Content Menu

● Introduction

● Understanding Aluminum Extrusions

● Common Methods for Connecting Aluminum Extrusions

>> 1. T-Slot Nuts and Bolts

>> 2. Corner Brackets

>> 3. Bolt Connectors

>> 4. Gusset Plates

>> 5. End-to-End Joining

>> 6. Snap-Fit Connections

● Advanced Techniques and Considerations

>> Custom Connectors

>> Welding Aluminum Extrusions

>> Adhesive Bonding

● Tips for Successful Aluminum Extrusion Assembly

● Conclusion

● Frequently Asked Questions

>> Q1: What is the strongest method for connecting aluminum extrusions?

>> Q2: Can I mix and match different connection methods in a single project?

>> Q3: How do I choose the right size T-slot nut for my extrusion?

>> Q4: Are there any special considerations when connecting aluminum extrusions for outdoor use?

>> Q5: Can I create curved structures with aluminum extrusions?

Introduction

Aluminum extrusions have revolutionized the world of construction and manufacturing, offering a versatile and cost-effective solution for creating sturdy frameworks and structures. Whether you're working on a DIY project or a large-scale industrial application, understanding how to connect aluminum extrusions is crucial for achieving optimal results. This comprehensive guide will explore various methods and techniques for joining aluminum profiles, providing you with the knowledge and skills to tackle any project with confidence.

Understanding Aluminum Extrusions

Before diving into connection methods, it's essential to understand what aluminum extrusions are and why they're so popular. Aluminum extrusions are lengths of aluminum that have been shaped by forcing heated aluminum through a die. This process creates profiles with consistent cross-sections, which can be designed to include features like T-slots, screw ports, and interlocking mechanisms.

The versatility of aluminum extrusions makes them ideal for a wide range of applications, from lightweight furniture to heavy-duty industrial equipment. Their strength-to-weight ratio, corrosion resistance, and ease of customization have made them a go-to material for engineers and designers across various industries.

Common Methods for Connecting Aluminum Extrusions

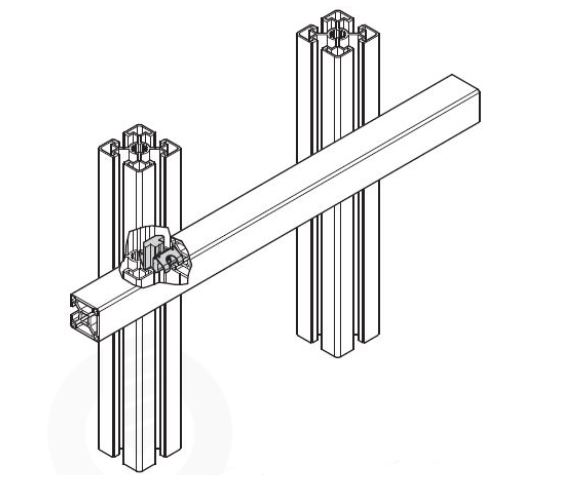

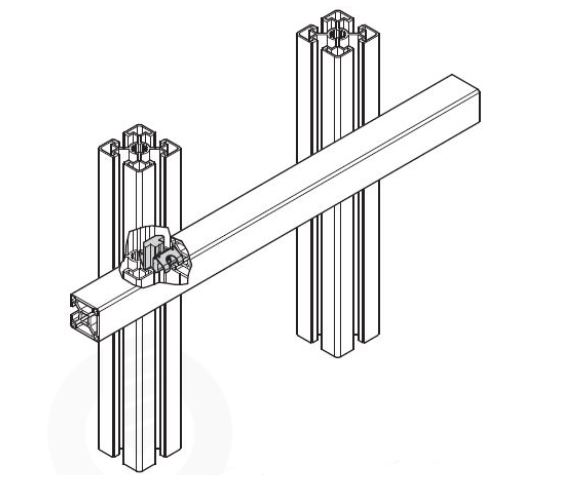

1. T-Slot Nuts and Bolts

One of the most popular and versatile methods for connecting aluminum extrusions is using T-slot nuts and bolts. This method takes advantage of the T-shaped channels that run along the length of many extrusion profiles.

To connect two extrusions using this method:

1. Slide a T-slot nut into the channel of each extrusion you want to join.

2. Align the extrusions as desired.

3. Insert a bolt through one extrusion and into the T-slot nut of the other.

4. Tighten the bolt to secure the connection.

This method allows for easy adjustment and disassembly, making it ideal for prototyping or structures that may need to be modified in the future.

