Content Menu

● Understanding UPVC Extrusion Machinery

>> What is UPVC Extrusion Machinery?

>> Key Components of UPVC Extrusion Machinery

● Why UPVC Extrusion Machinery is Essential

>> 1. High Efficiency and Cost-Effectiveness

>> 2. Versatility and Customization

>> 3. Superior Product Quality and Consistency

>> 4. Energy Efficiency and Sustainability

>> 5. Reduced Labor and Maintenance Costs

● Applications of UPVC Extrusion Machinery in the Plastic Industry

>> Construction Industry

>> Automotive Industry

>> Electrical and Furniture Industries

● How UPVC Extrusion Machinery Works: A Brief Overview

● Maintenance of UPVC Extrusion Machinery

● Conclusion

● FAQ

>> 1. What materials can UPVC extrusion machinery process?

>> 2. How does UPVC extrusion machinery contribute to sustainability?

>> 3. What industries benefit most from UPVC extrusion machinery?

>> 4. What are common maintenance tasks for UPVC extrusion machines?

>> 5. How does UPVC extrusion machinery ensure product quality?

● Citations:

The plastic industry has witnessed remarkable growth and innovation over the past several decades, with extrusion technology playing a pivotal role in this advancement. Among the various types of extrusion machinery, UPVC extrusion machinery stands out as an essential asset for manufacturing durable, versatile, and cost-effective plastic products. This article explores why UPVC extrusion machinery is indispensable in the plastic industry by examining its operational principles, advantages, applications, and impact on manufacturing efficiency and sustainability.

Understanding UPVC Extrusion Machinery

What is UPVC Extrusion Machinery?

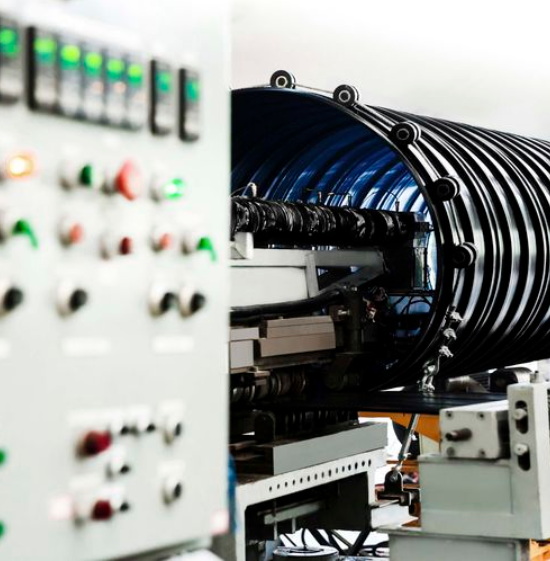

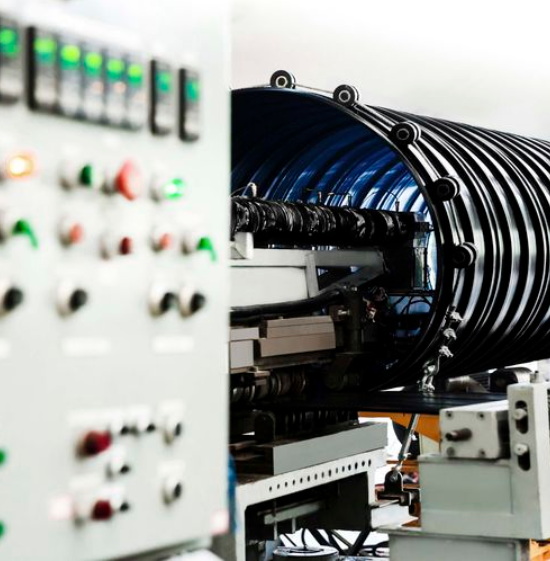

UPVC extrusion machinery is specialized equipment designed to process unplasticized polyvinyl chloride (UPVC) into continuous profiles such as pipes, window frames, door profiles, and other complex shapes. The machinery melts UPVC raw material and forces it through a die to form precise cross-sectional profiles, which are then cooled and cut to desired lengths. This process is continuous and highly efficient, making it ideal for mass production in various industries[2][9].

Key Components of UPVC Extrusion Machinery

A typical UPVC extrusion machine consists of several critical components:

- Extruder: Melts and homogenizes the UPVC material.

- Die: Shapes the molten material into the desired profile.

- Cooling System: Solidifies the extruded profile, often using water baths or air cooling.

- Cutting Unit: Cuts the profiles into specified lengths.

- Control System: Monitors and adjusts temperature, pressure, and speed to ensure quality and consistency[2][8][9].

Why UPVC Extrusion Machinery is Essential

1. High Efficiency and Cost-Effectiveness

UPVC extrusion machinery enables manufacturers to produce large volumes of plastic profiles rapidly and with minimal waste. The continuous extrusion process allows machines to operate 24/7, significantly reducing production downtime and inventory shortages. Moreover, the ability to reuse waste UPVC material by re-melting helps lower raw material costs and disposal expenses. These factors combine to make UPVC extrusion one of the most economical manufacturing methods in the plastic industry[1][2][8].

