Content Menu

● Understanding the Aluminum Extrusion Process

● Basic Steps in Aluminum Extrusion

● Components of an Aluminum Extruder Machine

>> The Working Process of an Aluminum Extruder Machine

● Types of Aluminum Extrusion Machines

● Advantages of Aluminum Extrusion Machines

● Post-Extrusion Processes in Detail

● Applications of Aluminum Extrusion

● Evolution of Aluminum Extrusion Machines

● The Role of Die Design

● Modern Advances in Aluminum Extrusion Technology

● Choosing the Right Aluminum Extrusion Machine

● Maintaining an Aluminum Extruder Machine

● Conclusion

● FAQ: Frequently Asked Questions About Aluminum Extrusion Machines

>> 1. What is an aluminum extruder machine?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the main components of an aluminum extruder machine?

>> 4. What are the advantages of using an aluminum extruder machine?

>> 5. What industries use aluminum extrusion?

● Citations:

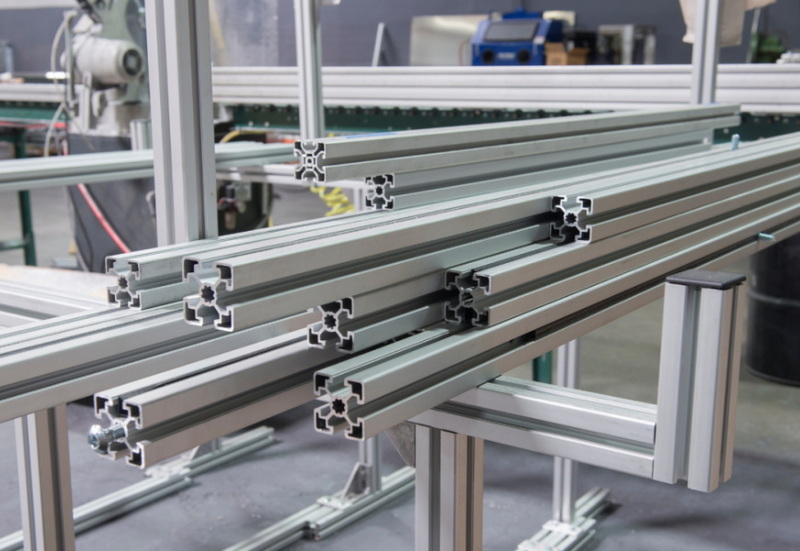

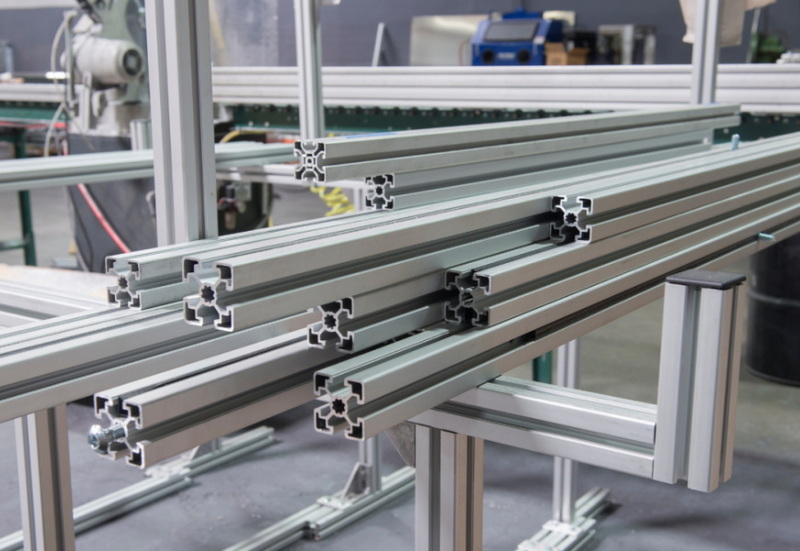

Aluminum extrusion is a versatile process used to create a wide array of products with specific cross-sectional profiles[7]. The process involves forcing aluminum alloy through a die, resulting in shapes that can be solid, hollow, or semi-hollow[2][5]. The machinery that facilitates this process is known as an aluminum extruder machine. This article delves into the workings of aluminum extruder machines, their components, the extrusion process, and more.

