Content Menu

● Introduction to 2020 Aluminum Extrusion

● What is 2020 Aluminum Extrusion?

● Strength and Properties of 2020 Aluminum Extrusion

● Applications of 2020 Aluminum Extrusion

● Comparing 2020 Aluminum Extrusion to Other Sizes

● Advantages of Using 2020 Aluminum Extrusion

● Tips for Working with 2020 Aluminum Extrusion

● The Future of Aluminum Extrusion in Construction and Engineering

● Conclusion

● Frequently Asked Questions

>> Q1: What is the maximum load capacity of a 2020 aluminum extrusion?

>> Q2: Can 2020 aluminum extrusion be used outdoors?

>> Q3: How do I cut 2020 aluminum extrusion?

>> Q4: Is 2020 aluminum extrusion compatible with 3D printed parts?

>> Q5: How does 2020 aluminum extrusion compare to steel in terms of strength?

Introduction to 2020 Aluminum Extrusion

In the world of construction and engineering, 2020 aluminum extrusion has emerged as a popular choice for various applications. This versatile material offers a unique combination of strength, lightweight properties, and flexibility that makes it ideal for both industrial and DIY projects. In this comprehensive guide, we'll explore the characteristics, applications, and benefits of 2020 aluminum extrusion, as well as compare it to other sizes and materials.

What is 2020 Aluminum Extrusion?

