Content Menu

● Understanding Aluminum Extrusion

● Key Players in Custom Aluminum Extrusion Press Manufacturing

>> Hydro Extrusion

>> PSI Industries

>> Wellste Aluminum

>> Minalex Corporation

>> Macrodyne

● Factors to Consider When Choosing an Aluminum Extrusion Manufacturer

● The Custom Aluminum Extrusion Process

● Applications of Custom Aluminum Extrusions

● Innovations in Aluminum Extrusion Technology

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. What are the advantages of using custom aluminum extrusions?

>> 3. How do I choose the right aluminum extrusion manufacturer?

>> 4. What industries benefit from aluminum extrusions?

>> 5. Can I get prototypes made before full-scale production?

● Citations:

Aluminum extrusion is a vital process in manufacturing various products across multiple industries, including automotive, construction, and aerospace. The ability to create custom profiles and shapes makes aluminum extrusion an attractive option for manufacturers looking to meet specific design requirements. This article explores the leading aluminum extrusion press manufacturers that provide custom solutions, their capabilities, and factors to consider when choosing a manufacturer.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create specific shapes. The process can produce a wide range of profiles, from simple to complex designs. There are two primary methods of aluminum extrusion:

- Direct Extrusion: The aluminum billet is pushed through a stationary die, creating the desired shape as it exits.

- Indirect Extrusion: The die moves towards the billet, allowing for better control of material flow and reduced friction.

Both methods have their advantages and applications, depending on the required profile and production volume.

Key Players in Custom Aluminum Extrusion Press Manufacturing

Several manufacturers stand out in the aluminum extrusion industry for their ability to provide custom solutions. Below is an overview of some leading companies:

Hydro Extrusion

Hydro Extrusion is one of the largest aluminum profile companies globally, known for its extensive capabilities in custom aluminum extrusions.

- Capabilities: Hydro offers a broad range of extrusion options, including direct and indirect presses, with extensive engineering support for design and application assistance.

- Quality Control: They maintain tight quality control throughout the extrusion process, ensuring consistent results.

- Sustainability: Hydro emphasizes sustainability by using recycled materials and minimizing waste during production.

PSI Industries

PSI Industries specializes in providing high-quality custom aluminum extrusions with fast lead times.

- ISO Certification: Their facilities are ISO 9001:2015 certified, ensuring adherence to quality standards.

- Custom Solutions: They offer a variety of services, including prototyping and high-volume production runs tailored to client specifications.

Wellste Aluminum

Wellste is recognized for its comprehensive range of custom aluminum extrusions.

- Diverse Applications: They cater to various industries with products suitable for windows, doors, and industrial applications.

- Advanced Manufacturing: Wellste employs modern techniques such as pre-heating and quenching to ensure high-quality extrusions.

Minalex Corporation

Minalex focuses on precision manufacturing of small profile aluminum extrusions.

- High Tolerance: They excel at producing custom shapes with tight tolerances, making them suitable for specialized applications in aerospace and military sectors.

- Value-Added Services: Minalex provides additional services such as CNC machining and finishing to enhance product quality.

