Content Menu

● What is Plastic Sheet Extrusion?

● Understanding the Extrusion Process

>> Key Components of the Sheet Extrusion System

>> How Does an Extruder Work?

>> Variety of Plastic Materials for Extrusion

>> Steps in the Sheet Extrusion Manufacturing Process

>> Cooling and Cutting the Extruded Sheet

>> Ensuring Precision and Consistency

● Benefits of Using Plastic Sheet Extrusion Equipment

● Applications of Plastic Sheet Extrusion

● Innovations in Plastic Sheet Extrusion Technology

● Challenges and Solutions in Plastic Sheet Extrusion

● Future Trends in Automatic Plastic Sheet Extrusion

● Conclusion

● FAQ

>> Q1: What is plastic sheet extrusion?

>> Q2: What materials are commonly used in plastic sheet extrusion?

>> Q3: How do extrusion machines work?

>> Q4: What role does the extrusion die play in the process?

>> Q5: What are the advantages of using plastic sheet extrusion?

● Citations:

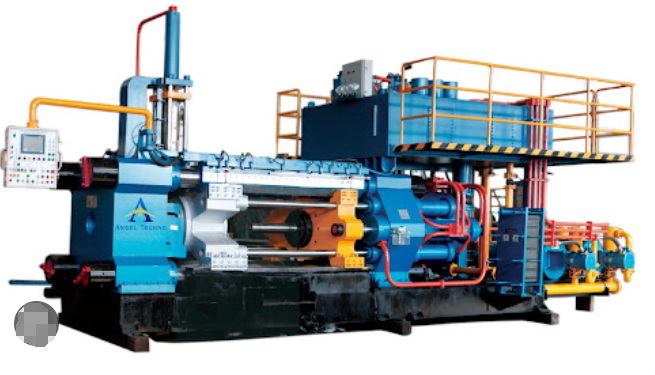

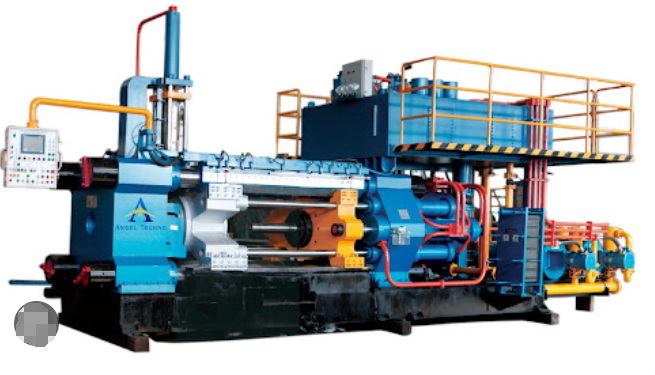

Plastic sheet extrusion equipment has revolutionized the manufacturing industry, providing a highly efficient and versatile method for producing plastic sheets. This process involves melting raw plastic material and shaping it into a continuous sheet through a die. Plastic sheet extrusion is gaining popularity worldwide, proving its potential for use in a variety of industries[6]. This article explores the key benefits of using plastic sheet extrusion equipment, its processes, components, and applications.

What is Plastic Sheet Extrusion?

Plastic sheet extrusion is a continuous process where polymer materials are melted and formed into thin, flat sheets with consistent thickness and surface quality[6]. The method of manufacturing plastic sheets is done by melting raw plastic in the form of raw pellets[6]. Next, the material is forced through a flat die in order to create a continuous sheet with the specific desired thickness and width[6]. In addition, this process requires a high level of temperature control[6]. Special instruments known as extruders, chill rolls, and winding units must also be used[6]. These sheets are then cooled, trimmed, and ordered for use in packaging, construction, and automobile parts[6]. This method is favorable because it is simple, quick, and economical to create sheets of a specific thickness and high quality[6].

Understanding the Extrusion Process

The extrusion process begins with the preparation of raw materials, typically thermoplastic resins, granules, or pellets, known as the feedstock[6]. These materials are fed into the extruder through a hopper, where they are heated by the barrel and built-in heating zones[6]. As the materials move through the rotating screw, pressure is applied, ensuring the polymer melts and becomes homogeneous[6].

Once the polymer melt reaches the die, it is formed into a sheet with the required dimensions[6]. The design of the die is crucial as it directly affects the output quantity and quality[6]. After exiting the die, the extrudate undergoes a cooling process, which may involve water baths, air cooling, or chill rolls, to set its dimensions and characteristics[6].

