Content Menu

● Overview of No Drying Extrusion Granulation

● Advantages of No Drying Extrusion Granulation Production Lines

● Key Components of No Drying Extrusion Granulation Production Lines

● Industries That Utilize No Drying Extrusion Granulation Production Lines

>> Pharmaceuticals

>> Fertilizers

>> Food Industry

>> Chemical Industry

>> Animal Feed Production

● Recent Innovations in No Drying Extrusion Granulation Technology

● Challenges Faced by No Drying Extrusion Granulation Production Lines

● Conclusion

● FAQs

>> 1. What materials can be processed using no drying extrusion granulation?

>> 2. How does no drying extrusion granulation improve product quality?

>> 3. What are the main benefits of using no drying extrusion granulation production lines?

>> 4. Which industries benefit most from no drying extrusion granulation?

>> 5. What recent advancements have been made in no drying extrusion granulation technology?

● Citations:

No drying extrusion granulation production lines represent a significant innovation in manufacturing processes, particularly for industries that require efficient and environmentally friendly methods of producing granules. This article explores the various industries that utilize these production lines, their advantages, and the technology behind them.

Overview of No Drying Extrusion Granulation

No drying extrusion granulation is a process that combines the principles of extrusion and granulation without requiring a drying phase. Traditional granulation methods often involve adding moisture to bind particles together, followed by a drying step to remove excess water. In contrast, no drying extrusion granulation employs high pressure and shear forces to compact materials directly into granules, eliminating the need for drying equipment. This process is particularly beneficial in industries where moisture-sensitive materials are involved.

Advantages of No Drying Extrusion Granulation Production Lines

- Energy Efficiency: By removing the drying phase, manufacturers can significantly reduce energy costs associated with heating and cooling systems.

- Reduced Processing Time: The absence of drying steps accelerates production cycles, allowing for higher throughput.

- Improved Product Quality: Controlled environments during extrusion minimize degradation of sensitive materials, resulting in higher quality granules.

- Lower Operational Costs: Reduced equipment requirements for drying lead to lower capital and operational expenditures.

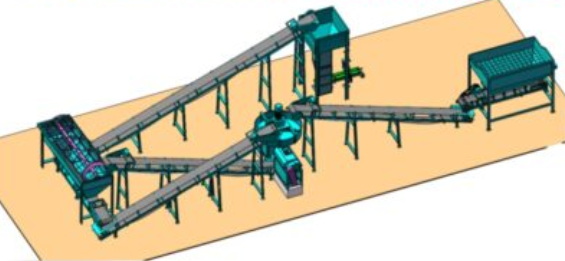

Key Components of No Drying Extrusion Granulation Production Lines

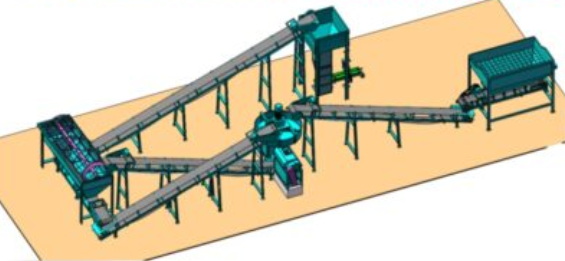

Understanding the components involved in no drying extrusion granulation production lines is crucial for appreciating their functionality:

- Extruder: The heart of the production line where raw materials are fed and subjected to high pressure.

- Rollers: Counter-rotating rollers compress the material into sheets or pellets.

- Cooling System: Although drying is not required, cooling may still be necessary to maintain product integrity after extrusion.

- Screening Equipment: Ensures uniformity in granule size by separating oversized or undersized particles.

- Packaging System: Automatically packages the finished granules for distribution.

Industries That Utilize No Drying Extrusion Granulation Production Lines

No drying extrusion granulation production lines are versatile and can be applied across various industries:

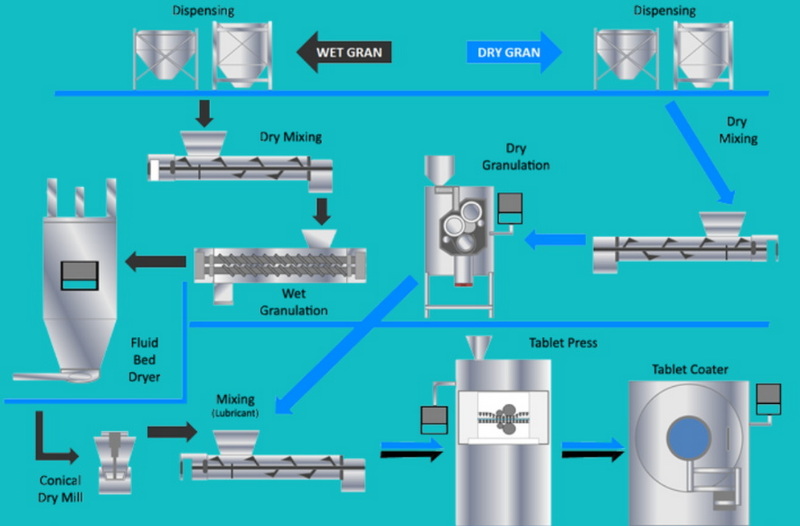

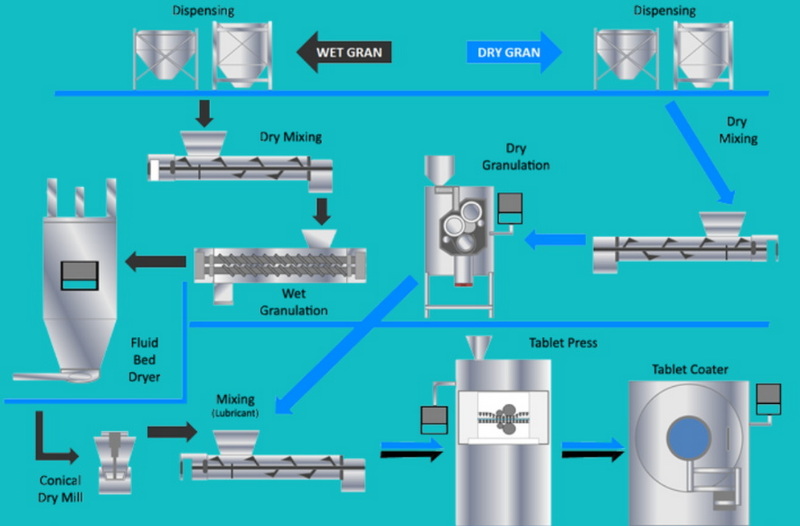

Pharmaceuticals

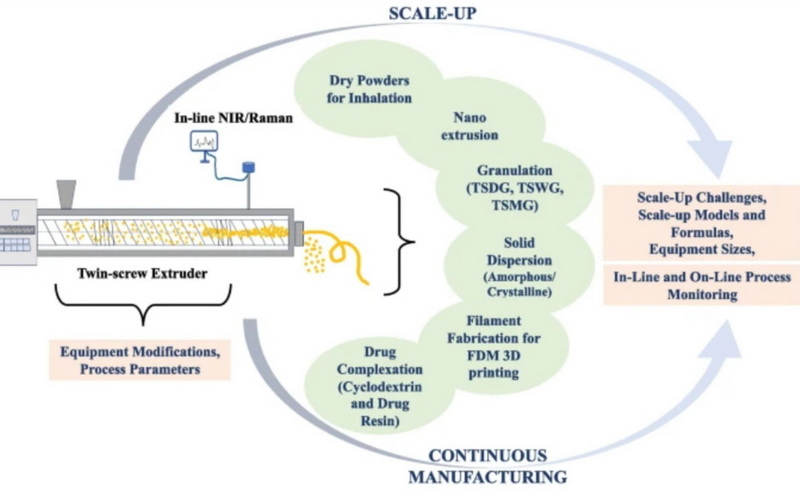

In the pharmaceutical industry, no drying extrusion granulation is used for producing solid dosage forms where moisture-sensitive active pharmaceutical ingredients (APIs) are involved. The ability to process materials without adding moisture ensures that the integrity and efficacy of the APIs are maintained. This method is particularly advantageous for formulations requiring precise control over particle size and distribution.

Fertilizers

The fertilizer industry benefits significantly from no drying extrusion granulation production lines. These systems can produce high-density fertilizer granules without water addition, enhancing nutrient release profiles. The technology allows for the creation of compound fertilizers with varying concentrations tailored to specific crop needs. Additionally, the process minimizes environmental impact by reducing waste generation and energy consumption.

Food Industry

In the food industry, no drying extrusion granulation is employed in producing food additives and supplements where moisture control is critical. This method ensures that sensitive ingredients retain their functional properties while being processed into granules suitable for incorporation into various food products.

Chemical Industry

The chemical industry uses no drying extrusion granulation for producing various chemical compounds. This technology allows for the efficient processing of powders into granules without introducing moisture that could affect chemical reactions or product stability. It is particularly useful for creating fertilizers, pesticides, and other chemical formulations that require precise particle characteristics.

Animal Feed Production

In animal feed production, no drying extrusion granulation enables manufacturers to produce high-quality feed pellets efficiently. The process allows for the incorporation of various nutrients and additives while maintaining the integrity of sensitive components like vitamins and minerals. The resulting pellets are uniform in size and shape, ensuring consistent feeding quality for livestock.

