Content Menu

● Introduction to Lab Extrusion Equipment

● Key Components of Lab Extrusion Equipment

>> Feed Hopper

>> Screw(s)

>> Barrel

>> Die

>> Temperature Control System

>> Control System

● How Does Lab Extrusion Equipment Work?

>> 1. Material Feeding

>> 2. Conveying and Melting

>> 3. Mixing and Homogenization

>> 4. Shaping

>> 5. Cooling and Collection

● Types of Lab Extruders

>> Single-Screw Extruders

>> Twin-Screw Extruders

>> Table-Top/Bench-Top Extruders

● Main Applications of Lab Extrusion Equipment

● Advantages of Lab Extrusion Equipment

● Considerations for Selecting Lab Extrusion Equipment

● Maintenance and Safety in Lab Extrusion

● Conclusion

● FAQs

>> 1. What distinguishes lab extrusion equipment from industrial extruders?

>> 2. Can lab extrusion equipment handle both single-screw and twin-screw configurations?

>> 3. What are the main considerations when selecting lab extrusion equipment for a specific application?

>> 4. How does lab extrusion equipment contribute to cost savings in R&D?

>> 5. Is it possible to scale up results from lab extrusion equipment to industrial production?

● Citations:

Lab extrusion equipment is a cornerstone of modern research and development across industries such as polymers, pharmaceuticals, and food technology. These compact yet powerful machines enable scientists and engineers to test, develop, and optimize new materials and processes on a manageable scale before scaling up to full production. In this comprehensive guide, we will explore the definition, components, working principles, applications, and benefits of lab extrusion equipment, alongside frequently asked questions to clarify common queries.

Introduction to Lab Extrusion Equipment

Lab extrusion equipment refers to scaled-down versions of industrial extruders designed specifically for laboratory use. These machines are engineered to process small batches of raw materials, allowing researchers to create semi-finished or finished products for testing, development, and quality control[2][3][4]. The core function of lab extrusion equipment is to apply heat, pressure, and mechanical shear to a material, transforming it into a new form or structure.

Laboratory extruders are essential tools in research and development because they:

- Enable rapid prototyping and formulation testing

- Conserve valuable materials by operating at low throughput

- Provide precise control over processing parameters

- Allow for easy modification and customization to suit specific experiments[3][4]

Key Components of Lab Extrusion Equipment

Understanding the structure of lab extrusion equipment is key to appreciating its versatility and effectiveness. The fundamental components include:

Feed Hopper

The feed hopper is where raw materials are introduced into the extruder. Its design ensures even feeding and prevents blockages, which is critical for consistent operation[2].

Screw(s)

The screw (or screws, in the case of twin-screw extruders) is the heart of the extrusion process. As it rotates within the barrel, it conveys, compresses, and melts the material. Key parameters include screw diameter, length-to-diameter (L/D) ratio, and rotation speed[2][3][5].

Barrel

The barrel houses the screw(s) and provides the heated environment necessary for melting and mixing the material. It is typically divided into multiple heating zones for precise temperature control[2][3].

Die

The die shapes the extruded material as it exits the barrel. The die's geometry determines the final form of the product, such as pellets, sheets, or filaments[2].

Temperature Control System

This system includes heaters, thermocouples, and sometimes cooling elements to maintain optimal processing temperatures throughout the barrel[2].

Control System

Modern lab extrusion equipment is equipped with advanced control systems, often featuring computer interfaces for real-time monitoring and adjustment of parameters like screw speed, temperature, and feed rate[2][3].

How Does Lab Extrusion Equipment Work?

The operation of lab extrusion equipment involves a sequence of carefully controlled steps:

1. Material Feeding

Raw materials are loaded into the feed hopper. The design ensures a steady, uniform feed to the screw(s)[2].

2. Conveying and Melting

The rotating screw(s) transport the material through the heated barrel. As the material moves forward, it is subjected to increasing pressure and temperature, causing it to soften and melt[2][3].

3. Mixing and Homogenization

Mechanical shear generated by the screw(s) thoroughly mixes and homogenizes the material, ensuring a consistent composition throughout[2][5].

4. Shaping

The molten, homogenized material is forced through the die at the end of the barrel. The die imparts the desired shape to the extrudate, such as a strand, pellet, or sheet[2].

5. Cooling and Collection

After exiting the die, the extrudate is cooled (usually by air or water) and collected for further testing or processing[2][3].

This continuous process allows for efficient transformation of raw materials into testable forms, making lab extrusion equipment invaluable for product development and quality assurance.

