Content Menu

● Why Aluminum?

● Key Features of the A10 Aluminum Extruder Tension Arm

● Installation and Adjustment

● Fine-Tuning Extruder Tension

● Troubleshooting

● Alternatives and Upgrades

● Aluminum Extrusion Beyond the Tension Arm

● Extrusion Tension and Material Properties

● Conclusion

● FAQ

>> 1. What printers are compatible with the A10 aluminum extruder tension arm?

>> 2. How do I adjust the tension on the A10 aluminum extruder tension arm?

>> 3. What are the signs of incorrect extruder tension?

>> 4. Can I use the A10 aluminum extruder tension arm with flexible filaments like TPU?

>> 5. Where can I purchase the A10 aluminum extruder tension arm?

● Citations:

The "a10 aluminum extruder tension arm" is a critical component in 3D printers, responsible for maintaining consistent filament feed and, consequently, print quality. Upgrading to an aluminum extruder tension arm, like the MK8 Extruder Aluminum Feeder Kit, is a popular modification for printers such as the Geeetech A10, A20, and A30[2][5]. This article delves into the key features, benefits, and considerations surrounding the "a10 aluminum extruder tension arm".

Why Aluminum?

The original extruders on many 3D printers often come with plastic components, including the tension arm. While functional, plastic parts are prone to wear, cracking, and eventual failure[8][10]. Aluminum offers a significant upgrade in terms of durability and reliability.

- Enhanced Durability: Aluminum tension arms are far more resistant to the stresses and strains of repeated use compared to their plastic counterparts[8]. This is especially important given the constant pressure and movement involved in filament extrusion.

- Consistent Performance: Aluminum maintains its shape and structural integrity better than plastic under similar conditions. This translates to more consistent tension on the filament, leading to more reliable extrusion and fewer print failures.

- Heat Resistance: While not a primary concern for the tension arm itself, aluminum's higher heat resistance can be beneficial in enclosed printer setups or environments where ambient temperatures may rise.

Key Features of the A10 Aluminum Extruder Tension Arm

When considering an "a10 aluminum extruder tension arm", several features contribute to its overall performance:

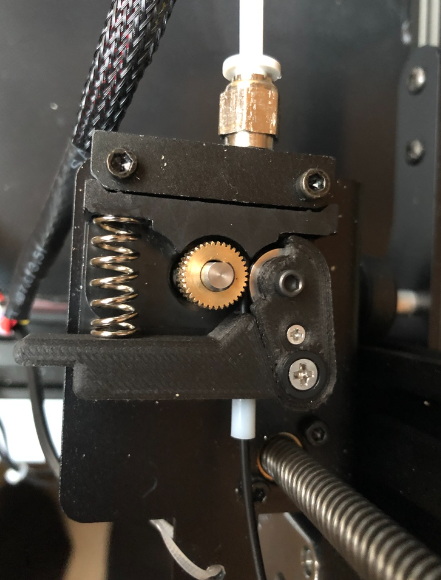

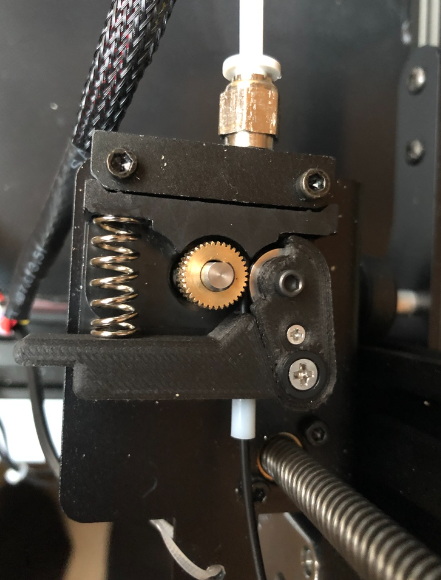

- Tension Adjustment Mechanism: The ability to adjust the tension on the filament is crucial. Too little tension, and the extruder gear may slip, leading to under-extrusion. Too much tension, and the filament can be deformed or crushed, causing jams and inconsistent flow[1][11]. An adjustable tension mechanism, typically involving a screw and spring, allows users to fine-tune the pressure for different filament types[3].

- Idler Wheel and Bearing: The idler wheel presses against the filament, holding it against the extruder gear. A high-quality idler wheel with a smooth, low-friction bearing ensures consistent filament movement. The a10 aluminum extruder tension arm often includes a 694zz U-groove idler wheel and a 694zz bearing for smooth operation[2][5].

