Content Menu

● Introduction to Food Extrusion

>> Components of Food Extrusion Equipment

● How Food Extrusion Equipment Works

● Applications of Food Extrusion Equipment

● Recent Advancements in Extrusion Technology

>> Sustainability and Extrusion

>> Nutritional Enhancements

● Innovations in Food Processing Equipment

● Conclusion

● FAQs

>> 1. What are the main components of food extrusion equipment?

>> 2. How does food extrusion equipment work?

>> 3. What types of products can be made using food extrusion equipment?

>> 4. What are the benefits of using food extrusion equipment?

>> 5. How does temperature control affect the extrusion process?

● Citations:

Food extrusion equipment is a crucial tool in the food processing industry, enabling the mass production of a wide range of food products with uniform quality and texture. This technology has been widely adopted for producing snacks, cereals, pasta, pet food, and many other products. In this article, we will delve into the details of food extrusion equipment, its components, how it works, and its applications.

Introduction to Food Extrusion

Food extrusion is a process where mixed ingredients are forced through a die to create a specific shape. This process can involve cooking, which transforms the raw materials into a semi-solid, plasticized state, allowing for shaping into various forms. The equipment used for this process is called a food extruder.

Components of Food Extrusion Equipment

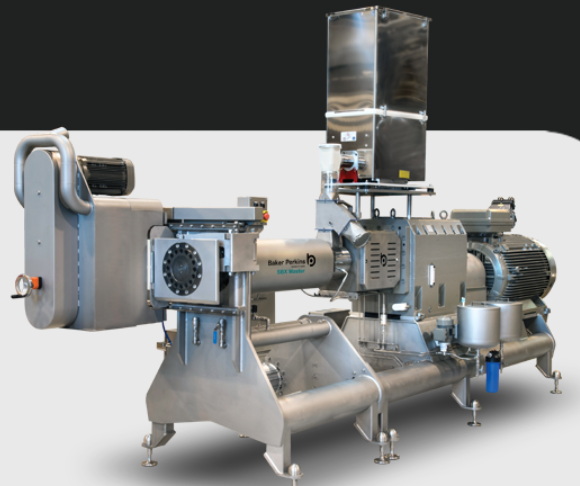

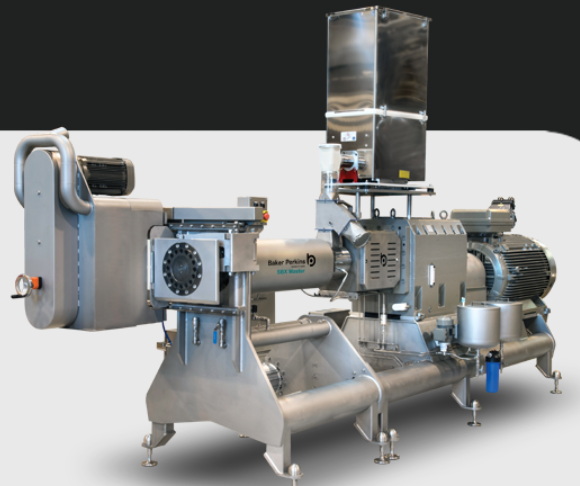

A typical food extruder consists of several key components:

1. Feed System: This ensures that raw materials are fed into the extruder at a consistent rate, maintaining uniformity in the final product.

2. Extruder Barrel: This is where the mixing, heating, and shearing of ingredients occur. The barrel is designed to withstand high temperatures and pressures.

3. Screw(s): These are responsible for conveying and kneading the ingredients. The design of the screw affects the texture and shape of the final product.

4. Die: Located at the end of the barrel, the die shapes the extrudate into the desired form. Different dies can produce various shapes and textures.

5. Cutter: This cuts the extruded product to the required length.

How Food Extrusion Equipment Works

The process involves several stages:

1. Pre-processing and Material Preparation: Raw materials are ground to a uniform particle size, similar to coarse flour. Moisture levels are adjusted, and additional ingredients like fats or dyes may be added.

2. Feeding and Mixing: The prepared mix is fed into the extruder, where it is mixed thoroughly.

3. Extrusion Cooking: The mix is heated and sheared within the extruder barrel. This process can induce starch gelatinization and protein denaturation.

4. Shaping and Forming: The plasticized mass is forced through the die to achieve the desired shape.

5. Expansion and Cooling: As the product exits the die, it expands due to the sudden drop in pressure. Cooling helps maintain the structure.

6. Cutting and Post-processing: The extruded product is cut to length and may undergo additional processing like drying or coating.

Applications of Food Extrusion Equipment

Food extrusion equipment is versatile and widely used in various industries:

- Snacks and Cereals: Many breakfast cereals and snacks are produced using extrusion. The process allows for the creation of puffed snacks with a crispy texture and a variety of flavors.

- Pasta and Bread Products: Extrusion is used for making pasta, bread sticks, and flatbreads. This method provides uniformity and consistency in the final product.

