures are safety protocols used to ensure that machines are properly shut down and cannot be started up again until maintenance or servicing is completed.

2. Why is machine guarding important?

Machine guarding is essential for preventing accidental contact with moving parts, which can result in severe injuries or fatalities.

3. What types of personal protective equipment (PPE) should be used in aluminum extrusion?

Workers should wear safety glasses, cut-resistant gloves, heat-resistant clothing, steel-toed boots, and hearing protection as necessary.

4. How often should training on safety measures be conducted?

Training should be conducted regularly based on operational needs but typically occurs at least quarterly or whenever new equipment or processes are introduced.

5. How can companies promote a culture of safety among employees?

Companies can encourage open communication about safety concerns, provide regular training sessions, recognize safe practices, and implement an incident reporting system without fear of reprisal.

Citations:

[1] https://www.zehllaw.com/osha-investigates-workers-death-at-texas-aluminum-extruding-company/

[2] https://www.yjing-extrusion.com/how-to-ensure-employee-safety-in-aluminum-extrusion-press-operations.html

[3] https://blog.knottsco.com/blog/bid/44509/Machine-Guarding-Aluminum-Extrusion-is-Serious-for-Plant-Safety

[4] https://www.cit.uscourts.gov/sites/cit/files/24-73.pdf

[5] https://www.wfmj.com/story/39389596/extrudex-managers-plead-not-guilty-to-obstructing-fatal-accident-probe?clienttype=mobile

[6] https://www.yjing-extrusion.com/what-are-the-key-safety-measures-for-alco-aluminum-extrusion-press.html

[7] http://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.217

[8] https://www.extrusion.net