Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Applications of Aluminum Extrusions

● Types of Aluminum Extrusions

>> 1. Standard Profiles

>> 2. Custom Profiles

>> 3. T-slot Aluminum Framing

● Where to Buy Aluminum Extrusions

>> 1. Direct from Manufacturers

>> 2. Distributors and Suppliers

>> 3. Specialty Aluminum Extrusion Suppliers

>> 4. Online Marketplaces

● Factors to Consider When Buying Aluminum Extrusions

>> 1. Alloy Selection

>> 2. Surface Finish

>> 3. Tolerances

>> 4. Minimum Order Quantities

>> 5. Lead Times

● The Aluminum Extrusion Design Process

● Sustainability in Aluminum Extrusion

● Emerging Trends in Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> Q1: What is the difference between standard and custom aluminum extrusions?

>> Q2: How do I choose the right aluminum alloy for my extrusion?

>> Q3: Can I order small quantities of aluminum extrusions?

>> Q4: How long does it take to receive a custom aluminum extrusion order?

>> Q5: Are aluminum extrusions environmentally friendly?

Introduction

Aluminum extrusion is a versatile and widely used manufacturing process that produces a variety of shapes and profiles for countless applications across industries. Whether you're a DIY enthusiast, a small business owner, or a large-scale manufacturer, knowing where to buy aluminum extrusion is crucial for your projects. This comprehensive guide will explore the world of aluminum extrusions, their applications, and the best places to purchase them.

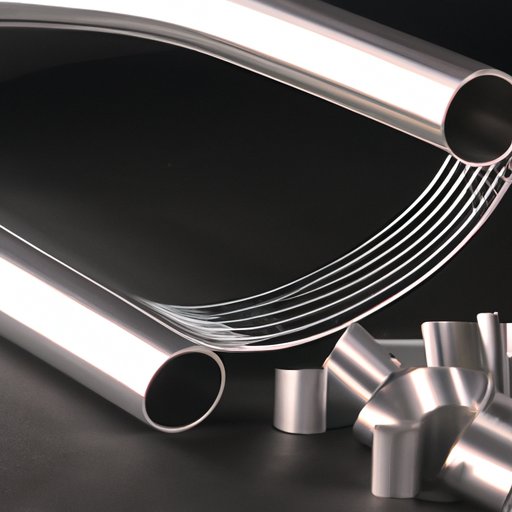

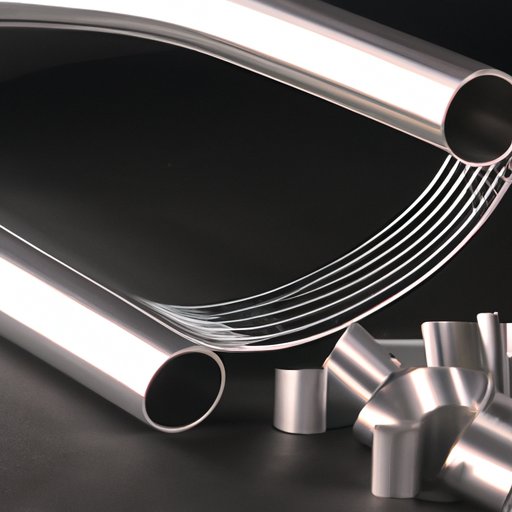

Understanding Aluminum Extrusion

Aluminum extrusion is a process where aluminum alloy is forced through a die with a specific cross-sectional profile. This results in a long, straight piece of aluminum with a consistent cross-section. The versatility of this process allows for the creation of complex shapes that would be difficult or impossible to produce using other manufacturing methods.

Applications of Aluminum Extrusions

Aluminum extrusions find applications in numerous industries due to their strength, lightweight nature, and corrosion resistance. Some common uses include:

1. Construction: Window frames, door frames, curtain walls

2. Transportation: Automotive components, railway car bodies, bicycle frames

3. Electronics: Heat sinks, LED housings, electronic enclosures

4. Aerospace: Aircraft structures, satellite components

5. Renewable Energy: Solar panel frames, wind turbine components

6. Furniture: Office partitions, display stands, shelving systems

Types of Aluminum Extrusions

1. Standard Profiles

Standard profiles are pre-designed shapes that are readily available from most suppliers. These include:

- Angles

- Channels

- T-bars

- I-beams

- Tubes (round, square, and rectangular)

2. Custom Profiles

Custom profiles are designed to meet specific project requirements. These can be created to suit unique applications and often require collaboration with the manufacturer's design team.

