Content Menu

● Understanding Single Screw Extrusion Equipment

>> What Is Single Screw Extrusion?

>> Key Components of a Single Screw Extruder

● The Strategic Advantage of Investing Near Aurora, IL

>> Access to Leading Manufacturers

>> Local Support and Collaboration

>> Economic and Logistical Benefits

● Key Features and Benefits of Single Screw Extrusion Equipment

>> 1. Simplicity and Reliability

>> 2. Versatility Across Applications

>> 3. Cost-Effectiveness

>> 4. Customization and Scalability

>> 5. Advanced Technology and Innovation

● Why Choose a Manufacturer of Single Screw Extrusion Equipment Near Aurora, IL?

>> Proven Expertise and Industry Leadership

>> Comprehensive Support and Services

>> Innovation Hubs and Technology Centers

>> Sustainable Manufacturing Practices

● Comparative Analysis: Single Screw vs. Twin Screw Extruders

● Applications of Single Screw Extrusion Equipment

>> Pipe and Tubing Production

>> Film and Sheet Extrusion

>> Wire and Cable Coating

>> Compounding and Blending

>> Recycling and Reprocessing

● Innovations from Manufacturers Near Aurora, IL

>> PTi's Super-G HighSpeed Extruder

>> Technology Development Center

>> Custom Engineering and Rapid Prototyping

● How to Select the Right Single Screw Extrusion Equipment

>> Factors to Consider

>> Working with a Local Manufacturer

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is a single screw extruder, and how does it work?

>> 2. What are the main advantages of single screw extrusion equipment over twin screw systems?

>> 3. Why should I choose a manufacturer of single screw extrusion equipment near Aurora, IL?

>> 4. What materials can be processed with single screw extrusion equipment?

>> 5. How do I determine the right single screw extruder for my application?

● Citations:

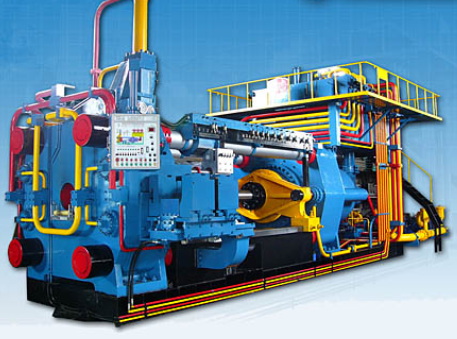

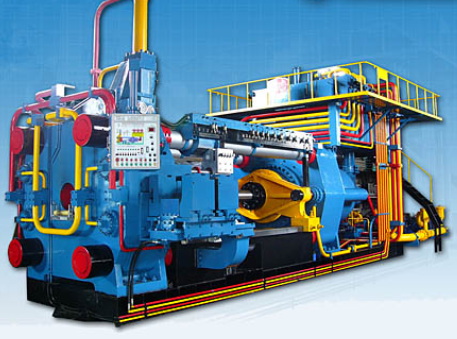

The manufacturing landscape in Aurora, Illinois, is rapidly evolving, with businesses seeking efficiency, reliability, and innovation in their production lines. Among the most critical investments for plastics and polymer processors is the choice of extrusion equipment. Single screw extrusion equipment, in particular, stands out for its simplicity, versatility, and cost-effectiveness. This article explores the compelling reasons to invest in single screw extrusion equipment near Aurora, IL, highlighting the advantages, applications, and the unique benefits of working with a local manufacturer of single screw extrusion equipment near Aurora, IL.

Understanding Single Screw Extrusion Equipment

What Is Single Screw Extrusion?

Single screw extrusion is a process in which raw materials—typically polymers—are melted, mixed, and forced through a die by a single rotating screw within a heated barrel. This continuous process produces a wide variety of products, including pipes, films, sheets, and coatings[3][5][6].

Key Components of a Single Screw Extruder

- Hopper: Feeds raw material into the barrel.

