Content Menu

● Introduction to Extrusion Press Equipment

● Metals Processed by Extrusion Press Equipment

>> Aluminum

>>> Key Properties:

>>> Applications:

>> Copper

>>> Key Properties:

>>> Applications:

>> Steel

>>> Key Properties:

>>> Applications:

>> Magnesium

>>> Key Properties:

>>> Applications:

>> Brass, Zinc, Lead, and Tin

>>> Key Properties:

>>> Applications:

>> Titanium

>>> Key Properties:

>>> Applications:

● Polymers and Plastics Processed by Extrusion Press Equipment

>> Polyethylene (PE)

>>> Key Properties:

>>> Applications:

>> Polypropylene (PP)

>>> Key Properties:

>>> Applications:

>> Polyvinyl Chloride (PVC)

>>> Key Properties:

>>> Applications:

>> Acrylonitrile Butadiene Styrene (ABS)

>>> Key Properties:

>>> Applications:

>> Nylon (Polyamides)

>>> Key Properties:

>>> Applications:

>> Thermoplastic Elastomers (TPE, TPO, TPV)

>>> Key Properties:

>>> Applications:

>> Polycarbonate (PC)

>>> Key Properties:

>>> Applications:

>> Specialty and Filled Resins

>>> Key Properties:

>>> Applications:

● Composite and Specialty Materials

● Applications Across Industries

● Key Considerations in Material Selection

● Conclusion

● FAQ

>> 1. What are the most common metals processed using extrusion press equipment?

>> 2. Can extrusion press equipment process both rigid and flexible plastics?

>> 3. What factors influence the choice of material for extrusion?

>> 4. Are composite materials suitable for extrusion press equipment?

>> 5. Which industries benefit most from the use of extrusion press equipment?

● Citations:

Extrusion press equipment is a cornerstone technology in modern manufacturing, enabling the efficient production of a vast array of products with consistent cross-sectional profiles. This process, which involves forcing material through a die of the desired shape, is widely used across industries such as automotive, construction, electronics, packaging, and more. The versatility of extrusion press equipment lies in its ability to handle a broad spectrum of materials—from metals and polymers to specialty composites—each offering unique properties and applications.

In this comprehensive guide, we will explore the various materials that can be processed using extrusion press equipment, their characteristics, applications, and the considerations involved in material selection. We will also address frequently asked questions to provide a holistic understanding of this essential manufacturing process.