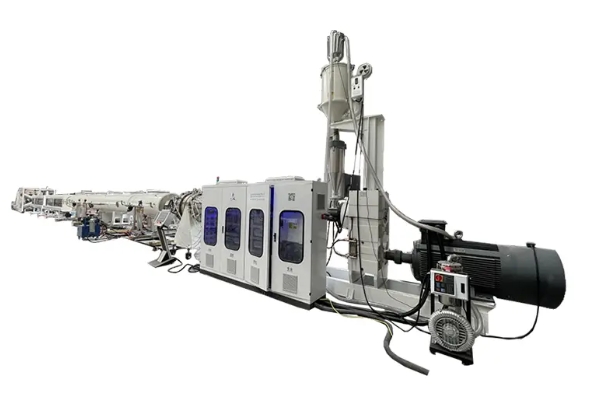

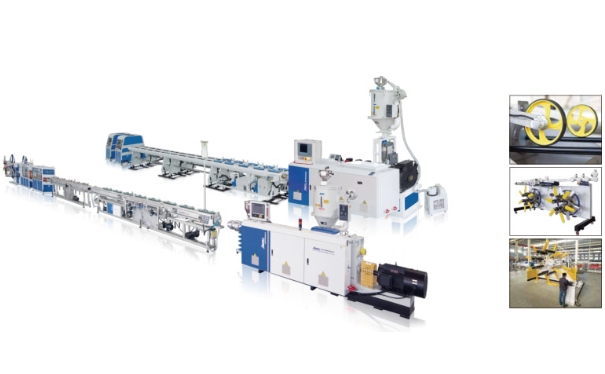

Types of Lab Extruders

Lab extrusion equipment comes in several configurations, each suited to different applications and material types:

| Type | Description | Typical Applications |

| Single-Screw | Features one rotating screw; ideal for straightforward processes and materials | Simple polymer melts, basic compounding |

| Twin-Screw | Two intermeshing screws; superior mixing, flexibility, and process control | Advanced polymer blends, pharmaceuticals, R&D |

| Table-Top/Bench-Top | Compact, portable units for very small batch or pilot-scale work | Rapid prototyping, education, formulation testing |

Single-Screw Extruders

These are best suited for simple extrusion tasks, such as melting and shaping thermoplastics. They offer straightforward operation and are often used for basic material testing[2][3].

Twin-Screw Extruders

Twin-screw lab extrusion equipment provides enhanced mixing and flexibility. The intermeshing screws allow for more complex processes, such as compounding, reactive extrusion, and processing of heat-sensitive materials[2][5]. They are widely used in research settings for their ability to handle a broad range of formulations.

Table-Top/Bench-Top Extruders

Designed for maximum convenience and portability, these extruders are ideal for quick tests, small batch runs, and educational purposes. They often feature easy disassembly for cleaning and rapid setup[6].

Main Applications of Lab Extrusion Equipment

Lab extrusion equipment is used in a wide array of fields, including:

- Polymer Research and Development

Enables the formulation and testing of new plastics, composites, and blends before scaling to industrial production[2][3][4].

- Pharmaceuticals

Used to develop solid dispersions, granules, and taste-masked formulations, improving drug release and bioavailability[1][3].

- Food Technology

Facilitates the creation of novel food textures, shapes, and formulations, such as snack foods and nutritional supplements[2][4].

- Material Science

Supports the investigation of new materials, additives, and processing methods, providing critical data for innovation[3][4].

- Quality Control and Education

Allows for routine testing of material properties and serves as a valuable teaching tool in academic settings[3][4][6].

Advantages of Lab Extrusion Equipment

The use of lab extrusion equipment offers several significant benefits:

- Material Efficiency

Processes small quantities, reducing waste and conserving expensive or limited raw materials[4][6].

- Process Flexibility

Easily adjustable parameters and interchangeable components accommodate a wide range of experiments and materials[2][3][5].

- Rapid Prototyping

Accelerates product development cycles by enabling quick formulation changes and immediate testing[3][4].

- Cost-Effectiveness

Lowers the cost of R&D by avoiding full-scale production trials and minimizing resource consumption[4][6].

- Scalability

Results obtained on lab extrusion equipment can often be reliably scaled up to industrial processes, facilitating smooth technology transfer[4].

- Enhanced Process Control

Advanced control systems allow for precise monitoring and adjustment, ensuring reproducible and high-quality results[2][3][5].

Considerations for Selecting Lab Extrusion Equipment

When choosing lab extrusion equipment, several factors should be evaluated:

- Material Compatibility

Ensure the extruder can process the specific materials and formulations of interest[3][4].

- Throughput Requirements

Select a machine with an appropriate capacity for your batch sizes and research needs[1][6].

- Screw Configuration

Decide between single-screw or twin-screw designs based on the complexity of your processes[2][5].

- Control Features

Look for advanced control systems with real-time monitoring and data logging capabilities[2][3].

- Ease of Cleaning and Maintenance

Choose equipment that can be quickly disassembled and cleaned, especially when working with multiple formulations[6].

- Customization and Expandability

Consider whether the extruder can be fitted with specialized dies, feeders, or auxiliary equipment for future needs[4][5].

Maintenance and Safety in Lab Extrusion

Proper maintenance and adherence to safety protocols are essential for the reliable and safe operation of lab extrusion equipment:

- Regular Cleaning

Disassemble and clean all material-contact parts after each use to prevent contamination and ensure consistent results[6].

- Routine Inspection

Check screws, barrels, and dies for wear or damage, and replace components as needed to maintain performance[3][6].

- Temperature and Pressure Monitoring

Always monitor operational parameters to prevent overheating, overpressure, or unsafe conditions[2][3].

- Training and Documentation

Ensure that all operators are trained in the use of the equipment and that operating procedures are well documented[3][4].

