Content Menu

● Introduction to XPS Foam

● Raw Materials and Production Process

>> Pre-Expansion Process

>> Extrusion Process

● Components of the 100 CO2 Fully Automatic XPS Foam Board Extrusion Line

● Operational Process

● Advantages of Using CO2 as a Blowing Agent

● Benefits of the 100 CO2 Fully Automatic XPS Foam Board Extrusion Line

● Applications of XPS Foam

● Market Trends and Future Developments

● Challenges and Solutions

● Conclusion

● FAQs

>> 1. What are the primary raw materials used in XPS foam production?

>> 2. How does the extrusion process create the closed-cell structure of XPS foam?

>> 3. What are the advantages of using CO2 as a blowing agent in XPS foam production?

>> 4. What is the typical thickness range of XPS foam boards produced by these extrusion lines?

>> 5. How does the fully automatic system enhance the efficiency of XPS foam board production?

The 100 CO2 fully automatic XPS foam board extrusion line is a cutting-edge manufacturing system designed to produce high-quality extruded polystyrene (XPS) foam boards using carbon dioxide (CO2) as a blowing agent. This technology is pivotal in the production of thermal insulation materials, which are widely used in construction and other industries. In this article, we will delve into the details of this production line, its components, and its operational process.

Introduction to XPS Foam

XPS foam is a type of rigid, closed-cell foam that is manufactured through an extrusion process. It is known for its excellent thermal insulation properties, durability, and moisture resistance, making it an ideal material for various applications, including building insulation, refrigeration, and packaging.

Raw Materials and Production Process

The production of XPS foam begins with polystyrene beads, which are combined with blowing agents like CO2, pentane, or butane. These materials are fed into an extruder where they are melted and mixed with other additives such as colorants and flame retardants. The molten mixture is then forced through a die, where it expands and solidifies into a foam sheet.

Pre-Expansion Process

Before extrusion, the polystyrene beads undergo a pre-expansion process using steam and heat. This step increases the volume of the beads, giving them a cellular structure that enhances the foam's insulation capabilities.

Extrusion Process

During the extrusion process, the pre-expanded beads are melted and mixed with blowing agents in a double-screw extruder. The mixture is then extruded through a die, where it expands and forms a sheet of foam. The blowing agent plays a crucial role in creating the foam's closed-cell structure, which is essential for its thermal insulation properties.

Components of the 100 CO2 Fully Automatic XPS Foam Board Extrusion Line

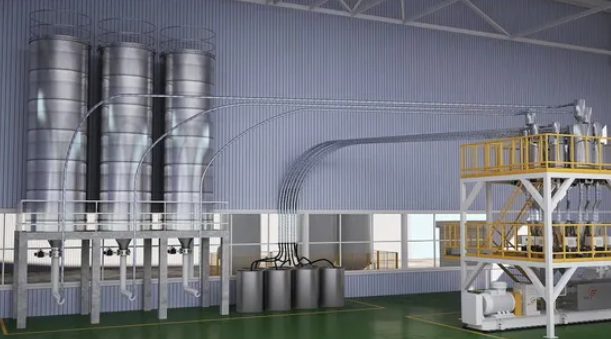

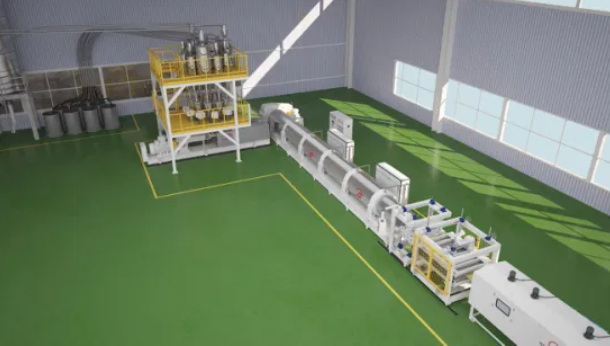

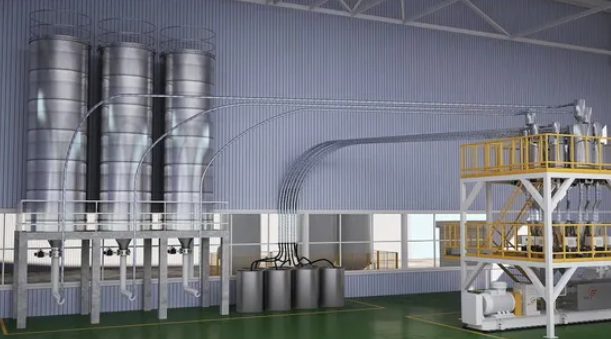

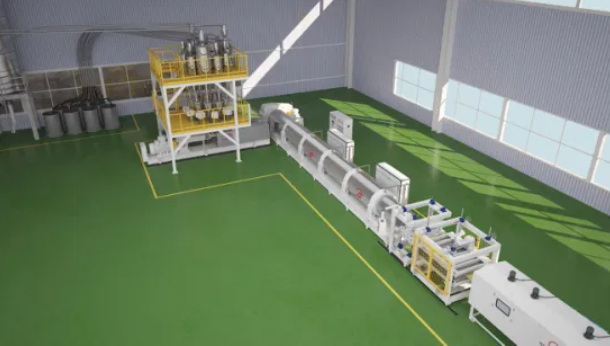

The 100 CO2 fully automatic XPS foam board extrusion line consists of several key components:

1. Feeding System: This includes a feeding device that accurately measures and supplies raw materials into the extruder.

2. Double-Screw Extruder: This is where the polystyrene beads are melted and mixed with blowing agents and other additives. The extruder ensures uniform heating and mixing, which is critical for producing consistent foam quality.

