Content Menu

● Understanding Extrusion Technology in Ice Cream Production

>> Key Components of Ice Cream Extrusion:

● Advantages of Extrusion Technology

● The Process of Ice Cream Extrusion

● Innovations in Extrusion Technology

● The Future of Ice Cream Production

● Detailed Examination of Low Temperature Extrusion (LTE)

>> Mechanisms Behind LTE:

>> Benefits of LTE:

● Market Trends Influencing Ice Cream Production

● Conclusion

● FAQ

>> 1. What is ice cream extrusion?

>> 2. How does extrusion improve ice cream quality?

>> 3. Can large inclusions be added during extrusion?

>> 4. What are some benefits of low-temperature extrusion?

>> 5. How does automation influence ice cream production?

● Citations:

The ice cream industry has undergone significant transformations over the years, with extrusion technology at the forefront of this revolution. This innovative method has not only enhanced production efficiency but also improved the quality and variety of ice cream products available in the market. In this article, we will explore how extrusion technology is reshaping ice cream production, its benefits, and the future of this delightful treat.

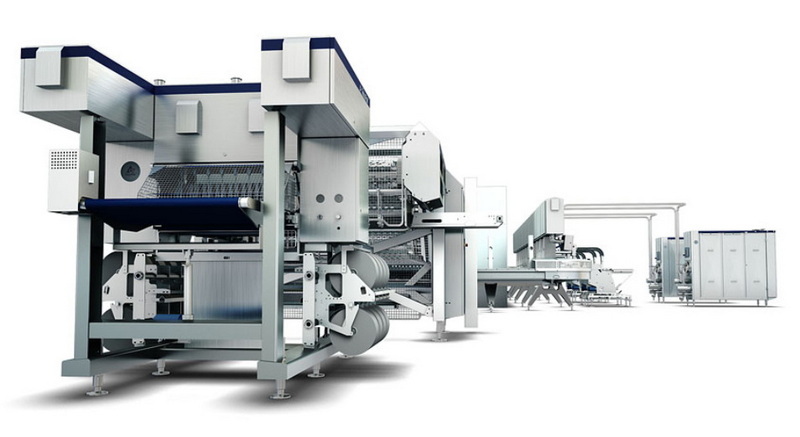

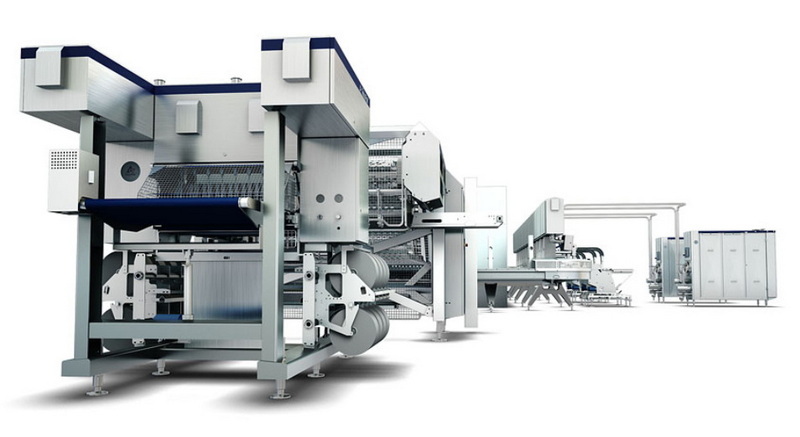

Understanding Extrusion Technology in Ice Cream Production

Extrusion technology involves forcing a mixture of ice cream ingredients through a machine to create various shapes and forms. This process typically occurs after the mixing and pasteurization stages, where the ice cream mix is cooled and then pushed through a narrow opening in the extruder. The result is a continuous stream of ice cream that can be shaped into bars, cones, or other novelty items.

Key Components of Ice Cream Extrusion:

- Extruder: The main machine used to shape the ice cream mix.

