Content Menu

● Understanding Extrusion Equipment

>> Key Components of Extrusion Equipment

● Types of Extrusion Equipment

>> Single Screw Extruders

>> Twin Screw Extruders

>> Ram Extruders

● Applications of Extrusion Equipment

>> Plastic Extrusion

>> Metal Extrusion

>> Food Extrusion

● Advantages of Extrusion Equipment

● Challenges in Extrusion Processes

● Innovations in Extrusion Technology

>> Smart Extrusion Systems

>> Sustainable Extrusion

>> Micro-Extrusion

● Selecting the Right Extrusion Equipment

● Maintenance of Extrusion Equipment

● Safety Considerations

● Future Trends in Extrusion Technology

● Case Studies

>> Case Study 1: Automotive Industry

>> Case Study 2: Sustainable Packaging

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of extrusion equipment?

>> 2. How does extrusion equipment contribute to sustainable manufacturing?

>> 3. What are the key factors to consider when selecting extrusion equipment?

>> 4. How is Industry 4.0 impacting extrusion equipment?

>> 5. What are the main safety considerations when operating extrusion equipment?

● Citations:

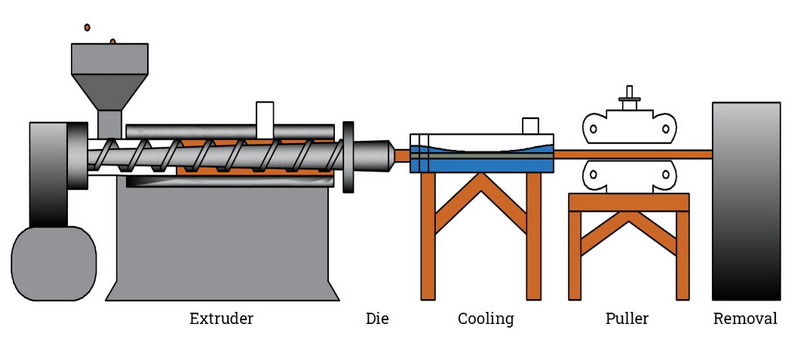

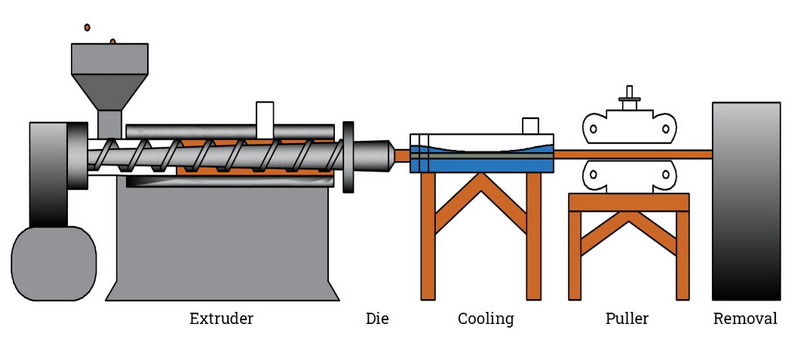

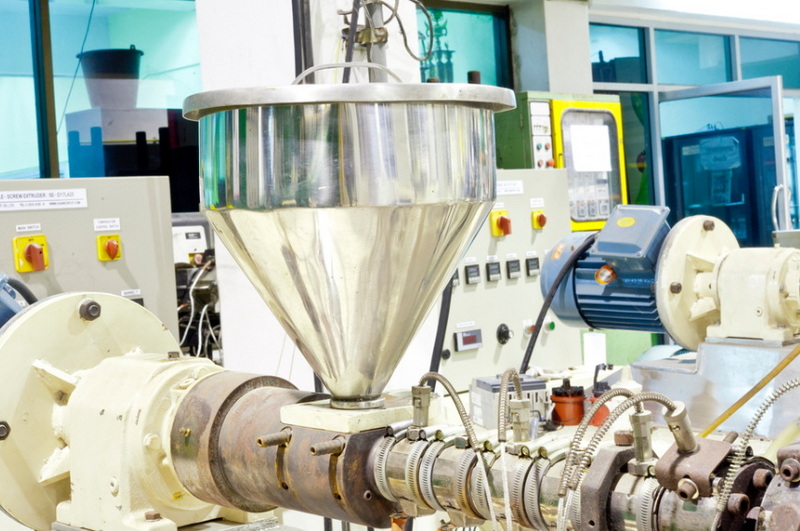

Extrusion equipment is a crucial component in various manufacturing processes, used to create products with consistent cross-sections by forcing materials through a die. This article will explore the intricacies of extrusion equipment, its types, applications, and importance in modern industry.

Understanding Extrusion Equipment

Extrusion equipment is designed to process raw materials into finished products by applying pressure and heat. The basic principle involves pushing material through a specially designed opening (die) to create a continuous profile with a uniform cross-section.

