Content Menu

● Understanding Non-Drying Extrusion Granulation

● Key Components of Non-Drying Extrusion Granulation Equipment

● Benefits of Non-Drying Extrusion Granulation Production Equipment

>> 1. Energy Efficiency

>> 2. Cost Savings

>> 3. Environmental Benefits

>> 4. High Granulation Rate

>> 5. Versatility in Applications

>> 6. Compact Design

● Operational Mechanism of Non-Drying Extrusion Granulation

● Applications Across Industries

● Recent Innovations in Non-Drying Extrusion Granulation Technology

● Challenges Faced by Non-Drying Extrusion Granulation Production Lines

● Conclusion

● FAQ

>> 1. What is non-drying extrusion granulation?

>> 2. How does non-drying extrusion improve efficiency?

>> 3. Can this technology handle organic materials?

>> 4. What are the main components of this production line?

>> 5. How does this method contribute to environmental sustainability?

● Citations:

Non-drying extrusion granulation production equipment is revolutionizing the manufacturing landscape across various industries, particularly in agriculture and pharmaceuticals. This innovative technology offers numerous advantages, making it a preferred choice for manufacturers aiming to enhance efficiency, reduce costs, and minimize environmental impact. In this article, we will explore the key benefits of non-drying extrusion granulation production equipment, its operational mechanisms, and its applications in different sectors.

Understanding Non-Drying Extrusion Granulation

Non-drying extrusion granulation is a process that combines the principles of extrusion and granulation without the need for drying. This method utilizes mechanical force to compact raw materials into granules, eliminating the additional drying phase typically required in traditional granulation processes. This technology has gained popularity due to its energy efficiency, cost-effectiveness, and environmental benefits.

Key Components of Non-Drying Extrusion Granulation Equipment

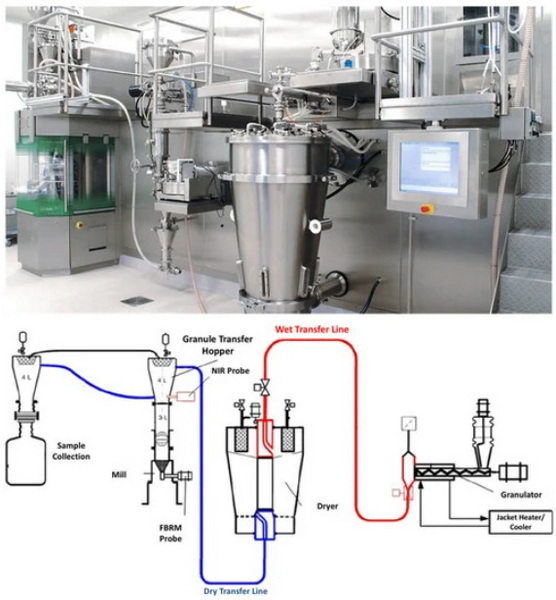

The non-drying extrusion granulation production line consists of several essential components that work together to produce high-quality granules:

- Raw Material Mixer: This machine combines various raw materials to create a homogeneous mixture suitable for granulation.

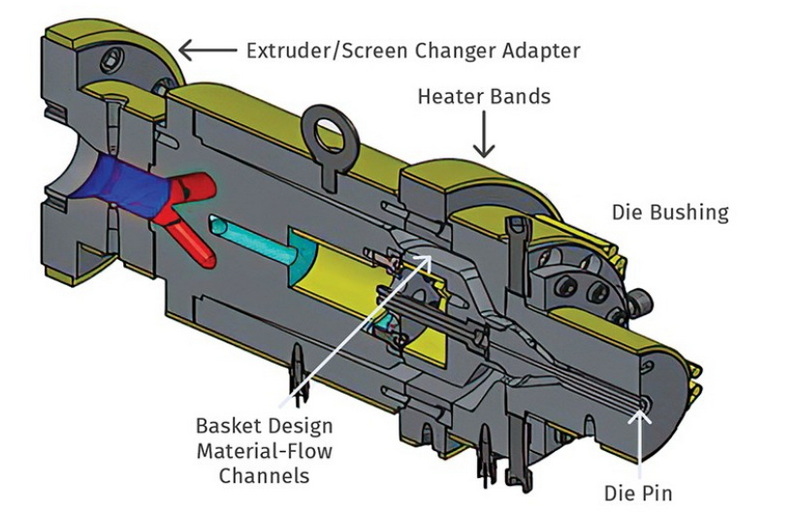

- Double Roller Extruder: The heart of the system, where the mixed raw materials are compressed into granules using high-pressure rollers.

