Content Menu

● Introduction to 2020 Aluminum Extrusion

● What is 2020 Aluminum Extrusion?

● Weight Capacity of 2020 Aluminum Extrusion

● Comparing 2020 to Other Aluminum Extrusion Profiles

● Applications of 2020 Aluminum Extrusion

● Advantages of Using 2020 Aluminum Extrusion

● Design Considerations for 2020 Aluminum Extrusion Projects

● Video: Understanding T-Slot Aluminum Design

● Conclusion

● Frequently Asked Questions

>> Q1: Can 2020 aluminum extrusion be used for outdoor applications?

>> Q2: How do I join 2020 aluminum extrusions together?

>> Q3: Is 2020 aluminum extrusion suitable for building a CNC machine frame?

>> Q4: How does the cost of 2020 aluminum extrusion compare to steel alternatives?

>> Q5: Can I paint 2020 aluminum extrusion?

Introduction to 2020 Aluminum Extrusion

Aluminum extrusion has revolutionized the way we approach structural design in various industries, from manufacturing to DIY projects. Among the many profiles available, the 2020 aluminum extrusion has gained significant popularity due to its versatility, strength, and cost-effectiveness. This article will delve into the weight-bearing capacity of 2020 aluminum extrusion, its applications, and how it compares to other profiles in the market.

What is 2020 Aluminum Extrusion?

