Content Menu

● Understanding Aluminum Extrusion

● Types of Aluminum Extrusion Equipment

● Where to Find Used Aluminum Extrusion Equipment

● Factors to Consider When Evaluating Used Equipment

● Inspection Tools for Aluminum Extrusion

● Maintaining Used Aluminum Extrusion Equipment

● Advantages of Aluminum Extrusions

● Negotiating and Purchasing Used Equipment

● Ensuring Reliability

● Finding Fair Deals

● The Role of Surface Inspection

● Choosing an Aluminum Extrusion Provider

● Conclusion

● FAQ

>> 1. What are the key factors to consider when buying used aluminum extrusion equipment?

>> 2. Where can I find reliable sources for used aluminum extrusion equipment?

>> 3. How important is the maintenance history of used aluminum extrusion equipment?

>> 4. What are some common issues to look for when inspecting used aluminum extrusion presses?

>> 5. How can I ensure the used equipment meets my specific production needs?

● Citations:

The aluminum extrusion industry relies on robust and precise machinery to transform aluminum billets into a vast array of profiles used in construction, automotive, aerospace, and many other sectors. Investing in used aluminum extrusion equipment can be a cost-effective strategy for businesses looking to expand or upgrade their capabilities without the hefty price tag of new machinery. However, finding reliable used aluminum extrusion equipment requires careful consideration, thorough research, and a strategic approach to ensure the equipment meets your specific needs and operational standards.

This article delves into the critical aspects of sourcing used aluminum extrusion equipment, providing insights into where to find it, what to look for, and how to evaluate potential purchases. Whether you are a seasoned industry professional or new to aluminum extrusion, this guide aims to equip you with the knowledge to make informed decisions and secure the best possible equipment for your investment.

Understanding Aluminum Extrusion

Aluminum extrusion is a process where aluminum alloy is forced through a die of a specific cross-section, creating complex and consistent shapes. This process is vital for producing everything from window frames and automotive parts to heat sinks and architectural elements[5]. The machinery involved in this process includes extrusion presses, dies, billet heaters, cooling tables, and handling systems.

Types of Aluminum Extrusion Equipment

Several types of equipment are essential in the aluminum extrusion process. Understanding these components is crucial when seeking used aluminum extrusion equipment.

- Extrusion Presses: These are the primary machines that apply the force needed to push the aluminum billet through the die. Presses vary in size and capacity, typically measured in tons (MT), ranging from 800 MT to over 4,000 MT depending on the application[1].

*Direct extrusion presses* are the most common, pushing the billet through the die using a ram. *Indirect extrusion presses* use a stationary container and a ram on the back for complex profiles requiring high precision. *Hydrostatic extrusion presses* utilize pressurized fluid for materials that are difficult to extrude or for producing very small parts.

- Dies: Dies are custom-shaped tools that define the profile of the extruded aluminum. They are made of hardened steel and must withstand high temperatures and pressures.

- Billet Heaters: Aluminum billets must be heated to a specific temperature to make them malleable enough for extrusion. Billet heaters use gas, electricity, or induction to achieve this.

- Cooling Tables: After extrusion, the aluminum profile needs to be cooled to maintain its shape and mechanical properties. Cooling tables use air or water to rapidly reduce the temperature of the extruded profile.

