Content Menu

● Introduction

● Understanding 2020 Aluminum Extrusion

● Choosing the Right Tools for Cutting Aluminum Extrusion

>> 1. Miter Saw

>> 2. Circular Saw

>> 3. Hacksaw

>> 4. Band Saw

● Preparing for the Cut

>> 1. Measure and Mark

>> 2. Secure the Extrusion

>> 3. Set Up Your Saw

>> 4. Safety First

● Cutting Techniques for 2020 Aluminum Extrusion

>> 1. Straight Cuts

>> 2. Angled Cuts

>> 3. Multiple Cuts

>> 4. Cutting with a Hacksaw

● Post-Cutting Procedures

>> 1. Deburring

>> 2. Cleaning

>> 3. Test Fit

● Tips for Perfect Cuts

● Common Applications and Projects

● Conclusion

● Frequently Asked Questions

>> Q1: What is the best saw for cutting 2020 aluminum extrusion?

>> Q2: Can I use a regular wood-cutting blade to cut aluminum extrusion?

>> Q3: How do I prevent the aluminum from scratching during the cutting process?

>> Q4: Is it necessary to use cutting fluid when sawing aluminum extrusion?

>> Q5: How do I ensure perfectly square cuts on my 2020 aluminum extrusion?

Introduction

Aluminum extrusions, particularly the popular 2020 profile, have become a staple in various industries, from 3D printing and CNC machines to custom furniture and industrial automation. Their versatility, strength, and ease of assembly make them an ideal choice for many projects. However, to fully harness the potential of these versatile components, one must master the art of cutting them accurately and safely. This comprehensive guide will walk you through everything you need to know about cutting 2020 aluminum extrusions, from choosing the right tools to executing precise cuts and ensuring your safety throughout the process.

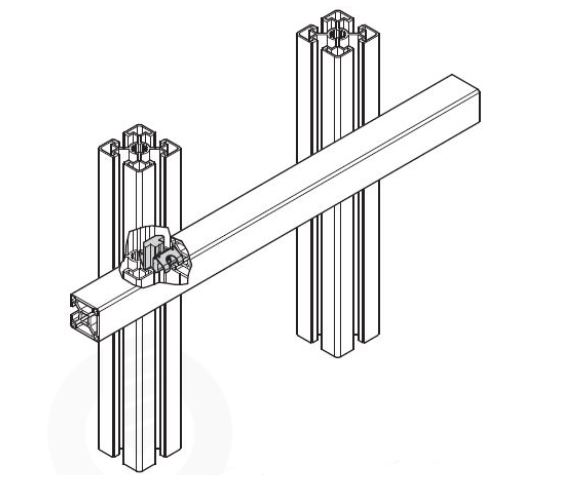

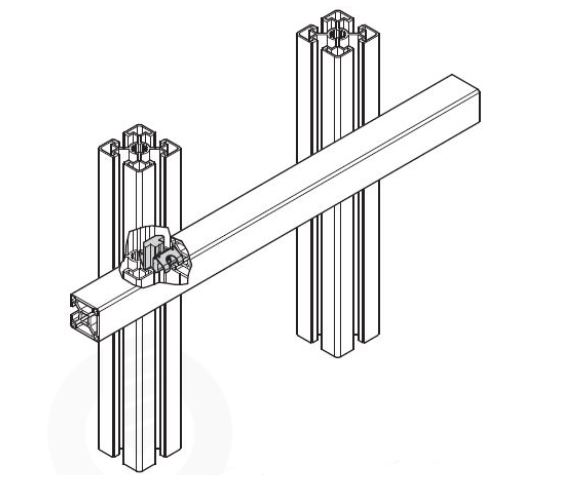

Understanding 2020 Aluminum Extrusion

Before diving into cutting techniques, it's essential to understand what 2020 aluminum extrusion is. The term "2020" refers to the profile's dimensions - 20mm x 20mm. This square profile features T-slots on all four sides, allowing for easy attachment of various components and accessories. The versatility of 2020 aluminum extrusion makes it popular in many applications, including:

- 3D printer frames

- CNC machine builds

- Custom workbenches and furniture

- Industrial automation systems

- Exhibition stands and displays

Choosing the Right Tools for Cutting Aluminum Extrusion

Selecting the appropriate tools is crucial for achieving clean, precise cuts on your 2020 aluminum extrusion. Here are some of the most effective tools for the job:

1. Miter Saw

A miter saw is arguably the best tool for cutting aluminum extrusions. It offers precision, speed, and the ability to make angled cuts easily. When using a miter saw, ensure you have a blade specifically designed for cutting non-ferrous metals like aluminum.

2. Circular Saw

A circular saw with a fine-toothed blade designed for aluminum can also be used effectively. While not as precise as a miter saw, it's more portable and can be a good option for on-site work.

3. Hacksaw

For those on a budget or working on smaller projects, a hacksaw can get the job done. It requires more effort and time but can produce acceptable results with practice.

4. Band Saw

A band saw is excellent for making curved cuts or working with larger pieces of aluminum extrusion. It provides smooth, continuous cutting action.

