Content Menu

● Introduction to Aluminum Extrusion

● Benefits of Buying an Aluminum Extruder Machine

>> 1. Cost Savings

>> 2. Immediate Availability

>> 3. Proven Performance

>> 4. Lower Depreciation Rates

>> 5. Quality and Durability

● Applications of Aluminum Extrusions

● How to Buy Aluminum Extruder Machine for Sale

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of purchasing a used aluminum extruder machine?

>> 2. How does the cost of a used aluminum extruder machine compare to a new one?

>> 3. What industries commonly use aluminum extrusions?

>> 4. Can aluminum extruder machines be upgraded with modern technology?

>> 5. What inspection methods are used to ensure the quality of aluminum extrusions?

● Citations:

Aluminum extruder machines are crucial in the manufacturing industry, particularly for producing aluminum profiles used in various sectors such as construction, automotive, and aerospace. These machines offer numerous benefits, from cost savings to design flexibility, making them a valuable investment for businesses looking to enhance their production capabilities. In this article, we will explore the advantages of purchasing an aluminum extruder machine and provide insights into how it can boost your manufacturing operations.

Introduction to Aluminum Extrusion

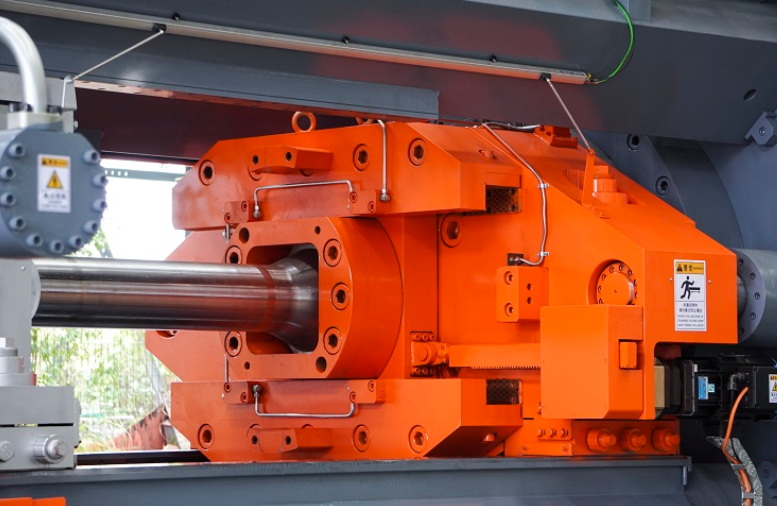

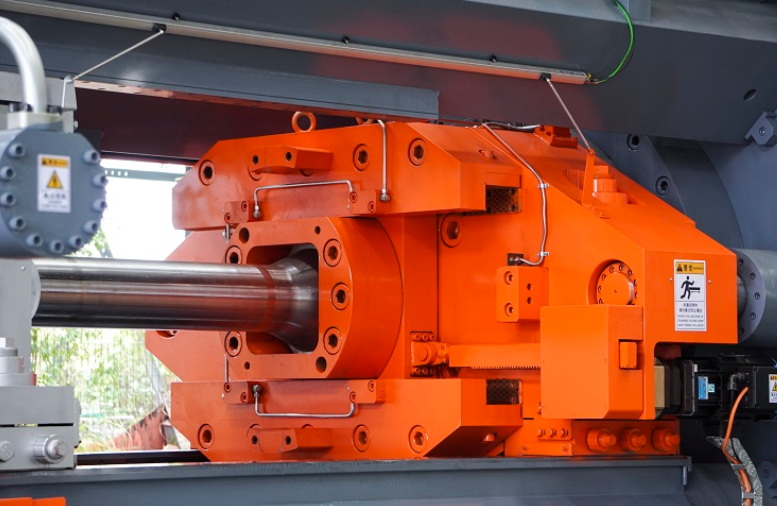

Aluminum extrusion is a process where aluminum is forced through a die to create profiles with specific cross-sectional shapes. This method allows for the creation of complex designs that are difficult to achieve with other manufacturing techniques. The process involves heating aluminum billets to a high temperature, typically around 900°F (482°C), and then pushing them through a die using a hydraulic press[4].

Benefits of Buying an Aluminum Extruder Machine

1. Cost Savings

One of the most significant advantages of purchasing an aluminum extruder machine is the cost savings associated with it. New extrusion presses can be quite expensive, often costing hundreds of thousands or even millions of dollars. By opting for a used machine, businesses can save a substantial amount of money, allowing them to allocate resources to other critical areas such as workforce training or raw materials[1].

2. Immediate Availability

Used aluminum extruder machines are often readily available for purchase, enabling businesses to get their operations up and running quickly. Unlike new machines, which may require long lead times for manufacturing and delivery, used presses can be operational shortly after the purchase is finalized[1].