- Cooling System: Maintains low temperatures during the extrusion process to prevent melting.

- Cutting Mechanism: Slices the extruded ice cream into desired lengths or shapes.

- Hardening Tunnel: Rapidly freezes the extruded products to ensure they maintain their shape and texture.

Advantages of Extrusion Technology

Extrusion technology offers numerous advantages over traditional ice cream production methods:

- Improved Texture and Quality: Extrusion allows for better control over the size of ice crystals and air bubbles in the ice cream, resulting in a smoother and creamier texture. The low-temperature extrusion process creates smaller ice crystals compared to conventional methods, enhancing the overall mouthfeel of the product.

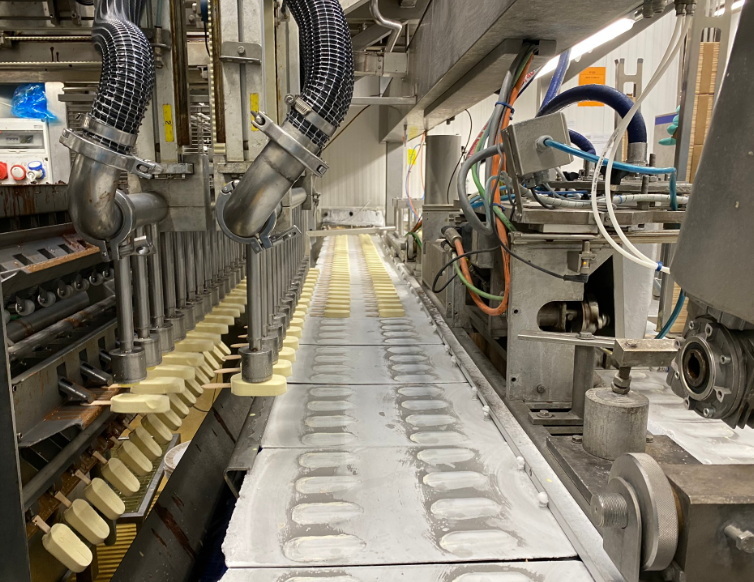

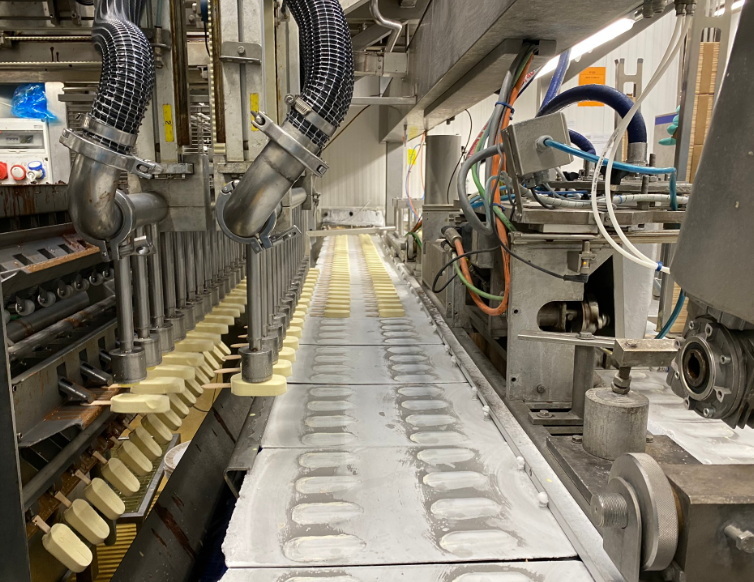

- Versatility in Product Design: This technology enables manufacturers to create a wide variety of shapes and sizes, including complex designs that were previously difficult to achieve. From traditional bars to innovative shapes like bites or bonbons, extrusion opens up new possibilities for product development.

- Inclusion of Large Ingredients: Advanced extruders can incorporate larger inclusions such as cookie chunks or fruit pieces without compromising their integrity. This capability meets consumer demands for more textured and flavorful ice creams.

