Content Menu

● Understanding Cold Extrusion

● Benefits of Cold Extrusion in Pet Food Production

● Challenges of Cold Extrusion

● The Role of Technology in Cold Extrusion

● Market Trends and Consumer Preferences in China

● The Economic Impact of Cold Extrusion

● Conclusion

● FAQs

>> 1. What is cold extrusion?

>> 2. How does cold extrusion improve pet food quality?

>> 3. What are some challenges associated with cold extrusion?

>> 4. Why is technology important in cold extrusion?

>> 5. How are consumer preferences influencing the pet food market in China?

● Citations:

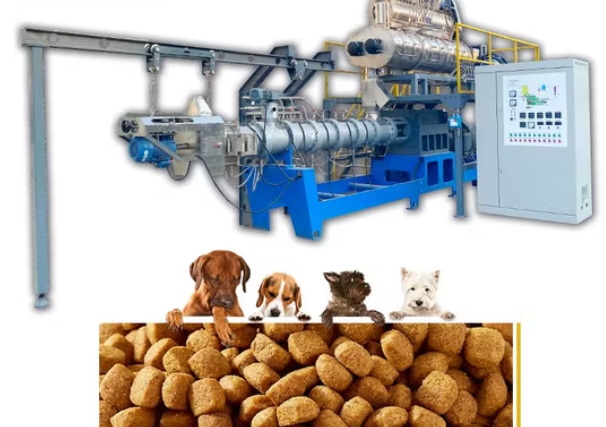

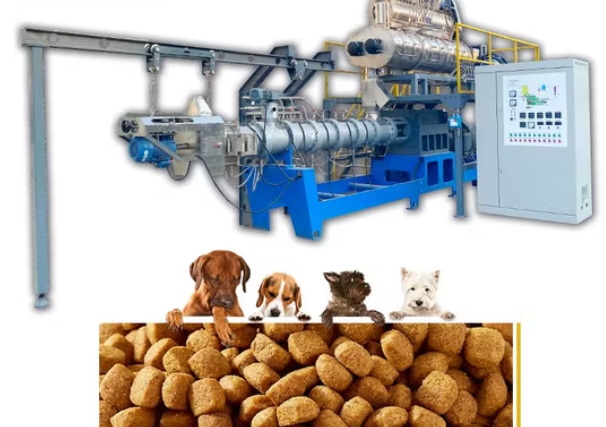

The pet food industry in China is rapidly evolving, with a growing demand for high-quality, nutritious products. One innovative method that has gained traction is cold extrusion, a process that enhances the quality and nutritional value of pet food while addressing consumer concerns about ingredient integrity. This article explores how cold extrusion improves pet food quality, the technology behind it, and its implications for the pet food market in China.

Understanding Cold Extrusion

Cold extrusion is a manufacturing process that shapes pet food without applying heat. Unlike traditional extrusion methods that involve high temperatures (often exceeding 100 degrees Celsius), cold extrusion operates at much lower temperatures, typically between -2°C to +5°C. This temperature control is crucial for preserving the nutritional content of ingredients, particularly heat-sensitive vitamins and probiotics.

The process begins with mixing raw ingredients into a dough-like consistency. The mixture is then forced through an extruder, where it is shaped into pellets or kibbles before being cut into the desired sizes. The absence of heat during this process allows for better retention of natural flavors and aromas, making the final product more appealing to pets.

Benefits of Cold Extrusion in Pet Food Production

1. Nutritional Preservation

Cold extrusion significantly reduces nutrient degradation that typically occurs during high-temperature processing. Essential vitamins, minerals, and probiotics remain intact, ensuring that pets receive a balanced diet rich in nutrients. The gentle heat used in cold extrusion helps prevent degradation of sensitive ingredients like omega-3 fatty acids and certain vitamins[1][4].

2. Enhanced Flavor and Aroma

The gentle processing conditions of cold extrusion help retain the natural flavors of ingredients. This results in pet food that is not only nutritious but also flavorful, catering to the preferences of picky eaters. The process allows for the incorporation of various natural flavorings without compromising their integrity[1][2].

3. Varied Textures

Cold extrusion allows manufacturers to create pet food with diverse textures, combining crunchy and chewy elements. This variety can enhance palatability and encourage pets to consume their meals. The ability to customize textures also caters to different species and breeds, enhancing overall consumer satisfaction[2][8].

4. Reduced Risk of Pathogens

While cold extrusion does not achieve the same level of pathogen elimination as traditional high-temperature methods, it does allow for better control over ingredient quality and safety through rigorous quality assurance measures. By avoiding high temperatures, manufacturers can limit the formation of harmful compounds that may arise during processing[4][10].

5. Environmental Sustainability

Cold extrusion processes often require less energy compared to traditional methods, contributing to a more sustainable production model. Additionally, the ability to use fresh ingredients without compromising their quality aligns with growing consumer preferences for environmentally friendly products[4][10].

Challenges of Cold Extrusion

Despite its advantages, cold extrusion presents certain challenges:

- Equipment Costs

Implementing cold extrusion requires specialized machinery that can be more expensive than traditional equipment. This initial investment may deter smaller manufacturers from adopting this technology.

