Content Menu

● Introduction to Candy Extrusion Equipment

>> Types of Candy Extruders

● Applications of Candy Extrusion Equipment

● Importance of Candy Extrusion Equipment

● Maintenance and Durability

● Innovations in Candy Extrusion Technology

>> Pre-Extrusion Processes

● Future Trends in Candy Extrusion

● Challenges and Opportunities

● Conclusion

● FAQ

>> 1. What types of candies can be produced using candy extrusion equipment?

>> 2. How does candy extrusion equipment ensure product consistency?

>> 3. What materials are used to construct candy extruders?

>> 4. How does automation benefit candy extrusion processes?

>> 5. What maintenance is required for candy extrusion equipment?

● Citations:

Candy extrusion equipment is a crucial component in the confectionery industry, used for producing a wide variety of candies by shaping and forming dough-like materials into desired shapes and sizes. This equipment plays a pivotal role in large-scale candy manufacturing, ensuring efficiency, consistency, and quality in the production process. In this article, we will delve into the uses, types, and applications of candy extrusion equipment, along with its importance in the candy-making process.

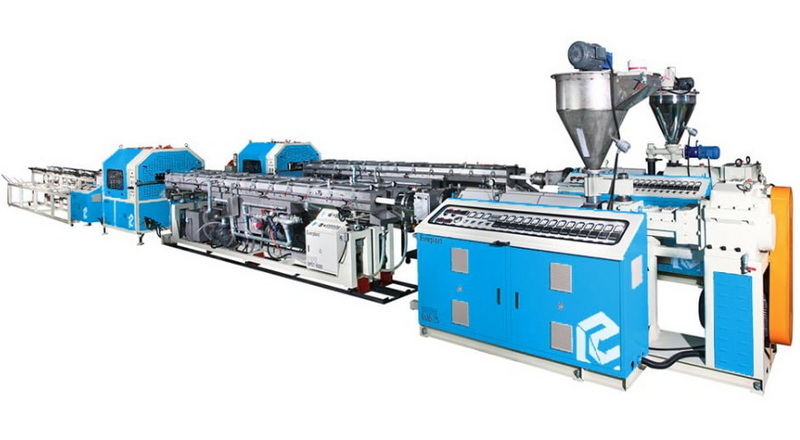

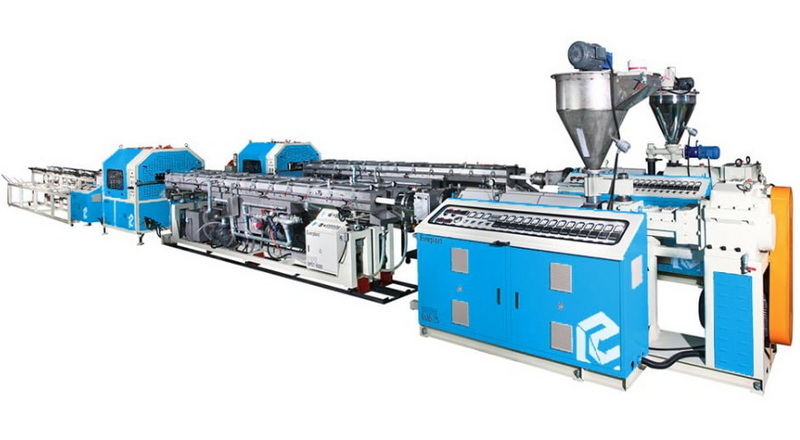

Introduction to Candy Extrusion Equipment

Candy extrusion equipment is designed to handle different types of candy masses, such as chewing gum, bubble gum, caramel, toffee, and gummies. These machines are capable of continuous production, allowing for high-volume output while maintaining product consistency. The process involves mixing ingredients, heating or cooling them as necessary, and then extruding the mixture through a die to achieve the desired shape.

Types of Candy Extruders

1. Single-Screw Extruders: These are simple to operate and suitable for producing a wide range of candies. They use a single screw to push the candy mass through a die, creating uniform shapes.

2. Twin-Screw Extruders: These are used for compounded or textured candies, offering better mixing and shear capabilities than single-screw extruders. Twin-screw extruders, such as the Evolum+ by Clextral, are particularly beneficial for handling healthy ingredients like finely ground flours, improving feed capability and overall system capacity[8].

3. Thermal Extruders: These combine heating and cooling zones to control the temperature profile of the candy mass, ideal for thermally sensitive materials like chocolate.

4. Hydraulic Extruders: These use hydraulic pressure to process very viscous candy compositions, such as firm candy masses or lollipop syrups.

5. Multi-Layer Extruders: These are used to create multi-layer or filled candies by introducing different materials through multiple feed ports. For instance, three-phase confectionery products can be made by co-extruding hard candy shells with chewy or semi-liquid fillings[5].

Applications of Candy Extrusion Equipment

Candy extrusion equipment is versatile and can be used in various applications across the confectionery industry:

- Chewing Gum Production: Extruders are used to shape gum bases into sticks or balls, ensuring even distribution of ingredients and enhancing texture.

- Licorice Candy Production: Licorice dough is extruded into ropes, which are then cut to desired lengths, allowing for consistent thickness.

- Gummy Candy Production: Extruders help distribute gelatin-based mixtures uniformly into molds, creating chewy textures.

- Chocolate-Coated Products: Extruders apply chocolate coatings onto nuts, fruits, or marshmallows, ensuring even coverage.