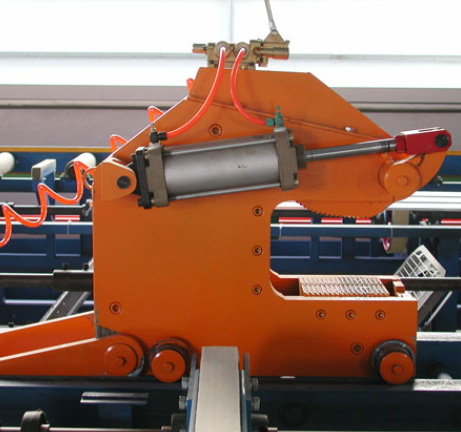

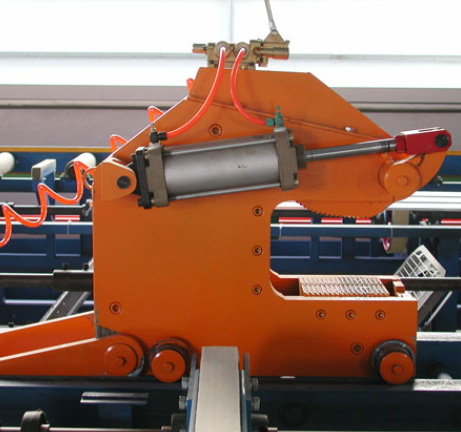

- Pullers: Pullers are used to guide the extruded profile along the cooling table, ensuring straightness and preventing distortion. Double pullers are one of the types[8].

- Handling Systems: These systems automate the movement of billets, dies, and extruded profiles throughout the extrusion process. They can include conveyors, robots, and stacking equipment.

- CNC Machines: Used 4 Axis CNC, Used 3 Axis CNC, Used 5 Axis CNC are available in used aluminum extrusion machinery market[3].

- Saws: Used Single Head Saw and Used Double Head Saw are available[3].

Where to Find Used Aluminum Extrusion Equipment

Finding reliable used aluminum extrusion equipment requires a strategic approach. Several avenues can be explored, each offering different advantages and considerations.

Online Marketplaces:

- Machinio: A popular online platform for industrial equipment listings, featuring a wide variety of used aluminum extrusion equipment from different brands[1].

- Alibaba: A global marketplace offering a range of second-hand machinery from various suppliers[1].

- MachineTools.com: This site specializes in listings for extrusion presses and other metalworking equipment[1].

- Industry-Specific Auctions: Auctions can be a competitive way to acquire used aluminum extrusion equipment. These events often feature equipment from companies that are upgrading or downsizing.

- Local Machinery Dealers: Contact local machinery dealers specializing in metalworking equipment. They may have inventory that is not listed online and can provide personalized service.

- Equipment Suppliers: Some aluminum extrusion equipment suppliers also deal in used aluminum extrusion equipment. These suppliers often recondition and certify the equipment before selling it.

- Direct from Manufacturers: In some cases, you may be able to purchase used aluminum extrusion equipment directly from manufacturers who are upgrading their facilities.

- Starlight Sales Corp: They provide used aluminum extrusion machinery[3].

- Extruderpress.com: They sell used extrusion presses[8].

Factors to Consider When Evaluating Used Equipment

When evaluating used aluminum extrusion equipment, several factors must be considered to ensure it meets your production needs and operational standards.

- Condition of the Equipment: Conduct a thorough inspection of the equipment to assess its condition. Look for signs of wear and tear, damage, or corrosion. Pay close attention to critical components such as the hydraulic system, cylinders, and controls. Check for unusual sounds or vibrations during operation[1].

- Maintenance History: Request maintenance records to understand how well the machine has been cared for. A well-maintained machine is more likely to be in good working order and have a longer lifespan[1].

- Operational Status: If possible, inspect the machine in person and see it in operation. This will allow you to assess its performance and identify any potential problems[1].

- Tonnage Capacity: Ensure the press has the appropriate tonnage capacity for your extrusion needs. The tonnage capacity determines the maximum force the press can exert, which affects the size and complexity of the profiles you can extrude[1].

- Die Size Compatibility: Verify that the press can accommodate your required die sizes. The die size determines the size and shape of the extruded profile[1].

- Production Speed: Evaluate how quickly the press can produce extrusions. The production speed affects your overall output and efficiency[1].

- Upgrades and Modifications: Determine if any upgrades or modifications have been made to the equipment. Upgrades can enhance performance or efficiency, but it's important to ensure they are compatible with your operations[1].

- Original Purchase Invoice: Request the original purchase invoice to verify the age and authenticity of the equipment[1].

- Certifications and Compliance Documents: Check for any certifications or compliance documents to ensure the equipment meets relevant safety and environmental standards[1].

Inspection Tools for Aluminum Extrusion

Various inspection tools are available to ensure that aluminum tubing and extruded shapes meet the necessary dimensional requirements.