- Shelf Life Concerns

The absence of high-temperature processing may result in a shorter shelf life for cold extruded products compared to their hot-extruded counterparts. Manufacturers must implement effective preservation strategies to ensure product longevity.

- Technical Complexity

Achieving consistent quality with cold extrusion can be technically challenging. Factors such as ingredient viscosity and moisture content must be carefully controlled to maintain product integrity throughout the extrusion process.

The Role of Technology in Cold Extrusion

Advancements in technology have played a significant role in enhancing the cold extrusion process. Modern equipment allows for precise control over mixing and emulsifying ingredients, ensuring consistent product quality across batches. Key technologies include:

- Vacuum Fillers

These systems minimize air incorporation during processing, reducing oxidation and improving the shelf life of the final product.

- In-line Grinding Systems

These systems can modify texture characteristics by adjusting particle size before extrusion, allowing for greater flexibility in product formulation.

- Advanced Mixing Equipment

Paddle and ribbon blenders ensure uniform distribution of ingredients, which is critical for achieving the desired nutritional profile and texture in the final product.

Market Trends and Consumer Preferences in China

The shift towards cold-extruded pet food aligns with broader trends in consumer preferences within China. Pet owners are increasingly seeking products that prioritize health and nutrition, driving demand for higher-quality ingredients processed using gentler methods. Key trends include:

- Focus on Natural Ingredients

Consumers are more aware of what goes into their pets' food, leading to a preference for products made with natural ingredients free from artificial additives.

- Health-Conscious Choices

There is a growing emphasis on functional pet foods that offer health benefits beyond basic nutrition, such as improved digestion or enhanced immune support.

- Sustainability Concerns

As environmental awareness increases among consumers, many are looking for brands that demonstrate sustainable practices throughout their production processes.

The Economic Impact of Cold Extrusion

Cold extrusion not only enhances product quality but also has economic implications for manufacturers in China:

- Cost Efficiency

By maximizing nutrient retention and minimizing waste during production, manufacturers can reduce overall costs while maintaining high-quality standards[8]. This efficiency can translate into competitive pricing for consumers.

- Market Differentiation

Brands that utilize cold extrusion can differentiate themselves in a crowded market by promoting superior nutritional profiles and sustainable practices[10]. This unique selling proposition can attract health-conscious consumers looking for premium pet food options.

- Increased Demand for High-Quality Products

As awareness grows regarding the importance of nutrition in pet diets, there is an increasing demand for high-quality products made using advanced manufacturing techniques like cold extrusion[6]. This trend encourages manufacturers to invest in new technologies and improve their offerings.

Conclusion

Cold extrusion represents a significant advancement in the pet food industry, particularly within the context of China's evolving market landscape. By preserving nutritional integrity, enhancing flavor profiles, and offering varied textures, this method meets consumer demands for high-quality pet food products. While challenges remain in terms of equipment costs and shelf life management, ongoing technological advancements are likely to mitigate these issues over time.

As pet owners continue to prioritize health and sustainability in their purchasing decisions, manufacturers adopting cold extrusion techniques will be well-positioned to thrive in this competitive market.

FAQs

1. What is cold extrusion?

Cold extrusion is a manufacturing process that shapes pet food without applying heat, preserving nutrients and enhancing flavor.

2. How does cold extrusion improve pet food quality?

It retains nutritional value by avoiding high temperatures that degrade vitamins and minerals while also enhancing flavor and aroma.

3. What are some challenges associated with cold extrusion?

Challenges include higher equipment costs, potential shorter shelf life compared to hot-extruded products, and technical complexity in achieving consistent quality.

4. Why is technology important in cold extrusion?

Technology enables precise control over ingredient mixing and processing conditions, ensuring consistent product quality across batches.

5. How are consumer preferences influencing the pet food market in China?

Consumers are increasingly seeking natural ingredients and health-focused products while prioritizing sustainability in their purchasing decisions.

Citations:

[1] https://www.dragonextruder.com/news/cold-extruding-for-pet-food-processing:-pros-and-cons.html

[2] https://www.adm.com/en-us/products-services/pet-nutrition/pet-academy/blogs-articles/halting-the-heat/

[3] https://www.darin.cn/Cold-Pet-Treat-Extrusion-Machine-pd46501543.html

[4] https://www.bonza.dog/cold-extruded-dog-food-nutritional-quality/

[5] https://www.darin.cn/Dog-Cat-Bird-Fish-Turtle-Rabbit-Horse-And-Other-Pet-Food-Extrusion-Production-Line-pd42230243.html

[6] https://www.jsixenterprises.com/blog/pet-food-extrusion-services/

[7] http://foodmachinerychina.com/1-4-pet-treats-cold-extrusion-machine.html

[8] https://en.allpetfood.net/entrada/what-are-the-benefits-and-challenges-of-cold-extrusion-in-the-pet-food-industry-23885

[9] https://www.alibaba.com/showroom/cold-extrusion-machine.html

[10] https://internationalpetfood.com/benefits-and-challenges-of-cold-extrusion-in-the-pet-food-industry/