- Pet Food: Dry and semi-moist pet foods are commonly produced through extrusion. The twin-screw extruder is particularly effective for pet food production, allowing for high inclusion rates of meat and other ingredients[6].

- Textured Vegetable Protein (TVP): Used in meat analogues and vegetarian products. Extrusion enhances the texture and nutritional value of TVP.

Recent Advancements in Extrusion Technology

Recent years have seen significant advancements in extrusion technology, particularly in terms of energy efficiency and sustainability. Thermal energy systems, such as steam or surface heating, are becoming more popular due to their potential for renewable energy sources and closed-loop efficiency[1]. Additionally, the use of fresh inclusions like meats and vegetable proteins is on the rise, offering sustainable and energy-efficient solutions[1].

Sustainability and Extrusion

Extrusion technology plays a crucial role in sustainable food production. It enables the use of local ingredients, reduces waste, and supports ongoing research and development in nutrition and quality[1]. For example, rice bran, a by-product of rice processing, can be extruded into nutritious snacks, contributing to food security and environmental health[4].

Nutritional Enhancements

Extrusion can enhance the nutritional value and digestibility of food products by modifying starch, protein, and fiber structures. It reduces the need for additives and preservatives by inactivating enzymes and microorganisms that can affect product quality and shelf life[3]. However, high temperatures can lead to nutrient loss, which must be managed carefully[5].

Innovations in Food Processing Equipment

The food processing industry is experiencing a technological revolution with innovations like smart packaging and AI-driven processing. These advancements improve production efficiency and ensure enhanced food quality[2]. Extrusion technology aligns well with these trends by offering high-speed production capabilities and flexibility in product formulation.

Conclusion

Food extrusion equipment plays a vital role in modern food processing, offering efficiency, uniformity, and versatility in product creation. Understanding its components and operation is essential for optimizing production processes and developing new food products.

FAQs

1. What are the main components of food extrusion equipment?

Answer: The main components include the feed system, extruder barrel, screw(s), die, and cutter. Each component plays a crucial role in the extrusion process.

2. How does food extrusion equipment work?

Answer: It works by feeding raw materials into the extruder, where they are mixed, heated, and sheared. The material is then forced through a die to achieve the desired shape and cut to length.

3. What types of products can be made using food extrusion equipment?

Answer: A wide range of products can be made, including snacks, cereals, pasta, pet food, and textured vegetable protein.

4. What are the benefits of using food extrusion equipment?

Answer: Benefits include high production efficiency, uniform product quality, and versatility in creating different shapes and textures.

5. How does temperature control affect the extrusion process?

Answer: Temperature control is crucial as it affects the texture and consistency of the final product. Proper temperature management ensures starch gelatinization and protein denaturation, leading to the desired product properties.

Citations:

[1] https://www.petfoodprocessing.net/articles/17125-recent-advancements-edging-extrusion-tech-toward-excellence

[2] https://www.plantautomation-technology.com/articles/innovations-in-food-processing-equipment

[3] https://www.linkedin.com/advice/0/how-can-extrusion-technology-improve-your-food-5q22e

[4] https://pubs.rsc.org/en/content/articlehtml/2024/fb/d4fb00027g

[5] https://petreatsmachine.com/en/disadvantages-of-extrusion/

[6] https://www.andritz.com/resource/blob/19088/0a743a4f125f7cefbc6a564a54e2aae9/1258-gb-extruders-brochure-feed-biofuel-data.pdf

[7] https://www.foodresearchlab.com/recent-trends-about-food/extrusion-trends-in-food-processing-industry/

[8] https://sga.com.au/extrusion-processing/

[9] https://www.petfoodindustry.com/production/pet-food-processing/article/15467323/what-does-sustainability-look-like-in-pet-food-extrusion

[10] https://coperion.com/en/know-how/ask-the-expert/healthy-snacks-extrusion

[11] https://pubmed.ncbi.nlm.nih.gov/36343331/

[12] https://www.linkedin.com/pulse/innovations-food-extrusion-market-revolution-processing-edward-scott

[13] https://pdfs.semanticscholar.org/4b60/a0ab05e2496ab7fefb62c6b71fcc9736ff8a.pdf

[14] https://www.thermofisher.com/blog/food/can-extrusion-processing-help-reduce-food-waste/

[15] https://cfaminternational.com/challenges-surrounding-high-meat-pet-food-extrusion/

[16] https://food-intelligence.de/en/news/food-extrusion/

[17] https://www.foodprocessing.com/manufacturing-equipment/extrusion

[18] https://cfaminternational.com/how-extrusion-has-changed-the-food-processing-industry/

[19] https://assets.thermofisher.com/TFS-Assets/MSD/Flyers/FL53327-interview-role-extrusion-within-sustainable-food-research.pdf

[20] https://www.coherentmarketinsights.com/industry-reports/food-extrusion-market/market-challenges-and-opportunities