- Micrometer: Used to measure wall thicknesses or the distance between two faces. Digital micrometers can measure down to the fifth decimal place, while analog ones can measure down to the fourth decimal place[2].

- Caliper: Used to measure the distance between two opposite sides of an object. It can measure distances much larger than a micrometer and can measure a tube's Outer Diameter (OD), Inner Diameter (ID), wall thickness, and space dimensions between walls. It's accurate to the third decimal place[2].

- Optical Comparator: Projects a magnified silhouette of an extrusion onto a screen, allowing for the measurement of angles, radii, and other geometric tolerances[2].

- Digital Vision Inspection System: Offers higher resolution and accuracy compared to traditional optical comparators. It can measure depth as well as 2-D dimensions and performs inspections based on a CAD file[2].

- Go/no-go Gages: Simple tools to check tubing inside diameters and gaps between walls[2].

Maintaining Used Aluminum Extrusion Equipment

Proper maintenance is crucial for extending the life and performance of used aluminum extrusion equipment. Regular maintenance can prevent costly repairs and downtime.

- Daily Inspections: Perform daily walk-around inspections to check for oil leaks, monitor hydraulic system temperatures, and ensure smooth movement of key components[4].

- Proper Alignment: Maintain proper alignment of all components to reduce strain and wear[4].

- Lubrication: Lubricate moving parts regularly to reduce friction and prevent damage[4].

- Hydraulic System Maintenance: Regularly check and maintain hydraulic system seals to prevent leaks[4].

- Cooling System Maintenance: Regularly clean and maintain cooling systems for optimal heat transfer[4].

- Energy Efficiency: Implement energy-saving maintenance procedures to reduce energy consumption[4].

- Overhauls: Perform comprehensive overhauls every 3-5 years, depending on usage and manufacturer recommendations[4].

Advantages of Aluminum Extrusions

Aluminum extrusions offer several advantages that make them a popular choice for various applications.

- Lightweight and Durable: Aluminum has a high strength-to-weight ratio, making it ideal for applications where weight matters[5].

- Versatile: The extrusion process allows for the creation of complex shapes and profiles to meet a wide range of manufacturing needs[5].

- Sustainable: Aluminum is highly recyclable, and the extrusion process itself is energy-efficient[5].

- Cost-Effective: The extrusion process is efficient, leading to lower production costs. Aluminum's long lifespan reduces maintenance and replacement costs[5].

- Excellent Thermal Properties: Aluminum has high thermal conductivity, making it suitable for applications such as heatsinks and radiators[5].

Negotiating and Purchasing Used Equipment

Once you have identified potential equipment, the next step is to negotiate the terms of the purchase.

- Negotiate Terms: Discuss payment terms, delivery options, and any additional costs, such as installation[1].

- Secure Financing: If necessary, explore financing options that suit your budget[1].

- Arrange Logistics: Plan for transportation and installation at your facility[1].

Ensuring Reliability

- Wear and Tear: Check for signs of excessive wear on critical components[1].

- Maintenance History: Request maintenance records to understand how well the machine has been cared for[1].

- Upgrades or Modifications: Determine if any upgrades have been made that enhance performance or efficiency[1].

Finding Fair Deals

- Market Research: Investigate current market prices for similar used aluminum extrusion presses[1].

- Negotiation: Be prepared to negotiate based on your findings[1].

The Role of Surface Inspection

Supreme surface quality is crucial for aluminum extrusion, especially for the automotive industry. Manual surface inspection by the human eye may lead to inconsistent quality decisions. Real-time in-line measurement solutions using artificial intelligence (AI) can detect a wide variety of surface defects[7].

Choosing an Aluminum Extrusion Provider

- Experience and Expertise: Look for a company with a proven track record and a solid reputation in the industry[6].

- Customization and Design Support: Ensure the provider can accommodate complex designs, tight tolerances, and various finishing options[6].

- Material Selection and Sourcing: A reputable provider should have a wide range of aluminum alloys available[6].

- Manufacturing Capabilities and Facilities: Evaluate the provider's manufacturing capabilities and facilities to ensure they can handle your project's size, complexity, and volume requirements[6].

- Customer Support and Communication: Good customer support and effective communication are critical for a successful partnership[6].

