Content Menu

● Introduction

● Understanding Aluminum Extrusions

● Tools for Cutting Aluminum Extrusions

● Preparing to Cut Aluminum Extrusions

● Techniques for Cutting Aluminum Extrusions by Hand

>> Using a Hand Saw

>> Using a Miter Saw

>> Using a Circular Saw

● Safety Tips for Cutting Aluminum Extrusions

● Post-Cutting Finishing Techniques

● Tips for Precision Cutting

● Common Mistakes to Avoid

● Conclusion

● Frequently Asked Questions

>> Q1: Can I use a wood-cutting saw blade to cut aluminum extrusions?

>> Q2: How do I prevent the aluminum from heating up too much during cutting?

>> Q3: What's the best way to make a perfectly straight cut on an aluminum extrusion?

>> Q4: How do I cut aluminum extrusions without leaving burrs?

>> Q5: Is it safe to cut aluminum extrusions outdoors?

Introduction

Aluminum extrusions are versatile components used in various industries, from construction to manufacturing. Whether you're a DIY enthusiast or a professional, knowing how to cut aluminum extrusions properly is an essential skill. This comprehensive guide will walk you through the process of cutting aluminum extrusions by hand, covering techniques, tools, and crucial safety tips to ensure precise and safe results.

Understanding Aluminum Extrusions

Before diving into cutting techniques, it's important to understand what aluminum extrusions are. Aluminum extrusions are lengths of aluminum that have been shaped by forcing heated aluminum through a die. This process creates profiles with consistent cross-sections, which can be customized for various applications.

Aluminum extrusions are popular due to their lightweight nature, corrosion resistance, and strength-to-weight ratio. They're commonly used in:

- Construction (window frames, door frames)

- Automotive industry (car parts)

- Aerospace (aircraft components)

- Furniture making

- Industrial machinery

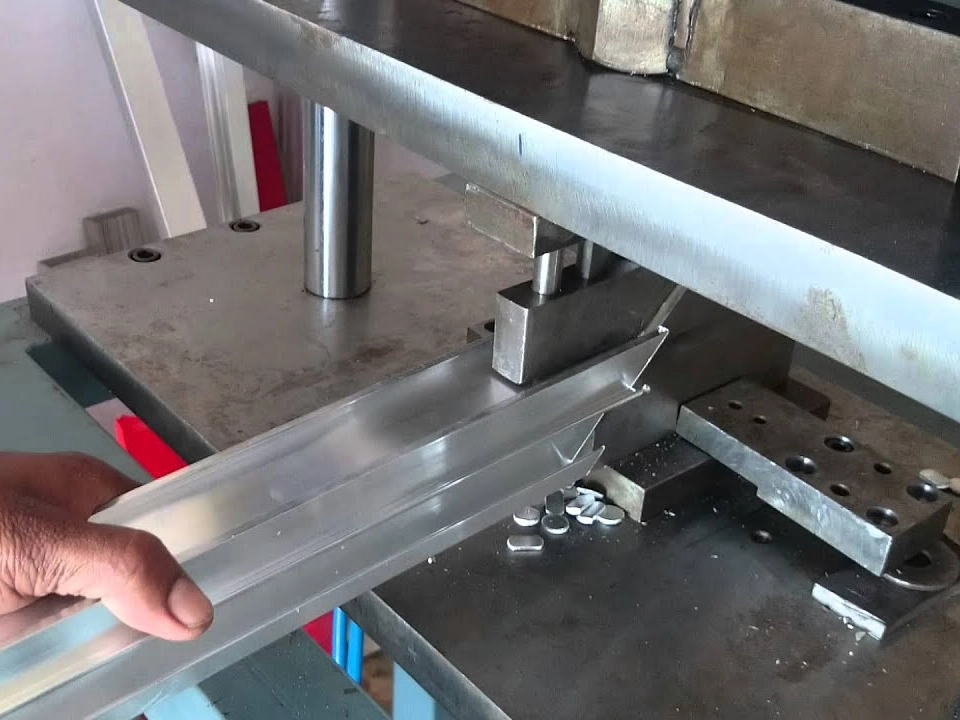

Tools for Cutting Aluminum Extrusions

To cut aluminum extrusions effectively, you'll need the right tools. Here are some options:

1. Hand Saw: A hacksaw or a fine-toothed hand saw designed for metal cutting.

2. Miter Saw: Ideal for precise angle cuts.

3. Circular Saw: Good for straight cuts on larger extrusions.

4. Bandsaw: Excellent for curved cuts and longer pieces.

5. Jigsaw: Useful for intricate cuts and shapes.

6. Rotary Tool: Great for small, detailed work.

When selecting a saw blade, opt for one specifically designed for cutting aluminum. These blades typically have more teeth per inch (TPI) to ensure a smoother cut.

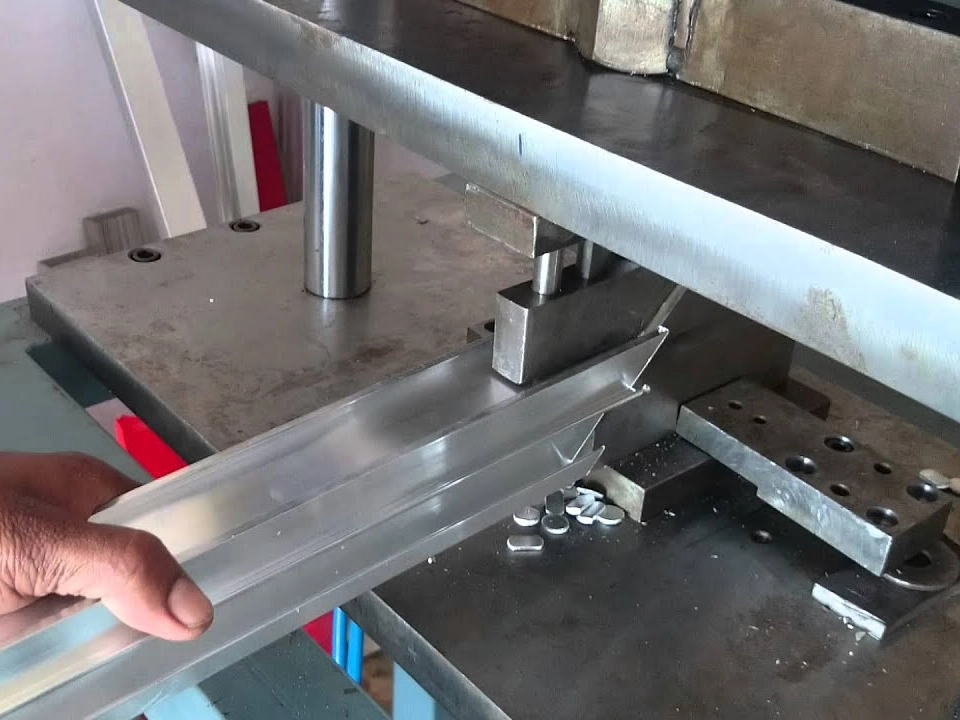

Preparing to Cut Aluminum Extrusions

Proper preparation is key to achieving clean, accurate cuts. Follow these steps:

1. Measure and mark: Use a measuring tape and a marker to precisely mark your cutting line.

2. Secure the extrusion: Clamp the aluminum extrusion firmly to your work surface to prevent movement during cutting.

3. Wear protective gear: Always wear safety glasses, gloves, and a dust mask.

4. Set up your workspace: Ensure you have adequate lighting and a stable work surface.

Techniques for Cutting Aluminum Extrusions by Hand

Using a Hand Saw

1. Start with a shallow guide cut to help keep the saw on track.

2. Apply steady, even pressure as you saw back and forth.

3. Let the saw do the work – don't force it through the material.

4. Keep the saw blade perpendicular to the extrusion for a straight cut.

Using a Miter Saw

1. Set the miter saw to the desired angle (if applicable).

2. Lower the blade slowly onto the extrusion.

3. Cut through the material at a steady pace.

4. Wait for the blade to stop completely before lifting it.

Using a Circular Saw

1. Attach a fine-toothed blade designed for cutting aluminum.

2. Set the depth of the blade to just below the thickness of the extrusion.

3. Guide the saw along the marked line, maintaining a consistent speed.

4. Use a straight edge or guide for perfectly straight cuts.

Safety Tips for Cutting Aluminum Extrusions

Safety should always be your top priority when working with power tools and metal. Here are some essential safety tips:

1. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

2. Ensure your work area is well-ventilated to avoid inhaling aluminum dust.

3. Keep your workspace clean and free of debris to prevent slips and falls.

4. Never force the cutting tool – let it do the work at its own pace.

5. Be aware of sharp edges on cut aluminum and handle with care.

6. Disconnect power tools when changing blades or making adjustments.

7. Never remove safety guards from power tools.

Post-Cutting Finishing Techniques

After cutting your aluminum extrusion, you may need to refine the cut edge. Here are some finishing techniques:

1. Filing: Use a metal file to smooth rough edges and remove burrs.

2. Sanding: Progress from coarse to fine-grit sandpaper for a smooth finish.

3. Deburring tool: Use a specialized deburring tool to quickly remove sharp edges.

4. Polishing: For a high-shine finish, use a polishing wheel or compound.

Remember to clean the aluminum thoroughly after finishing to remove any metal particles or debris.

Tips for Precision Cutting

To achieve the most accurate cuts possible:

1. Use a sharp, high-quality blade designed for aluminum.

2. Make a test cut on scrap material to ensure your setup is correct.

3. Take your time and avoid rushing the cutting process.

4. Use a stop block or fence for repetitive cuts of the same length.

5. Consider using cutting fluid or wax to reduce friction and improve cut quality.

Common Mistakes to Avoid

When cutting aluminum extrusions, be aware of these common pitfalls:

1. Using the wrong type of blade or saw

2. Cutting too quickly, which can cause the material to heat up and deform

3. Failing to secure the extrusion properly, leading to inaccurate cuts

4. Neglecting to wear proper safety equipment

5. Attempting to cut through multiple extrusions at once

Conclusion

Cutting aluminum extrusions by hand requires the right tools, techniques, and safety precautions. With practice and attention to detail, you can achieve professional-quality cuts for your projects. Remember to always prioritize safety and take your time to ensure accurate results.

Frequently Asked Questions

Q1: Can I use a wood-cutting saw blade to cut aluminum extrusions?

A1: It's not recommended. Wood-cutting blades have fewer teeth and can cause the aluminum to chip or bind. Always use a blade specifically designed for cutting aluminum or other non-ferrous metals.

Q2: How do I prevent the aluminum from heating up too much during cutting?

A2: To prevent overheating, use a lubricant like WD-40 or a specialized cutting fluid. Also, cut at a slower speed and ensure your blade is sharp. If the material gets too hot, pause to let it cool down before continuing.

Q3: What's the best way to make a perfectly straight cut on an aluminum extrusion?

A3: For the straightest cuts, use a miter saw or a circular saw with a guide rail. Mark your cutting line clearly, and take your time to follow it precisely. Using a stop block or fence can also help ensure consistency for multiple cuts.

Q4: How do I cut aluminum extrusions without leaving burrs?

A4: To minimize burrs, use a fine-toothed blade and cut at a moderate speed. After cutting, use a deburring tool or file to remove any remaining burrs. For the cleanest cuts, consider using a cold saw or a specialized aluminum cutting machine if available.

Q5: Is it safe to cut aluminum extrusions outdoors?

A5: While it's possible to cut aluminum extrusions outdoors, it's generally safer and more controlled to work indoors. If you must work outside, ensure you're in a well-ventilated area away from flammable materials. Be mindful of wind that could blow metal shavings, and always clean up thoroughly afterward.