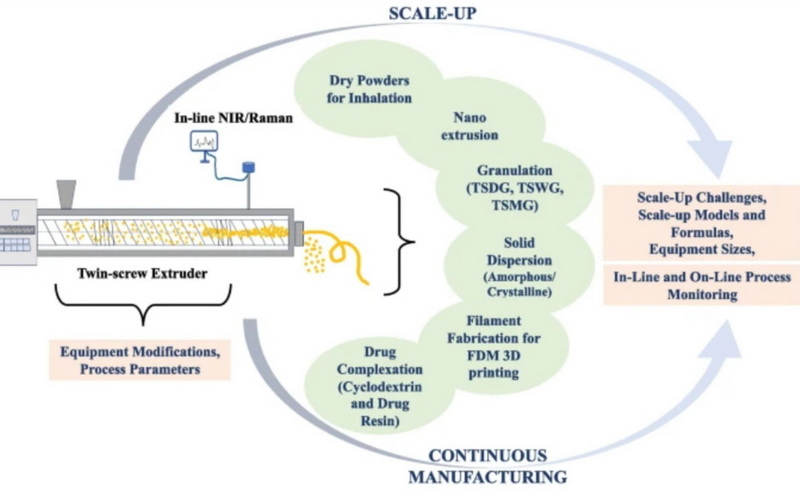

Recent Innovations in No Drying Extrusion Granulation Technology

Recent advancements in this field have focused on enhancing process control and automation:

1. Enhanced Process Control: Integration of Process Analytical Technology (PAT) allows real-time monitoring and adjustment of parameters such as temperature, pressure, and feed rates. This capability ensures consistent product quality and reduces waste.

2. Smart Automation: The incorporation of IoT devices enables predictive maintenance and remote monitoring of equipment performance, minimizing downtime and improving operational efficiency.

3. Sustainable Practices: Innovations aimed at reducing waste generation during production processes are becoming more prevalent. For instance, using recycled materials as feedstock can enhance sustainability efforts in manufacturing.

4. Modular Equipment Design: New designs allow for greater flexibility in production lines, enabling manufacturers to easily switch between different formulations or products without extensive reconfiguration.

5. Advanced Material Handling Systems: Improved feeding systems ensure consistent material flow into the extruder, which is crucial for maintaining product uniformity.

Challenges Faced by No Drying Extrusion Granulation Production Lines

While there are numerous advantages to using no drying extrusion granulation production lines, some challenges must be addressed:

- Material Variability: Different raw materials may behave unpredictably during processing due to variations in particle size or moisture content. Manufacturers must carefully select raw materials to ensure consistent quality.

- Equipment Maintenance: Regular maintenance is essential to prevent downtime caused by equipment malfunctions or wear over time. Investing in high-quality machinery can mitigate some of these issues but requires initial capital investment.

- Dust Generation: The mechanical nature of the process can lead to dust formation, which may pose contamination risks if not managed properly. Implementing efficient dust collection systems can help address this challenge.

Conclusion

No drying extrusion granulation production lines represent a significant advancement in manufacturing technology across various industries. By eliminating the need for drying processes, these systems offer substantial benefits in terms of energy efficiency, cost reduction, and product quality. As technology continues to evolve, manufacturers will need to adapt to new innovations while addressing challenges related to material variability and regulatory compliance. The future holds great promise for this innovative approach to granule production across various industries.

FAQs

1. What materials can be processed using no drying extrusion granulation?

No drying extrusion granulation can process a wide range of materials including pharmaceuticals (APIs), fertilizers (NPK), food additives, and other moisture-sensitive powders.

2. How does no drying extrusion granulation improve product quality?

The controlled environment during extrusion minimizes degradation of sensitive materials, resulting in higher quality granules with consistent size and distribution.

3. What are the main benefits of using no drying extrusion granulation production lines?

Key benefits include energy efficiency, reduced processing time, improved product quality, and lower operational costs due to eliminated drying steps.

4. Which industries benefit most from no drying extrusion granulation?

Industries such as pharmaceuticals, fertilizers, food production, chemicals, and animal feed all benefit significantly from this innovative production method.

5. What recent advancements have been made in no drying extrusion granulation technology?

Recent innovations include enhanced process control through PAT systems, increased automation with IoT integration, sustainable practices focusing on waste reduction, modular equipment designs for flexibility, and improved material handling systems for consistent flow.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-no-drying-extrusion-granulation-production-lines.html

[2] https://www.abbviecontractmfg.com/news-and-insights/how-can-extrusion-benefit-your-pharmaceutical-oral-drug-product.html

[3] https://pmc.ncbi.nlm.nih.gov/articles/PMC6568324/

[4] https://www.yjing-extrusion.com/what-are-the-advantages-of-no-drying-extrusion-granulation-production-equipment.html

[5] https://www.pharmtech.com/view/exploring-advances-in-twin-screw-extrusion-for-solid-dosage-drugs

[6] https://www.researchgate.net/publication/349399385_Recent_Development_Challenges_and_Prospects_of_Extrusion_Technology

[7] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-lines/

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC4401168/

[9] https://www.hywellco.com/Efficient-Dry-Granulation-for-Fertilizer-Production-A-Comprehensive-Process-Overview-id61850007.html

[10] https://www.linkedin.com/pulse/drying-dual-mode-extrusion-cylindrical-granulator-organic-yu-

[11] https://www.sciencedirect.com/science/article/pii/S2949866X24000674

[12] https://fertilizer-machine.net/product/fertilizer-granulator/double-roller-extrusion-granulator.html