Conclusion

Acquiring used aluminum extrusion equipment can be a strategic move for businesses aiming to optimize costs without compromising operational capabilities. By understanding the types of equipment available, knowing where to source them, and carefully evaluating their condition and history, you can make informed decisions that align with your production needs. Proper maintenance and regular inspections will further ensure the longevity and efficiency of your investment. Leveraging online marketplaces, industry auctions, and direct contact with manufacturers and dealers will provide a broad range of options. With due diligence and a comprehensive understanding of the factors involved, businesses can successfully integrate reliable used aluminum extrusion equipment into their operations.

FAQ

1. What are the key factors to consider when buying used aluminum extrusion equipment?

When buying used aluminum extrusion equipment, consider the condition of the equipment, maintenance history, operational status, tonnage capacity, die size compatibility, production speed, and any upgrades or modifications. A thorough inspection and review of documentation are essential.

2. Where can I find reliable sources for used aluminum extrusion equipment?

Reliable sources include online marketplaces like Machinio and Alibaba, industry-specific auctions, local machinery dealers, equipment suppliers, and direct contact with manufacturers. Each source offers different advantages in terms of selection and potential cost savings.

3. How important is the maintenance history of used aluminum extrusion equipment?

The maintenance history is crucial as it provides insights into how well the equipment has been cared for. A well-maintained machine is more likely to be in good working order and have a longer lifespan, reducing the risk of unexpected repairs and downtime.

4. What are some common issues to look for when inspecting used aluminum extrusion presses?

When inspecting used aluminum extrusion presses, look for signs of wear and tear, damage, or corrosion, especially on critical components such as the hydraulic system, cylinders, and controls. Also, check for unusual sounds or vibrations during operation, which could indicate underlying problems.

5. How can I ensure the used equipment meets my specific production needs?

Ensure the equipment meets your production needs by considering factors such as tonnage capacity, die size compatibility, and production speed. Verify that the equipment can handle the size and complexity of the profiles you intend to extrude, and that it can produce extrusions at a rate that meets your production targets.

Citations:

[1] https://www.yjing-extrusion.com/how-to-find-a-reliable-used-aluminum-extrusion-press-for-sale.html

[2] https://profileprecisionextrusions.com/aluminum-extrusion-inspection-tools/

[3] https://starlightcorp.co/en/used-machines/

[4] https://www.yjing-extrusion.com/how-to-maintain-an-aluminum-extrusion-press-for-optimal-performance.html

[5] https://www.renxin-precision.com/blogs-detail/-28

[6] https://orangealuminum.com/blog/factors-to-consider-for-your-aluminum-extrusion-provider/

[7] https://aec.org/extrusion-equipment

[8] https://extruderpress.com

[9] https://www.outashi.com/blog/safety-precautions-in-operating-aluminum-extrusion-machine-id35.html

[10] https://profiledecor.com/cost-of-aluminum-extrusion/

[11] https://www.sourcingallies.com/blog/aluminum-extrusion-companies

[12] https://www.outashi.com/blog/factors-to-consider-when-selecting-aluminum-extrusion-machine-id32.html

[13] https://machyintl.com/types/25507-presses-extrusion

[14] https://www.outashi.com/blog/tips-maintenance-aluminum-extrusion-press-id25.html

[15] http://scaluminum.com/2016/12/reduce-manufacturing-costs-use-aluminum-extrusion-solutions/

[16] https://kimsen.vn/custom-aluminum-extrusions:-5-important-tips-for-engineering-design-success-ne140.html

[17] https://help.facton.com/solutions/sc/v14.1/en-us/Topics/SC/CostModels/CostModelAluminumExtrusion.htm?TocPath=Calculations%7CCost+Models%7C_____19

[18] https://www.reddit.com/r/robotics/comments/1emqb0x/where_is_the_absolute_cheapest_place_to_get/

[19] https://www.castool.com/wp-content/uploads/2024/03/The-Maintenance-of-Extrusion-Presses.pdf

[20] https://www.linkedin.com/pulse/aluminum-extrusion-5-tips-help-you-reduce-costs-jonathan-chauvette