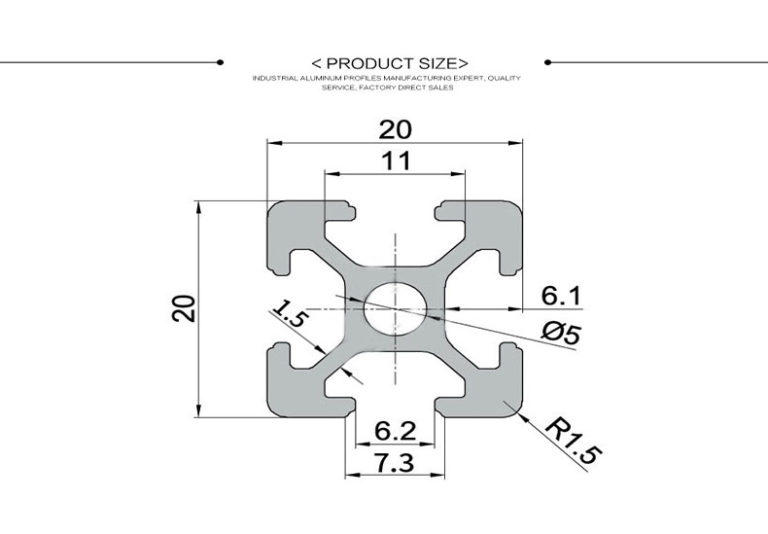

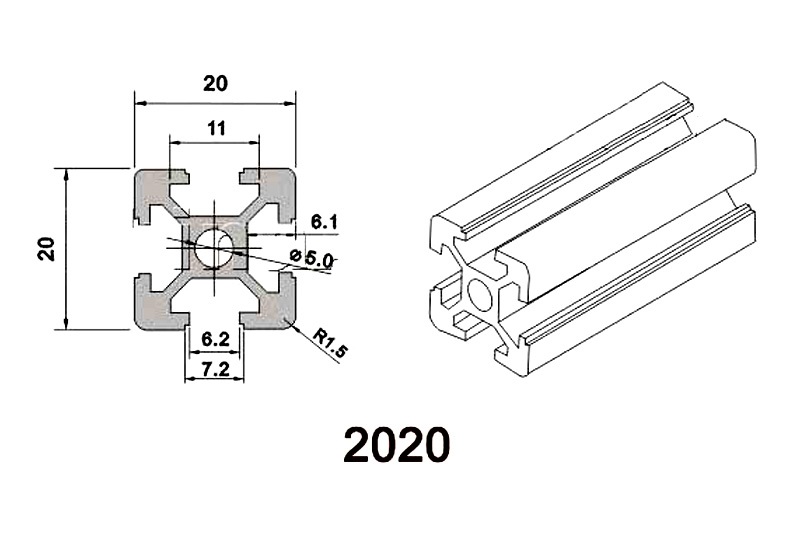

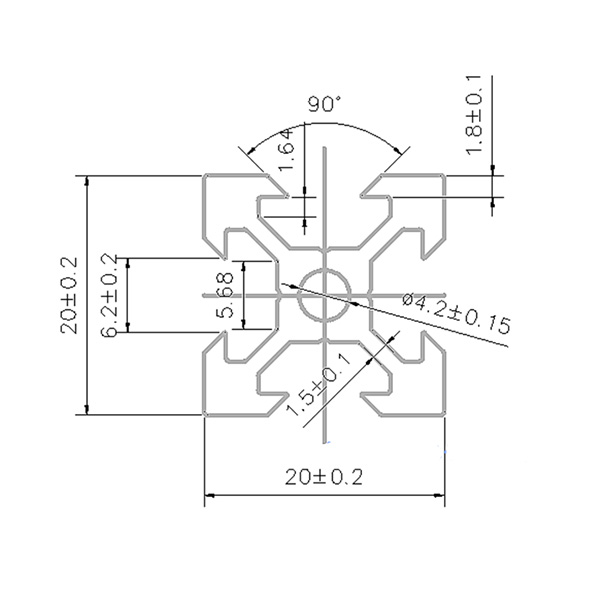

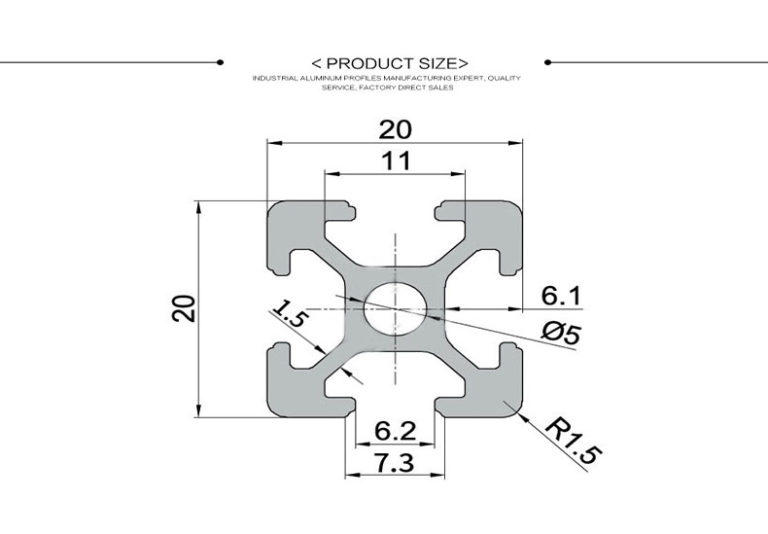

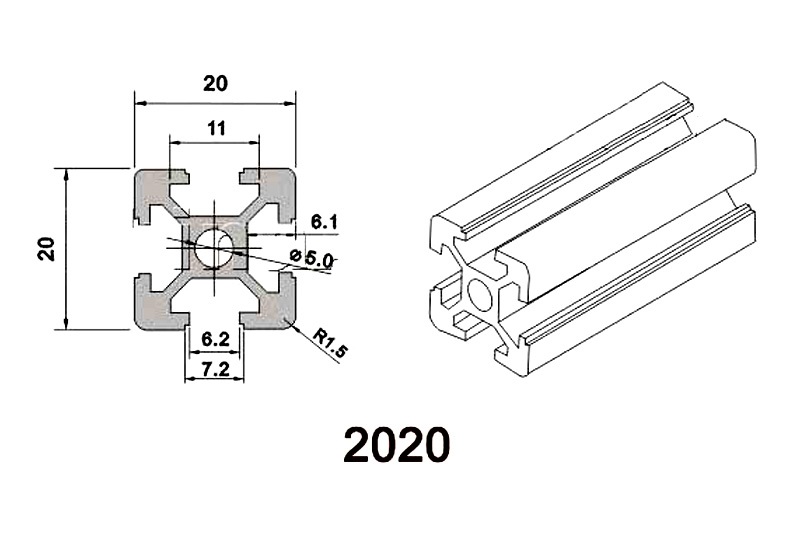

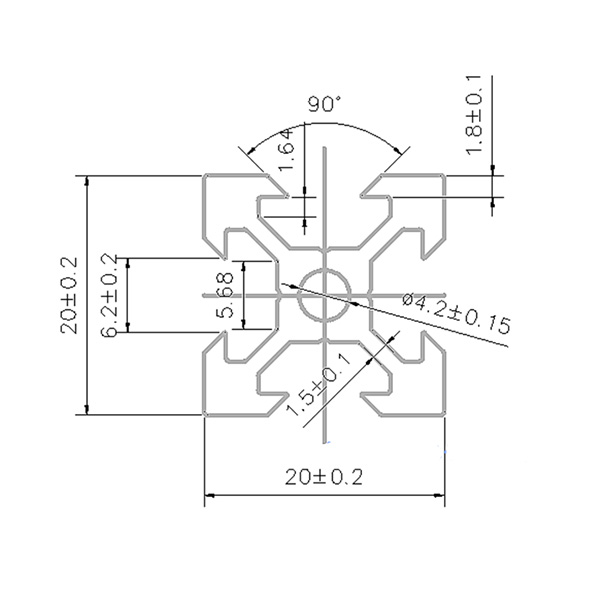

2020 aluminum extrusion refers to a specific profile size of extruded aluminum, typically measuring 20mm x 20mm in cross-section. The term "2020" directly relates to these dimensions. This type of extrusion is part of the broader category of T-slot aluminum profiles, which are characterized by their T-shaped grooves running along the length of the material.

These T-slots are a key feature of the extrusion, allowing for easy attachment of various components and accessories without the need for welding or drilling. This design aspect contributes significantly to the versatility and popularity of 2020 aluminum extrusion in modular framing systems and custom structural applications.

Strength and Properties of 2020 Aluminum Extrusion

One of the most common questions about 2020 aluminum extrusion is regarding its strength. The strength of this material is impressive, especially considering its lightweight nature. Here are some key properties that contribute to its structural integrity:

1. Tensile Strength: The tensile strength of 2020 aluminum extrusion typically ranges between 230-270 MPa, depending on the specific alloy used.

2. Yield Strength: The yield strength is approximately 214 MPa for common alloys used in 2020 extrusions.

3. Bending Strength: The bending strength of 2020 aluminum extrusion is generally between 150-180 MPa.

4. Weight: Despite its strength, 2020 aluminum extrusion is remarkably lightweight, making it easy to handle and transport.

5. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent corrosion resistance without the need for additional treatments.

These properties make 2020 aluminum extrusion an excellent choice for a wide range of applications, from light-duty framing to more demanding industrial uses.

Applications of 2020 Aluminum Extrusion

The versatility of 2020 aluminum extrusion has led to its adoption in numerous industries and applications. Some common uses include:

1. Industrial Machinery: Used in the construction of machine guards, workstations, and conveyor systems.

