Content Menu

● Post-Extrusion Processes: Inline vs. Offline

● Common Post-Extrusion Processes

● Essential Components of an Extrusion Machine

● Types of Post Extrusion Equipment

>> Dies

>> Cooling Equipment

>> Pullers and Take-Off Equipment

>> Cutting Equipment

>> Granulators and Scrap Reprocessing Equipment

>> Additional Post-Extrusion Equipment

● Applications of Post Extrusion Equipment in Different Industries

>> Plastics Industry

>> Food Industry

>> Construction Industry

>> Automotive Industry

>> Metals Industry

>> Other Industries

● Conclusion

● FAQ:

>> What are the essential components of a plastic extrusion machine?

>> What is the role of the die in the extrusion process?

>> How is scrap material managed in the extrusion process?

>> What are some common applications of extrusion in the food industry?

>> How does post-extrusion equipment contribute to product quality?

● Citations:

Extrusion is a high-volume manufacturing process where raw material is melted and formed into a continuous profile[10]. This process is employed across numerous industries to create a wide array of products, from simple pipes to complex profiles[1][2][8]. While the extruder itself is the core of the process, post extrusion equipment plays a crucial role in shaping, cooling, cutting, and handling the extruded material to meet specific requirements[3][4]. This article explores the various types of post extrusion equipment available and their applications in different industries.

Post-Extrusion Processes: Inline vs. Offline

Post extrusion processes can be applied either inline, directly after the material exits the extruder, or offline, in a separate operation[6]. Inline processes often involve standard or customized devices integrated into the extrusion line, while offline processes may involve manual labor or additional equipment at a separate location[6].

Common Post-Extrusion Processes

- Cutting: Extrusions are cut to specified lengths for finished products or convenient shipping. Offline cutting allows for tighter tolerances and angled cuts[6]. Fly cutters and guillotines can be used for smoother or shorter lengths at high speeds[6].

- Notching: This economical process uses punch tools to create notches, allowing parts to be bent into angles, corners, or frame sections[6].

- Printing: Inline printing provides traceability by adding identifiers such as websites, phone numbers, dates, lot/batch numbers, patent IDs, and barcodes[6].

- Punching: Holes and slots of various shapes and sizes can be punched into extruded parts for fasteners, venting, and alignment[6].

- Slitting: Spaces can be sliced into plastic extrusions[6].

- Taping: Magnetic tape, Velcro, foam, and other types of tape can be applied to extruded parts[6].

- Vacuum Sizing: This inline process suctions the exterior of the part to a water-cooled forming tool[6].

Essential Components of an Extrusion Machine

An extrusion machine consists of three essential components[2]:

- Feeder: Delivers raw material into the machine at a carefully controlled rate to ensure consistent quality[2].

- Barrel and Screw: The screw transports, melts, mixes, and pumps the raw material through the barrel. The screw design and barrel temperature affect the quality, consistency, and production rate[2].

- Die: Shapes the molten material into the desired profile as it exits the machine. Precise die design ensures the final product meets dimensional and quality standards[2].

Types of Post Extrusion Equipment

Dies

Dies are essential post extrusion equipment that shape the molten material into the desired profile[2]. Different types of dies are used for various applications[4]:

- Rod Dies: Used to create cylindrical shapes.

- Adjustable Slit Dies: Allow for varying the thickness of the extruded sheet or film.

- Blown Film Dies: Designed for producing thin plastic films by inflating a tube of molten plastic[1].

- Catheter Dies: Used for creating small diameter tubes, such as catheters.

- Fiber and Wire Coating Dies: Coat fibers and wires with a protective layer of plastic.

- Sheet Dies: Used for producing flat sheets of plastic[4].

Cooling Equipment

Cooling equipment is crucial for solidifying the extruded material and maintaining its shape[10]. Common types of cooling equipment include[3]:

- Water Baths: The extruded material is immersed in a water bath to cool it rapidly[4].

- Cooling Tanks: Provide a controlled cooling environment for the extruded product[3].

- Spray Cooling Systems: Spray water onto the extruded material for efficient cooling[3].

- Cooling Rollers: Used to cool and flatten extruded sheets or films.

- Air Rings: Used in blown film extrusion to cool the bubble of molten plastic[4].

Pullers and Take-Off Equipment

Pullers and take-off equipment are used to draw the extruded material from the die and maintain consistent speed and tension[3]. These include:

- Pull Rolls: Rubber-coated or metal rolls that grip the extruded material and pull it through the line.

- Belt Pullers: Use a belt to pull the extrusion, providing a wider contact area and more uniform pulling force.

- Take-Off Tables: Support the extruded material as it exits the cooling section.

- Automatic Coilers: Wind flexible tubing or film onto rolls for storage and transport[3].

- Unloaders and Racks: Handle finished products after cutting or coiling[3].

Cutting Equipment

Cutting equipment is used to cut the extruded material into specific lengths[6]. Types of cutting equipment include:

- Saws: Used for cutting rigid profiles and pipes.