Understanding the Aluminum Extrusion Process

The aluminum extrusion process can be likened to squeezing Play-Doh through a shaped opening[1]. In essence, a preheated aluminum billet is pushed through a die with a particular cross-sectional design, producing elongated parts with a consistent shape[2][8].

Basic Steps in Aluminum Extrusion

1. Die Preparation: A die is designed and crafted to shape the aluminum[2]. The die is preheated to between 450-500 degrees Celsius to maximize its life and ensure even metal flow[5].

2. Billet Preheating: The aluminum billet is preheated to ensure it is malleable, typically to a temperature between 400-500 degrees Celsius[2][5]. The melting point of aluminum is approximately 1,220° Fahrenheit (660° Centigrade). Extrusion operations typically take place with billet heated to temperatures in excess of 700°F (375°C), and (depending upon the alloy being extruded) as high as 930°F (500°C)[1].

3. Extrusion: The billet is transferred to the aluminum extruder machine, where it is forced through the die[2]. Hydraulic presses apply pressure, pushing the billet into the container[2]. The aluminum extruder machine uses a hydraulic system to extrude the heated aluminum[4].

4. Post-Extrusion Processes: After extrusion, the profiles undergo several processes, including cooling, stretching, cutting, and heat treatment, to achieve the desired mechanical properties[2].

Components of an Aluminum Extruder Machine

An aluminum extruder machine primarily consists of three main parts: the extrusion head, the hydraulic system, and the control system[4].

1. Extrusion Head: This is a critical part of the aluminum extruder machine, comprising a mold, heater, pretreatment device, and extrusion cavity[4].

- The mold forms the required profile shape.

- The heater heats the aluminum rod or plate.

- The pretreatment device removes oxide scale and applies lubricant.

- The extrusion cavity feeds the pretreated aluminum into the mold.

2. Hydraulic System: The hydraulic system is essential for generating the pressure needed for extrusion[4].

- It includes a fuel tank, an oil pump, a high-pressure cylinder, a low-pressure cylinder, valves, and pipelines.

- The oil pump sends hydraulic oil to the high-pressure oil cylinder, which generates the high pressure needed to extrude aluminum rods or plates.

- The low-pressure oil cylinder controls various parts of the machine.

3. Control System: This system controls the machine's operation and consists of a PLC controller, a human-machine interface, and electrical components[4].

- The PLC controller automates machine control.

- The human-machine interface allows operators to monitor and control the machine's operation.

- Electrical components include sensors and relays.

The Working Process of an Aluminum Extruder Machine

The working process of an aluminum extruder machine involves several steps[4]:

1. Heating: The aluminum rod or plate is heated to the appropriate temperature (generally 300-500°C) to make it soft and plastic[4].

2. Feeding: The heated aluminum is sent to the pretreatment device for oxide scale removal and lubricant application before being sent to the extrusion cavity[4].

3. Pretreatment: In the extrusion cavity, the aluminum is pre-extruded to fit closely with the mold, eliminate air and impurities, and reduce extrusion resistance[4].

4. Extrusion: The hydraulic system is activated to generate high pressure, pushing the aluminum through the mold to form the required profile shape[4].

5. Cutting: The extruded profile is cut into predetermined lengths[4].

Types of Aluminum Extrusion Machines

Aluminum extruder machines can be categorized based on different standards, including horizontal and vertical types, small and super-large sizes, low-speed and high-speed operations, and normal temperature and super-heat processes[4].

Advantages of Aluminum Extrusion Machines

Aluminum extruder machines offer several advantages[4]:

- Efficiency: They can produce large quantities of high-quality aluminum profiles quickly.

- Energy Saving: They utilize the high efficiency and low energy consumption of the hydraulic system.

- Environmental Protection: They use recycling and filtration of hydraulic oil to reduce waste and pollution.

- Flexibility: They can produce various shapes and sizes by changing molds.

Post-Extrusion Processes in Detail

After the aluminum extrusion process, several post-extrusion processes are performed to refine the material's properties and dimensions[2]:

1. Quenching and Handling:

- The extruded material is guided along a runout table[2].

- Profiles are promptly quenched, rapidly cooling them to temper and set their shape[2]. This is often achieved using a water bath or fans[5].

2. Shearing and Cooling:

- The profiles are sheared to manageable lengths[2].

- They are cooled to room temperature to ensure structural stability[2].

