Content Menu

● Introduction to Food Co-Extrusion Equipment

● How Food Co-Extrusion Machines Work

● Key Features of Food Co-Extrusion Machines

>> 1. Modular and Flexible Design

>> 2. Precise Portion and Weight Control

>> 3. High Automation and Continuous Operation

>> 4. Versatile Product Shaping and Sizing

>> 5. Enhanced Food Safety and Hygiene

>> 6. Cost Efficiency and Resource Optimization

>> 7. Precise Process Control

>> 8. High Capacity and Scalability

● Types of Food Co-Extrusion Equipment

● Advantages of Food Co-Extrusion Technology

● Applications of Food Co-Extrusion Equipment

● Operational Considerations and Process Control

>> Material Handling and Feeding

>> Temperature and Moisture Control

>> Cutting and Portioning

>> Cleaning and Maintenance

● Innovations and Trends in Food Co-Extrusion

● Conclusion

● FAQ: Food Co-Extrusion Equipment

>> 1. What types of products can be made with food co-extrusion equipment?

>> 2. How does co-extrusion improve food safety compared to traditional methods?

>> 3. What are the main cost-saving benefits of using food co-extrusion equipment?

>> 4. Can food co-extrusion machines handle different product sizes and shapes?

>> 5. What are the key operational parameters that affect co-extruded product quality?

● Citations:

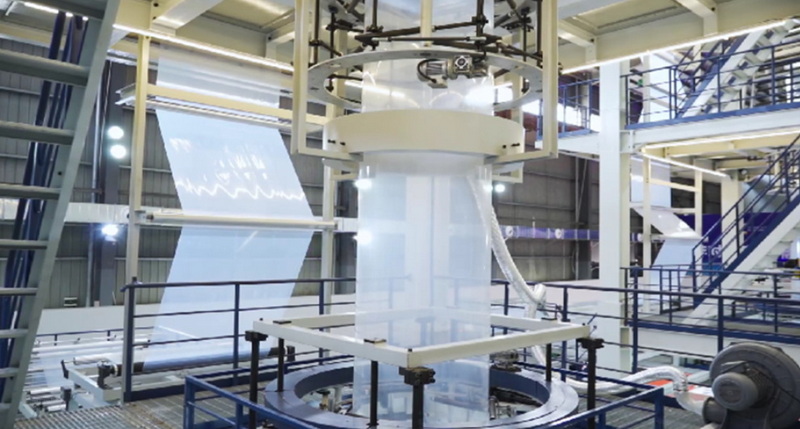

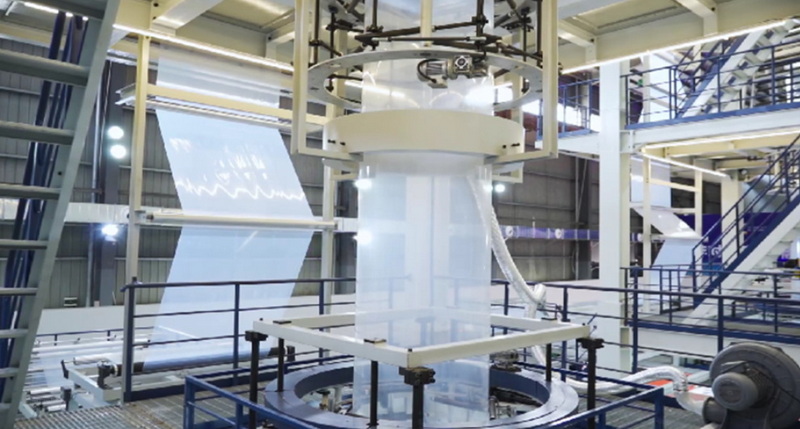

Food co-extrusion equipment has revolutionized the food processing industry, enabling manufacturers to produce innovative, high-quality, and cost-efficient products at scale. From filled snacks and dual-texture pet foods to premium sausages and confectionery, co-extrusion technology offers unmatched versatility and efficiency. This article explores the key features of food co-extrusion machines, their operational principles, advantages, and applications, providing a comprehensive guide for food technologists, manufacturers, and industry professionals.

Introduction to Food Co-Extrusion Equipment

Food co-extrusion equipment is designed to simultaneously process two or more different food materials, combining them into a single product with distinct layers or fillings. Unlike traditional extrusion, which produces a homogeneous product, co-extrusion enables the creation of complex structures—such as a crispy shell with a creamy center or a meat product with a flavored casing—by extruding multiple streams through concentric dies[8].

This technology has become a cornerstone in the production of value-added foods, offering manufacturers the ability to innovate and differentiate their products in a competitive market.

How Food Co-Extrusion Machines Work

The core principle of food co-extrusion equipment involves the synchronized extrusion of two or more food masses. Typically, the equipment consists of:

- Multiple feed hoppers for different materials (e.g., dough and filling)

- Separate extrusion screws or pumps for each material

- A co-extrusion die that shapes and combines the streams into the desired product form

- An integrated cutting and portioning system to produce uniform product sizes[8]

The process is continuous, highly automated, and designed to minimize manual intervention, thereby improving product consistency and food safety.

