Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Choosing the Right Tools for Cutting Aluminum Extrusion

>> 1. Miter Saw

>> 2. Circular Saw

>> 3. Band Saw

>> 4. Hacksaw

● Techniques for Cutting Aluminum Extrusion

>> 1. Measuring and Marking

>> 2. Securing the Workpiece

>> 3. Choosing the Right Blade

>> 4. Cutting Technique

>> 5. Cooling and Lubrication

● Safety Considerations

● Advanced Techniques and Tips

>> 1. Using a Stop Block

>> 2. Creating Custom Jigs

>> 3. Finishing Techniques

● Conclusion

● Frequently Asked Questions

>> Q1: Can I use a wood-cutting blade to cut aluminum extrusion?

>> Q2: How can I prevent the aluminum from melting during cutting?

>> Q3: What's the best way to make angled cuts in aluminum extrusion?

>> Q4: How do I cut T-slot aluminum profiles without damaging the slots?

>> Q5: Is it necessary to wear a mask when cutting aluminum extrusion?

Introduction

Aluminum extrusion is a versatile material used in various industries, from construction to manufacturing. Its lightweight nature, corrosion resistance, and strength make it an ideal choice for many applications. However, working with aluminum extrusion requires specific knowledge and techniques, especially when it comes to cutting. In this comprehensive guide, we'll explore the best methods, tools, and safety practices for cutting aluminum extrusion, ensuring you achieve precise and clean results every time.

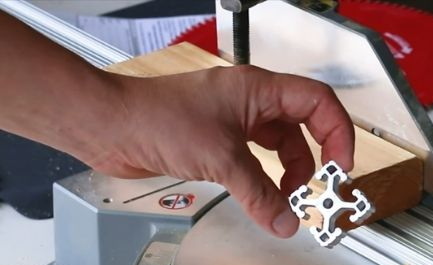

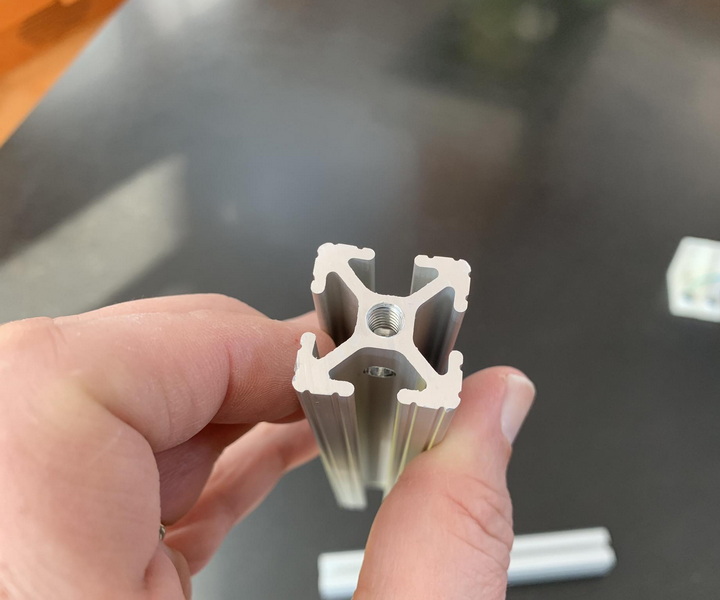

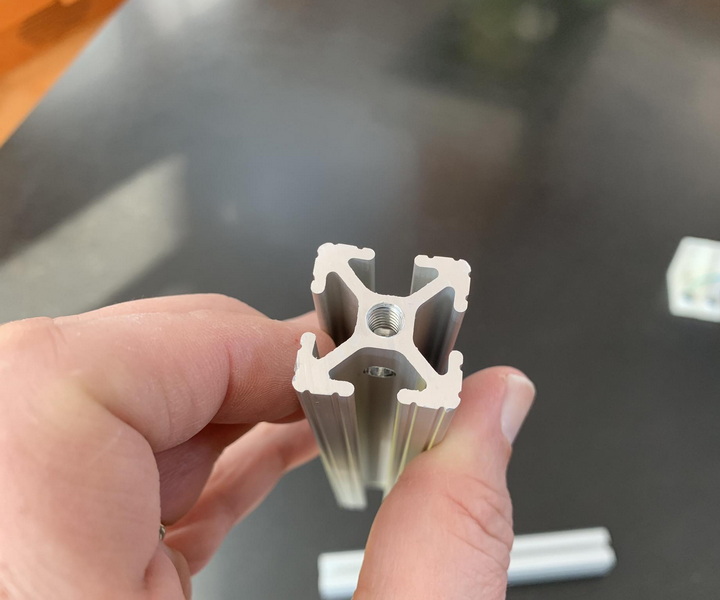

Understanding Aluminum Extrusion

Before diving into cutting techniques, it's essential to understand what aluminum extrusion is. Aluminum extrusion is a process where aluminum alloy material is forced through a die of the desired cross-section. This process creates profiles with consistent dimensions and properties, which can be used in a wide range of applications, from window frames to industrial machinery components.