2. Versatility and Customization

One of the greatest strengths of UPVC extrusion machinery is its versatility. Manufacturers can customize the shape, size, color, texture, and thickness of the extruded profiles to meet specific customer requirements. This flexibility is crucial for serving diverse sectors such as construction, automotive, electrical, and furniture industries. For example, UPVC profiles are widely used for window and door frames in construction due to their durability and weather resistance, while in automotive applications, they are used for trim and sealing components[2][7].

3. Superior Product Quality and Consistency

UPVC extrusion machinery ensures that each profile produced meets strict quality standards. Advanced control systems maintain precise temperature and pressure throughout the extrusion process, resulting in uniform profiles with minimal defects such as air bubbles, uneven flow, or surface irregularities. This consistency enhances product reliability and reduces customer returns, which is vital for maintaining brand reputation[5][9].

4. Energy Efficiency and Sustainability

Modern UPVC extrusion machines incorporate energy-saving technologies such as optimized heating systems and automated controls to minimize energy consumption. Additionally, these machines support recycling by allowing leftover or defective UPVC material to be reprocessed, reducing waste and promoting a circular economy. The use of eco-friendly UPVC compounds further aligns the extrusion process with global sustainability goals, lowering the carbon footprint of plastic manufacturing[8].

5. Reduced Labor and Maintenance Costs

UPVC extrusion machinery is designed for durability and minimal maintenance. Automated operation reduces the need for manual intervention, cutting labor costs and minimizing human error. Routine maintenance, such as lubrication and temperature monitoring, ensures long machine life and prevents unexpected breakdowns. This reliability translates into uninterrupted production and lower operational costs[5][6].

Applications of UPVC Extrusion Machinery in the Plastic Industry

Construction Industry

UPVC profiles produced by extrusion machinery are extensively used in windows, doors, frames, and piping systems. Their resistance to weather, corrosion, and UV radiation makes them ideal for building materials, contributing to energy-efficient and low-maintenance structures[2][7].

Automotive Industry

UPVC extrusion machinery manufactures interior and exterior components such as trims, seals, and weather stripping. The precision and durability of extruded profiles ensure they meet stringent automotive standards for safety and aesthetics[2].

Electrical and Furniture Industries

UPVC profiles are used for cable conduits, electrical enclosures, and furniture components due to their insulating properties and ease of fabrication. The ability to produce custom profiles allows manufacturers to meet diverse design and functional requirements[2][7].

How UPVC Extrusion Machinery Works: A Brief Overview

The extrusion process begins with feeding UPVC raw material, usually in powder or pellet form, into the hopper of the extruder. Inside the barrel, the material is heated and melted by heaters and mechanical work from a rotating screw. The molten UPVC is then forced through a die that shapes the material into the desired profile. After extrusion, the profile is cooled rapidly to retain its shape and then cut to length by the cutting unit. Throughout the process, sensors and controllers regulate temperature, pressure, and speed to maintain quality and efficiency[4][9].

Maintenance of UPVC Extrusion Machinery

Proper maintenance is crucial for maximizing the lifespan and performance of UPVC extrusion machinery. Key maintenance practices include:

- Daily inspections for wear and lubrication of moving parts.

- Regular cleaning to prevent blockages.

- Monitoring and controlling temperature settings.

- Checking electrical components and safety systems.

- Replacing worn-out parts promptly.

- Calibrating machine settings for optimal performance.

- Training operators in maintenance procedures and safety protocols[6].

Conclusion

UPVC extrusion machinery is a cornerstone of the plastic industry due to its efficiency, versatility, and ability to produce high-quality, customized plastic profiles. It supports a wide range of applications, from construction to automotive, while promoting sustainability through energy efficiency and material recycling. The machinery's reliability and low maintenance requirements further enhance its value, making it an indispensable investment for manufacturers aiming to stay competitive in the evolving plastic market. As technology advances, UPVC extrusion machinery will continue to drive innovation and sustainability in plastic manufacturing.

FAQ

1. What materials can UPVC extrusion machinery process?

UPVC extrusion machinery primarily processes unplasticized polyvinyl chloride (UPVC), but it can also handle PVC mixed powders and compounds with additives for enhanced properties like UV resistance and fire retardancy[2][10].

2. How does UPVC extrusion machinery contribute to sustainability?

These machines reduce energy consumption through advanced heating and control systems and promote recycling by allowing leftover UPVC material to be re-melted and reused, minimizing waste and environmental impact[8].

3. What industries benefit most from UPVC extrusion machinery?

The construction industry (windows, doors, pipes), automotive sector (trims, seals), electrical industry (cable conduits), and furniture manufacturing all benefit significantly from UPVC extrusion machinery[2][7].

4. What are common maintenance tasks for UPVC extrusion machines?

Maintenance includes daily inspections, cleaning, temperature monitoring, lubrication, electrical checks, parts replacement, calibration, and operator training to ensure smooth operation and longevity[6].