- Screening Equipment: This separates qualified granules from oversized or undersized particles, ensuring uniformity in the final product.

- Packaging Machine: The final step involves packaging the finished granules for distribution and sale.

Benefits of Non-Drying Extrusion Granulation Production Equipment

The adoption of non-drying extrusion granulation production equipment offers several compelling benefits:

1. Energy Efficiency

One of the most significant advantages of non-drying extrusion granulation is its energy efficiency. By eliminating the drying process, manufacturers can significantly reduce energy consumption. Traditional methods often require substantial energy input for drying and cooling, while non-drying extrusion operates at normal temperatures, conserving energy and lowering operational costs.

2. Cost Savings

The absence of drying equipment translates into lower initial investment costs as well as ongoing operational expenses related to energy consumption and maintenance. Manufacturers can allocate these savings to other critical areas of their operations, enhancing overall profitability.

3. Environmental Benefits

Non-drying extrusion granulation contributes to more sustainable manufacturing practices. The process generates minimal emissions and waste compared to traditional methods that require heating systems for drying. Additionally, by reducing greenhouse gas emissions associated with fertilizer production, this technology aligns with global efforts toward environmental conservation.

4. High Granulation Rate

The extrusion process boasts a high granulation rate (up to 95%), ensuring that a significant percentage of the raw materials are converted into usable fertilizer granules. This high efficiency maximizes resource utilization and minimizes waste.

5. Versatility in Applications

Non-drying extrusion granulation is versatile and can accommodate a variety of raw materials, including organic and inorganic fertilizers. It is suitable for producing high, medium, and low concentration compound fertilizers tailored to specific crop needs.

6. Compact Design

The layout of a non-drying extrusion production line is typically more compact than traditional setups. This not only saves space but also simplifies installation and operation.