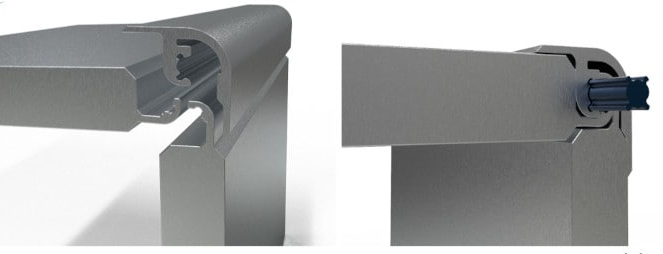

2. Corner Brackets

Corner brackets are excellent for creating 90-degree connections between extrusions. They're particularly useful for building frame structures and enclosures.

To use corner brackets:

1. Choose a bracket that matches the size of your extrusions.

2. Align the bracket with the ends of the extrusions you want to join.

3. Secure the bracket to each extrusion using screws or bolts.

4. For added stability, consider using multiple brackets at each corner.

Corner brackets come in various styles, including internal and external options, allowing you to choose the best fit for your specific application.

3. Bolt Connectors

For joints that require maximum strength, bolt connectors are an excellent choice. This method involves drilling a hole through one extrusion and into the end of another, then using a specialized bolt to join them.

To use a bolt connector:

1. Drill a hole through the side of one extrusion and into the end of the other.

2. Insert a barrel nut into the end of the second extrusion.

3. Pass a bolt through the drilled hole and into the barrel nut.

4. Tighten the bolt to secure the connection.

This method creates a very strong joint but requires more preparation and is less easily adjustable than some other methods.

4. Gusset Plates

Gusset plates are triangular pieces of metal that can be used to reinforce connections between extrusions, particularly at corners or T-joints.

To use gusset plates:

1. Position the gusset plate at the junction of the extrusions.

2. Secure the plate to each extrusion using bolts or screws.

3. For added strength, use gusset plates on both sides of the joint.

Gusset plates not only strengthen the connection but also provide a clean, professional look to your structure.

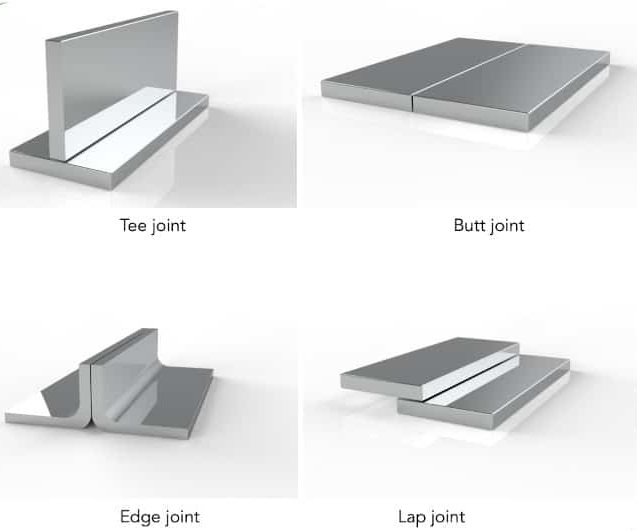

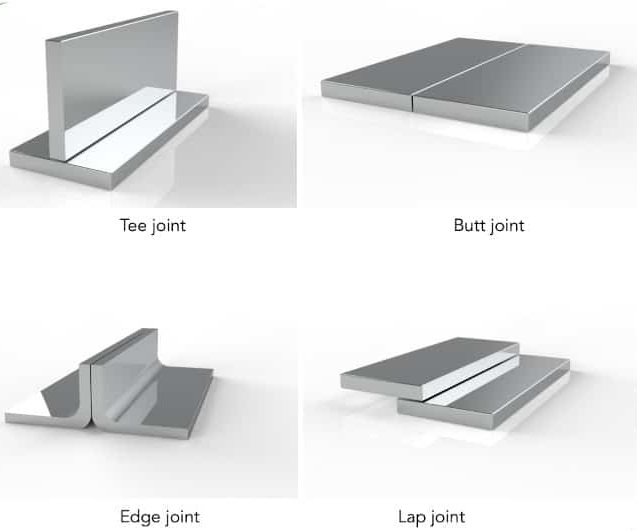

5. End-to-End Joining

When you need to extend the length of an extrusion or create a seamless joint, end-to-end joining methods come into play.

Common end-to-end joining techniques include:

- Using internal joining plates that slide into the T-slots of both extrusions

- Employing specialized end connectors that fit snugly into the ends of the profiles

- Utilizing butt joint connectors for a flush finish

Each of these methods has its advantages, depending on the load requirements and aesthetic considerations of your project.