5. How does UPVC extrusion machinery ensure product quality?

By maintaining precise control over temperature, pressure, and speed during extrusion, the machinery produces consistent profiles with minimal defects, ensuring high product quality and customer satisfaction[5][9].

Citations:

[1] https://plasticextrusiontech.net/benefits-of-plastic-extrusion/

[2] https://www.anda-china.com/Versatility-of-UPVC-Profile-Extrusion-Machines-for-Diverse-Applications-id42559376.html

[3] https://windsormachines.com/upvc-pipe-manufacturing-plant/

[4] https://www.jwellmachine.com/upvc-extrusion-equipment-and-formula-adjustment/

[5] https://www.anda-china.com/How-does-upvc-profile-extrusion-machine-work-id49422337.html

[6] https://www.langboextruder.com/news/the-ultimate-upvc-pipe-machine-maintenance-checklist/

[7] https://www.accextrusion.com/news/the-importance-of-pvc-profile-extrusion-machines/

[8] https://www.anda-china.com/Energy-Efficient-and-Sustainable-UPVC-Profile-Extrusion-Machine-id43559376.html

[9] https://jieyatwinscrew.com/blog/pvc-extruder-machine-everything-you-need-to-know/

[10] https://www.extruders-machine.com/quality-13729511-window-upvc-profile-extrusion-machine-upvc-window-extrusion-profiles

[11] https://protecnic.es/en/por-que-usar-la-extrusion-de-plastico/

[12] https://www.caisumachinery.com/why-pvc-extruder-machines-are-essential-in-plastic-industry/

[13] https://www.jwellmachine.com/upvc-extrusion-equipment-and-formula-adjustment/

[14] https://www.taizhengmachine.com/why-plastic-extrusion-is-one-of-the-most-important-plastic-machinery-equipment.html

[15] https://jfextruder.com/what-is-a-plastic-extruder-machine/

[16] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[17] https://jieyatwinscrew.com/blog/pvc-extruder-machine-everything-you-need-to-know/

[18] https://www.plastikcity.co.uk/blog/what-is-plastic-extrusion/

[19] https://www.fangliextru.com/news-show-1069125.html

[20] https://www.cnchaoxu.com/news-center/plastic-sheet-extrusion-machine-a-key-equipment-in-the-plastics-industry

[21] https://okotech.in/blog/decoding-extrusion-upvc-profile-manufacturing/

[22] https://www.euroextrusions.com/plastic-extrusion-advantages-benefits/

[23] https://www.sharcpm.com/product/upvc-window-profile-extrusion-machine/

[24] https://www.polytimetech.com/upvc-window-profile-extrusion-machine/

[25] https://www.adremac.com/pipe-extruders-comprehensive-guide-to-technology-applications-and-innovations-in-plastic-pipe-manufacturing/

[26] https://dkmachine.en.made-in-china.com/product/sdUaRGOKZTpX/China-UPVC-Profile-Extrusion-Machine-PVC-Profile-Making-Machine.html

[27] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[28] https://www.hansweber.de/en/products-services/extrusion/translate-to-english-whitepaper-pvc-extrusion

[29] https://www.hindustanplastics.in/upvc-profile-machine.htm

[30] https://jwellmachinery.en.made-in-china.com/product/TBIENhGkamad/China-UPVC-Door-Window-Profile-Extrusion-Machine.html

[31] https://jjindustriesindia.com/plastic-extrusion-machine-faqs/

[32] https://www.veka.in/blog/upvc-windows-and-doors/

[33] https://www.jwellmachine.com/analysis-and-solution-of-common-failures-of-plastic-extruder/

[34] https://www.polytechmachine.com/news/daily-maintenance-of-plastic-extrusion-product-78932188.html

[35] https://blog.goldsupplier.com/plastic-extrusion-machines/

[36] https://windsormachines.com/upvc-pipe-manufacturing-plant/

[37] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[38] https://www.bausano.com/en/press-and-news/common-problems-in-the-plastic-extrusion-process

[39] https://www.qiangshengplas.com/news/ensuring-optimal-performance-a-comprehensive-daily-maintenance-checklist-for-pvc-profile-extrusion-machines/

[40] https://trustymachine.en.made-in-china.com/product/bOLtEqvDYmYi/China-PVC-UPVC-Windows-and-Door-Profile-Production-Line-Extrusion-Machine.html

[41] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[42] https://paulmurphyplastics.com/industry-news-blog/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[43] https://ppcorrugatedsheetmachine.com/upvc-window-door-profile-extrusion-machine/

[44] https://www.extruders-machine.com/quality-13729511-window-upvc-profile-extrusion-machine-upvc-window-extrusion-profiles

[45] https://www.jwellextrusions.com/common-problems-and-solutions-of-pe-pipe-extrusion-line.html

[46] https://www.tgtextrusion.com/pvc-window-and-door-profile-extrusion-line-plastic-extruder-upvc-windows-profile-door-frame-making-machine-2-product/