- Lever Design: The design of the tension lever arm itself influences the ease of use and effectiveness of the tension adjustment. A well-designed lever should provide sufficient leverage for applying pressure to the filament while also being easy to manipulate for filament loading and unloading[6].

- Mounting and Compatibility: The a10 aluminum extruder tension arm is specifically designed as a replacement for the stock extruder arm on A10, A20, and A30 printers[2][5]. Compatibility ensures a straightforward installation process without requiring extensive modifications.

Installation and Adjustment

Upgrading to an "a10 aluminum extruder tension arm" is generally a simple process[8]:

1. Remove the Old Extruder Arm: Disconnect the printer from power and carefully disassemble the existing extruder assembly, removing the old tension arm, spring, and idler wheel.

2. Install the New Arm: Assemble the new a10 aluminum extruder tension arm, ensuring the idler wheel and bearing are properly seated.

3. Reattach the Spring and Tension Screw: Place the spring between the arm and the extruder body and re-insert the tension screw.

4. Adjust Tension: This is a critical step. Start with a low tension setting and gradually increase it until the filament is gripped firmly by the extruder gear without being crushed[11].

Fine-Tuning Extruder Tension

Achieving the correct extruder tension is crucial for optimal print quality. Here's how to fine-tune it:

- Observe Filament Indentation: The extruder gear should leave a slight indentation on the filament[1]. If there are no visible marks, increase the tension. If the filament is severely deformed or flattened, reduce the tension.

- Listen for Skipping: During printing, listen for the extruder motor skipping or clicking. This indicates that the gear is not gripping the filament properly, and the tension needs to be increased[11].

- Check for Under-Extrusion: Under-extrusion can be a sign of insufficient tension. If you notice gaps or thin layers in your prints, try increasing the tension slightly.

- Consider Filament Type: Different filament types require different tension settings[11]. Softer filaments like TPU require less tension than harder filaments like PLA or ABS.

Troubleshooting

Even with an upgraded "a10 aluminum extruder tension arm", you may encounter some issues:

- Filament Grinding: If the extruder is grinding away at the filament without feeding it properly, the tension may be too low, or the extruder gear may be worn[11].

- Jams: Jams can occur if the tension is too high, causing the filament to deform and get stuck in the extruder[11].

- Cracked Extruder Arm: While aluminum arms are more durable, they can still crack under extreme stress or due to manufacturing defects. Inspect the arm regularly for any signs of damage[10].

- Inconsistent Extrusion: Fluctuations in extrusion flow can be caused by inconsistent tension, a worn idler wheel bearing, or a partially clogged nozzle.

Alternatives and Upgrades

While the "a10 aluminum extruder tension arm" is a significant improvement over plastic arms, other alternatives and upgrades are available:

- Dual-Drive Extruders: Dual-drive extruders use two gears to grip the filament from both sides, providing a more secure and consistent feed[1]. These extruders are less sensitive to tension adjustments and can handle flexible filaments more effectively.

- BMG Extruders: Bondtech Mini Geared (BMG) extruders are known for their compact size, high torque, and reliable performance[11]. They use an internal gear reduction to increase the force applied to the filament.

- Adjustable Tension Mods: Some users create their own adjustable tension mods using readily available hardware like screws, washers, and springs[3][6]. These mods can be a cost-effective way to fine-tune the extruder tension.