Preparing for the Cut

Proper preparation is key to achieving accurate and safe cuts. Follow these steps before making your first cut:

1. Measure and Mark

Use a precise measuring tool, such as a digital caliper or a steel ruler, to measure the desired length of your extrusion. Mark the cutting line clearly using a fine-point marker or a scribe.

2. Secure the Extrusion

Firmly clamp the aluminum extrusion to your work surface or the saw's fence. This prevents movement during cutting, ensuring accuracy and safety.

3. Set Up Your Saw

If using a power saw, ensure the blade is sharp and appropriate for cutting aluminum. Adjust the saw's speed settings if possible - a slower speed is generally better for cutting aluminum.

4. Safety First

Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and a dust mask. Avoid loose clothing that could get caught in the saw.

Cutting Techniques for 2020 Aluminum Extrusion

Now that you're prepared, let's explore the techniques for cutting your 2020 aluminum extrusion:

1. Straight Cuts

For straight cuts, align your marked cutting line with the saw blade. If using a miter saw, slowly lower the blade while it's running at full speed. Apply steady, gentle pressure to avoid binding or kickback.

2. Angled Cuts

When making angled cuts for joints or special applications, adjust your miter saw to the desired angle. Double-check the angle before making the cut to ensure accuracy.

3. Multiple Cuts

If you need to make multiple cuts of the same length, set up a stop block on your saw. This ensures consistency across all pieces.

4. Cutting with a Hacksaw

If using a hacksaw, start with gentle, slow strokes to create a groove. Once established, you can increase your speed and pressure. Keep the blade perpendicular to the extrusion for a straight cut.

Post-Cutting Procedures

After making your cuts, there are a few important steps to follow:

1. Deburring

Use a deburring tool or fine-grit sandpaper to remove any sharp edges or burrs left by the cutting process. This step is crucial for safety and ensures a clean finish.

2. Cleaning

Clean the cut ends of the extrusion to remove any aluminum chips or debris. This is particularly important if you plan to use end caps or connectors.

3. Test Fit

If you're working on a project that requires precise measurements, do a test fit of your cut pieces before proceeding with assembly.

Tips for Perfect Cuts

To achieve the best results when cutting 2020 aluminum extrusion, keep these tips in mind:

1. Use cutting lubricant or wax to reduce friction and heat buildup during cutting.

2. Take your time and avoid rushing the cut to prevent mistakes and ensure safety.

3. For very precise cuts, consider leaving a small allowance and then filing down to the exact measurement.

4. Regularly clean your saw blade to prevent buildup of aluminum particles, which can affect cut quality.

5. If possible, practice on scrap pieces before cutting your final project materials.

Common Applications and Projects

Now that you've mastered cutting 2020 aluminum extrusion, let's explore some popular applications and projects:

1. Custom 3D Printer Frames: Build a robust and customizable frame for your 3D printer.

2. Workbench Construction: Create a sturdy, modular workbench for your workshop or garage.

3. CNC Machine Builds: Construct a precise and rigid frame for your DIY CNC machine.

4. Exhibition Displays: Design lightweight and easily assembled display stands for trade shows.

5. Home Automation Projects: Build custom enclosures or mounting systems for smart home devices.

Conclusion

Mastering the art of cutting 2020 aluminum extrusion opens up a world of possibilities for your DIY and professional projects. With the right tools, techniques, and safety precautions, you can achieve precise, clean cuts that will elevate the quality of your builds. Remember to always prioritize safety, take your time, and practice to refine your skills. Whether you're a hobbyist or a professional, the versatility of 2020 aluminum extrusion combined with your cutting expertise will undoubtedly lead to impressive and functional creations.

Frequently Asked Questions

Q1: What is the best saw for cutting 2020 aluminum extrusion?

A1: The best saw for cutting 2020 aluminum extrusion is generally considered to be a miter saw with a blade specifically designed for non-ferrous metals. Miter saws offer precision, speed, and the ability to make both straight and angled cuts easily.

Q2: Can I use a regular wood-cutting blade to cut aluminum extrusion?

A2: It's not recommended to use a regular wood-cutting blade for aluminum extrusion. Wood blades have fewer teeth and a different tooth geometry, which can lead to rough cuts, binding, or even dangerous kickback. Always use a blade specifically designed for cutting aluminum or non-ferrous metals.

Q3: How do I prevent the aluminum from scratching during the cutting process?

A3: To prevent scratching, you can apply masking tape or painter's tape to the area where you'll be cutting. This protects the surface from scratches and can also help prevent chipping along the cut edge. Additionally, ensure your work surface is clean and free from debris that could cause scratches.

Q4: Is it necessary to use cutting fluid when sawing aluminum extrusion?

A4: While not absolutely necessary, using a cutting fluid or lubricant is highly recommended when cutting aluminum extrusion. It helps reduce friction and heat buildup, which can lead to smoother cuts, extended blade life, and reduced risk of the aluminum binding to the blade teeth.

Q5: How do I ensure perfectly square cuts on my 2020 aluminum extrusion?

A5: To ensure square cuts, start by using a precise measuring tool and marking your cut line carefully. Use a square to check that your mark is perpendicular to the extrusion's length. When cutting, use a miter saw or a guided circular saw set to exactly 90 degrees. After cutting, you can use a machinist's square to check the cut's accuracy and make any necessary adjustments with a file.