- Guillotines: Provide a clean, straight cut for various materials[6].

- Rotary Cutters: Offer high-speed cutting for continuous extrusion processes[10].

- Fly Cutters: Used for cutting smoother or shorter lengths of extrusions very quickly[6].

Granulators and Scrap Reprocessing Equipment

Granulators are essential for reprocessing scrap material generated during the extrusion process[3]. They grind scrap parts, edge trim, and off-spec products into regrind, which can be reintroduced into the extrusion process[3]. Different types of granulation systems include:

- In-Line Granulators: Continuously granulate scrap material for immediate reuse[3].

- Machine-Side Granulators: Located next to the extrusion line for convenient scrap processing[3].

- Centralized Granulation Systems: Handle scrap from multiple extrusion lines[3].

Additional Post-Extrusion Equipment

- In-Line Measurement Systems: Provide continuous monitoring of the extruded product's dimensions, ensuring quality control[3].

- Temperature Control Units (TCUs): Maintain precise temperature control of the cooling water or oil used in the cooling equipment[3].

- Chillers: Cool the water or oil used in cooling systems[3].

- Conveyor Belts: Transport extruded profiles and strands[4].

- 3D Filament Spoolers: Spool 3D printing filament with variable line speed and coil diameter control[4].

- Wire Coating Take-Off Units: Provide defined take-off, cooling, and winding of coated cables[4].

- Blown Film Take-Off Units: Accurately take off blown films with collapsing guides and integrated blowers for cooling and diameter adjustment[4].

Applications of Post Extrusion Equipment in Different Industries

Plastics Industry

In the plastics industry, post extrusion equipment is used to produce a wide variety of products, including pipes, sheets, films, and profiles[1][2].

- Pipe Extrusion: Extruders create plastic pipes, such as PVC pipes, used in plumbing and drainage systems[2].

- Sheet Extrusion: Extruders produce plastic sheets for packaging, thermoforming, and other applications[2].

- Blown Film Extrusion: Extruders produce thin, flexible films for packaging[1][2].

- Profile Extrusion: Extruders create complex shapes for construction, automotive, and furniture industries[1][2].

Food Industry

The food industry uses extrusion to produce snacks, cereals, pasta, and pet foods[1]. The extrusion process can modify the texture, shape, and nutritional content of food products[1].

- Snack Food Production: Extruders are used to create various snack foods with different shapes and textures.

- Cereal Production: Extruders play a vital role in producing breakfast cereals.

- Pasta Production: Extrusion is used to make different types of pasta.

- Pet Food Production: Specialized extruders are used to produce pet food, managing a diverse array of ingredients while maintaining nutritional integrity and palatability[2].

Construction Industry

In the construction sector, extrusion is used to produce components such as pipes, panels, and seals[2]. The process allows for creating complex shapes with high precision, ensuring a perfect fit in the final construction assembly[2].

- Pipe Production: Extruders create pipes for plumbing and drainage systems.

- Panel Production: Extrusion is used to produce panels for walls and ceilings.

- Seal Production: Extruders create seals for windows and doors.

Automotive Industry

The automotive industry employs extrusion machinery for producing structural parts, tubing for fluid transfer, and various interior components[2]. Extrusion allows for the creation of lightweight parts, contributing to fuel efficiency and overall vehicle performance[2].

- Structural Parts: Extruders produce lightweight structural components.

- Fluid Transfer Tubing: Extrusion creates tubing for transferring fluids within vehicles.

- Interior Components: Extruders produce various interior components, such as trim and seals.

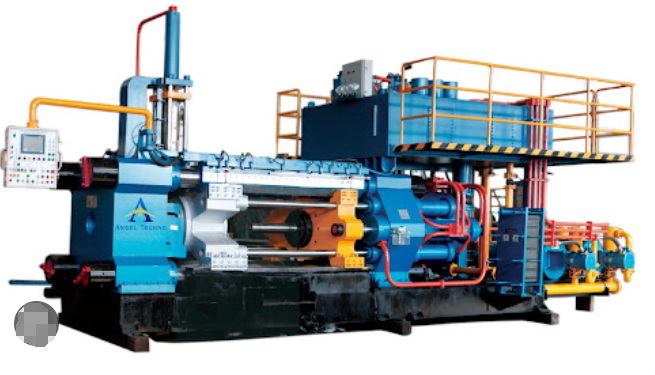

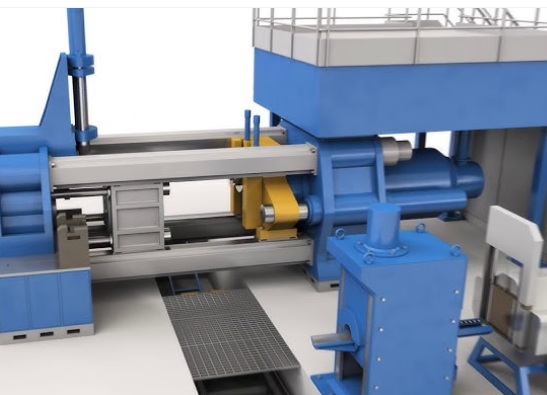

Metals Industry

Metal extrusion is used to create complex shapes and profiles from metals such as aluminum, copper, and steel[1]. This process is commonly used in the automotive, aerospace, and construction industries[1].