3. Proven Performance

Many used aluminum extruder machines have a track record of reliable performance. These machines may have been in operation for several years, providing potential buyers with insights into their reliability and efficiency. Additionally, reputable sellers often provide maintenance records that can help assess the machine's condition[1].

4. Lower Depreciation Rates

New machinery typically depreciates rapidly within the first few years of operation. In contrast, used aluminum extruder machines have already undergone this initial depreciation phase, making them a more stable investment in terms of value retention[1].

5. Quality and Durability

Aluminum extruder machines are built to last, often featuring robust construction that withstands heavy use over time. Many used machines are still in excellent working condition and can deliver high-quality extrusions comparable to new models[1].

Applications of Aluminum Extrusions

Aluminum extrusions are widely used in various industries due to their versatility and adaptability:

- Construction: Aluminum extrusions are used in building facades, window frames, curtain walls, and structural components due to their strength and resistance to corrosion[1].

- Automotive: The automotive industry employs aluminum extrusions for lightweight components such as chassis parts and body panels, improving fuel efficiency and performance while maintaining structural integrity[1].

- Aerospace: The aerospace industry relies on aluminum extrusions for structural components where weight reduction is critical for performance without sacrificing strength or durability[1].

How to Buy Aluminum Extruder Machine for Sale

When considering purchasing an aluminum extruder machine, several factors should be taken into account:

1. Cost and Budget: Determine your budget and compare prices from different suppliers. Used machines can offer significant cost savings compared to new ones[1].

Buy Aluminum Extruder Machine for Sale: Look for reputable suppliers offering used machines at competitive prices.

2. Machine Condition: Inspect the machine for signs of wear and tear, rust, mechanical issues, and request maintenance records from the seller[1].

3. Brand and Quality: Opt for machines from reputable brands known for producing high-quality machinery, such as Danieli-Breda, Schloemann, and Loewy[1].

4. Warranty and Support: Check if the seller offers any warranty or post-sales support services[1].

5. Upgrades and Customization: Consider whether the machine can be upgraded with modern technology or components to improve efficiency and performance[1].

Conclusion

Buying an aluminum extruder machine can offer significant advantages for businesses looking to enhance their production capabilities while managing costs effectively. With careful consideration during the purchasing process and ongoing maintenance efforts, companies can benefit from reliable performance and substantial savings over time. The benefits extend beyond just cost; they encompass design flexibility, material efficiency, strength-to-weight ratio benefits, corrosion resistance, and wide applicability across various industries.

Frequently Asked Questions

1. What are the primary benefits of purchasing a used aluminum extruder machine?

Purchasing a used aluminum extruder machine offers several benefits, including cost savings, immediate availability, proven performance, lower depreciation rates, and quality and durability comparable to new machines[1].

2. How does the cost of a used aluminum extruder machine compare to a new one?

Used aluminum extruder machines are generally much cheaper than new ones, with prices ranging from $50,000 to $200,000 compared to $300,000 to $1,000,000 for new machines[1].

3. What industries commonly use aluminum extrusions?

Aluminum extrusions are widely used in industries such as construction, automotive, aerospace, and electronics due to their strength, corrosion resistance, and lightweight properties[1][2].

4. Can aluminum extruder machines be upgraded with modern technology?

Yes, many older models of aluminum extruder machines can be upgraded with modern components or technology to improve efficiency and performance. It is advisable to consult with experts on feasible upgrades based on specific needs[1].

5. What inspection methods are used to ensure the quality of aluminum extrusions?

Quality inspection methods for aluminum extrusions include CMM (Coordinate Measuring Machine), video measuring, hand tools, and various metallurgical tests such as tensile and fracture toughness tests[6].

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-benefits-of-purchasing-a-used-aluminum-extrusion-press.html

[2] https://www.yuhfield.net/en/news/aluminum-extrusion/aluminum-machining-benefits-applications

[3] https://www.alamy.com/stock-photo/extrusion-machine.html

[4] https://www.youtube.com/watch?v=iiGlq7408ME

[5] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion_Machine_Price.html

[6] https://aec.org/faqs

[7] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[8] https://amcaluminum.ph/advantages-of-aluminum-extrusion-products/

[9] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion_Machine.html

[10] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[11] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[12] https://kundel.com/some-interesting-facts-about-using-aluminum-extrusion/

[13] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[14] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[15] https://www.outashi.com/blog/factors-to-consider-when-selecting-aluminum-extrusion-machine-id32.html

[16] https://www.fszhelu.com/extrusion-press-machine-product/

[17] https://www.outashi.com/blog/what-is-cost-aluminum-extrusion-machine-id18.html