Aluminum Extrusion Beyond the Tension Arm

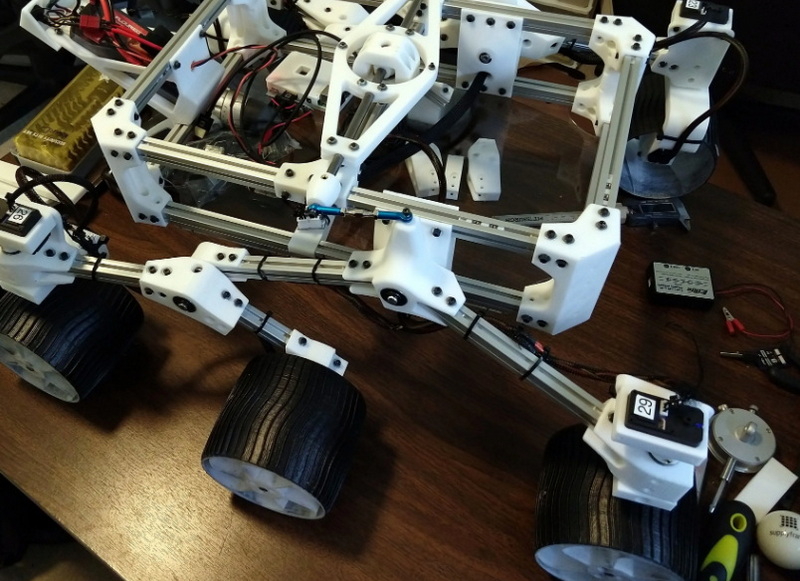

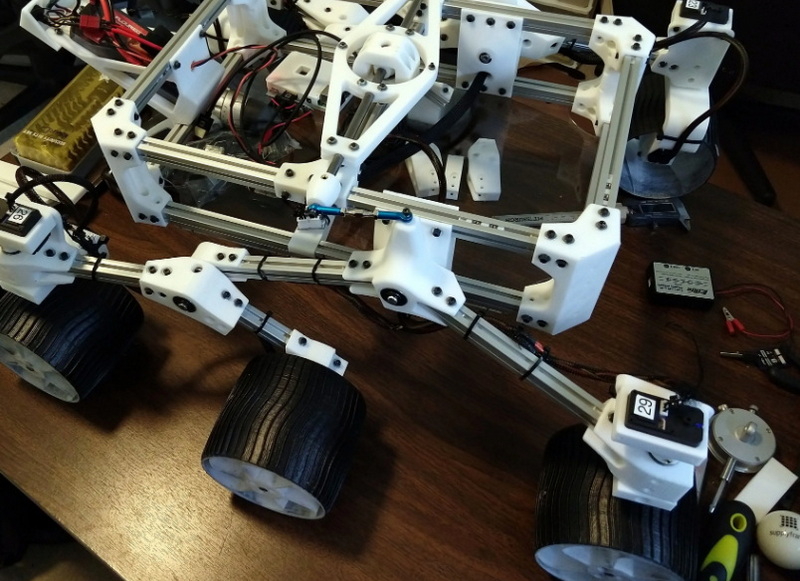

The benefits of aluminum extend beyond just the extruder tension arm. Aluminum extrusions are widely used in 3D printer construction for frames and structural components[7][9]. Their strength, rigidity, and ease of assembly make them ideal for creating stable and accurate printer platforms.

- Frame Construction: Aluminum extrusions provide a rigid and stable frame for 3D printers, minimizing vibrations and ensuring accurate movement of the print head and bed[7].

- Modularity: Aluminum extrusion systems allow for easy modification and expansion of the printer frame. Additional components, such as enclosures, spool holders, and lighting, can be easily attached to the frame using standard hardware[9].

- Precision: Aluminum extrusions are manufactured to tight tolerances, ensuring accurate alignment and consistent dimensions[9][12]. This is crucial for achieving high-quality prints.

Extrusion Tension and Material Properties

The ideal extrusion tension is also closely related to the material properties of the aluminum alloy used in the tension arm. Factors such as grain structure, particle size, and stress levels can influence the overall performance and durability of the component[4].

- Alloy Composition: Different aluminum alloys have varying strengths andductilities. The choice of alloy can affect the tension arm's resistance to cracking and deformation.

- Grain Structure: The grain structure of the aluminum can influence its notch sensitivity and resistance to crack propagation[4].

- Particle Size: The size and distribution of constituent particles within the aluminum can affect void nucleation and, consequently, the material's overall toughness[4].

Conclusion

The "a10 aluminum extruder tension arm" is a worthwhile upgrade for Geeetech A10, A20, and A30 3D printers. Its enhanced durability, consistent performance, and adjustable tension mechanism contribute to improved filament feed and print quality. By understanding the key features, installation process, and troubleshooting techniques associated with the "a10 aluminum extruder tension arm", users can optimize their 3D printing experience and achieve more reliable and consistent results. While alternatives like dual-drive extruders offer further advancements, the "a10 aluminum extruder tension arm" provides a cost-effective and straightforward way to enhance the performance of existing printer setups. Remember to always fine-tune the tension based on the specific filament being used and to regularly inspect the arm for any signs of wear or damage. With proper installation and adjustment, the "a10 aluminum extruder tension arm" can significantly improve the reliability and quality of your 3D prints.

FAQ

Here are some frequently asked questions about the "a10 aluminum extruder tension arm":

1. What printers are compatible with the A10 aluminum extruder tension arm?

The "a10 aluminum extruder tension arm" is specifically designed for Geeetech A10, A20, and A30 3D printers[2][5]. It is not compatible with A10M, A20M, or A30M models.