Macrodyne

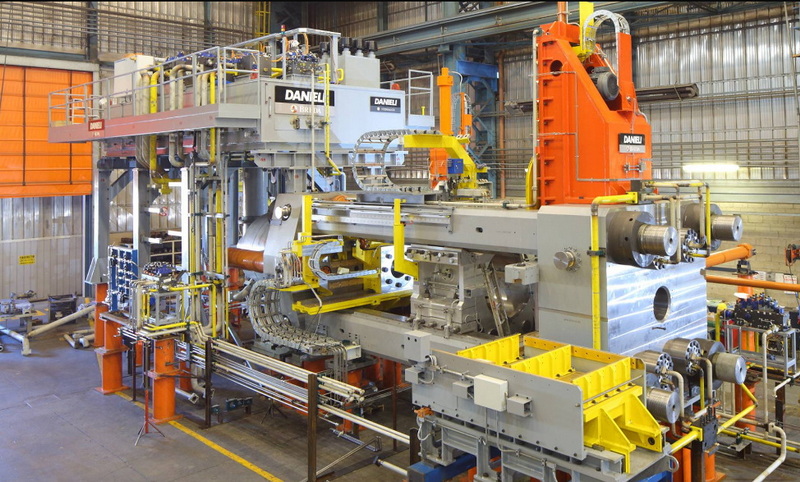

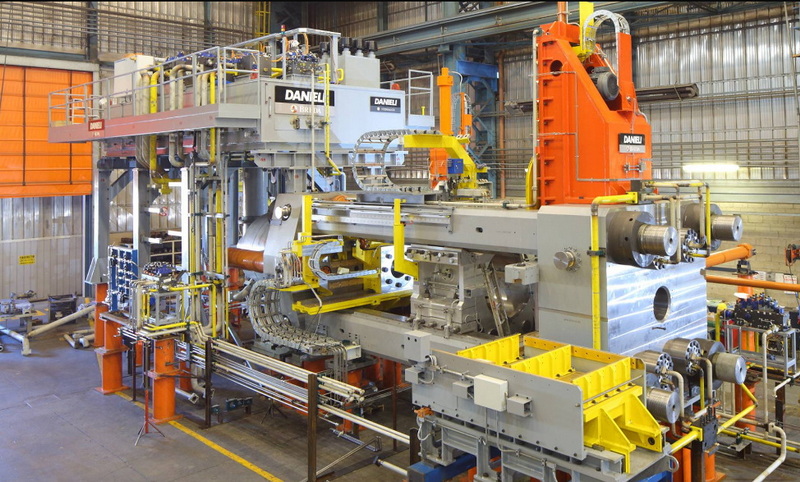

Macrodyne manufactures hydraulic extrusion presses designed for both hot and cold applications.

- Custom Design: They offer tailored solutions based on client needs, ensuring optimal performance for various profiles.

- Turnkey Solutions: Macrodyne provides complete systems that include all necessary components for efficient operation.

Factors to Consider When Choosing an Aluminum Extrusion Manufacturer

When selecting an aluminum extrusion press manufacturer for custom solutions, consider the following factors:

- Experience and Reputation: Look for manufacturers with a proven track record in the industry. Established companies often have better resources and expertise.

- Customization Capabilities: Ensure the manufacturer can meet your specific design requirements. This includes flexibility in production volumes and the ability to create complex profiles.

- Quality Assurance: Check if the manufacturer adheres to industry standards and has robust quality control processes in place.

- Lead Times: Evaluate the manufacturer's ability to deliver products within your required timeframe. Quick turnaround times can be crucial in competitive markets.

- Sustainability Practices: Consider manufacturers that prioritize environmentally friendly practices, such as using recycled materials or reducing waste during production.

The Custom Aluminum Extrusion Process

The process of creating custom aluminum extrusions begins with understanding client requirements. Here's a detailed overview of how this process unfolds:

1. Design Phase: Every custom aluminum extrusion project starts with a concept. Engineers collaborate with designers to draft blueprints of the desired cross-section. The versatility of aluminum means nearly any shape can be produced—from hollow profiles to solid structures.

2. Die Manufacturing: Once the design is finalized, a custom die is created. This die acts as a mold that determines the shape of the aluminum profile. Precision during this stage is crucial since it directly impacts the quality of the final product.

3. Billet Heating: An aluminum billet (a cylindrical piece of aluminum) is loaded into a furnace and heated to around 900°F (approximately 482°C). Heating makes the aluminum malleable and ready for extrusion.

4. Extrusion Tooling Process: The heated billet is pushed through the die using a hydraulic press. The pressure forces the aluminum to take on the shape of the die's opening. As it passes through, it forms the desired profile.

5. Cooling and Cutting: After extrusion, the profiles are cooled and stretched to ensure they retain their shape and strength. The profiles are then cut to length based on specifications provided by clients.

6. Finishing Touches: Depending on client specifications, further finishing processes may be applied. This can include surface treatments like anodizing or powder coating to enhance durability or aesthetic appeal, followed by assembly and packaging as needed[14][23].

Applications of Custom Aluminum Extrusions

Custom aluminum extrusions find applications across various industries due to their lightweight nature, strength-to-weight ratio, corrosion resistance, and versatility in design:

- Automotive Industry: Used extensively in vehicle frames, body panels, heat exchangers, and structural components due to their lightweight properties that contribute to fuel efficiency.

- Construction Sector: Commonly utilized in window frames, curtain walls, roofing systems, and structural supports because they provide durability while being aesthetically pleasing.

- Aerospace Applications: Essential for manufacturing components that require high strength-to-weight ratios while adhering to strict safety standards.

- Consumer Goods: Found in products ranging from electronics enclosures to furniture frames where both functionality and design are critical.

- Renewable Energy Systems: Used in solar panel frames and wind turbine components due to their lightweight nature combined with excellent strength characteristics[6][10][12].

