Leave a Message

- Home

- About Us

-

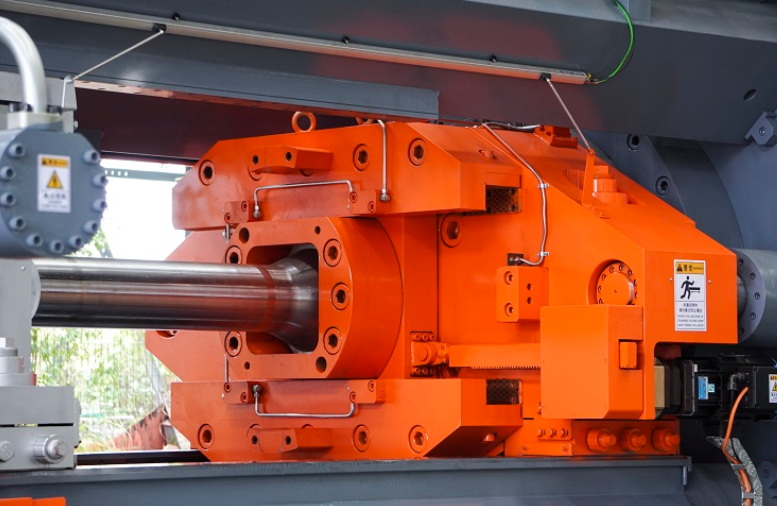

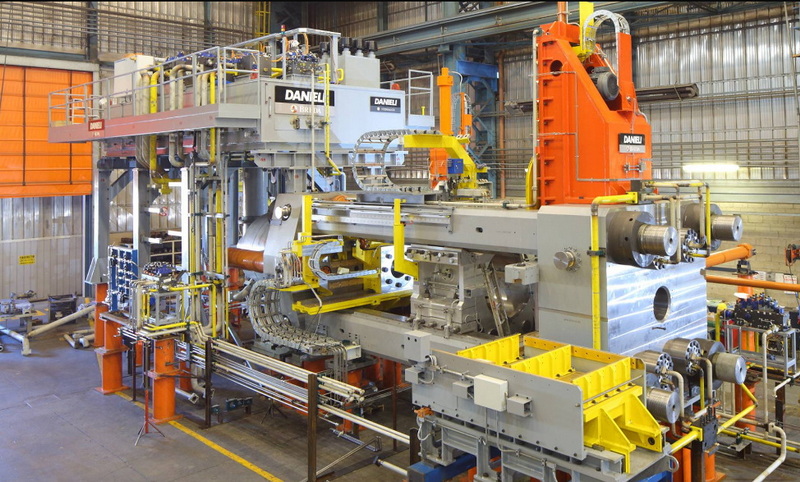

- Aluminum Extrusion Press Manufacturer

- Aluminum Extrusion Press Supplier

- Aluminum Extruder Manufacturer

- Aluminum Extruder Supplier

- Extrusion Press Machine Manufacturer

- Extrusion Press Machine Supplier

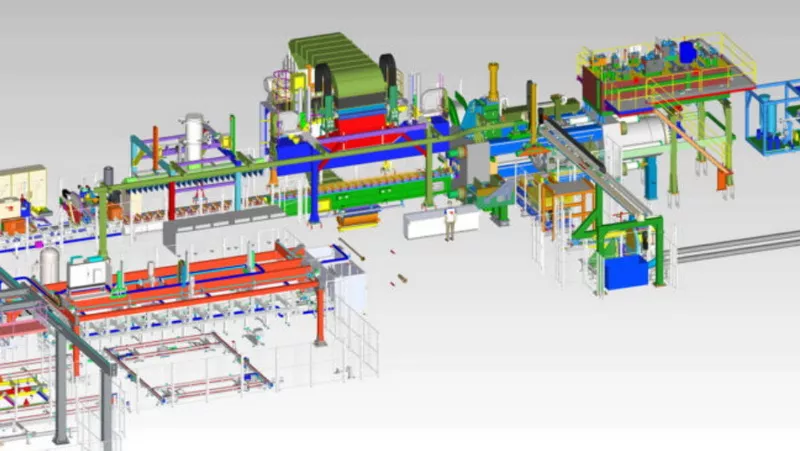

- Aluminum Extrusion Line Manufacturer

- Aluminum Extrusion Line Supplier

- Automatic Extrusion Line Manufacturer

- Automatic Extrusion Line Supplier

-

-

-

- Products

- Equipment

- Strength

- Video

- Service

- News

- Contact Us

close

Choose Your Site

Global

Social Media

- Home

- About Us

-

- Aluminum Extrusion Press Manufacturer

- Aluminum Extrusion Press Supplier

- Aluminum Extruder Manufacturer

- Aluminum Extruder Supplier

- Extrusion Press Machine Manufacturer

- Extrusion Press Machine Supplier

- Aluminum Extrusion Line Manufacturer

- Aluminum Extrusion Line Supplier

- Automatic Extrusion Line Manufacturer

- Automatic Extrusion Line Supplier

-

-

-

- Products

- Equipment

- Strength

- Video

- Service

- News

- Contact Us