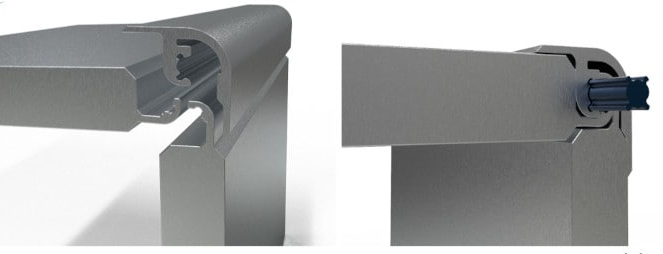

6. Snap-Fit Connections

For quick assembly and disassembly, snap-fit connections can be incredibly useful. These connections rely on the inherent flexibility of aluminum and specially designed profile shapes.

To create a snap-fit connection:

1. Choose extrusions with compatible snap-fit profiles.

2. Align the extrusions so that the snap-fit features line up.

3. Apply pressure to push the profiles together until they click into place.

While not as strong as some other methods, snap-fit connections are perfect for temporary structures or applications where frequent reconfiguration is necessary.

Advanced Techniques and Considerations

Custom Connectors

For specialized applications, custom connectors can be designed and manufactured to meet specific requirements. These might include:

- Multi-way connectors for complex junctions

- Adjustable angle connectors for non-standard geometries

- Load-bearing connectors for high-stress applications

Working with a manufacturer or engineer can help you develop custom solutions tailored to your unique needs.

Welding Aluminum Extrusions

While less common due to the specialized equipment and skills required, welding aluminum extrusions can create extremely strong, permanent connections. This method is typically reserved for high-stress applications or when a seamless appearance is crucial.

Adhesive Bonding

In some cases, adhesive bonding can be used to join aluminum extrusions. This method can create strong, waterproof seals and is particularly useful when mechanical fasteners are not desirable. However, it requires careful surface preparation and the selection of an appropriate adhesive for aluminum.

Tips for Successful Aluminum Extrusion Assembly

1. Plan your structure carefully before beginning assembly.

2. Ensure all cutting and drilling are done precisely to ensure proper alignment.

3. Use the appropriate tools, including Allen wrenches, torque wrenches, and specialized extrusion assembly tools.

4. Consider the load-bearing requirements of your structure when selecting connection methods.

5. For large or complex structures, create a detailed assembly plan or use 3D modeling software to visualize the final product.

Conclusion

Connecting aluminum extrusions is a skill that combines engineering principles with practical craftsmanship. By understanding the various methods available and their appropriate applications, you can create strong, versatile structures that meet a wide range of needs. Whether you're building a simple frame or a complex machine, the right connection technique can make all the difference in the success of your project.

Remember to always prioritize safety, follow manufacturer guidelines, and don't hesitate to seek professional advice for challenging or critical applications. With practice and experience, you'll develop the expertise to tackle even the most complex aluminum extrusion projects with confidence.

Frequently Asked Questions

Q1: What is the strongest method for connecting aluminum extrusions?

A1: The strongest method for connecting aluminum extrusions is typically the bolt connector method. This involves drilling through one extrusion into another and using a specialized bolt and barrel nut to create a very secure joint. However, the strength of the connection also depends on the specific application and load requirements.

Q2: Can I mix and match different connection methods in a single project?

A2: Yes, you can mix and match different connection methods in a single project. In fact, this is often necessary to achieve the best balance of strength, flexibility, and ease of assembly. For example, you might use bolt connectors for critical load-bearing joints and T-slot nuts for easily adjustable connections.

Q3: How do I choose the right size T-slot nut for my extrusion?

A3: To choose the right size T-slot nut, you need to know the dimensions of your extrusion's T-slot. Most manufacturers provide this information in their product specifications. The nut should fit snugly into the slot without being too tight or too loose. It's always a good idea to test a few nuts before purchasing in bulk for your project.

Q4: Are there any special considerations when connecting aluminum extrusions for outdoor use?

A4: For outdoor use, consider the following:

1. Use stainless steel fasteners to prevent galvanic corrosion.

2. Apply a protective coating or anodization to the aluminum for additional corrosion resistance.

3. Ensure proper drainage in your design to prevent water accumulation.

4. Use weatherproof sealants at joints if water tightness is required.

5. Consider thermal expansion and contraction in your design, especially for large structures.

Q5: Can I create curved structures with aluminum extrusions?

A5: While aluminum extrusions are typically straight, you can create curved structures using several methods:

1. Use flexible extrusions designed to bend along one axis.

2. Create curves by joining short, straight sections at slight angles.3. Use specialized curved connectors or brackets.

4. For gentle curves, some aluminum profiles can be cold-formed, but this requires specialized equipment and expertise.

For complex curves, it may be necessary to use custom-machined or cast components in conjunction with standard extrusions.