Content Menu

● Understanding Aluminum Extrusion Defects

>> Types of Defects

>> Common Surface Defects

● Causes of Surface Defects

● Preventive Measures

>> 1. Material Selection

>> 2. Proper Lubrication

>> 3. Temperature Control

>> 4. Die Design and Maintenance

>> 5. Handling Practices

● Advanced Techniques for Minimizing Defects

>> 1. Coolant Usage

>> 2. Burp Cycles

>> 3. Quality Control Measures

● Training and Skill Development

>> 1. Operator Training Programs

>> 2. Continuous Improvement Culture

● Case Studies on Successful Implementation

>> Case Study 1: Automotive Industry

>> Case Study 2: Architectural Applications

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are the most common defects in aluminum extrusion?

>> 2. How does lubrication affect aluminum extrusion?

>> 3. What role does temperature play in preventing defects?

>> 4. How can I ensure my aluminum billets are of high quality?

>> 5. What inspection methods can be used to detect defects?

Aluminum extrusion is a widely used manufacturing process that allows for the creation of complex shapes and profiles. However, surface defects can significantly impact the quality and performance of extruded products. Understanding the causes and implementing effective prevention strategies is crucial for manufacturers aiming to minimize these defects. This article explores common aluminum extrusion defects and remedies, providing insights into how to achieve high-quality extrusions.

Understanding Aluminum Extrusion Defects

Types of Defects

Aluminum extrusion defects can be categorized into three main types:

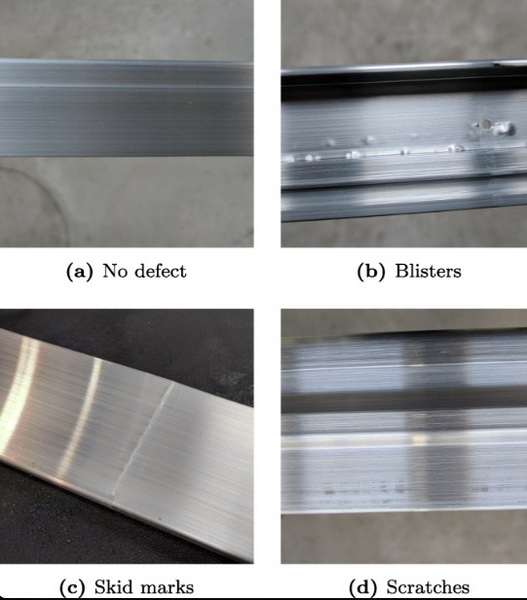

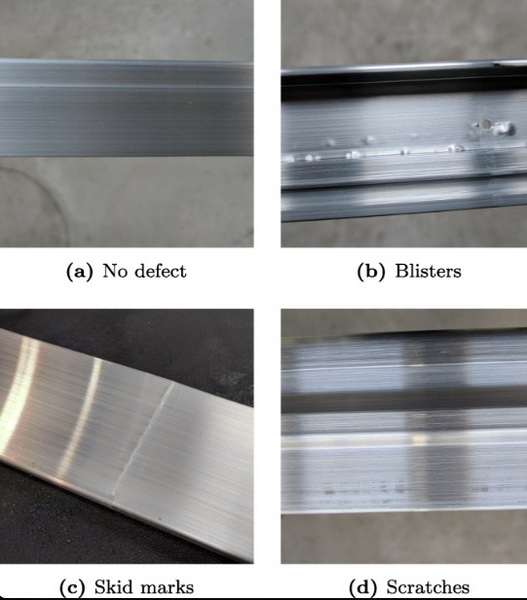

1. Surface Defects: These include scratches, streaks, and die lines that affect the appearance of the extruded product.

2. Dimensional Defects: These involve inaccuracies in the dimensions of the extruded profiles, impacting their fit and function.

3. Internal Defects: These are not visible on the surface but can compromise the structural integrity of the product.

Common Surface Defects

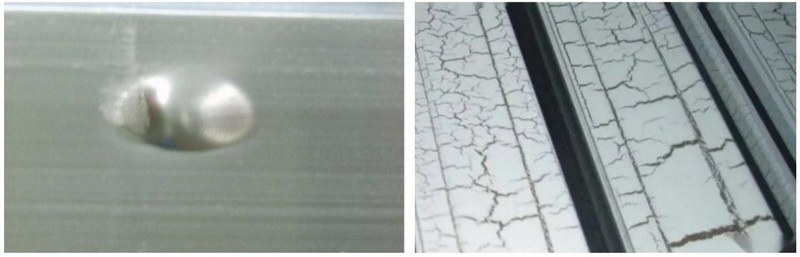

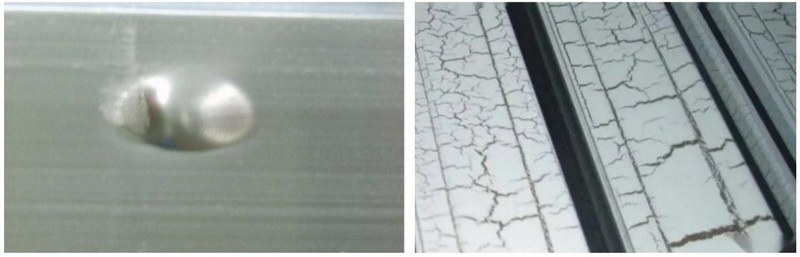

- Scratches: Superficial abrasions caused by contact with other materials during handling or extrusion.

- Streaks: Variations in surface finish often due to inconsistent material flow or contamination.