Operational Mechanism of Non-Drying Extrusion Granulation

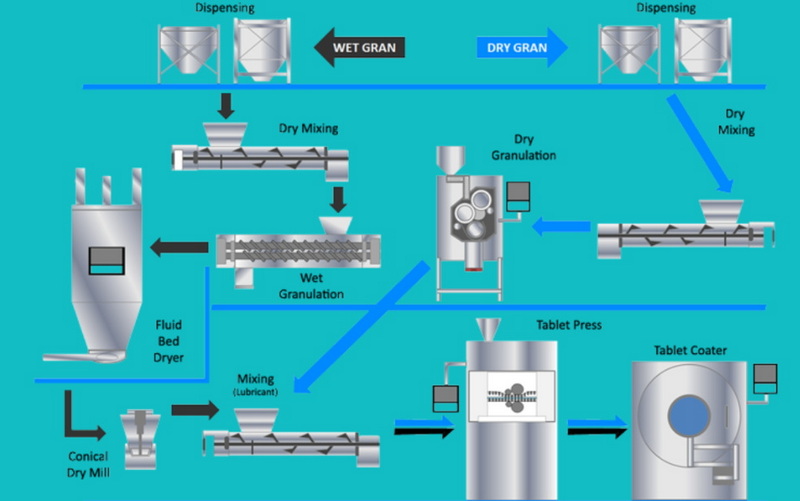

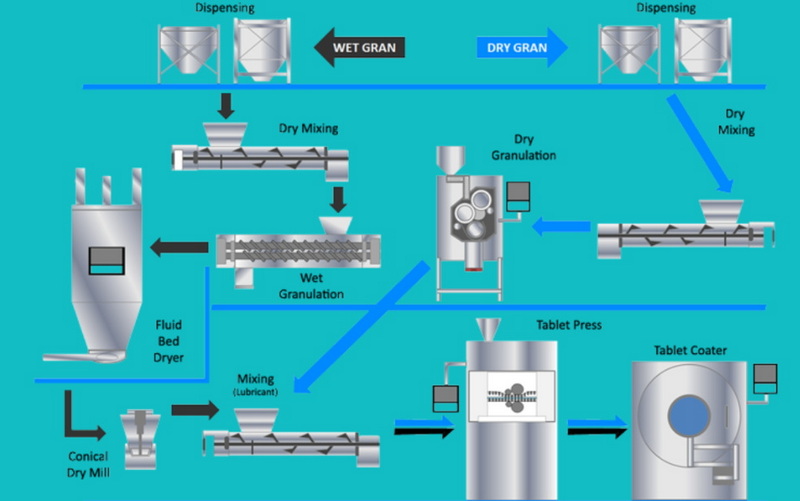

The operation of a non-drying extrusion granulation production line involves several key steps:

1. Raw Material Preparation: Raw materials such as urea, ammonium sulfate, potassium chloride, and other nutrients are precisely measured and mixed using an automated batching system to ensure accurate formulation.

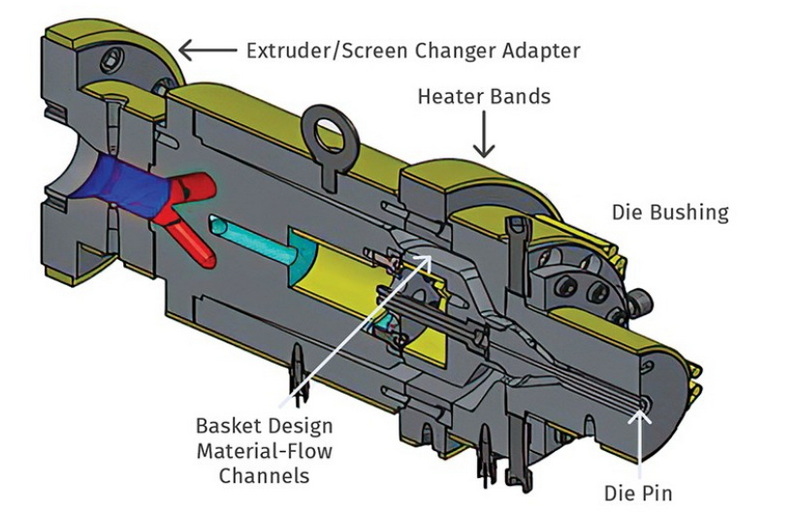

2. Granulation Process: The mixed materials are fed into the double roller extruder where they are subjected to high pressure. This pressure compacts the materials into dense sheets.

3. Particle Formation: The compressed sheets are then broken down into granules through a crushing mechanism that ensures uniform particle size.

4. Screening: Oversized particles are separated out and returned to the mixer for reprocessing, ensuring that only granules within the desired size range proceed to packaging.

5. Packaging: Finally, the qualified granules are automatically packaged for distribution.

Applications Across Industries

Non-drying extrusion granulation technology finds applications across various industries:

- Agriculture: In fertilizer production, this method allows for precise control over nutrient release characteristics by adjusting the formulation during production.

- Pharmaceuticals: The technology is utilized to produce solid dosage forms such as tablets and capsules without moisture exposure, ensuring stability for sensitive active pharmaceutical ingredients (APIs).

- Food Processing: Non-drying extrusion can also be employed in creating uniform granular products such as flavorings and nutritional supplements.

Recent Innovations in Non-Drying Extrusion Granulation Technology

As industries evolve, so does technology in non-drying extrusion granulation. Recent innovations include:

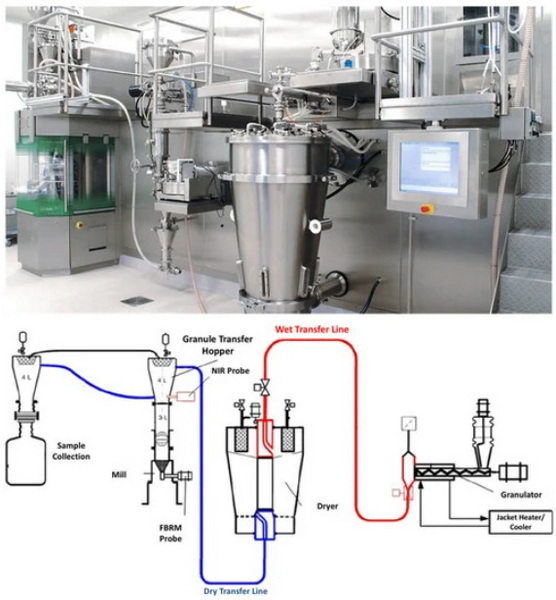

- Enhanced Process Control: Implementation of Process Analytical Technology (PAT) systems allows real-time monitoring during production to maintain optimal conditions.