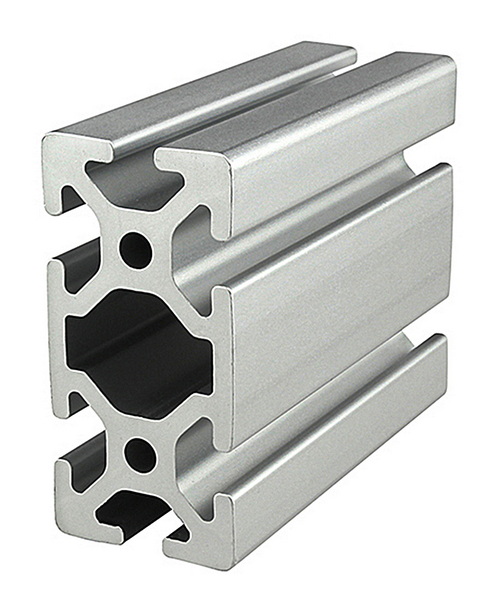

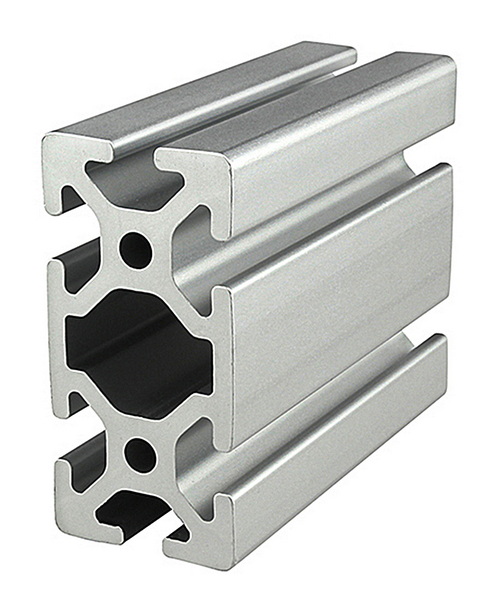

3. T-slot Aluminum Framing

T-slot framing systems are a popular type of aluminum extrusion used for creating modular structures. These profiles feature T-shaped slots that allow for easy assembly and reconfiguration.

Where to Buy Aluminum Extrusions

1. Direct from Manufacturers

Many aluminum extrusion manufacturers sell directly to customers. This option is ideal for large orders or custom profiles. Some reputable manufacturers include:

- Alcoa

- Hydro Aluminum

- Sapa Group

- Kaiser Aluminum

2. Distributors and Suppliers

Distributors often carry a wide range of standard profiles and can source custom extrusions from manufacturers. They may offer additional services such as cutting and finishing. Popular distributors include:

- Online Metals

- McMaster-Carr

- Grainger

- Metals Depot

3. Specialty Aluminum Extrusion Suppliers

Some companies specialize exclusively in aluminum extrusions and offer a comprehensive range of products and services. Examples include:

- 80/20 Inc.

- Extrude-A-Trim

- Eagle Aluminum

- Orange Aluminum

4. Online Marketplaces

Online marketplaces like Amazon and eBay often have a selection of aluminum extrusions available, particularly for smaller quantities or DIY projects.

Factors to Consider When Buying Aluminum Extrusions

1. Alloy Selection

Different aluminum alloys offer varying properties. Common alloys for extrusions include:

- 6061: Good strength and corrosion resistance

- 6063: Excellent for architectural applications

- 7075: High strength, often used in aerospace

2. Surface Finish

Aluminum extrusions can be finished in various ways to enhance their appearance or performance:

- Mill finish: Unprocessed surface

- Anodized: Electrochemically treated for increased corrosion resistance and color options

- Powder coated: Painted with a durable, colored finish

3. Tolerances

Ensure that the supplier can meet the required tolerances for your project. Tighter tolerances may increase costs but are necessary for precision applications.

4. Minimum Order Quantities

Some suppliers have minimum order quantities, especially for custom profiles. Consider your project needs and storage capabilities when ordering.

5. Lead Times

Standard profiles are often available immediately, while custom extrusions may require several weeks for production. Plan accordingly for your project timeline.