The final steps include cutting, trimming, and coiling or stacking the sheets, depending on the product requirements[6]. These procedures ensure the material has the required thickness and width and is as uniform as possible[6]. Extruded materials are most often used for packaging films, construction panels, and automotive trim parts because they are easily mass-produced[6].

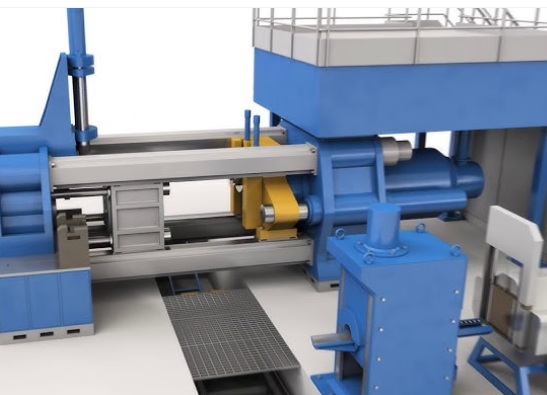

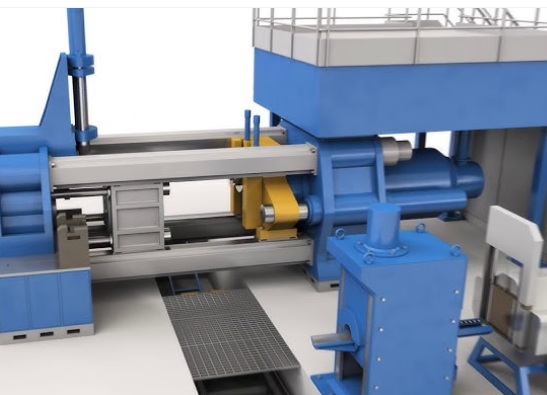

Key Components of the Sheet Extrusion System

The sheet extrusion system's functionality relies on several key components[6]. The extruder melts and blends the polymer materials using controlled heating zones and a revolving screw[6]. The flat die evenly distributes the molten polymer to form the sheet[6]. Calendering or chill roll systems freeze and finish the sheet through rapid rolling, ensuring surface quality and appropriate thickness[6]. Pullers, winders, and trimmers are ancillary equipment that shapes and collects the extruded sheet[6].

How Does an Extruder Work?

A[Raw Materials (Pellets, Powder, Granules)] --> B(Hopper)

B --> C(Extruder Barrel with Rotating Screw)

C --> D{Feeding Zone}

D --> E{Melting/Compression Zone}

E --> F{Metering Zone}

F --> G(Die Exit - Desired Shape)

G --> H(Cooling System)

H --> I(Finished Product - Tubing, Films, Complex Shapes)

An extruder shapes objects by pushing material through a die crafted for that purpose[6]. Raw materials, such as pellets, powder, or granules, are placed into a hopper[6]. These materials are then sent into the barrel of a rotating extruder screw powered by a motor[6]. As the screw rotates, it compresses, heats, and shears the material, moving it forward[6].

The extrusion process has several key stages[6]:

1. Feeding Zone A solid feed into the screw-conveying barrel section allows for consistent material feeding[6]. The rotary movement of the screw pushes the material towards the die[6].

2. Melting or Compression Zone Material softening or melting occurs through heat generated from external barrel heaters and the friction created by rotation[6]. The barrel's temperature is typically set between 150 and 300 degrees Celsius, but it varies depending on the material, such as polypropylene or polyethylene[6].

3. Metering Zone The heated material is kept under constant pressure until it is ready for extrusion[6]. Depending on the screw's design and the properties of the material, the standard rotation speed ranges from 50 to 150 RPM[6].

4. Die Exit The desired material is poured into a die of the desired shape and size[6]. The shape of the final cross-section of the die determines the final product's appearance[6].

The pressure during extrusion ranges from 10–200 MPa[6]. Temperatures during and after the extrusion cooling procedures (which can include air or water-bath systems), and even the screw's length-to-diameter ratios (L/D ratios) which is usually between 20:1 and 40:1 in most cases, affect the extrusion process[6]. The output is a highly accurate shape with a good finish and uniform material characteristics, which allows the part to be used as tubing, films, or even more complex shapes[6].