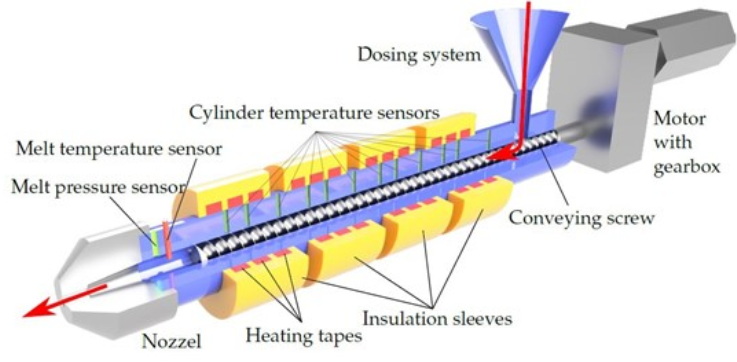

Key Components of Extrusion Equipment

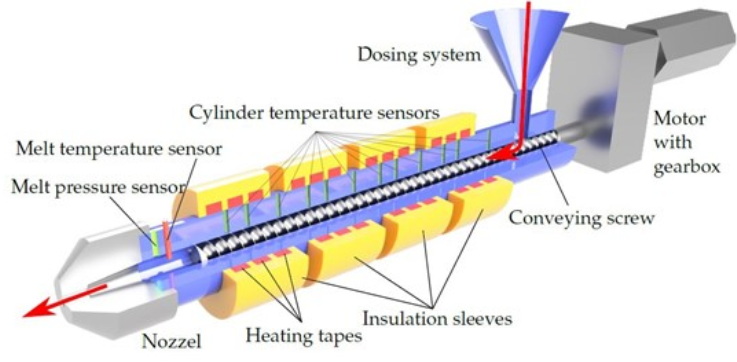

1. Hopper: The feeding mechanism that introduces raw material into the extruder.

2. Barrel: A cylindrical chamber that houses the screw.

3. Screw: The heart of the extruder, responsible for conveying, melting, and mixing the material.

4. Heaters: External heating elements that help melt the material.

5. Die: The shaping tool that gives the final form to the extruded product.

6. Cooling System: Helps solidify the extruded material.

Types of Extrusion Equipment

Extrusion equipment can be categorized based on various factors, including the number of screws and the materials they process.

Single Screw Extruders

Single screw extruders are the most common type of extrusion equipment. They are versatile and can handle a wide range of materials.

Twin Screw Extruders

Twin screw extruders offer better mixing capabilities and are often used for more complex formulations or when processing temperature-sensitive materials.

Ram Extruders

Ram extruders use a piston to force material through the die, making them suitable for materials that are difficult to process with screw extruders.

Applications of Extrusion Equipment

Extrusion equipment finds applications across various industries, contributing to the production of a wide array of products.

Plastic Extrusion

Plastic extrusion is one of the most common applications, used to produce items such as pipes, tubing, window frames, and plastic sheets.

Metal Extrusion

Metal extrusion is used to create profiles for construction, automotive parts, and aerospace components.

Food Extrusion

In the food industry, extrusion equipment is used to produce cereals, snacks, and pet food.

Advantages of Extrusion Equipment

1. Continuous Production: Extrusion allows for non-stop production, increasing efficiency.

2. Versatility: Can process a wide range of materials and create complex shapes.

3. Cost-Effective: High production rates and minimal waste make extrusion economical.

4. Consistency: Produces uniform products with tight tolerances.

Challenges in Extrusion Processes

While extrusion equipment offers numerous benefits, there are challenges to consider:

1. Material Degradation: High temperatures and shear forces can degrade some materials.

2. Die Design: Complex profiles require carefully designed dies.

3. Process Control: Maintaining consistent quality requires precise control of various parameters.

Innovations in Extrusion Technology

Recent advancements have led to significant improvements in extrusion equipment:

Smart Extrusion Systems

Integration of sensors and AI-driven control systems for real-time process optimization.

Sustainable Extrusion

Development of equipment capable of processing recycled and bio-based materials.

Micro-Extrusion

Specialized equipment for producing extremely small profiles, crucial in medical device manufacturing.

Selecting the Right Extrusion Equipment

Choosing the appropriate extrusion equipment depends on several factors:

1. Material Properties: Different materials require specific extrusion conditions.

2. Production Volume: Output requirements influence the size and type of extruder needed.

3. Product Specifications: The complexity of the final product shapes the choice of die and screw design.

4. Budget Constraints: Initial investment and operating costs vary among different types of extruders.

Maintenance of Extrusion Equipment

Proper maintenance is crucial for the longevity and performance of extrusion equipment:

1. Regular Cleaning: Prevents material buildup and contamination.

2. Screw and Barrel Inspection: Checks for wear and tear to maintain efficiency.

3. Die Maintenance: Ensures consistent product quality.

4. Calibration: Regular calibration of temperature and pressure sensors is essential.

Safety Considerations

Operating extrusion equipment requires adherence to strict safety protocols:

1. Proper Training: Operators must be well-versed in equipment operation and safety procedures.

2. Protective Gear: Use of appropriate personal protective equipment (PPE) is mandatory.

3. Emergency Protocols: Clear procedures for handling potential emergencies must be in place.

Future Trends in Extrusion Technology

The extrusion industry is continuously evolving, with several trends shaping its future:

1. Industry 4.0 Integration: Increased connectivity and data analytics for smarter manufacturing.

2. Hybrid Extrusion Systems: Combining different extrusion technologies for enhanced capabilities.

3. Nano-Extrusion: Development of equipment capable of producing nano-scale extrudates.

Case Studies

Case Study 1: Automotive Industry

A leading automotive parts manufacturer implemented a new twin-screw extrusion line to produce lightweight composite components, resulting in a 30% reduction in part weight and improved fuel efficiency for vehicles.