- Increased Production Efficiency: Extrusion systems are designed for high throughput, allowing manufacturers to produce large quantities of ice cream quickly. For example, modern lines can produce up to 43,200 products per hour, significantly reducing production time and costs.

The Process of Ice Cream Extrusion

The extrusion process consists of several key stages:

1. Mixing: Ingredients such as milk, sugar, stabilizers, and flavorings are blended together.

2. Pasteurization: The mixture is heated to eliminate harmful bacteria.

3. Homogenization: This step breaks down fat globules to ensure a smooth consistency.

4. Aging: The mixture is allowed to rest at low temperatures for several hours to improve texture.

5. Extrusion: The aged mixture is pumped into the extruder where it is shaped and cooled.

6. Hardening: The extruded product is quickly frozen in a hardening tunnel to maintain its shape.

7. Packaging: Finally, the frozen products are packaged for distribution.

Innovations in Extrusion Technology

Recent advancements in extrusion technology have further enhanced its capabilities:

- Low Temperature Extrusion (LTE): This novel approach allows for lower operating temperatures during the extrusion process, which results in finer microstructures with smaller ice crystals. LTE has been shown to improve sensory qualities such as melting rate and consistency.

- Smart Sensors and IoT Integration: Manufacturers are increasingly using smart sensors to monitor extrusion processes in real-time. This technology allows for precise adjustments to temperature and flow rates, ensuring optimal product quality.

- Sustainable Practices: As consumer preferences shift towards sustainability, many manufacturers are adopting eco-friendly practices by using plant-based ingredients and biodegradable packaging materials.

The Future of Ice Cream Production

The future of ice cream production is bright with extrusion technology leading the way. As consumer demands continue to evolve, manufacturers will need to innovate constantly. Here are some trends shaping the future:

- Customization: Consumers are increasingly seeking personalized products tailored to their preferences. Extrusion technology allows for greater flexibility in creating unique flavors and textures.

- Health-Conscious Options: There is a growing demand for healthier alternatives in the ice cream market. Manufacturers can use extrusion technology to create lower-fat options without sacrificing taste or texture.

- Automation and AI Integration: Automation will play a crucial role in streamlining production processes while maintaining high-quality standards. AI can optimize recipes based on consumer feedback and preferences.

Detailed Examination of Low Temperature Extrusion (LTE)

Low Temperature Extrusion (LTE) represents a significant advancement in ice cream production technology by improving both product quality and operational efficiency. By operating at lower temperatures—typically between -10°C and -20°C—this method reduces the size of ice crystals significantly compared to traditional freezing methods.

Mechanisms Behind LTE:

- Shear Stress Application: During LTE, high shear forces are applied within the extruder which helps break down larger ice crystals into much smaller ones. This results in a smoother texture that enhances mouthfeel—a critical factor for consumer satisfaction[3][6].

- Microstructural Improvements: The combination of rapid cooling with shear stress not only influences ice crystal size but also affects air bubble distribution within the mix. Smaller air cells contribute to an increased perception of creaminess[9][10].

Benefits of LTE:

1. Enhanced Sensory Qualities: Products produced via LTE exhibit improved melting rates and consistency, making them more appealing to consumers.

2. Reduced Ingredient Needs: By achieving higher quality with smaller fat globules through LTE, manufacturers may reduce fat content without compromising flavor or texture[3][6].

3. Energy Efficiency: LTE systems allow for energy savings by eliminating extensive hardening processes traditionally required after freezing[9][10].

Market Trends Influencing Ice Cream Production

The global market for extruded ice cream is projected to grow significantly due to several factors:

- Consumer Preferences for Novelty Products: As consumers seek unique flavors and textures, extruded products like sandwiches or stick bars have gained popularity[8][15].

- Rising Demand for Healthier Alternatives: With health-conscious consumers looking for lower-calorie options, manufacturers are innovating recipes that use less sugar or fat while maintaining taste through advanced processing techniques[4][8].