The Aluminum Extrusion Design Process

When working with custom aluminum extrusions, the design process typically involves the following steps:

1. Concept Development: Outline your requirements and create initial sketches.

2. Design Consultation: Work with the manufacturer's design team to refine your concept.

3. 3D Modeling: Create a detailed 3D model of the extrusion profile.

4. Die Design: The manufacturer designs the extrusion die based on the 3D model.

5. Prototyping: Produce a small batch of extrusions for testing and approval.

6. Production: Once approved, full-scale production begins.

Sustainability in Aluminum Extrusion

Aluminum extrusion is an environmentally friendly process due to the material's recyclability. Nearly 75% of all aluminum ever produced is still in use today. When choosing a supplier, consider their sustainability practices and whether they use recycled aluminum in their extrusions.

Emerging Trends in Aluminum Extrusion

The aluminum extrusion industry continues to evolve, with several emerging trends:

1. Additive Manufacturing: 3D printing of aluminum parts is becoming more common for prototyping and small-scale production.

2. Smart Extrusions: Integration of sensors and electronics into aluminum profiles for IoT applications.

3. Micro-Extrusions: Production of extremely small profiles for use in electronics and medical devices.

4. Advanced Alloys: Development of new aluminum alloys with enhanced properties for specific applications.

Conclusion

Knowing where to buy aluminum extrusion is essential for anyone working with this versatile material. Whether you need standard profiles or custom designs, there are numerous options available from manufacturers, distributors, and specialized suppliers. By considering factors such as alloy selection, surface finish, and order quantities, you can find the perfect aluminum extrusion solution for your project.

As the industry continues to innovate, aluminum extrusions will play an increasingly important role in various sectors, from construction to aerospace. By staying informed about the latest developments and maintaining relationships with reliable suppliers, you can ensure that you always have access to the high-quality aluminum extrusions you need for your projects.

Frequently Asked Questions

Q1: What is the difference between standard and custom aluminum extrusions?

A1: Standard aluminum extrusions are pre-designed profiles that are readily available from suppliers. They include common shapes like angles, channels, and tubes. Custom aluminum extrusions are specifically designed to meet unique project requirements and are manufactured to order. Custom extrusions offer more flexibility in terms of shape and size but may have longer lead times and higher minimum order quantities.

Q2: How do I choose the right aluminum alloy for my extrusion?

A2: Choosing the right aluminum alloy depends on your specific application requirements. Consider factors such as strength, corrosion resistance, and machinability. For example, 6061 alloy is widely used for its good strength and corrosion resistance, while 6063 is popular for architectural applications due to its excellent finish. Consult with your supplier or a materials engineer to determine the best alloy for your needs.

Q3: Can I order small quantities of aluminum extrusions?

A3: Yes, many suppliers offer small quantities of standard aluminum extrusions. However, for custom profiles, there may be minimum order quantities due to the cost of creating custom dies. Online retailers and some specialty suppliers cater to customers who need smaller amounts. If you only need a small quantity of a custom profile, consider looking for a supplier who offers "die share" programs, where you can split the cost of a custom die with other customers.

Q4: How long does it take to receive a custom aluminum extrusion order?

A4: The lead time for custom aluminum extrusions can vary depending on the complexity of the design, the manufacturer's current workload, and the quantity ordered. Typically, you can expect a lead time of 4-8 weeks for a new custom extrusion. This includes time for design approval, die manufacturing, and production. For repeat orders using an existing die, lead times are usually shorter. Always discuss lead times with your supplier when planning your project.

Q5: Are aluminum extrusions environmentally friendly?

A5: Yes, aluminum extrusions are considered environmentally friendly for several reasons. Aluminum is 100% recyclable and can be recycled indefinitely without losing its properties. The recycling process for aluminum requires only about 5% of the energy needed to produce new aluminum from raw materials. Additionally, many manufacturers use a significant percentage of recycled aluminum in their extrusions. The lightweight nature of aluminum also contributes to fuel efficiency in transportation applications, further reducing its environmental impact.

Hot Tags: Aluminum Extrusion Suppliers, Custom Aluminum Profiles, T-slot Aluminum Framing, Extruded Aluminum Shapes, Aluminum Extrusion Manufacturers, Aluminum Extrusion Design Services, Architectural Aluminum Extrusions, Industrial Aluminum Extrusions, Aluminum Profile Systems, Structural Aluminum Channels, China, manufacturing company, manufacturers, suppliers, factory, price, Pricelist, quotation, wholesale