2. 3D Printers and CNC Machines: Many DIY and commercial 3D printers and CNC machines use 2020 extrusions for their frames.

3. Exhibition Stands: The ease of assembly and disassembly makes it perfect for temporary structures at trade shows and exhibitions.

4. Laboratory Equipment: Clean room environments often utilize aluminum extrusions for their corrosion resistance and ease of cleaning.

5. Automotive Prototyping: Lightweight and strong, these extrusions are ideal for creating prototype vehicle frames and components.

6. Home DIY Projects: From custom furniture to greenhouse structures, 2020 extrusions are popular among hobbyists and DIY enthusiasts.

Comparing 2020 Aluminum Extrusion to Other Sizes

While 2020 is a popular size, it's important to understand how it compares to other common extrusion profiles:

1. 2020 vs. 4040: The 4040 profile (40mm x 40mm) offers greater strength and rigidity compared to 2020, making it suitable for heavier-duty applications. However, it's also heavier and more expensive.

2. 2020 vs. 3030: The 3030 profile (30mm x 30mm) provides a middle ground between 2020 and 4040, offering increased strength over 2020 while maintaining a relatively compact size.

3. 2020 vs. 8020: The term "8020" often refers to a brand of aluminum extrusion rather than a specific size. 8020 extrusions are generally made from higher-strength alloys and come in various sizes, including profiles similar to 2020.

When choosing between these sizes, consider factors such as load requirements, space constraints, and budget. For many applications, 2020 extrusions offer an excellent balance of strength, size, and cost-effectiveness.

Advantages of Using 2020 Aluminum Extrusion

There are several reasons why 2020 aluminum extrusion has become a go-to material for many projects:

1. Modularity: The T-slot design allows for easy assembly and reconfiguration of structures.

2. Lightweight: Despite its strength, aluminum is much lighter than steel, making it easier to work with and transport.

3. Corrosion Resistance: Aluminum's natural oxide layer provides excellent protection against rust and corrosion.

4. Cost-Effective: While not the cheapest material, the longevity and reusability of aluminum extrusions often make them a cost-effective choice in the long run.