Key Features of Food Co-Extrusion Machines

1. Modular and Flexible Design

Modern food co-extrusion equipment is modular, allowing manufacturers to adapt the system for various product types and sizes. The modular design enables quick changeovers between products, easy cleaning, and scalability for different production capacities[8].

2. Precise Portion and Weight Control

Advanced co-extrusion machines employ dosing pumps and servo-controlled systems to ensure accurate control of both core and shell materials. This results in products with consistent weight, size, and filling-to-shell ratios, which is critical for quality assurance and regulatory compliance[8].

3. High Automation and Continuous Operation

Food co-extrusion equipment is fully automated, from material feeding to cutting and packaging. Automation reduces labor costs, minimizes human error, and enhances food safety by limiting product handling[8].

4. Versatile Product Shaping and Sizing

The use of interchangeable dies and adjustable cutting mechanisms allows for the production of a wide variety of shapes, sizes, and textures. Whether producing filled snacks, sausages, or confectionery, manufacturers can easily switch between product formats to meet market demands[8].

5. Enhanced Food Safety and Hygiene

Co-extrusion systems are designed with food safety in mind. The fully enclosed, in-line process minimizes the risk of contamination, and many machines feature CIP (Clean-In-Place) systems for efficient sanitation. The “cook in the pack” principle, where products are cooked and chilled in their final packaging, further enhances safety and extends shelf life[8].

6. Cost Efficiency and Resource Optimization

By automating casing formation (as in sausage production) and reducing reliance on expensive natural casings, co-extrusion technology significantly lowers material and labor costs. The continuous process also reduces waste and maximizes ingredient utilization[8].

7. Precise Process Control

State-of-the-art control systems monitor and regulate key parameters such as temperature, pressure, humidity, and air speed during processing. This ensures stable production conditions and consistent product quality, even during high-volume runs[8].

8. High Capacity and Scalability

Food co-extrusion equipment is capable of high throughput, making it suitable for large-scale industrial production. Modular systems can be expanded or reconfigured to accommodate growing production needs[8].

Types of Food Co-Extrusion Equipment

Food co-extrusion equipment comes in various configurations, tailored to specific applications:

- Single-Lane Co-Extruders: Suitable for small-scale or specialty products.

- Multi-Lane Co-Extruders: Designed for high-volume production, with multiple product streams running in parallel.

- Rotary Co-Extruders: Used for round or cylindrical products, such as filled cookies or sausages.

- Twin-Screw Co-Extruders: Offer enhanced mixing, shearing, and process control, ideal for complex formulations[3].

Each type can be further customized with auxiliary systems for pre-conditioning, drying, smoking, or packaging, depending on the product requirements.

Advantages of Food Co-Extrusion Technology

Food co-extrusion equipment offers several compelling advantages over traditional processing methods:

- Product Innovation: Enables the creation of novel products with unique textures, flavors, and visual appeal.

- Consistent Quality: Automation and process control ensure uniformity in every batch.

- Reduced Labor and Material Costs: Automated casing and filling processes lower operational expenses.

- Improved Food Safety: Enclosed systems and minimal handling reduce contamination risks.

- Extended Shelf Life: Products can be cooked and sealed in their final packaging, preserving freshness[8].

- Versatility: Suitable for a wide range of applications, from snacks and bakery products to meat, dairy, and pet foods[5][6].

Applications of Food Co-Extrusion Equipment

The versatility of food co-extrusion equipment is evident in its broad range of applications:

- Sausages and Meat Products: Automated production of sausages with edible casings, consistent size, and high food safety standards[8].

- Filled Snacks: Production of crispy shells with creamy or savory centers, such as cheese-filled crackers or chocolate-filled biscuits.

- Confectionery: Manufacturing of layered or filled candies, licorice, and toffee[6].

- Pet Foods: Creation of dual-texture kibbles with soft fillings for enhanced palatability.

- Bakery and Cereal Products: Filled breakfast cereals, bars, and cookies with diverse flavor and texture combinations[5][6].

- Dairy and Cheese Analogues: Production of processed cheeses and cheese analogues with customizable textures and flavors[6].

Operational Considerations and Process Control

Material Handling and Feeding

Efficient feeding systems are essential for consistent product quality. Modern food co-extrusion equipment features automated feeders with precise dosing capabilities, preventing material bridging and ensuring uniform flow[7].

Temperature and Moisture Control

Accurate control of temperature and moisture is critical for product texture and safety. Advanced machines use integrated sensors and feedback systems to maintain optimal processing conditions throughout the extrusion and co-extrusion stages[2][4].