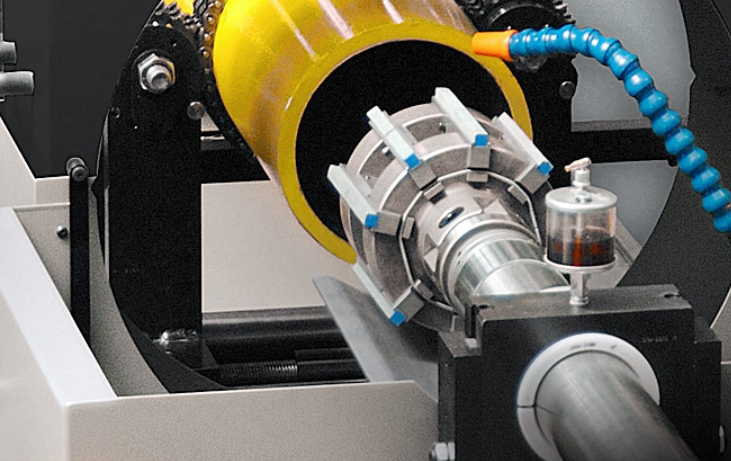

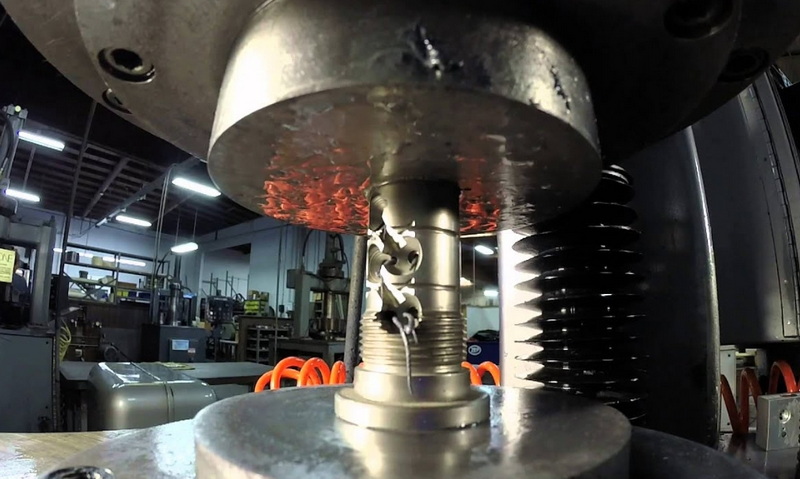

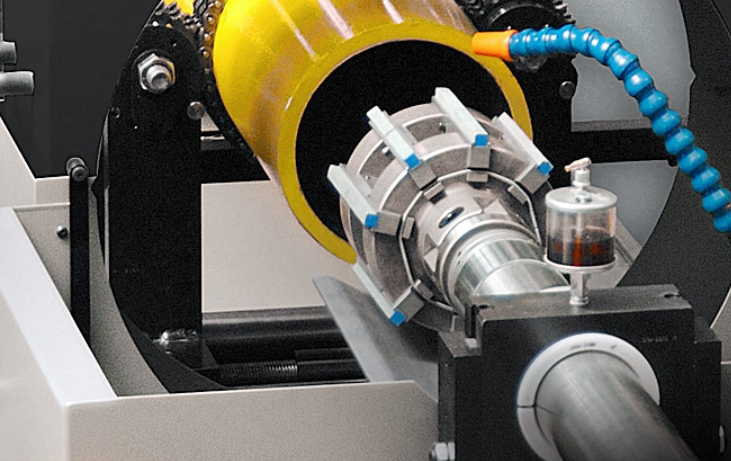

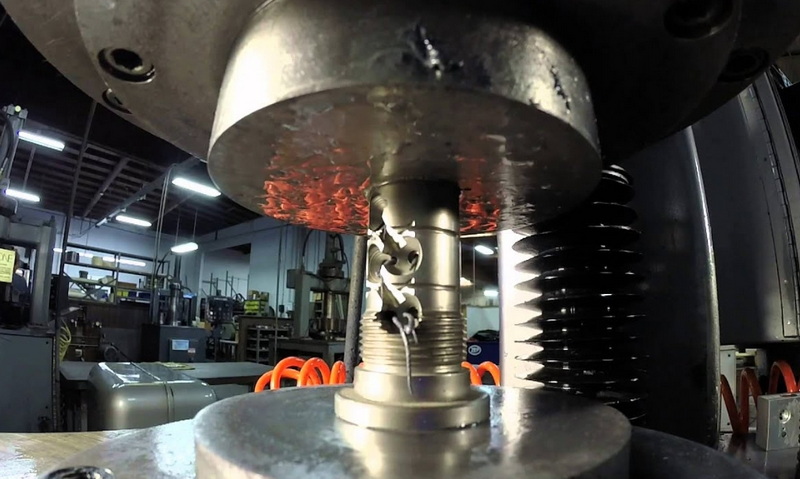

Introduction to Extrusion Press Equipment

Extrusion press equipment is designed to shape materials by forcing them through a die, resulting in products with a uniform cross-section. The process can be direct or indirect, and the equipment itself can be tailored for specific materials, such as metals or plastics. The versatility and efficiency of extrusion press equipment make it indispensable in manufacturing, enabling the production of everything from structural beams and window frames to pipes, wires, and intricate profiles[1][6].

Metals Processed by Extrusion Press Equipment

Aluminum

Aluminum is the most commonly extruded metal due to its excellent malleability, corrosion resistance, and favorable strength-to-weight ratio. It can be extruded hot or cold, with hot extrusion being the most prevalent. Aluminum extrusions are widely used in construction (window frames, curtain walls), transportation (automotive and railway components), electronics (heat sinks), and consumer goods[1][6].

Key Properties:

- Lightweight and strong

- Corrosion-resistant

- Easily alloyed for enhanced properties

Applications:

- Structural profiles

- Tracks and rails

- Frames and supports

Copper

Copper and copper alloys are extruded to produce tubes, rods, wires, and bars. Copper's excellent electrical and thermal conductivity makes it ideal for electrical wiring, plumbing, and heat exchangers. Specialized extrusion presses, such as direct double-action presses, are used for copper to ensure high-quality, uniform products[1][6].

Key Properties:

- High electrical and thermal conductivity

- Corrosion resistance

Applications:

- Electrical conductors

- Plumbing pipes

- Heat exchanger components

Steel

Steel, including carbon steel, alloy steel, and stainless steel, can be extruded at high temperatures. Extruded steel products are used in construction, automotive, and heavy machinery for components requiring strength and durability[3][6].