5. Aesthetically Pleasing: The clean, modern look of aluminum extrusions is appealing in many applications, from industrial to residential.

6. Customizable: With a wide range of accessories and connectors available, 2020 extrusions can be adapted to suit almost any project requirement.

Tips for Working with 2020 Aluminum Extrusion

If you're planning to use 2020 aluminum extrusion in your next project, here are some helpful tips:

1. Use the Right Tools: Invest in proper cutting tools designed for aluminum to ensure clean, precise cuts.

2. Plan Your Design: Take advantage of CAD software to plan your structure before purchasing materials.

3. Consider Load Distribution: While 2020 extrusions are strong, distribute loads evenly for optimal performance.

4. Use Appropriate Fasteners: Choose fasteners designed for use with T-slot extrusions to ensure secure connections.

5. Maintain Cleanliness: Keep T-slots clean to ensure smooth assembly and prevent issues with connections.

The Future of Aluminum Extrusion in Construction and Engineering

As the demand for lightweight, strong, and versatile materials continues to grow, 2020 aluminum extrusion and similar profiles are likely to play an increasingly important role in various industries. Ongoing research and development in aluminum alloys and extrusion techniques promise even stronger and more versatile profiles in the future.

The trend towards modular and reconfigurable designs in manufacturing and construction aligns perfectly with the strengths of aluminum extrusions. As sustainability becomes a greater concern, the recyclability and longevity of aluminum extrusions make them an attractive option for environmentally conscious projects.

Conclusion

2020 aluminum extrusion represents a perfect balance of strength, versatility, and ease of use. Its wide range of applications, from industrial machinery to DIY projects, demonstrates its adaptability to various needs. By understanding the properties and advantages of this material, engineers, makers, and hobbyists can leverage its strengths to create efficient, durable, and innovative structures and machines.

Whether you're building a 3D printer frame, designing an industrial workstation, or creating custom furniture, 2020 aluminum extrusion offers a reliable and flexible solution. As we continue to push the boundaries of design and engineering, materials like 2020 aluminum extrusion will undoubtedly play a crucial role in shaping the future of construction and manufacturing.

Frequently Asked Questions

Q1: What is the maximum load capacity of a 2020 aluminum extrusion?

A1: The maximum load capacity of a 2020 aluminum extrusion depends on various factors, including the length of the extrusion, the type of load (point load or distributed load), and the specific alloy used. Generally, for a short span under a distributed load, a single 2020 extrusion can support several hundred pounds. However, for precise load calculations, it's best to consult with the manufacturer or a structural engineer.

Q2: Can 2020 aluminum extrusion be used outdoors?

A2: Yes, 2020 aluminum extrusion can be used outdoors. Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance. However, for prolonged outdoor use, especially in harsh environments, it's recommended to use anodized aluminum extrusions or apply a protective coating to enhance durability.

Q3: How do I cut 2020 aluminum extrusion?

A3: 2020 aluminum extrusion can be cut using various methods, including:

- A miter saw with a blade designed for cutting aluminum

- A bandsaw with the appropriate blade

- A hacksaw (for small projects or limited cuts)

It's important to use sharp blades and appropriate cutting speeds to ensure clean cuts and prevent damage to the material.

Q4: Is 2020 aluminum extrusion compatible with 3D printed parts?

A4: Yes, 2020 aluminum extrusion is highly compatible with 3D printed parts. Many 3D printing enthusiasts use 2020 extrusions to build printer frames and combine them with 3D printed brackets, mounts, and other accessories. The T-slots in the extrusion make it easy to attach 3D printed components using appropriate fasteners.

Q5: How does 2020 aluminum extrusion compare to steel in terms of strength?

A5: While steel is generally stronger than aluminum, 2020 aluminum extrusion offers an excellent strength-to-weight ratio. Aluminum is about one-third the weight of steel, making it easier to work with and transport. For many applications, the strength of 2020 aluminum extrusion is more than sufficient, and its lighter weight can be advantageous. However, for extremely high-load applications, steel might be preferred. The choice between aluminum and steel often depends on the specific requirements of the project, including weight constraints, corrosion resistance needs, and budget considerations.