Cutting and Portioning

Automated cutting devices, often servo-driven, enable precise portioning and shaping of co-extruded products. Adjustable cutting speeds and die configurations allow for rapid product changeovers and customization[7].

Cleaning and Maintenance

Hygienic design and easy disassembly are key features of modern co-extrusion equipment, facilitating thorough cleaning and reducing downtime between production runs[8].

Innovations and Trends in Food Co-Extrusion

The food co-extrusion sector continues to evolve, driven by consumer demand for healthier, more diverse, and convenient products. Key trends and innovations include:

- Integration with 3D Printing: Combining extrusion with 3D printing for complex shapes and personalized nutrition[2].

- Supercritical Fluid Extrusion: Use of supercritical CO₂ for lower-temperature processing, preserving nutrients and reducing energy consumption[2].

- Advanced Process Monitoring: Incorporation of spectrometers, rheometers, and simulation software for real-time quality control and process optimization[2].

- Sustainable Production: Focus on reducing waste, energy use, and reliance on animal-derived materials, aligning with global sustainability goals[2][3].

Conclusion

Food co-extrusion equipment stands at the forefront of modern food manufacturing, offering unparalleled flexibility, efficiency, and product innovation. Its key features—modular design, precise control, automation, hygiene, and scalability—empower manufacturers to create a diverse array of high-quality, safe, and cost-effective products. As technology advances, the capabilities of food co-extrusion machines will continue to expand, driving new possibilities in the global food industry.

FAQ: Food Co-Extrusion Equipment

1. What types of products can be made with food co-extrusion equipment?

Food co-extrusion equipment can produce a wide variety of products, including filled snacks, sausages with edible casings, confectionery, dual-texture pet foods, filled bakery items, and processed cheeses. The technology supports both sweet and savory applications, offering flexibility for manufacturers to innovate[6][8].

2. How does co-extrusion improve food safety compared to traditional methods?

Co-extrusion systems are fully automated and enclosed, minimizing human contact and reducing the risk of contamination. The "cook in the pack" process, where products are cooked and sealed in their final packaging, further enhances food safety and extends shelf life[8].

3. What are the main cost-saving benefits of using food co-extrusion equipment?

Food co-extrusion equipment reduces labor costs through automation and lowers material expenses by using less expensive casing gels instead of natural or preformed casings. The continuous process also optimizes ingredient usage and minimizes waste, resulting in significant cost savings[8].

4. Can food co-extrusion machines handle different product sizes and shapes?

Yes, modern co-extrusion machines are highly versatile. By changing dies and adjusting cutting mechanisms, manufacturers can produce a wide range of product sizes, shapes, and textures, enabling rapid adaptation to market trends and consumer preferences[8].

5. What are the key operational parameters that affect co-extruded product quality?

Critical parameters include feed rate, material particle size, barrel temperature, screw speed, and moisture content. Precise control of these variables ensures consistent product texture, appearance, and safety. Advanced machines use integrated sensors and control systems to monitor and adjust these parameters in real time[5][6].

Citations:

[1] https://www.eolss.net/sample-chapters/c10/e5-10-04-09.pdf

[2] https://www.linkedin.com/pulse/food-extrusion-equipment-technology-its-mechanism-jessica-zhang-xslte

[3] https://www.dragonextruder.com/news/advantages-of-twin-screw-extruders-for-food-extrusion.html

[4] https://www.davidpublisher.com/Public/uploads/Contribute/577b2b188e315.pdf

[5] https://ptfe-machinery.com/extrusion-applications-food/

[6] https://en.wikipedia.org/wiki/Food_extrusion

[7] https://m.loyalfoodmachine.com/what-are-the-basic-functions-and-main-features-of-the-extruder-machine/

[8] https://marel.com/media/mbdjduqi/coextrusion-technology.pdf

[9] https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/food-extrusion

[10] https://www.dennisforte.com.au/second-edition-extrusion-table-of-contents

[11] https://daextrusion.com/applications/food-extruders/

[12] https://medcraveonline.com/MOJFPT/applications-of-food-extrusion-technology.html

[13] https://www.bakerperkins.com/food-extrusion/products/filled-snacks/

[14] https://www.handtmann.de/en/filling-and-portioning-systems/products/functions/additional-equipment/87-22-87-30-87-40-co-extrusion-systems

[15] https://cfaminternational.com/advantages-of-twin-screw-extrusion-in-the-food-processing-industry/

[16] https://ijiset.com/vol2/v2s4/IJISET_V2_I4_51.pdf

[17] https://www.handtmann.de/en/filling-and-portioning-systems/products/functions/forming-and-cutting/koex-multi-former

[18] https://onlytrainings.com/Co-extrusion-Process-Applications-Benefits-Over-Extrusion-by-onlytrainings

[19] https://en.engormix.com/feed-machinery/extrusion/why-food-technology-extrusion_a54524/

[20] https://www.rxpelletmachine.com/info/snack-food-extrusion-advantages-and-considera-95664458.html