Content Menu

● Introduction to Extrusion Technology

>> How Extrusion Works

● Applications of Extrusion Technology

>> Extrusion Snacks Food Machinery

● Benefits of Extrusion Technology

>> Environmental Impact

● Recent Developments and Trends

>> Innovative Products

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary applications of extrusion technology in snack food manufacturing?

>> 2. How does extrusion technology enhance food safety?

>> 3. What are the environmental benefits of using extrusion technology?

>> 4. Can extrusion technology be used to produce healthier snack options?

>> 5. How does extrusion technology support innovation in snack food production?

● Citations:

Extrusion technology is a versatile and widely used method in snack food manufacturing, enabling the production of a diverse range of products with unique textures, shapes, and flavors. This technology involves forcing raw materials through a die under high temperature and pressure conditions, transforming them into various snack foods such as puffed snacks, breakfast cereals, and meat analogs. In this article, we will delve into the principles, applications, and benefits of extrusion technology in snack food manufacturing.

Introduction to Extrusion Technology

Extrusion technology is derived from the polymer and plastic industries but has become a cornerstone in the food processing sector. It is commonly referred to as extrusion cooking, where raw materials are heated and mechanically conveyed through a barrel and screw assembly, then extruded through a die to form the final product[8]. This process enhances the digestibility, palatability, and sensory characteristics of the food products.

How Extrusion Works

The extrusion process begins with the preparation of raw materials, which are mixed and conditioned to create a dough-like consistency. This mixture is then fed into an extruder, where it is subjected to high temperatures and pressures. The mechanical shear generated by the screw(s) and external heating elements cooks the mixture, gelatinizing starches and denaturing proteins. Upon exiting the die, the sudden drop in pressure causes the product to expand and solidify into its final shape and texture[4].

Illustration of the Extrusion Process:

A[Raw Materials] --> B[Mixing & Conditioning]

B --> C[Extruder]

C --> D[Die]

D --> E[Final Product]

Applications of Extrusion Technology

Extrusion technology is highly adaptable and can produce a wide variety of snack foods, including:

- Puffed Snacks: Products like cheese balls and onion rings are made by extruding dough through a die, followed by rapid expansion due to the release of pressure[5].

- Breakfast Cereals: Many breakfast cereals are produced using extrusion, allowing for a range of shapes and textures[2].

- Meat Analogs: Textured vegetable proteins (TVP) are created through extrusion to mimic the texture of meat[2].

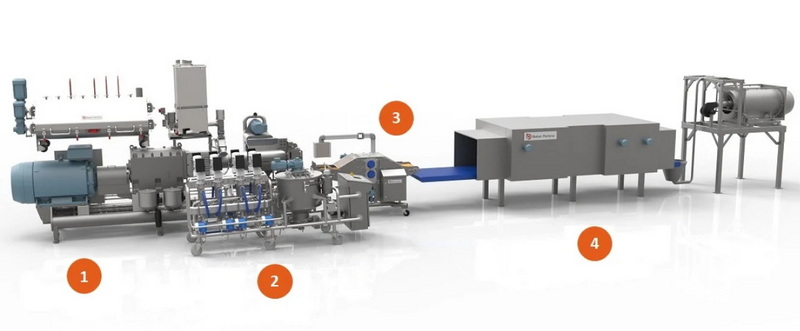

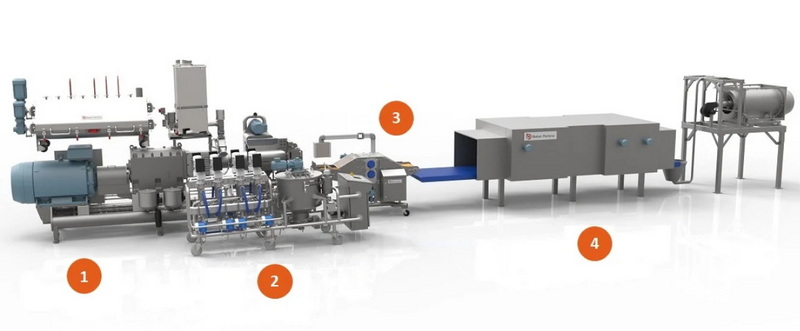

Extrusion Snacks Food Machinery

The machinery used in extrusion is sophisticated and includes single or twin screw systems. These systems combine mixing, conveying, forming, shearing, cooking, and texturizing operations in one process[2]. The extruder's design allows for precise control over temperature, pressure, and shear forces, enabling the production of consistent and high-quality products.