Case Study 2: Sustainable Packaging

A packaging company utilized a specially designed extrusion system to process recycled plastics, creating eco-friendly packaging solutions and reducing their carbon footprint by 40%.

Conclusion

Extrusion equipment plays a pivotal role in modern manufacturing, offering versatility, efficiency, and consistency in production. From plastic pipes to food products, the applications of extrusion technology are vast and continue to expand. As industries strive for more sustainable and efficient production methods, innovations in extrusion equipment will undoubtedly play a crucial role in shaping the future of manufacturing.

The continuous advancement in materials science, coupled with the integration of smart technologies, promises to further enhance the capabilities of extrusion equipment. Whether it's producing complex aerospace components or creating sustainable packaging solutions, extrusion equipment will remain at the forefront of industrial innovation.

As we look to the future, the extrusion industry faces both challenges and opportunities. The push for more sustainable practices, the need for processing new and advanced materials, and the demand for higher precision and efficiency will drive further innovations in extrusion technology. Manufacturers and researchers alike must continue to collaborate to develop solutions that meet these evolving needs while maintaining the cost-effectiveness and reliability that have made extrusion a cornerstone of modern manufacturing.

Frequently Asked Questions

1. What are the main types of extrusion equipment?

The main types of extrusion equipment include single screw extruders, twin screw extruders, and ram extruders. Single screw extruders are the most common and versatile, suitable for a wide range of materials. Twin screw extruders offer better mixing capabilities and are often used for more complex formulations. Ram extruders use a piston mechanism and are suitable for materials that are difficult to process with screw extruders.

2. How does extrusion equipment contribute to sustainable manufacturing?

Extrusion equipment contributes to sustainable manufacturing in several ways. Modern extruders are designed to be energy-efficient, reducing overall power consumption. Many are capable of processing recycled materials, contributing to the circular economy. Additionally, extrusion processes typically produce minimal waste, as excess material can often be reprocessed. Some advanced extrusion systems are also being developed to work with bio-based and biodegradable materials, further enhancing sustainability in manufacturing.

3. What are the key factors to consider when selecting extrusion equipment?

When selecting extrusion equipment, several key factors should be considered:

- Material properties: Different materials require specific extrusion conditions.

- Production volume: Output requirements influence the size and type of extruder needed.

- Product specifications: The complexity of the final product shapes the choice of die and screw design.

- Budget constraints: Initial investment and operating costs vary among different types of extruders.

- Space limitations: The physical size of the equipment must fit within the available manufacturing space.

- Energy efficiency: More efficient equipment can lead to significant cost savings over time.

4. How is Industry 4.0 impacting extrusion equipment?

Industry 4.0 is significantly impacting extrusion equipment through:

- Integration of sensors for real-time monitoring of process parameters.

- Implementation of AI and machine learning for predictive maintenance and process optimization.

- Enhanced connectivity allowing for remote monitoring and control of extrusion lines.

- Data analytics capabilities for improving product quality and production efficiency.

- Automation of material handling and post-extrusion processes for a more streamlined production flow.

5. What are the main safety considerations when operating extrusion equipment?

The main safety considerations when operating extrusion equipment include:

- Proper training: All operators must be thoroughly trained in equipment operation and safety procedures.

- Use of protective gear: Appropriate personal protective equipment (PPE) such as heat-resistant gloves, safety glasses, and ear protection should be worn.

- Machine guarding: All moving parts should be properly guarded to prevent accidents.

- Emergency protocols: Clear procedures for handling potential emergencies, such as material fires or equipment malfunctions, must be in place and regularly practiced.

- Regular maintenance: Proper maintenance helps prevent equipment failures that could lead to safety hazards.

- Ventilation: Adequate ventilation is crucial, especially when processing materials that may emit fumes or particles.

Citations:

[1] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[2] https://omnexus.specialchem.com/selection-guide/an-in-depth-look-at-extrusion

[3] https://thebonnotco.com/what-is-an-extruder/

[4] https://www.sct-straw.com/en/news/152-extrusion-machine-types

[5] https://www.alamy.com/stock-photo/extrusion-machine.html

[6] https://www.youtube.com/watch?v=Y75IQksBb0M

[7] https://www.youtube.com/watch?v=9Hmp4K3NwB0

[8] https://www.faygo.cn/Extruder-FAQ/

[9] https://www.inplexllc.com/blog/plastic-extrusion-faq/

[10] https://www.clarkrandp.com/6-common-applications-of-plastic-extrusion/

[11] https://create.vista.com/photos/extruder-machine/