Variety of Plastic Materials for Extrusion

Several types of plastic materials are utilized in sheet extrusion, each with distinct technical parameters suited for specific applications[6].

| Material | Density (g/cm³) | Melting Temperature (°C) / Glass Transition Temperature (°C) | Key Properties | Common Applications |

| Polyethylene (PE) | 0.91–0.96 | 120–130 | Highly flexible, excellent chemical resistance, low moisture absorption. | Packaging, consumer goods, industrial films |

| Polypropylene (PP) | 0.90–0.92 | 160–170 | High stiffness, good fatigue resistance, resistance to heat and chemicals. | Automotive parts, food containers, medical components |

| Polystyrene (PS) | 1.04–1.07 | ~100 (Glass Transition) | High rigidity, good optical clarity (in transparent form), ease of molding. | Disposable packaging, consumer products |

| Polycarbonate (PC) | 1.20 | 225–230 | Exceptional impact strength, high optical transparency, excellent thermal resistance. | Safety applications, electronics, optical media |

| Polyvinyl Chloride (PVC) | 1.30–1.45 | 160–200 (Processing Temperature) | High durability, flame retardancy, chemical resistance. | Construction, signage, protective applications |

Manufacturers ensure that the extruded sheets meet the required mechanical stability, thermal tolerance, and application-specific criteria by selecting the appropriate material and optimizing process conditions[6]. Additives like plasticizers, stabilizers, and fillers can also be tailored to refine material properties further[6].

Steps in the Sheet Extrusion Manufacturing Process

1. Feeding: Thermoplastic pellets/granules are loaded into a hopper, which supplies the extrusion machine[6]. Factors like particle size, moisture content, melt flow index, etc., are very important at this stage so that uniform feeding and processing is achieved[6].

2. Melting and Mixing: The thermoplastic material is conveyed through a heated barrel using a screw[6]. The material is melted using friction and external heaters[6]. The screw also provides sufficient mixing to achieve a uniform melt[6].

3. Sheet Extrusion: The molten polymer is pushed through a flat sheet die which sets the width and thickness of the sheet[6]. The Die temperature and the gap controls are very important for achieving uniformity and accuracy in dimensions[6].

4. Cooling and Solidification: The extruded sheet is passed over cooled rollers, which quickly cool the sheet for solidification[6]. The roller temperature has to be adequately controlled to avoid thermal stresses and warping[6].

5. Trimming and Cutting: The sheet is first trimmed at the edges and then cut to the desired length[6]. Due to the high precision and low speed requirements, automated systems are usually used for cutting and trimming[6].

6. Winding or Stacking: Depending on the application, the final sheets are finished either by rolling them into stacks for shipment or stacking them as flat sheets[6]. Careful treatment at this stage reduces superficial defects and guarantees material quality[6].

This particular process relies on accurate temperature, speed, and pressure control at every stage to produce high-quality sheets appropriate for industrial use[6].

Cooling and Cutting the Extruded Sheet

The cooling procedure during the extrusion process is critical to achieving a smooth and defectless sheet[6]. The extruded sheet cools off quickly thanks to a set of rollers set in the temperature range of 50-75F (10-24C), which varies depending on the type of plastic[6]. With proper alignment of the rollers and constant cooling, thermal warping, stress, or uneven thickness is easily avoidable[6].

Once the sheet is sufficiently cooled, it is directed towards the cutting or slitting section[6]. Edges are shaved and the sheet is cut to size with automated equipment such as guillotine cutters or rotary knives[6]. The target roll length or roll width is preset[6]. The cutting tolerances are precision high; they lie within ±0.010 inches[6]. This step is critical in preparing the sheets for further steps in the processes of meeting the required dimensional accuracy for their intended applications[6].

The critical parameters in this phase are the reel temperature, cutting angle, blade sharpness, and line speed which usually is set between 50-150 ft/min depending on the the thickness of the sheet[6]. All these ones that have to do with the physical attributes of the equipment need to be set depending on the product's attributes to maintain product quality and minimize waste[6]. Making these adjustments guarantees the extruded sheet is suitable for packaging or other processes[6].