2. How do I adjust the tension on the A10 aluminum extruder tension arm?

The tension is adjusted using a screw and spring mechanism. Tightening the screw increases the tension, while loosening it decreases the tension. The ideal tension is when the filament is gripped firmly without being crushed[3][11].

3. What are the signs of incorrect extruder tension?

Signs of incorrect tension include filament grinding, skipping, under-extrusion, jams, and deformed filament[11]. Adjust the tension until the filament is fed smoothly and consistently.

4. Can I use the A10 aluminum extruder tension arm with flexible filaments like TPU?

Yes, but flexible filaments require lower tension settings than rigid filaments like PLA or ABS[11]. Start with a very low tension and gradually increase it until the filament is gripped without being deformed.

5. Where can I purchase the A10 aluminum extruder tension arm?

The "a10 aluminum extruder tension arm" can be purchased from online retailers such as Geeetech[2][5] and other 3D printer parts suppliers.

Citations:

[1] https://www.cnckitchen.com/blog/how-to-set-extruder-tension

[2] https://m.geeetech.com/mk8-extruder-aluminum-feeder-kit-for-175mm-filament-for-single-extruder-printer-a10-a20-a30-can-not-fit-a10m-a20m-a30m-a10t-a20t-a30t-p-995.html

[3] https://print3d.world/simple-free-ender-3-extruder-fix-tension-mod/

[4] https://www.mdpi.com/2075-4701/11/4/557

[5] https://www.geeetech.com/mk8-extruder-aluminum-feeder-kit-for-175mm-filament-p-995.html

[6] https://www.stlfinder.com/3dmodels/extruder-tension/

[7] https://el34world.com/Misc/Cnc/CNC23.htm

[8] https://kobee.com.au/blogs/3d-printing/how-to-upgrade-the-extruder-on-a-creality-ender-3-or-cr-10-printer

[9] https://www.leanproducts.eu/images/uploaded/Download/SuS%202019%20ENG.pdf

[10] https://www.reddit.com/r/FixMyPrint/comments/rphevh/how_to_adjust_extruder_spring_tension_or_is_this/

[11] https://www.youtube.com/watch?v=5UEUFDP8M30

[12] https://www.tslots.com/media/23dfnnrt/tslots-catalog-website.pdf

[13] https://www.printables.com/model/701498-neptune-4-maxplus-extruder-tension-arm-lever

[14] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[15] https://hackaday.com/2021/05/25/getting-started-with-aluminum-extrusions/

[16] https://www.saskatoon.ca/sites/default/files/documents/transportation-utilities/construction-design/construction-services/Previous%20set%20of%20All%20Specifications%20and%20Drawings%20Feb%203,%202023.pdf?jK7Qr3x9Wo=3rgRD

[17] https://dl.mitsubishielectric.co.jp/dl/fa/document/catalog/clutch/sh-170011eng/sh170011-c.pdf

[18] https://images-na.ssl-images-amazon.com/images/I/C1ikqT5qYLS.pdf

[19] https://www.reddit.com/r/FixMyPrint/comments/rphevh/how_to_adjust_extruder_spring_tension_or_is_this/

[20] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[21] https://www.capral.com.au/wp-content/uploads/2023/07/Capral-Green-Book.pdf

[22] https://dyzedesign.com/feed/

[23] https://www.yeggi.com/q/geeetech+a10+extruder/3/

[24] https://www.thingiverse.com/thing:3392655

[25] https://www.youtube.com/watch?v=5UEUFDP8M30

[26] https://www.yeggi.com/q/extruder+spring/

[27] https://www.reddit.com/r/ender3/comments/dfegm2/all_metal_extruder_causing_under_extrusion/

[28] https://www.youtube.com/watch?v=s6sT4e-oo3Q

[29] https://www.youtube.com/watch?v=idDPzKghHTU

[30] https://www.stlfinder.com/3dmodels/ormerod-extruder/?page=244

[31] https://www.youtube.com/watch?v=FhiPiCln63w

[32] https://www.bis.gov/ear/title-15/subtitle-b/chapter-vii/subchapter-c/part-774/supplement-no-1-part-774-commerce-control

[33] https://www.youtube.com/watch?v=XXxSTbmmGLk

[34] https://www.cnckitchen.com/blog/how-to-set-extruder-tension