Conclusion

Lab extrusion equipment is an indispensable tool in modern research and development, offering unparalleled flexibility, control, and efficiency for material processing on a small scale. By enabling precise experimentation with minimal resource consumption, lab extruders accelerate innovation across industries from plastics and pharmaceuticals to food science and beyond. Their modular design, advanced control systems, and adaptability make them ideal for everything from rapid prototyping to advanced material research.

Whether you are developing a new polymer blend, testing pharmaceutical formulations, or teaching the next generation of engineers, lab extrusion equipment provides the reliability and performance needed to turn ideas into reality.

FAQs

1. What distinguishes lab extrusion equipment from industrial extruders?

Lab extrusion equipment is specifically designed for small batch processing, research, and development. While industrial extruders focus on high-volume, continuous production, lab extruders offer greater control, flexibility, and ease of modification, making them ideal for experimentation and prototyping[5].

2. Can lab extrusion equipment handle both single-screw and twin-screw configurations?

Yes, lab extrusion equipment is available in both single-screw and twin-screw designs. Single-screw extruders are suitable for simple processes, while twin-screw extruders provide enhanced mixing and process control for more complex formulations[2][5].

3. What are the main considerations when selecting lab extrusion equipment for a specific application?

Key factors include material compatibility, throughput requirements, screw configuration, control features, ease of cleaning, and the ability to customize or expand the system for future needs[3][4][5].

4. How does lab extrusion equipment contribute to cost savings in R&D?

By processing small quantities of material, lab extrusion equipment minimizes waste and conserves expensive resources. It also allows for rapid prototyping and testing, reducing the need for costly full-scale production trials[4][6].

5. Is it possible to scale up results from lab extrusion equipment to industrial production?

Yes, one of the primary benefits of lab extrusion equipment is its scalability. Well-designed lab extruders can replicate the processing conditions of industrial machines, enabling reliable scale-up of formulations and processes[4].

Citations:

[1] https://www.directindustry.com/industrial-manufacturer/laboratory-extruder-148155.html

[2] https://jieyatwinscrew.com/blog/lab-extruder/

[3] https://www.haisiextrusion.com/What-is-the-function-of-the-lab-extruder-id3440389.html

[4] https://daextrusion.com/applications/laboratory-extruders/

[5] https://jieyatwinscrew.com/blog/what-is-a-lab-extruder/

[6] https://www.shaktipharmatech.com/lab-extruder-sle/

[7] https://www.thermofisher.com/us/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment.html

[8] https://www.alibaba.com/showroom/laboratory-lab-extruder-equipment.html

[9] https://www.bausano.com/en/press-and-news/what-is-an-extruder-and-how-does-it-work

[10] https://www.goettfert.com/products/laboratory-extruder

[11] https://www.thermofisher.com/us/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment/applications.html

[12] https://www.chitramechtech.com/blog/salient-features-of-our-lab-extruder-and-powder-extruder-machinery/

[13] https://www.aasabimachines.com

[14] https://torontech.com/twin-screw-extruder-explained-from-basics-to-applications/

[15] https://www.uml.edu/engineering/plastics/about-us/labs/extrusion.aspx

[16] https://daextrusion.com/applications/

[17] https://www.thermofisher.com/mx/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment.html

[18] https://www.bausano.com/en/extruders-range/laboratory-extruder-md-30

[19] https://www.cowellextrusion.com/understanding-lab-extruder/

[20] https://www.cowinextrusion.com/faq/

[21] https://www.lubrizol.com/-/media/Lubrizol/Health/Literature/LSP-Extrusion-Guide.pdf

[22] https://www.yjing-extrusion.com/how-accurate-is-lab-extrusion-machinery-for-small-scale-production.html

[23] https://www.goodfishgroup.com/plastic-extrusion-company

[24] https://wiki.bambulab.com/en/x1/troubleshooting/extruder-clog

[25] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[26] https://www.cowinextrusion.com/key-points-to-pay-attention-to-when-selecting-plastic-extruder/

[27] https://www.youtube.com/watch?v=rmBp0hgwZHg

[28] https://www.thermofisher.com/sa/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment/services.html

[29] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[30] https://www.haisiextrusion.com/Mini-extruder-Lab-extruder-for-laboratory-use-pd41308166.html

[31] https://en.wikipedia.org/wiki/Extrusion

[32] https://www.plasticsmachinerymanufacturing.com/blow-molding/article/13001454/special-report-lab-extruders-provide-way-to-test-materials-prior-to-production

[33] https://www.anton-paar.com/corp-en/products/details/twinlab/

[34] https://www.youtube.com/watch?v=WKCccsy29bI

[35] https://www.haisiextrusion.com/Maintenance-And-Repair-of-Extruder-Screws-And-Barrels-id45197566.html

[36] https://elearning.uniroma1.it/pluginfile.php/897161/mod_resource/content/1/OM_Process%2011_GB_v1%2001.pdf

[37] https://www.medicalextruders.com/info/extrusion-equipment-maintenance-method-24455647.html

[38] https://www.distrupol.com/Hytrel_Extrusion_Manual.pdf