- Multi-Layer Confections: Extruders can create complex candies with multiple layers, such as laminated candy products made by rolling layers of candy mass and fatty paste[7].

Importance of Candy Extrusion Equipment

Candy extrusion equipment is essential for maintaining efficiency and quality in candy production. It offers several benefits:

- High Production Volume: Capable of handling large quantities, making it ideal for industrial-scale production.

- Consistency: Ensures uniformity in product shape and size.

- Flexibility: Can produce a wide range of candies by changing dies or formulations.

- Automation: Reduces manual labor, increasing precision and reducing production time.

Maintenance and Durability

Candy extrusion equipment, particularly those made from stainless steel, is durable and resistant to corrosion. Regular maintenance is crucial to ensure optimal performance and longevity:

- Cleaning: Easy to clean due to stainless steel construction.

- Inspection: Regular checks for wear and tear.

- Replacement: Timely replacement of worn parts.

Innovations in Candy Extrusion Technology

The candy extruder market is experiencing significant transformation driven by several key factors:

- Technological Advancements: Automation, precision control systems, and high-speed continuous motion bagging machines are enhancing efficiency and reducing waste[2][3].

- Sustainable Manufacturing: Adoption of eco-friendly materials and energy-efficient technologies is becoming increasingly critical[3].

- 3D Printing and Additive Manufacturing: Allows for highly customized and complex candy shapes[3].

- Personalized Candy Products: Growing demand for customized production lines to meet consumer preferences for unique products[3].

Pre-Extrusion Processes

Pre-extrusion processes, such as those using the Flextruder system, offer advantages like continuous graining or crystallization of soft candy, elimination of lumps, and improved texture. These systems automate the feeding of final extruders, reducing manual work and increasing precision[1].

Future Trends in Candy Extrusion

The future of candy extrusion equipment is marked by trends towards increased automation, sustainability, and customization. Manufacturers are focusing on developing healthier candy options and adopting smart manufacturing technologies to optimize processes and improve quality control[3][6].

Challenges and Opportunities

Despite the advancements, the candy extruder market faces challenges such as high initial investment costs, stringent food safety regulations, and fluctuations in raw material prices[3]. However, these challenges also present opportunities for innovation and strategic partnerships to maintain market share.

Conclusion

Candy extrusion equipment is a vital tool in the confectionery industry, enabling the production of a diverse range of candies efficiently and consistently. Its versatility, durability, and ability to handle large volumes make it indispensable for both small-scale and industrial candy manufacturing. As technology continues to evolve, candy extrusion equipment will play an increasingly important role in meeting consumer demands for innovative, healthier, and more sustainable confectionery products.

FAQ

Here are some frequently asked questions about candy extrusion equipment:

1. What types of candies can be produced using candy extrusion equipment?

Candy extrusion equipment can produce a wide variety of candies, including chewing gum, bubble gum, licorice, gummies, and chocolate-coated products.

2. How does candy extrusion equipment ensure product consistency?

Candy extrusion equipment ensures consistency by using precise temperature control, uniform mixing, and consistent die shapes, resulting in uniform product sizes and textures.

3. What materials are used to construct candy extruders?

Candy extruders are commonly made from stainless steel due to its durability and resistance to corrosion, which is essential for handling acidic and sugary ingredients.

4. How does automation benefit candy extrusion processes?

Automation in candy extrusion equipment reduces manual labor, increases precision, and speeds up production, leading to higher efficiency and reduced waste.

5. What maintenance is required for candy extrusion equipment?

Regular cleaning, inspection for wear and tear, and timely replacement of worn parts are essential for maintaining the performance and longevity of candy extrusion equipment.

Citations:

[1] https://www.euromec.it/chewing-gum-bubble-gum-machine/pre-extruder/

[2] https://www.yuchomachine.com/blog/candy-equipment-features-uses/

[3] https://www.datainsightsmarket.com/reports/candy-extruder-38663

[4] https://patents.google.com/patent/US20090311385A1/en

[5] https://patents.google.com/patent/WO2002056698A1/en

[6] https://www.yinrich.com/a-news-the-latest-innovations-in-confectionery-equipment-technology

[7] https://patents.google.com/patent/US6616963B1/en

[8] https://www.confectioneryproduction.com/feature/36288/focus-exploring-behind-the-scenes-of-extrusion-technology-for-confectionery/

[9] https://www.eganfoodtech.com/news/Addressing-Trends-And-Technology-Choices

[10] https://kennedysconfection.co.uk/getting-flexible-with-forming-and-extrusion/

[11] https://www.yinrich.com/a-news-the-future-of-candy-production-lines-trends-to-watch

[12] https://in-confectionery.com/moguls-extruders-and-soft-sweets/

[13] https://pmarketresearch.com/auto/candy-extruder-market/

[14] https://www.datainsightsmarket.com/reports/candy-extruder-38236

[15] https://lejackson.com/pdf/BCH-Confectionery-Process-System-Brochure-2023.pdf

[16] https://www.yinrich.com/a-news-innovations-in-technology-for-modern-commercial-candy-making-equipment

[17] https://www.eganfoodtech.com/news?tag=extrusion

[18] https://www.yinrich.com/a-news-the-future-of-confectionery-equipment-predictions-and-trends

[19] https://patents.google.com/patent/US3556021A/en

[20] https://www.bakingbusiness.com/articles/61145-snack-producers-double-down-on-innovation-with-extrusion