Ensuring Precision and Consistency

Controlling variables like line speed, roller pressure, and temperature avoids errors during the extrusion process[6]. Attempts to reduce deviations include implementing real-time monitoring systems and automated escalations, which assist in maintaining strict tolerances for cutting at ±0.010 inches[6]. Advanced quality control programs such as non-contact measurement systems are also utilized to check the predetermined specifications of each sheet[6]. This method increases product reliability whilst reducing waste at the same time[6].

Benefits of Using Plastic Sheet Extrusion Equipment

The use of plastic sheet extrusion equipment offers several advantages that enhance efficiency, quality, and sustainability[10]. These benefits include:

1. High-Speed Production Plastic extrusion is continuous and can establish a high-volume output[3]. Extrusion machines can operate 24 hours a day, reducing the chances of inventory shortage[1]. Automatic machines can produce plastic sheets at high speeds, significantly increasing productivity compared to manual or semi-automatic processes[10].

2. Cost-Effectiveness Plastic extrusion has a low cost relative to other molding processes, due to its efficiency[2]. The thermoplastics used during the process undergo repeated melting and hardening, allowing any waste from the process to be reused[2]. The costs for materials and disposal for an extrusion operation are lower than with any other molding process[8].

3. Design Flexibility Plastic extrusion can be used to create a range of shapes in a variety of thicknesses, textures, colors, and sizes in a short amount of time[2]. The extrusion die can produce complex shapes as long as the cross-section remains the same[1]. A wide range of die profiles with different lengths and other characteristics can be used[8].

4. Material Versatility Plastic extrusion can be used with many different types of plastics including polypropylene, polyethylene, PVC, and acrylic[1]. Automatic plastic sheet extrusion machines can handle a wide range of plastic materials, including PET, PP, PVC, and more[10].

5. Post-Extrusion Alterations When the plastic leaves the extruder, it's still hot, which allows for post-extrusion manipulation[2]. Manufacturers can use a variety of rollers, dies, and extrusion shoes to ensure their extruded product fits their exact requirements[2]. The product is automatically ready for thermoforming, without needing to waste time curing the extruded roll stock[8].

6. Consistent Quality The automated process ensures that every sheet produced meets the desired specifications, reducing defects and waste[10]. Real-time data collection helps optimize production parameters for better quality and efficiency[10].

7. Reduced Labor Costs By automating the production process, the need for manual labor is minimized, leading to cost savings[10]. Automated raw material handling reduces manual labor and ensures a smooth production flow[10].

8. Energy Efficiency Modern machines are designed to consume less energy, reducing operational costs and environmental impact[10]. Innovations such as servo-driven extruders and high-efficiency heaters reduce energy consumption while enhancing product consistency and quality[10].

9. Reduced Waste The ability to recycle excess plastic material minimizes waste and supports sustainable manufacturing practices[10].

10. Longer Product Lifespan Extruded plastic sheets are durable and long-lasting, reducing the need for frequent replacements[10].

Applications of Plastic Sheet Extrusion

Automatic plastic sheet extrusion machines are widely used in various industries[10]:

- Packaging Industry For producing plastic films and sheets used in food packaging and other applications[10].

- Construction Industry Produces sheets used in roofing and insulation materials[10].

- Automotive Industry Creates components like dashboard trim and interior panels[10].

Innovations in Plastic Sheet Extrusion Technology

Recent advancements in plastic extrusion technology have significantly improved the efficiency and precision of the process[10]. Innovations such as servo-driven extruders and high-efficiency heaters reduce energy consumption while enhancing product consistency and quality[10]. Additionally, co-extrusion techniques allow for the simultaneous extrusion of multiple layers, enabling the creation of complex structures with enhanced functionalities[10].

Artificial Intelligence (AI) plays a crucial role in optimizing extrusion processes by analyzing data and making real-time adjustments to parameters like temperature and pressure[10]. This ensures optimal performance and reduces material waste[10].

Modern cooling systems are designed to expedite the solidification process, improving the dimensional stability of extruded products while reducing energy consumption[10]. These systems are integral to maintaining high-quality outputs and enhancing production efficiency[10].

Challenges and Solutions in Plastic Sheet Extrusion

Despite the benefits, plastic sheet extrusion faces challenges such as die swell, temperature control, and equipment maintenance[10]. To address these issues, manufacturers invest in advanced machinery with precise temperature control systems and predictive maintenance technologies to minimize downtime and ensure consistent product quality[10].