- Automotive Components: Extrusion is used to produce various automotive components.

- Aerospace Components: Extruded metal profiles are used in aircraft construction.

- Construction Materials: Extrusion creates metal profiles for building construction.

Other Industries

Extrusion is also used in other industries, such as:

- Pharmaceuticals: Extruders are used in pharmaceutical applications[1].

- Ceramics and Composites: Extrusion is used to process ceramics and composites[1].

Conclusion

Post extrusion equipment is integral to the extrusion process, enabling the production of a wide variety of products across diverse industries[3]. From dies that shape the molten material to cooling systems that solidify it and cutting equipment that ensures precise dimensions, each piece of post extrusion equipment plays a vital role in achieving the desired final product[4][6][10]. The selection of appropriate post extrusion equipment is crucial for optimizing productivity, ensuring product quality, and maintaining cost-effectiveness[2]. As industries continue to evolve, so too will the technology and innovation in post extrusion equipment, driving further advancements in manufacturing capabilities.

FAQ:

What are the essential components of a plastic extrusion machine?

A plastic extrusion machine comprises a hopper, barrel, extruder screw, heaters, die, cooling system, and cutter[10]. The hopper feeds raw material into the barrel, where the screw melts the plastic using heat from the heaters. The molten plastic is shaped by the die, cooled by the cooling system, and cut to the required lengths by the cutter[10].

What is the role of the die in the extrusion process?

The die is a crucial component that shapes the molten plastic into the desired profile as it exits the machine[2][10]. It is custom-designed according to the product's specifications and ensures the final product meets the required dimensions and quality standards[2][10].

How is scrap material managed in the extrusion process?

Scrap material is minimized through the use of granulators and scrap-reprocessing equipment[3]. Granulators grind scrap parts, edge trim, and off-spec products into regrind, which is then reintroduced into the extrusion process, creating a closed-loop system that maximizes raw material investment and reduces waste[3].

What are some common applications of extrusion in the food industry?

In the food industry, extrusion is commonly used to produce snacks, cereals, pasta, and pet foods[1]. The extrusion process can modify the texture, shape, and nutritional content of food products, making it a valuable tool for food manufacturers[1].

How does post-extrusion equipment contribute to product quality?

Post extrusion equipment significantly contributes to product quality by ensuring precise shaping, cooling, and cutting of the extruded material[3][6][10]. In-line measurement systems provide continuous monitoring of dimensions, while temperature control units maintain optimal cooling conditions, all of which help to achieve consistent and high-quality final products[3].

Citations:

[1] https://engitech.in/extrusion-machines-and-extruders-guide/

[2] https://jieyatwinscrew.com/blog/exploring-extrusion-equipment/

[3] https://www.conairgroup.com/resources/resource/extrusion-processing-basic-guide-to-auxiliary-equipment/

[4] https://www.thermofisher.com/ru/ru/home/industrial/spectroscopy-elemental-isotope-analysis/materials-science-research/compounding-rheology/compounding-solutions-material-development/material-compounding-accessories.html

[5] https://www.amsyscoinc.com/2010/01/28/video-extrusion-post-tensioning/

[6] https://upcinc.wordpress.com/2013/05/20/the-abcs-of-post-extrusion-processes/

[7] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[8] https://www.adremac.com/different-types-of-extruder-machines/

[9] https://www.plasticstoday.com/plastics-processing/extrusion-q-a-the-answers-to-your-tough-questions

[10] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[11] https://www.polystarco.com/blog-detail/frequently-asked-questions-about-blown-film-machines/

[12] https://www.thermofisher.com/hk/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment/accessories.html

[13] https://www.movacolor.com/knowledge/process/extrusion/what-is-extrusion-applications-process-steps/

[14] https://www.azom.com/article.aspx?ArticleID=13566

[15] https://cfaminternational.com/top-commercial-applications-of-extrusion-technology/

[16] https://www.priyankamachines.com/post-extrusion-machines.html

[17] https://www.rdnmfg.com/pipe-extrusion-equipment/

[18] https://www.dynisco.com/userfiles/files/The_Die_and_Post_Extrusion_Equipment.pdf

[19] https://www.tfgusa.com/understanding-extrusion-a-fundamental-manufacturing-process/

[20] https://www.outashi.com/blog/what-is-equipment-used-in-extrusion-process-id19.html

[21] https://www.dynisco.com/userfiles/files/Introduction_To_Extrusion.pdf

[22] https://en.wikipedia.org/wiki/Extrusion

[23] https://www.istockphoto.com/photos/extrusion

[24] https://www.shutterstock.com/search/extrusion-machine

[25] https://www.youtube.com/watch?v=zNGuuSKE1pY