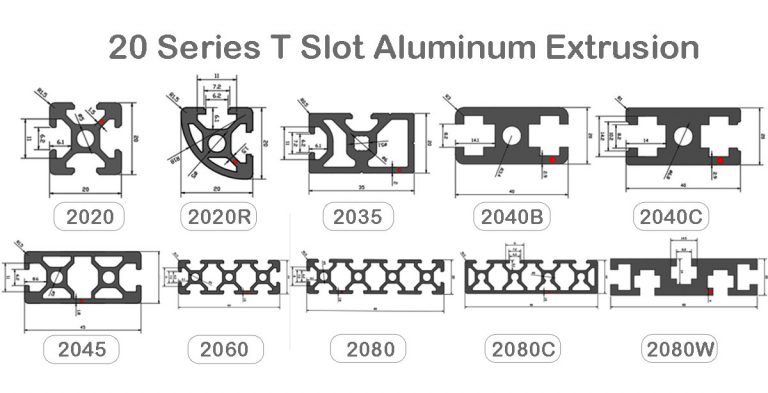

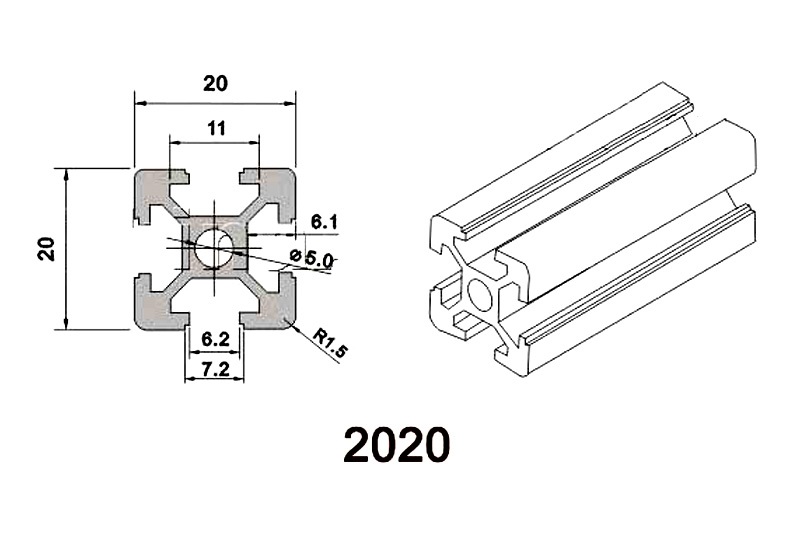

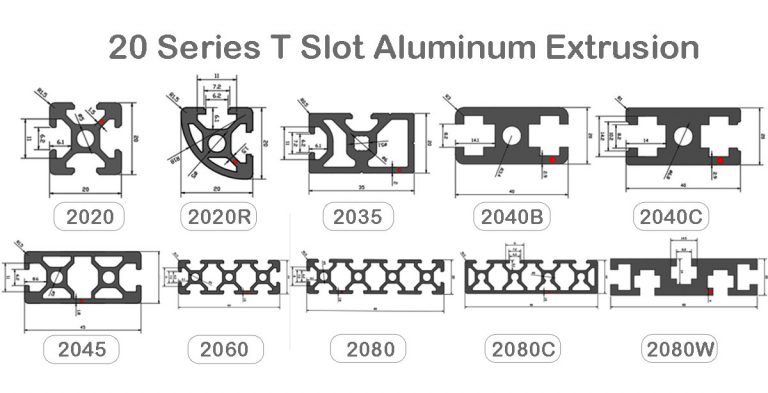

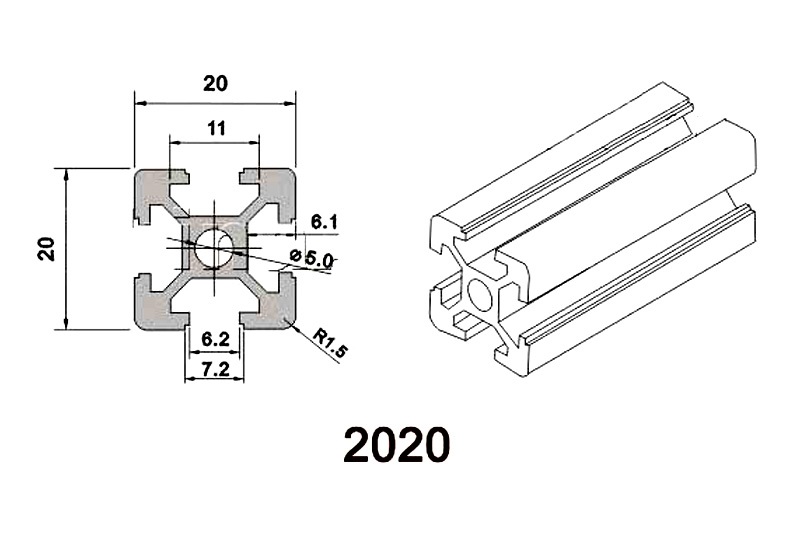

2020 aluminum extrusion refers to a profile that measures 20mm x 20mm in cross-section. It is part of the 20 series of T-slot aluminum profiles, which are widely used in constructing frames, workstations, and various structural applications. The "20" in its name denotes its size, making it easy for users to identify and work with.

This profile features four open T-slots, one on each side, which allow for easy attachment of accessories, panels, and other components. The lightweight nature of aluminum, combined with the structural integrity of the extrusion process, makes 2020 profiles an excellent choice for many applications.

Weight Capacity of 2020 Aluminum Extrusion

One of the most common questions about 2020 aluminum extrusion is how much weight it can hold. The answer to this question is not straightforward, as it depends on various factors:

1. Length of the extrusion

2. Type of load (point load vs. distributed load)

3. Direction of the force applied

4. Quality of the aluminum alloy used

5. Design of the overall structure

However, we can provide some general guidelines based on industry standards and manufacturer specifications.

Typically, a 2020 aluminum extrusion can support a significant amount of weight relative to its size. For example, when used in a 36-inch span with both ends supported, a 2020 profile can often hold between 100 to 200 pounds (45 to 90 kg) at its center point before experiencing noticeable deflection. This capacity can increase dramatically when the load is distributed evenly along the length of the extrusion.

It's important to note that these figures are general estimates, and actual load-bearing capacity can vary based on the specific application and design of the structure. For critical applications, it's always recommended to consult with a structural engineer or the manufacturer's specifications.

Comparing 2020 to Other Aluminum Extrusion Profiles

To better understand the capabilities of 2020 aluminum extrusion, it's helpful to compare it with other common profiles:

1. 2020 vs. 4040 Aluminum Extrusion:

The 4040 profile, measuring 40mm x 40mm, offers significantly higher load-bearing capacity compared to 2020. It's often used in applications requiring greater strength and stability.

2. 2020 vs. 8020 Aluminum Extrusion:

8020 refers to a brand rather than a size, but it's often associated with larger profiles. These typically offer even greater strength and are used in heavy-duty industrial applications.