3. Stretching and Alignment:

- Profiles are moved to a stretcher, where they are elongated to correct any distortions, ensuring perfect alignment[2].

- This step is vital for maintaining the straightness and uniformity of the profiles[2].

4. Cutting to Length and Inspection:

- Finally, the profiles are cut to the desired length and inspected for quality[2].

Applications of Aluminum Extrusion

Aluminum extrusion is used across various industries due to its versatility and efficiency[4]. These industries include:

- Construction

- Transportation

- Aviation

- Electronics

Evolution of Aluminum Extrusion Machines

The development of aluminum extruder machines can be traced back to the late 19th century when German Joseph Bramah invented the first hydraulic extrusion press for making lead pipes[4]. Over time, these machines have evolved from manual operation to automated control, from single horizontal types to various vertical types, and from low-speed normal temperature extrusion to high-speed extrusion[4].

The Role of Die Design

The die plays a crucial role in the aluminum extrusion process. It is meticulously designed and crafted to ensure the final product meets the required specifications[2]. The die's shape determines the cross-sectional profile of the extruded aluminum[2].

Modern Advances in Aluminum Extrusion Technology

Modern aluminum extruder machines incorporate several advanced technologies to improve their performance[4]:

- Automated Control: PLC controllers and human-machine interfaces enhance precision and ease of operation.

- High-Speed Extrusion: Advanced hydraulic systems enable faster extrusion rates, increasing productivity.

- Super Heat Extrusion: This technique allows for the extrusion of more complex shapes and alloys.

Choosing the Right Aluminum Extrusion Machine

Selecting the appropriate aluminum extruder machine depends on specific needs and requirements[4]. Factors to consider include:

- Size and Type of Profiles: Different machines are suitable for various profile sizes and complexities.

- Production Volume: High-volume production may require high-speed machines.

- Alloy Type: Some machines are better suited for specific aluminum alloys.

Maintaining an Aluminum Extruder Machine

Proper maintenance is essential for ensuring the longevity and efficiency of an aluminum extruder machine[4]. Key maintenance tasks include:

- Regular inspection of hydraulic components.

- Lubrication of moving parts.

- Cleaning and replacement of filters.

- Calibration of control systems.

Conclusion

The "aluminum extruder machine" is a vital piece of equipment in the manufacturing industry, enabling the creation of a wide range of aluminum profiles with precision and efficiency. The process involves preheating aluminum billets and forcing them through a die to produce consistent shapes. Modern machines incorporate advanced technologies for enhanced performance, and proper maintenance ensures their longevity. From construction to transportation, "aluminum extrusion" plays a significant role in shaping the world around us.

FAQ: Frequently Asked Questions About Aluminum Extrusion Machines

1. What is an aluminum extruder machine?

An aluminum extruder machine is a machine that uses a hydraulic system to extrude heated aluminum rods or plates into desired shapes. It is composed of an extrusion head, a hydraulic system, and a control system[4].

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating an aluminum billet and forcing it through a die with a specific cross-sectional profile using high pressure. The resulting extrusion is then cooled, stretched, cut, and heat-treated[2].

3. What are the main components of an aluminum extruder machine?

The main components of an aluminum extruder machine include the extrusion head (mold, heater, pretreatment device, and extrusion cavity), the hydraulic system (fuel tank, oil pump, cylinders, valves, and pipelines), and the control system (PLC controller, human-machine interface, and electrical components)[4].

4. What are the advantages of using an aluminum extruder machine?

The advantages of using an aluminum extruder machine include high efficiency, energy saving, environmental protection, and flexibility in producing various shapes and sizes of aluminum profiles[4].

5. What industries use aluminum extrusion?

Aluminum extrusion is used in various industries, including construction, transportation, aviation, and electronics[4].

Citations:

[1] https://aec.org/aluminum-extrusion-process

[2] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[3] https://www.youtube.com/watch?v=baM5hNnBcT8

[4] https://extruderpress.com/aluminum-extrusion-press/

[5] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[6] https://huananmachine.en.made-in-china.com/product-group/FeCTzvBHlPku/Aluminium-Extruder-Machine-catalog-1.html

[7] https://eagle-aluminum.com/what-is-extruded-aluminum/

[8] https://waykenrm.com/blogs/aluminum-extrusion/

[9] https://www.aluminum-extrusion-machine.com