- Screw: Rotates to convey, melt, and mix material.

- Barrel: Houses the screw and provides heating.

- Die: Shapes the molten material.

- Temperature Control System: Maintains precise process temperatures.

- Drive Mechanism: Powers the screw's rotation[5][6].

The Strategic Advantage of Investing Near Aurora, IL

Access to Leading Manufacturers

Aurora, IL, is home to some of the industry's most respected manufacturers of single screw extrusion equipment. One prominent example is Processing Technologies International, LLC (PTi), a global leader in high-performance sheet extrusion machinery based in Aurora. PTi has a long-standing reputation for engineering excellence and offers advanced extrusion systems for a wide range of applications[2][7][8].

Local Support and Collaboration

Choosing a manufacturer of single screw extrusion equipment near Aurora, IL, enables direct collaboration and personalized support. Local manufacturers provide:

- Faster response times for service and support

- On-site training and process optimization

- Quick access to spare parts and repairs

- Opportunities for joint development and customization[1][2][7]

Economic and Logistical Benefits

- Reduced shipping costs and lead times

- Support for the local economy and job creation

- Easier site visits and factory acceptance tests

- Streamlined communication and project management[2][7][8]

Key Features and Benefits of Single Screw Extrusion Equipment

1. Simplicity and Reliability

Single screw extruders are renowned for their straightforward design, making them easy to operate and maintain. This simplicity translates to fewer breakdowns, lower maintenance costs, and greater uptime[3][5][9].

2. Versatility Across Applications

These machines can process a broad spectrum of materials, including:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Engineering plastics

- Rubbers and composites

Applications include pipe and tubing extrusion, film production, cable coating, compounding, and recycling[3][10].

3. Cost-Effectiveness

Compared to twin screw extruders, single screw systems are less expensive to purchase, operate, and maintain. Their energy-efficient operation and lower component count further reduce total cost of ownership[3][4][9].

4. Customization and Scalability

Many manufacturers of single screw extrusion equipment near Aurora, IL, offer custom solutions tailored to specific production requirements. Whether you need a compact system for small batches or a high-output line for mass production, equipment can be scaled and configured accordingly[1][2][4].

5. Advanced Technology and Innovation

Modern single screw extruders feature:

- Digital control systems for precise process monitoring

- Energy-saving motors and advanced heating elements

- Innovative screw geometries for improved mixing and output

- Integration with Industry 4.0 and smart factory systems[3][4][8]

Why Choose a Manufacturer of Single Screw Extrusion Equipment Near Aurora, IL?

Proven Expertise and Industry Leadership

Manufacturers like PTi have decades of experience serving global markets, with a focus on quality, performance, and innovation. Their systems are engineered to exacting standards, ensuring consistent, high-quality output for demanding applications[2][7][8].

Comprehensive Support and Services

Working with a local manufacturer provides access to:

- Application engineering and process optimization

- Custom design and fabrication

- Preventive maintenance and rapid repairs

- Operator training and technical support[1][2][7]

Innovation Hubs and Technology Centers

PTi's Technology Development Center in Aurora offers customers the opportunity to conduct product development, process trials, and operator training on full-scale production systems. This hands-on access accelerates innovation and reduces risk when scaling up new products[8].

Sustainable Manufacturing Practices

Local manufacturers are increasingly adopting sustainable practices, such as energy-efficient equipment design and support for recycling applications. By investing in advanced single screw extrusion equipment, companies can reduce their environmental footprint and support circular economy initiatives[3][4].

Comparative Analysis: Single Screw vs. Twin Screw Extruders

| Feature | Single Screw Extruder | Twin Screw Extruder |

| Design Complexity | Simple, easy to operate and maintain | Complex, requires specialized knowledge |

| Cost | Lower initial and operating costs | Higher costs due to complexity |

| Mixing Capability | Good for basic mixing | Superior for advanced compounding |

| Material Compatibility | Wide range of polymers | Handles complex formulations |

| Output Consistency | High for standard applications | Higher for demanding applications |

| Maintenance | Straightforward, less downtime | More involved, higher maintenance |

| Application Suitability | Pipes, films, coatings, recycling | Compounding, specialty blends |

Single screw extruders strike a balance between cost, simplicity, and versatility, making them ideal for most standard extrusion needs[3][4][5][9].