- Increased Automation: Automation technologies have improved efficiency by minimizing manual intervention and reducing labor costs across manufacturing processes.

- Sustainable Practices: Innovations focusing on waste reduction during production processes are becoming increasingly prevalent as industries strive towards sustainability.

- Modular Equipment Designs: These designs provide flexibility in scaling operations up or down based on demand without significant capital investment.

Challenges Faced by Non-Drying Extrusion Granulation Production Lines

While there are numerous advantages to using non-drying extrusion granulation production lines, some challenges must be addressed:

- Material Variability: Different raw materials may behave unpredictably during processing due to variations in particle size or moisture content. Manufacturers must carefully select raw materials to ensure consistent quality.

- Equipment Maintenance: Regular maintenance is essential to prevent downtime caused by equipment malfunctions or wear over time. Investing in high-quality machinery can mitigate some of these issues but requires initial capital investment.

- Dust Generation: The mechanical nature of the process can lead to dust formation, which may pose contamination risks if not managed properly. Implementing efficient dust collection systems can help address this challenge.

Conclusion

In conclusion, non-drying extrusion granulation production equipment represents a significant advancement in manufacturing technology across multiple industries. Its energy efficiency, cost savings, environmental benefits, high granulation rates, versatility in applications, and compact design make it an attractive option for manufacturers looking to optimize their processes while contributing positively to sustainability efforts. As industries continue to seek innovative solutions for efficient production practices, non-drying extrusion granulation is poised to play a pivotal role in shaping the future of manufacturing.

FAQ

1. What is non-drying extrusion granulation?

Non-drying extrusion granulation is a manufacturing process that combines extrusion and granulation without requiring a drying phase, making it energy-efficient and environmentally friendly.

2. How does non-drying extrusion improve efficiency?

By eliminating the drying phase, manufacturers significantly reduce energy consumption and processing time while achieving higher throughput compared to traditional methods.

3. Can this technology handle organic materials?

Yes, non-drying extrusion granulation is versatile enough to accommodate both organic and inorganic raw materials for producing various types of fertilizers.

4. What are the main components of this production line?

Key components include a raw material mixer, double roller extruder, screening equipment, and packaging machine.

5. How does this method contribute to environmental sustainability?

This process generates minimal emissions and waste compared to traditional methods that require heating systems for drying, thereby reducing greenhouse gas emissions associated with manufacturing.

Citations:

[1] https://www.yjing-extrusion.com/why-choose-a-no-drying-extrusion-fertilizer-production-line-for-your-farm.html

[2] https://www.yjing-extrusion.com/news/No-Drying-Granulation.html

[3] https://www.yjing-extrusion.com/what-industries-use-no-drying-extrusion-granulation-production-lines.html

[4] https://www.yjing-extrusion.com/what-factors-affect-the-price-of-a-no-drying-extrusion-granulation-production-line.html

[5] https://pmc.ncbi.nlm.nih.gov/articles/PMC8148162/

[6] https://www.abbviecontractmfg.com/news-and-insights/how-can-extrusion-benefit-your-pharmaceutical-oral-drug-product.html

[7] https://www.matconibc.com/blog/how-to-increase-production-output-of-your-granulation-process-equipment-and-improve-your-profitability

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC4401168/

[9] https://www.pharmtech.com/view/comparing-different-granulation-techniques

[10] https://www.wastetofertilizer.com/dry-granulation-machine/

[11] https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/LR79-dry-granulation-twin-screw-process-pharmaceutical-applications.pdf

[12] https://asmedigitalcollection.asme.org/astm-ebooks/book/2013/chapter-abstract/27872569/Granulation-Without-a-Drying-Step-Using-Dielectric?redirectedFrom=fulltext

[13] https://upperton.com/25th-february-2020-granulation-overview/