3. Die and Shaping System: The molten mixture is forced through a die, where it takes the shape of a sheet. The die is designed to control the thickness and width of the foam sheet.

4. Cooling and Solidification System: After extrusion, the foam sheet passes through a cooling chamber where it solidifies and maintains its shape.

5. Cutting and Trimming System: The solidified foam sheets are then cut to the desired length and trimmed to remove excess material.

6. Packaging System: Finally, the foam boards are packaged and prepared for transportation.

Operational Process

The operational process of the 100 CO2 fully automatic XPS foam board extrusion line involves several stages:

1. Raw Material Preparation: Polystyrene beads and blowing agents are prepared and fed into the extruder.

2. Extrusion: The mixture is melted and extruded through a die to form a foam sheet.

3. Cooling and Solidification: The foam sheet is cooled and solidified.

4. Cutting and Trimming: The foam sheets are cut to size and trimmed.

5. Packaging: The foam boards are packaged and prepared for shipping.

Advantages of Using CO2 as a Blowing Agent

Using CO2 as a blowing agent in the 100 CO2 fully automatic XPS foam board extrusion line offers several advantages:

- Environmental Benefits: CO2 is a more environmentally friendly option compared to traditional blowing agents like HCFCs and HFCs, which have higher global warming potentials.

- Cost-Effective: CO2 is generally less expensive than other blowing agents, reducing production costs.

- Improved Foam Quality: CO2 can produce foam with a more consistent cell structure, enhancing its thermal insulation properties.

Benefits of the 100 CO2 Fully Automatic XPS Foam Board Extrusion Line

The 100 CO2 fully automatic XPS foam board extrusion line offers several benefits:

- High Efficiency: The fully automatic system ensures continuous production with minimal manual intervention.

- Consistent Quality: The precise control over temperature and pressure ensures consistent foam quality.

- Environmental Sustainability: The use of CO2 as a blowing agent reduces environmental impact.

Applications of XPS Foam

XPS foam is widely used in various applications due to its excellent thermal insulation properties:

- Building Insulation: XPS foam is used in walls, floors, and roofs to reduce heat loss and improve energy efficiency.

- Refrigeration: It is used in refrigerated containers and cold storage facilities to maintain low temperatures.

- Packaging: XPS foam is used in packaging materials to protect products from temperature fluctuations.

Market Trends and Future Developments

The demand for XPS foam is expected to grow due to increasing awareness of energy efficiency and environmental sustainability. As technology advances, we can expect improvements in production efficiency and foam quality. Additionally, the use of more environmentally friendly blowing agents will continue to be a focus in the industry.

Challenges and Solutions

One of the challenges faced by manufacturers is maintaining consistent foam quality while reducing environmental impact. To address this, manufacturers are investing in advanced extrusion technologies and optimizing production processes to minimize waste and improve efficiency.

Conclusion

The 100 CO2 fully automatic XPS foam board extrusion line is a sophisticated manufacturing system that combines efficiency, quality, and environmental sustainability. By utilizing CO2 as a blowing agent, this production line not only reduces costs but also contributes to a more environmentally friendly manufacturing process. As the demand for high-quality thermal insulation materials continues to grow, this technology plays a crucial role in meeting those needs.

FAQs

1. What are the primary raw materials used in XPS foam production?

The primary raw materials used in XPS foam production are polystyrene beads and blowing agents such as CO2 or pentane. Other additives like colorants and flame retardants may also be included depending on the application.

2. How does the extrusion process create the closed-cell structure of XPS foam?

The extrusion process involves melting the polystyrene beads with blowing agents, which expand as they pass through the die, creating a closed-cell structure. This structure is essential for the foam's thermal insulation properties.

3. What are the advantages of using CO2 as a blowing agent in XPS foam production?

Using CO2 as a blowing agent offers environmental benefits, cost savings, and improved foam quality. CO2 is more environmentally friendly than traditional blowing agents and can produce foam with a consistent cell structure.

4. What is the typical thickness range of XPS foam boards produced by these extrusion lines?

The typical thickness range of XPS foam boards can vary but is commonly between 20mm and 120mm, depending on the specific application and production line capabilities.

5. How does the fully automatic system enhance the efficiency of XPS foam board production?

The fully automatic system enhances efficiency by allowing continuous production with minimal manual intervention. This reduces labor costs and ensures consistent product quality throughout the production process.