Applications of Single Screw Extrusion Equipment

Pipe and Tubing Production

Used extensively for manufacturing pipes and tubes for plumbing, irrigation, and industrial applications, single screw extruders deliver consistent wall thickness and high throughput[3][10].

Film and Sheet Extrusion

From packaging films to construction sheets, these machines enable the production of thin, uniform films and robust sheets for diverse industries[2][3][7].

Wire and Cable Coating

In the electrical industry, single screw extruders apply protective coatings to wires and cables, ensuring insulation and durability[3].

Compounding and Blending

Single screw extruders are used to blend polymers with additives, fillers, and colorants, creating custom material formulations for specific applications[3][5].

Recycling and Reprocessing

These machines play a vital role in recycling operations by reprocessing scrap plastics into reusable pellets or products, supporting sustainability goals[3][4].

Innovations from Manufacturers Near Aurora, IL

PTi's Super-G HighSpeed Extruder

PTi's Super-G HighSpeed Extruder, developed in Aurora, features advanced screw technology for improved melt quality and higher output. Integrated digital controls and configurable roll stands enhance flexibility and productivity[8].

Technology Development Center

PTi's 15,000-square-foot Technology Development Center in Aurora showcases the latest in extrusion technology, offering customers hands-on experience with production-scale systems for trials and training[8].

Custom Engineering and Rapid Prototyping

Local manufacturers offer custom engineering services, allowing clients to prototype new products, optimize processes, and quickly scale up to full production[1][2][8].

How to Select the Right Single Screw Extrusion Equipment

Factors to Consider

- Material Compatibility: Ensure the extruder can handle your specific polymers and additives.

- Screw Design: Choose the appropriate screw geometry for your process (e.g., barrier, mixing, vented).

- Output Requirements: Match the machine's throughput to your production needs.

- Control Systems: Look for advanced controls for precise process management.

- Maintenance: Opt for models with easy access for cleaning and part replacement.

- Customization: Work with a manufacturer that offers tailored solutions for your application[5][6][10].

Working with a Local Manufacturer

Engage early with a manufacturer of single screw extrusion equipment near Aurora, IL, to discuss your application, tour their facilities, and review case studies of similar projects. This collaborative approach ensures the best fit for your needs and long-term support[1][2][7].

Conclusion

Investing in single screw extrusion equipment near Aurora, IL, offers manufacturers a strategic advantage in terms of technology, support, and economic benefits. Local manufacturers like PTi provide world-class equipment, expert engineering, and comprehensive services that enable businesses to maximize productivity, minimize downtime, and innovate with confidence. With the flexibility, efficiency, and reliability of modern single screw extrusion systems, companies can address a wide range of production needs—from pipes and films to custom blends and recycled materials—while supporting sustainable manufacturing practices.

Frequently Asked Questions (FAQ)

1. What is a single screw extruder, and how does it work?

A single screw extruder is a machine that processes raw materials—such as plastics or polymers—by melting, mixing, and forcing them through a die using a single rotating screw inside a heated barrel. The result is a continuous flow of material that can be shaped into various products[3][5][6].

2. What are the main advantages of single screw extrusion equipment over twin screw systems?

Single screw extruders are simpler, more cost-effective, and easier to maintain than twin screw systems. They are ideal for standard extrusion tasks where advanced compounding or mixing is not required, making them suitable for a wide range of applications with lower operating costs[3][4][9].