While larger profiles can handle more weight, the 2020 extrusion offers an excellent balance between strength and weight, making it ideal for many applications where a compact, lightweight solution is needed.

Applications of 2020 Aluminum Extrusion

The versatility of 2020 aluminum extrusion makes it suitable for a wide range of applications:

1. 3D Printer Frames: Many DIY and commercial 3D printers use 2020 extrusions for their frame, providing a sturdy yet lightweight structure.

2. Light-Duty Workstations: In industrial settings, 2020 profiles are often used to construct adjustable workstations and assembly tables.

3. Exhibition Stands: The ease of assembly and disassembly makes 2020 extrusions popular for creating modular exhibition stands.

4. Automation Equipment: Many automated systems use 2020 profiles for guards, enclosures, and light structural elements.

5. Home DIY Projects: From custom furniture to home automation projects, 2020 extrusions are favored by hobbyists for their versatility.

Advantages of Using 2020 Aluminum Extrusion

There are several reasons why 2020 aluminum extrusion is widely used across various industries:

1. Lightweight: Aluminum is significantly lighter than steel, making structures easier to transport and manipulate.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion.

3. Modularity: The T-slot design allows for easy attachment and reconfiguration of components.

4. Cost-Effective: Compared to custom fabrication, using standardized extrusions can significantly reduce costs.

5. Aesthetically Pleasing: The clean lines and silver finish of aluminum extrusions give projects a modern, professional look.

Design Considerations for 2020 Aluminum Extrusion Projects

When designing structures using 2020 aluminum extrusion, consider the following:

1. Load Distribution: Distribute loads evenly when possible to maximize the structure's strength.

2. Reinforcement: For heavier loads, consider using gussets or additional support members.

3. Connection Methods: Choose appropriate connectors and fasteners for your specific application.

4. Thermal Expansion: Remember that aluminum expands and contracts with temperature changes.

5. Surface Finish: Consider whether anodizing or other surface treatments are necessary for your application.

Video: Understanding T-Slot Aluminum Design

To better understand how to design with aluminum extrusions like the 2020 profile, watch this informative video:

This video provides valuable insights into selecting the right profile based on load requirements and structural needs.

Conclusion

2020 aluminum extrusion offers a remarkable combination of strength, versatility, and cost-effectiveness. While its weight capacity depends on various factors, it's capable of supporting significant loads relative to its size. Whether you're working on a DIY project or designing industrial equipment, understanding the capabilities and proper use of 2020 aluminum extrusion can help you create efficient, durable, and adaptable structures.

As technology advances and new alloys are developed, we can expect even greater performance from aluminum extrusions in the future. The key to success lies in choosing the right profile for your specific needs and designing your structure with careful consideration of load distribution and support.

Frequently Asked Questions

Q1: Can 2020 aluminum extrusion be used for outdoor applications?

A1: Yes, 2020 aluminum extrusion can be used outdoors. Aluminum naturally forms a protective oxide layer that resists corrosion. However, for harsh environments or coastal areas, consider anodizing the aluminum for additional protection.

Q2: How do I join 2020 aluminum extrusions together?

A2: There are several methods to join 2020 extrusions, including:

- Corner brackets

- T-nuts and bolts

- Specialized connectors designed for 2020 profiles

- Welding (though this is less common and requires specific skills)

Q3: Is 2020 aluminum extrusion suitable for building a CNC machine frame?

A3: While 2020 extrusion can be used for small, light-duty CNC machines, larger or more precise machines typically require more robust profiles like 4040 or 8080 for increased rigidity and stability.

Q4: How does the cost of 2020 aluminum extrusion compare to steel alternatives?

A4: Generally, 2020 aluminum extrusion is more expensive per unit weight than steel. However, when considering the total cost of a project, aluminum can be more cost-effective due to easier machining, no need for painting, and reduced labor costs for assembly and modification.

Q5: Can I paint 2020 aluminum extrusion?

A5: Yes, you can paint 2020 aluminum extrusion. However, proper surface preparation is crucial for good paint adhesion. This typically involves cleaning, degreasing, and possibly applying a primer designed for aluminum. Powder coating is another durable finish option for aluminum extrusions.

Come and contact us to shop! ! !