Innovations in Aluminum Extrusion Technology

The aluminum extrusion industry continuously evolves through technological advancements aimed at improving efficiency and product quality:

- High-Speed Billet Production: Companies are focusing on producing high-performance billets that enhance productivity during extrusion operations.

- Sustainable Practices: Many manufacturers are adopting closed-loop recycling systems that minimize waste by reusing scrap material generated during production.

- Advanced Finishing Techniques: Innovations in surface treatment technologies allow for improved durability while providing aesthetic options like various colors or textures[3][7][17].

Conclusion

In conclusion, numerous aluminum extrusion press manufacturers offer custom solutions tailored to various industries' needs. Companies like Hydro Extrusion, PSI Industries, Wellste Aluminum, Minalex Corporation, and Macrodyne stand out for their capabilities in producing high-quality extrusions while maintaining strict quality control measures. When choosing a manufacturer, consider their experience, customization capabilities, quality assurance processes, lead times, and sustainability practices to ensure you partner with a company that meets your specific requirements effectively.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where heated aluminum is forced through a die to create specific shapes or profiles used in various applications.

2. What are the advantages of using custom aluminum extrusions?

Custom aluminum extrusions allow manufacturers to create unique shapes tailored to specific design requirements while benefiting from aluminum's lightweight and durable properties.

3. How do I choose the right aluminum extrusion manufacturer?

Consider factors such as experience, customization capabilities, quality assurance processes, lead times, and sustainability practices when selecting an aluminum extrusion manufacturer.

4. What industries benefit from aluminum extrusions?

Industries such as automotive, construction, aerospace, electronics, and renewable energy utilize aluminum extrusions for various applications due to their versatility and strength.

5. Can I get prototypes made before full-scale production?

Yes! Many manufacturers offer prototyping services that allow you to test designs before committing to full-scale production runs.

Citations:

[1] https://www.sms-group.com/plants/light-metal-extrusion-presses

[2] https://us.metoree.com/categories/100086/

[3] https://www.precedenceresearch.com/aluminum-extrusion-market

[4] https://mmgmfg.com/capabilities/aluminum-extrusion/

[5] https://www.wellste.com/custom-aluminum-extrusions/

[6] https://jmaluminium.com/extrusion/

[7] https://www.imarcgroup.com/aluminium-extrusion-market-statistics

[8] https://mmgextrusions.com/capabilities/custom-aluminum-extrusions/

[9] https://www.apt-alu-products.com/en/technologies/extrusion/

[10] https://www.alcircle.com/news/update-top-five-aluminium-extrusion-companies-in-the-world-33870

[11] https://www.3erp.com/services/aluminum-extrusion/

[12] https://starext.com/aluminum-extrusions

[13] https://www.researchandmarkets.com/reports/5685580/aluminum-extrusion-market-forecast-2025-2032

[14] https://nationalindustries.world/2024/09/10/from-concept-to-creation-the-power-of-custom-aluminum-extrusion/

[15] https://www.rivexa.com/industrial-goods/extrusion/aluminium-extrusion

[16] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-aluminum-extrusion-suppliers-in-the-usa/

[17] https://straitsresearch.com/report/aluminum-extrusion-market

[18] http://scaluminum.com/2017/09/common-everyday-uses-of-custom-aluminum-extrusion-by-consumers/

[19] https://starext.com/news/custom-standard-aluminum-extrusion-profiles

[20] https://ud-machine.com/blog/aluminium-extrusion-manufacturers/

[21] https://www.alcircle.com/news/building-construction-will-pave-the-path-for-aluminium-extrusion-growth-at-a-cagr-of-5-9-till-2025-94921

[22] https://www.hydro.com/en/global/aluminium/products/extruded-profiles/aluminium-extrusions-in-use/extrusions-for-big-sized-applications/

[23] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/manufacturing-custom-aluminum-extrusion-profiles/

[24] https://zjaluminum-cnc.com/top-10-aluminum-extrusion-product-manufacturers-from-china/

[25] https://www.globenewswire.com/news-release/2024/11/21/2985360/0/en/North-America-Aluminum-Extrusion-Market-Size-to-Surpass-USD-18-56-Bn-by-2033.html

[26] https://www.xometry.com/capabilities/metal-extrusion-services/custom-aluminum-extrusions/

[27] https://www.qyresearch.com/customize/3452512

[28] https://www.psiextrusions.com/capabilities/custom-aluminum-extrusions/

[29] https://www.researchandmarkets.com/reports/5685568/aluminium-extrusion-market-forecast-2025-2032

[30] http://scaluminum.com/2014/07/top-extrusions-everyday-uses-for-custom-aluminum-products/