3. Why should I choose a manufacturer of single screw extrusion equipment near Aurora, IL?

Choosing a local manufacturer provides faster service, personalized support, easier access to spare parts, and opportunities for collaboration on custom solutions. Aurora-based manufacturers like PTi also offer advanced technology centers for product development and training[2][7][8].

4. What materials can be processed with single screw extrusion equipment?

Single screw extruders can process a wide variety of materials, including polyethylene (PE), polypropylene (PP), PVC, engineering plastics, rubbers, and composites. They are also widely used in recycling applications[3][4][10].

5. How do I determine the right single screw extruder for my application?

Consider factors such as material compatibility, required output rate, screw design, control system sophistication, and maintenance needs. Collaborate with a reputable manufacturer of single screw extrusion equipment near Aurora, IL, to ensure the equipment is tailored to your specific requirements[5][6][10].

Citations:

[1] https://santafemachine.com

[2] https://www.ptiextruders.com/news/article/current/2018/05/01/100038/pti-marks-30th-anniversary-as-leading-supplier-of-sheet-extrusion-systems-in-north-america

[3] https://www.caisumachinery.com/single-screw-extruder-key-features-and-benefits/

[4] https://www.sourcifychina.com/top-single-screw-extruder-manufacturers-compare/

[5] https://jieyatwinscrew.com/blog/single-screw-extruder/

[6] https://jieyatwinscrew.com/blog/screw-extruder/

[7] https://www.linkedin.com/company/processing-technologies-international-llc

[8] https://www.ptonline.com/articles/pti-opens-tech-center-at-illinois-hq-(2)

[9] https://ud-machine.com/blog/difference-between-single-and-twin-screw-extruder/

[10] https://scsequipment.com/project/single-screw-extruders/

[11] https://www.ptiextruders.com/overview

[12] https://www.ptiextruders.com/manufacturing-electrical-supervisor

[13] https://www.thomasnet.com/suppliers/illinois/all-cities/extruding-machinery-46791802

[14] https://www.plasticstoday.com/plastics-processing/extrusion-equipment-manufacturers-think-big

[15] https://plasticsbusinessmag.com/press-release/2025/pti-announces-its-newest-dryerless-twin-screw-extruder-series/

[16] https://www.asarengineering.com/illinois/single-screw-extruder.htm

[17] https://www.plasticstoday.com/extrusion-film-sheet/sheet-extrusion-systems-maker-pti-initiates-10-million-expansion

[18] https://windsormachines.com/single-screw-pipe-extruder/

[19] https://www.recyclingtoday.com/article/mixing-things-up/

[20] https://ptfe-machinery.com/single-screw-extrusion/

[21] https://www.plasticstoday.com/plastics-processing/single-screw-extruder-with-production-benefits

[22] https://sunpring.com/single-screw-extruder-vs-twin-screw-extruder/

[23] https://www.plasticsnews.com/machinery/extrusion-machinery-outlook-2024-momentum-builds-after-orders-drop

[24] https://cfaminternational.com/should-snack-producers-opt-for-single-or-twin-screw-extrusion/

[25] https://www.linkedin.com/company/processing-technologies-international-llc

[26] https://www.cowinextrusion.com/all-that-you-must-know-about-single-screw-extruder/

[27] https://www.omegabarrelscrew.com/what-are-the-advantages-single-screw-extruders-a-249.html

[28] https://www.snsinsider.com/reports/extruders-market-2192

[29] https://www.neoplast.com/products/single-screw-extruder

[30] https://www.kalshine.com/info/advantages-and-disadvantages-of-single-screw-e-24858195.html

[31] https://www.ptiextruders.com/hvtse-technology

[32] https://www.globalseafood.org/advocate/twin-screw-extruders-outperform-simpler-single-screw-machines/

[33] https://www.sciencedirect.com/topics/materials-science/single-screw-extrusion

[34] https://www.blessonextrusion.com/faqs/

[35] https://granuwelextruder.com/a-complete-guide-to-single-screw-extruder-parts-applications-advantages%EF%BF%BC/