Key Properties:

- High strength and toughness

- Wide range of alloy compositions

Applications:

- Rods and tracks

- Shafts and beams

- Engineering machinery components

Magnesium

Magnesium is notable for its lightweight and is used in aerospace, automotive, and electronics industries. It is about as extrudable as aluminum and is often chosen for applications where weight reduction is critical[6].

Key Properties:

- Extremely lightweight

- Good strength-to-weight ratio

Applications:

- Aircraft parts

- Automotive components

Brass, Zinc, Lead, and Tin

Other metals such as brass, zinc, lead, and tin are also processed using extrusion press equipment. Brass is used for corrosion-resistant rods and fittings, zinc for hardware components and handrails, and lead and tin for pipes, wires, and cable sheathing[6].

Key Properties:

- Brass: Corrosion resistance, machinability

- Zinc: Moderate strength, corrosion resistance

- Lead/Tin: Malleability, chemical resistance

Applications:

- Pipe fittings

- Cable sheathing

- Hardware components

Titanium

Titanium is extruded for high-performance applications, especially in the aerospace and medical sectors, due to its exceptional strength, corrosion resistance, and biocompatibility[6].

Key Properties:

- High strength-to-weight ratio

- Corrosion resistance

- Biocompatibility

Applications:

- Aircraft seat tracks

- Engine rings

- Medical implants

Polymers and Plastics Processed by Extrusion Press Equipment

Extrusion press equipment is widely used in the plastics industry, enabling the production of a variety of profiles, sheets, tubes, and films. The choice of polymer depends on the desired mechanical, thermal, and chemical properties[2][4][7].

Polyethylene (PE)

Polyethylene is available in several densities: low (LDPE), medium (MDPE), and high (HDPE). It is valued for its chemical resistance, flexibility (LDPE), and strength (HDPE)[2][5][7].

Key Properties:

- Chemical resistance

- Flexibility (LDPE) or rigidity (HDPE)

- Low cost

Applications:

- Pipes and tubing

- Sheets and films

- Packaging materials

Polypropylene (PP)

Polypropylene is a versatile, stiff, and chemically resistant polymer. It is commonly used in automotive, packaging, and consumer goods[2][5].

Key Properties:

- High rigidity and impact strength

- Excellent chemical resistance

- Good heat stability

Applications:

- Automotive components

- Containers and packaging

- Fibers and textiles

Polyvinyl Chloride (PVC)

PVC can be rigid or flexible, making it suitable for a wide range of applications. Rigid PVC is used in pipes and window frames, while flexible PVC is used for cables and hoses[2][7].

Key Properties:

- Flame retardant

- Chemical resistance

- Versatility (rigid or flexible)

Applications:

- Pipes and fittings

- Window and door profiles

- Electrical cable insulation

Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough, impact-resistant plastic used in automotive parts, consumer electronics, and toys[2][5].

Key Properties:

- High impact strength

- Good rigidity

- Medium cost

Applications:

- Automotive trim

- Appliance housings

- Toys and consumer goods

Nylon (Polyamides)

Nylon is strong, abrasion-resistant, and used in demanding engineering applications. Variants such as nylon 6, 6-6, and 11 are used depending on specific requirements[2][5].

Key Properties:

- High strength and toughness

- Excellent wear resistance

- Good chemical resistance

Applications:

- Gears and bearings

- Tubing and hoses

- Electrical insulators

Thermoplastic Elastomers (TPE, TPO, TPV)

These materials combine the properties of rubber and plastic, offering flexibility, resilience, and processability. They are used in automotive seals, soft-touch grips, and medical devices[2].

Key Properties:

- Flexibility and elasticity

- Chemical resistance

- Excellent impact strength

Applications:

- Seals and gaskets

- Soft-touch handles

- Medical tubing

Polycarbonate (PC)

Polycarbonate is a high-performance plastic known for its transparency, toughness, and heat resistance. It is used in safety equipment, glazing, and electronics[2].

Key Properties:

- High impact resistance

- Good heat stability

- Optical clarity

Applications:

- Safety goggles

- Machine guards

- Electronic housings

Specialty and Filled Resins

Extrusion press equipment can also process specialty resins and filled polymers, such as glass-filled or talc-filled compounds, to enhance specific properties like strength, stiffness, or heat resistance[2].