Future Trends in Automatic Plastic Sheet Extrusion

The future of plastic sheet extrusion is poised to be shaped by technological innovations and sustainability initiatives[10]. As demand for high-quality plastic products continues to grow, manufacturers are focusing on integrating more automation and sustainable practices into their production processes[10]. This includes the use of renewable energy sources and recycled materials to reduce environmental impact[10].

Conclusion

Automatic plastic sheet extrusion machines offer a multitude of benefits that make them indispensable in modern plastic manufacturing[10]. Their ability to enhance efficiency, reduce costs, and promote sustainability aligns with the evolving needs of industries seeking high-quality plastic products[10]. The process, key components, and variety of plastic materials used in sheet extrusion provide manufacturers with the flexibility to create products tailored to specific application needs. Through continuous innovation and a focus on sustainability, plastic sheet extrusion equipment will continue to play a vital role in various industries.

FAQ

Q1: What is plastic sheet extrusion?

Plastic sheet extrusion is the process where plastic is melted and formed into a continuous sheet product[6]. It involves pushing plastic granules through an extrusion die using a screw inside the extruder[6].

Q2: What materials are commonly used in plastic sheet extrusion?

Manufacturers can choose from a wide variety of materials including polyethylene (PE), polypropylene (PP), and other thermoplastics[6]. Each material offers specific properties suitable for different applications[6].

Q3: How do extrusion machines work?

Extrusion machines use a rotating screw inside the extruder to melt and push the plastic through an extrusion die[6]. This forms a continuous sheet of plastic, which is then cooled and cut to the desired thickness[6].

Q4: What role does the extrusion die play in the process?

The extrusion die is crucial for shaping the melted plastic into the desired form[6]. It ensures the sheet products have the correct thickness and width, impacting the final product quality[6].

Q5: What are the advantages of using plastic sheet extrusion?

Plastic sheet extrusion allows for the production of a wide range of sheet products with specific properties[6]. It's one of the most efficient methods for creating large volumes of plastic sheets with consistent quality[6].

Citations:

[1] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[2] https://www.rayda.co.uk/blog/advantages-and-disadvantages-of-plastic-extrusion/

[3] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[4] https://www.youtube.com/watch?v=lh4edjYWzqg

[5] https://www.youtube.com/watch?v=rn7oTBbMMEw

[6] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-sheet-extrusion/

[7] https://www.plasticonline.com.au/versatile-world-of-plastic-extrusion/

[8] https://www.boyuextruder.com/Blog/5-advantages-plastic-extrusion.html

[9] https://www.pexco.com/custom-plastic-extrusion-basics-benefits-and-future-explained/

[10] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-an-automatic-plastic-sheet-extrusion-machine.html

[11] https://insights.made-in-china.com/5-Advantages-of-Plastic-Sheet-Making-Machines-Meeting-Modern-Manufacturing-Needs_ctUaXkKzsQlg.html

[12] https://www.euroextrusions.com/plastic-extrusion-advantages-benefits/

[13] https://www.cnchaoxu.com/news-center/plastic-sheet-extrusion-machine-a-key-equipment-in-the-plastics-industry

[14] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[15] https://www.pros-thermoforming.com/Benefits-of-Using-Plastic-Sheet-Extrusion-Machines-in-Manufacturing-id48569036.html

[16] https://www.fangliextru.com/news-show-1069376.html

[17] https://www.youtube.com/watch?v=JM1WVhOnEjU

[18] https://www.shutterstock.com/video/search/plastic-extrusion-machine

[19] https://www.youtube.com/watch?v=9aiTTC94g3s

[20] https://www.shutterstock.com/search/plastic-extruder

[21] https://www.youtube.com/watch?v=fsNayzzP4Kc

[22] https://www.shutterstock.com/search/plastic-extrusion-machine

[23] https://www.youtube.com/watch?v=3BFV-2jZliw

[24] https://stock.adobe.com/search?k=plastic+extrusion+machine

[25] https://www.youtube.com/playlist?list=PL8B1r8zT-52EYf149q_TDvFNg0-lzLsYA

[26] https://stock.adobe.com/search?k=plastic+extrusion

[27] https://www.youtube.com/playlist?list=PLgd4RJOZ1V4s0wshosfudCHjUUIDaJUxU

[28] https://www.dreamstime.com/photos-images/plastic-extrusion-machine.html

[29] https://www.plastar-machine.com/en/news/faq.html

[30] https://www.trustymachine.com/faq.html