Benefits of Extrusion Technology

Extrusion technology offers several advantages over traditional manufacturing methods:

1. Versatility: Allows for the creation of diverse products with different textures and flavors by adjusting ingredients and processing conditions[3].

2. Nutritional Enhancement: Enables the incorporation of nutritious ingredients like whole grains and vegetables, making snacks healthier[3].

3. Cost-Effectiveness: Uses fewer resources, reducing waste and operational costs[3].

4. Energy Efficiency: Continuous processing reduces energy consumption and labor costs[7].

5. Food Safety: High temperatures during extrusion help eliminate microorganisms, enhancing food safety[7].

Environmental Impact

Extrusion technology is considered eco-friendly due to its minimal environmental impact. It requires less space and energy compared to other food processing methods, aligning with sustainable manufacturing practices[1].

Recent Developments and Trends

Recent advancements in extrusion technology include improved process control systems and the integration of biopolymer and plant-based ingredients. These developments enhance the nutritional value and texture variety of extruded snacks, catering to evolving consumer preferences for healthier and more sustainable options[7].

Innovative Products

Innovative products such as two-colored snacks and spiral-shaped extrudates are being developed using advanced extrusion techniques. These products not only offer unique visual appeal but also provide opportunities for varied flavor profiles and textures[5].

Conclusion

Extrusion technology plays a pivotal role in snack food manufacturing, offering versatility, nutritional enhancement, cost-effectiveness, and environmental sustainability. As consumer preferences continue to evolve, the adaptability of extrusion technology ensures its relevance in producing a wide range of snack foods that meet diverse market demands.

Frequently Asked Questions

1. What are the primary applications of extrusion technology in snack food manufacturing?

Extrusion technology is used to produce a variety of snack foods, including puffed snacks, breakfast cereals, meat analogs, and pasta. It allows for the creation of diverse products with unique textures and flavors.

2. How does extrusion technology enhance food safety?

Extrusion technology enhances food safety by applying high temperatures during the process, which helps eliminate microorganisms and reduce anti-nutritional factors in the final product.

3. What are the environmental benefits of using extrusion technology?

Extrusion technology is energy-efficient and requires less space compared to traditional methods, making it an eco-friendly option for food manufacturing. It also generates fewer effluents, contributing to a cleaner production environment.

4. Can extrusion technology be used to produce healthier snack options?

Yes, extrusion technology allows for the incorporation of nutritious ingredients like whole grains, vegetables, and proteins, making snack foods healthier and more nutritious.

5. How does extrusion technology support innovation in snack food production?

Extrusion technology supports innovation by allowing manufacturers to experiment with different ingredients, shapes, and textures. This flexibility enables the creation of new and innovative snack products that cater to evolving consumer preferences.

Citations:

[1] https://medcraveonline.com/MOJFPT/applications-of-food-extrusion-technology.html

[2] https://content.ces.ncsu.edu/extrusion-processing-a-versatile-technology-for-production-of-foods-and-feeds

[3] https://www.rxpelletmachine.com/info/snack-food-extrusion-advantages-and-considera-95664458.html

[4] https://loyal-machine.com/blog/snack-food-extruder-machine/

[5] https://www.foodextrusion.de/en/snacks

[6] https://loyal-machine.com/blog/extrusion-snacks/

[7] https://ud-machine.com/blog/the-process-of-extruded-snacks/

[8] https://www.academia.edu/96049076/Thermoplastic_food_extrusion_questions_and_answers_A_simplified_approach_Atena_Editora_

[9] https://dpointernational.com/wp-content/uploads/2023/08/Aug-2023-Manufacturing-Process-of-Extruded-Snacks.pdf

[10] https://loyalmachines.com/blog/the-manufacturing-process-of-extruded-food-products/

[11] https://www.linkedin.com/advice/1/how-can-extrusion-technology-create-innovative

[12] https://en.wikipedia.org/wiki/Food_extrusion

[13] https://en.engormix.com/feed-machinery/extrusion/why-food-technology-extrusion_a54524/

[14] https://ud-machine.com/blog/what-are-extruded-snacks-examples/

[15] http://ecoursesonline.iasri.res.in/mod/page/view.php?id=19175