Key Properties:

- Tailored mechanical and thermal properties

- Enhanced performance

Applications:

- Structural components

- High-performance parts

Composite and Specialty Materials

Composite materials, which combine two or more constituents to achieve superior properties, are increasingly processed using extrusion press equipment. Examples include fiber-reinforced polymers, metal matrix composites, and multi-material extrusions. These materials are used in aerospace, automotive, and construction for their high strength-to-weight ratios and tailored performance characteristics[2][6].

Applications Across Industries

Extrusion press equipment is vital across a range of industries, each leveraging the unique capabilities of the process and the materials involved[1][3][6]:

- Automotive: Lightweight structural parts, battery casings, trim, and seals.

- Construction: Window frames, curtain walls, pipes, and siding.

- Electronics: Heat sinks, cable insulation, and housings.

- Packaging: Films, bottles, containers, and protective wraps.

- Engineering Machinery: Shafts, beams, and casings for heavy equipment.

- Consumer Goods: Toys, appliances, and furniture components.

Key Considerations in Material Selection

Selecting the right material for extrusion involves evaluating several factors:

- Mechanical Properties: Strength, rigidity, impact resistance

- Thermal Properties: Heat stability, melting point

- Chemical Resistance: Suitability for harsh environments

- Cost: Material and processing costs

- Application Requirements: Dimensional accuracy, surface finish, color, and regulatory compliance

Consulting with extrusion press equipment experts and material suppliers is crucial to ensure the chosen material meets the specific needs of the application[2].

Conclusion

Extrusion press equipment stands as a versatile and indispensable tool in modern manufacturing, capable of processing a wide spectrum of materials. From lightweight aluminum and resilient steel to flexible polymers and advanced composites, the range of materials that can be shaped by extrusion presses is vast and continually expanding. This capability enables industries to innovate and meet the evolving demands of performance, efficiency, and sustainability. As material science advances, extrusion press equipment will continue to play a pivotal role in shaping the products and infrastructure of tomorrow.

FAQ

1. What are the most common metals processed using extrusion press equipment?

The most common metals include aluminum, copper, steel, magnesium, brass, zinc, lead, tin, and titanium. Aluminum is the most widely extruded due to its excellent properties and versatility[1][6].

2. Can extrusion press equipment process both rigid and flexible plastics?

Yes, extrusion press equipment can process a wide range of plastics, including rigid types like PVC and ABS, as well as flexible materials such as thermoplastic elastomers (TPE, TPO, TPV) and flexible PVC[2][7].

3. What factors influence the choice of material for extrusion?

Key factors include mechanical and thermal properties, chemical resistance, cost, and the specific requirements of the end application. Consulting with experts ensures optimal material selection for extrusion press equipment[2].

4. Are composite materials suitable for extrusion press equipment?

Yes, many composite materials, including fiber-reinforced polymers and filled resins, can be processed using extrusion press equipment to achieve enhanced performance characteristics for demanding applications[2][6].

5. Which industries benefit most from the use of extrusion press equipment?

Industries such as automotive, construction, electronics, packaging, engineering machinery, and consumer goods benefit significantly from the versatility and efficiency of extrusion press equipment[1][3][6].

Citations:

[1] https://www.ubemachinery.co.jp/english/product/extrusion/index.html

[2] https://geminigroup.net/engineered-plastics/profile-extrusion-co-extrusion/materials/

[3] https://sites.google.com/view/tradelyric/fluxtrade/extrusion-press-market-by-application

[4] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[5] https://cmppin.com/blog/types-of-material-used-in-extrusion-blow-moulding-machine/

[6] https://en.wikipedia.org/wiki/Extrusion

[7] https://www.guangduanpresses.ru/extrusion-press-a-guide-to-hydraulic-extrusion-presses.html

[8] https://www.outashi.com/blog/what-is-equipment-used-in-extrusion-process-id19.html

[9] https://www.conairgroup.com/resources/resource/extrusion-processing-basic-guide-to-auxiliary-equipment/

[10] https://www.thermofisher.com/hk/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment/applications.html

[11] https://www.sms-group.com/en-us/plants/extrusion-presses-for-steel

[12] https://jieyatwinscrew.com/blog/what-3-major-materials-are-used-in-the-extrusion-process/

[13] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[14] https://www.hitachi-iesa.com/by-application/extrusion-equipment

[15] http://www.industrialextrusionmachinery.com/extrusion_materials.html

[16] https://macrodynepress.com/hydraulic-presses/extrusion-presses/

[17] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[18] https://www.bausano.com/en/press-and-news/what-types-of-materials-can-be-extruded

[19] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[20] https://paulmurphyplastics.com/industry-news-blog/types-of-plastic-extrusion-materials/