Choosing the Right Tools for Cutting Aluminum Extrusion

Selecting the appropriate tools is crucial for achieving clean and accurate cuts in aluminum extrusion. Here are some of the most effective tools for the job:

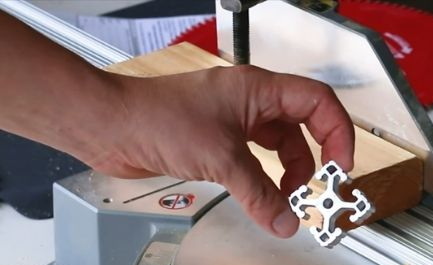

1. Miter Saw

A miter saw is one of the most popular and efficient tools for cutting aluminum extrusion. It offers precision and the ability to make angled cuts, which is often necessary when working with aluminum profiles.

2. Circular Saw

For longer cuts or when working with larger pieces of aluminum extrusion, a circular saw can be an excellent choice. It's versatile and can handle a variety of cutting tasks.

3. Band Saw

A band saw is ideal for making curved cuts or working with thicker aluminum extrusions. It provides a smooth, continuous cut and can handle more complex shapes.

4. Hacksaw

For smaller projects or when power tools are not available, a hacksaw can be used to cut aluminum extrusion. While it requires more manual effort, it can still produce accurate cuts when used correctly.

Techniques for Cutting Aluminum Extrusion

Now that we've covered the tools, let's explore the techniques for cutting aluminum extrusion effectively:

1. Measuring and Marking

Accurate measurement is crucial for precise cuts. Use a tape measure and a square to mark your cutting line clearly on the aluminum extrusion. Double-check your measurements to avoid costly mistakes.

2. Securing the Workpiece

Always clamp your aluminum extrusion securely before cutting. This prevents movement during the cutting process, ensuring safety and accuracy.

3. Choosing the Right Blade

For best results, use a blade specifically designed for cutting non-ferrous metals like aluminum. These blades typically have a higher tooth count and are designed to prevent the aluminum from melting or gumming up the blade.

4. Cutting Technique

When using a power saw, allow the blade to reach full speed before making contact with the aluminum. Apply steady, even pressure as you guide the saw through the material. Avoid forcing the blade, as this can lead to rough cuts or damage to the extrusion.

5. Cooling and Lubrication

Aluminum can heat up quickly during cutting, which can affect the quality of the cut and potentially damage your tools. Consider using a cutting lubricant or wax to reduce friction and heat buildup.

Safety Considerations

Safety should always be your top priority when cutting aluminum extrusion. Here are some essential safety tips:

1. Wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves.

2. Ensure your work area is well-ventilated to avoid inhaling aluminum dust.

3. Never remove safety guards from power tools.

4. Keep your work area clean and free of debris to prevent slips and falls.

5. Disconnect power tools when changing blades or making adjustments.

Advanced Techniques and Tips

For those looking to take their aluminum extrusion cutting skills to the next level, consider these advanced techniques:

1. Using a Stop Block

When making multiple cuts of the same length, use a stop block to ensure consistency. This is particularly useful when working on large projects that require many identical pieces.

2. Creating Custom Jigs

For complex or repetitive cuts, consider creating custom jigs. These can help you maintain accuracy and speed up your workflow, especially when working with T-slot profiles or other specialized extrusions.

3. Finishing Techniques

After cutting, you may need to finish the edges of your aluminum extrusion. Use a file or deburring tool to smooth any rough edges or burrs left by the cutting process. For a more polished look, you can also use sandpaper or a buffing wheel.

Conclusion

Cutting aluminum extrusion may seem daunting at first, but with the right tools, techniques, and safety precautions, you can achieve professional-quality results. Whether you're working on a DIY project or in an industrial setting, mastering the art of cutting aluminum extrusion will open up a world of possibilities for your designs and constructions.

Remember to always prioritize safety, choose the right tools for the job, and practice your technique to improve your skills over time. With patience and persistence, you'll soon be cutting aluminum extrusion like a pro.

Frequently Asked Questions

To help you further, here are five common questions about cutting aluminum extrusion, along with their answers:

Q1: Can I use a wood-cutting blade to cut aluminum extrusion?

A1: While it's possible to use a wood-cutting blade, it's not recommended. Wood-cutting blades have fewer teeth and are not designed for metal, which can lead to rough cuts, blade damage, or even safety hazards. Always use a blade specifically designed for cutting non-ferrous metals like aluminum for the best and safest results.

Q2: How can I prevent the aluminum from melting during cutting?

A2: To prevent melting, use a blade with a high tooth count, apply cutting lubricant or wax, and avoid applying too much pressure. Make sure your cuts are slow and steady, allowing the blade to do the work without generating excessive heat.

Q3: What's the best way to make angled cuts in aluminum extrusion?

A3: A miter saw is ideal for making angled cuts in aluminum extrusion. Set the saw to the desired angle, secure the extrusion firmly, and make the cut slowly and steadily. For complex angles, you may need to use a combination of cuts or create a custom jig.

Q4: How do I cut T-slot aluminum profiles without damaging the slots?

A4: When cutting T-slot profiles, use a blade with a high tooth count and make sure the profile is securely clamped. Cut slowly and steadily to avoid chipping or damaging the slots. You can also insert a piece of scrap material into the slots to provide additional support during cutting.

Q5: Is it necessary to wear a mask when cutting aluminum extrusion?

A5: Yes, it's highly recommended to wear a dust mask or respirator when cutting aluminum extrusion. The cutting process can generate fine aluminum dust, which can be harmful if inhaled. Always work in a well-ventilated area and use proper personal protective equipment to ensure your safety.

By following the techniques and tips outlined in this guide, and keeping these FAQs in mind, you'll be well-equipped to tackle any aluminum extrusion cutting project with confidence and precision.