- Sustainability Initiatives: Companies are increasingly focusing on sustainable practices—from sourcing ingredients responsibly to adopting eco-friendly packaging solutions[2][4].

Conclusion

Extrusion technology has revolutionized ice cream production by enhancing efficiency, improving product quality, and expanding creative possibilities. As this technology continues to evolve, it will undoubtedly lead to even more exciting innovations within the industry that cater to changing consumer preferences while maintaining high standards of quality.

FAQ

1. What is ice cream extrusion?

Ice cream extrusion is a manufacturing process where ingredients are forced through an extruder machine to create various shapes and forms of ice cream products.

2. How does extrusion improve ice cream quality?

Extrusion allows for better control over ice crystal size and air incorporation, resulting in smoother and creamier textures compared to traditional methods.

3. Can large inclusions be added during extrusion?

Yes! Advanced extruders can incorporate large chunks like fruits or cookies without compromising their structure or integrity during processing.

4. What are some benefits of low-temperature extrusion?

Low-temperature extrusion produces smaller ice crystals and enhances sensory attributes like melting behavior and consistency while reducing energy costs associated with traditional freezing methods.

5. How does automation influence ice cream production?

Automation streamlines production processes, enhances efficiency, reduces labor costs, and ensures consistent product quality across batches.

Citations:

[1] https://machine.goldsupplier.com/blog/ice-cream-extruder/

[2] https://www.innodelice.com/post/hot-topics-and-trends-in-ice-cream-technology

[3] https://www.primescholars.com/articles/low-temperature-extrusion-of-icecream-a-review-94052.html

[4] https://www.aiche.org/resources/publications/cep/2019/may/engineering-frozen-desserts

[5] https://www.tetrapak.com/en-us/solutions/integrated-solutions-equipment/processing-equipment/extrusion

[6] https://www.newfoodmagazine.com/article/2333/the-evolution-of-ice-cream-technology/

[7] https://www.ijpab.com/form/2020%20Volume%208,%20issue%205/IJPAB-2020-8-5-90-97.pdf

[8] https://www.fortunebusinessinsights.com/extruded-ice-cream-market-108596

[9] https://www.primescholars.com/articles/low-temperature-extrusion-of-icecream-a-review.pdf

[10] https://packagingeurope.com/re-inventing-the-wheel-the-technology-behind-ice-cream-with-large-chunks/1904.article

[11] https://medcraveonline.com/MOJFPT/applications-of-food-extrusion-technology.html

[12] https://www.linkedin.com/pulse/ice-cream-extrusion-equipment-market-overview-dynamics-lywme/

[13] https://www.sciencedirect.com/science/article/abs/pii/S0958694600000716

[14] https://www.refrigeratedfrozenfood.com/articles/95160-re-inventing-the-wheelthe-technology-behind-ice-cream-with-large-inclusions

[15] https://rivercountry.newschannelnebraska.com/story/50919827/extruded-ice-cream-market-size-trend-analysis-and-future-forecast-up-to-2030

[16] https://www.tetrapak.com/en-us/solutions/integrated-solutions-equipment/processing-equipment/extrusion/tetra-pak-extrusion-wheel/impulse-ice-creams-with-large-inclusions

[17] https://www.bakerperkins.com/news/extrusion-brings-ingredient-production-cost-savings/

[18] https://www.htv10.tv/story/51201081/extruded-ice-cream-market-size-share-growth-and-forecast-overview-through-2030

[19] https://www.foodingredientsfirst.com/news/tetra-pak-doubles-ice-cream-production-with-innovative-extrusion-wheel.html

[20] https://www.linkedin.com/pulse/ice-cream-extrusion-equipment-market-trends-pn3ec/

[21] https://www.researchgate.net/publication/269764286_Extrusion_A_novel_technology_for_the_manufacture_of_ice_cream