- Die Lines: Marks left on the surface due to poor die conditions or wear.

Causes of Surface Defects

Understanding the root causes of surface defects is essential for prevention. Some primary factors include:

- Material Quality: Poor quality billets can contain impurities that lead to defects.

- Extrusion Process Parameters: Incorrect temperature, speed, and pressure can cause excessive deformation or poor metal flow.

- Handling Practices: Rough handling or inadequate cleaning can introduce scratches and contaminants.

Preventive Measures

1. Material Selection

Choosing high-quality aluminum alloys is critical. Alloys should be free from pores, cracks, and impurities to minimize susceptibility to defects. Manufacturers should consider:

- Alloy Composition: Select alloys with good deformation properties. Alloys such as 6061 and 6063 are popular choices due to their excellent mechanical properties and surface finish capabilities.

- Billet Quality: Ensure billets are well-cast and free from defects before extrusion. Regular testing for chemical composition and physical properties can help maintain quality.

2. Proper Lubrication

Lubrication plays a vital role in reducing friction during the extrusion process. Using high-quality lubricants helps prevent scratches and improves surface finish. Key practices include:

- Lubricant Selection: Use lubricants that are compatible with aluminum and provide adequate coverage. Water-soluble lubricants are often preferred for their effectiveness in cooling and lubrication.

- Application Techniques: Ensure uniform application of lubricant on dies and extruder surfaces. Automated lubrication systems can help maintain consistency.

3. Temperature Control

Maintaining optimal temperatures throughout the extrusion process is crucial for preventing defects. Strategies include:

- Isothermal Extrusion: Implement temperature control techniques to maintain consistent temperatures at the die outlet. This helps in achieving uniform material flow.

- Preheating Billets: Preheat billets to remove moisture and ensure uniform flow during extrusion. The preheating temperature should be carefully monitored to avoid overheating.

4. Die Design and Maintenance

The design and condition of extrusion dies significantly affect product quality. Manufacturers should focus on:

- Die Selection: Choose dies made from wear-resistant materials to reduce wear and tear. Tool steels or carbide-coated dies can enhance durability.

- Regular Maintenance: Conduct routine inspections and maintenance to keep dies clean and in good condition. Regular polishing can help maintain a smooth die surface, which is critical for preventing die lines.

5. Handling Practices

Proper handling of extruded products is essential to prevent damage post-extrusion. Best practices include:

- Careful Handling: Train staff on proper handling techniques to avoid scratching surfaces. Using padded equipment or protective coverings can help safeguard finished products.

- Cleaning Procedures: Implement cleaning protocols for both tools and work environments to minimize contamination. Regular cleaning schedules should be established for all equipment involved in the extrusion process.

Advanced Techniques for Minimizing Defects

In addition to basic preventive measures, manufacturers can adopt advanced techniques to further enhance product quality:

1. Coolant Usage

Using coolants such as liquid nitrogen can help manage temperatures during extrusion, reducing friction and minimizing defects. Coolants also aid in maintaining die temperature stability, which is crucial for consistent product quality.

2. Burp Cycles

Implementing burp cycles during extrusion allows trapped air or moisture to escape, preventing blistering in aluminum profiles. This technique involves periodic pauses during the extrusion process, allowing gases to vent out without compromising material flow.

3. Quality Control Measures

Regular inspection using advanced techniques such as ultrasonic testing can help identify defects early in the production process. Employing non-destructive testing methods ensures that internal flaws are detected before products reach customers.

Training and Skill Development

An often-overlooked aspect of preventing aluminum extrusion defects is workforce training. Skilled operators are essential for maintaining quality throughout the extrusion process.

1. Operator Training Programs

Implement comprehensive training programs for operators that cover:

- Understanding Extrusion Mechanics: Educate staff about how material properties affect extrusion outcomes.

- Identifying Defect Causes: Train operators to recognize signs of potential defects early in the process.

2. Continuous Improvement Culture

Encourage a culture of continuous improvement where employees feel empowered to suggest changes that could enhance product quality or streamline processes.

Case Studies on Successful Implementation

Several companies have successfully implemented measures to reduce surface defects in aluminum extrusion processes, leading to improved product quality and customer satisfaction.

Case Study 1: Automotive Industry

A leading automotive parts manufacturer faced challenges with surface defects on extruded components used in vehicle frames. By investing in high-quality alloys and upgrading their lubrication systems, they reduced defect rates by over 30% within six months.

Case Study 2: Architectural Applications

An architectural supplier specializing in aluminum window frames implemented rigorous temperature control measures alongside advanced die maintenance protocols. As a result, they achieved a significant improvement in surface finish consistency, leading to increased market share.

Conclusion

Preventing surface defects in aluminum extrusion requires a comprehensive approach that encompasses material selection, process control, lubrication, die maintenance, handling practices, operator training, and continuous improvement initiatives. By implementing these strategies effectively, manufacturers can significantly enhance the quality of their extruded products, ensuring they meet customer standards and expectations while reducing waste and production costs.

Frequently Asked Questions (FAQs)

1. What are the most common defects in aluminum extrusion?

Common defects include scratches, streaks, die lines, porosity, inclusions, and cracks.

2. How does lubrication affect aluminum extrusion?

Proper lubrication reduces friction between aluminum and die surfaces, minimizing scratches and improving surface finish.

3. What role does temperature play in preventing defects?

Maintaining optimal temperatures ensures uniform metal flow during extrusion, reducing the likelihood of defects such as tearing or blistering.

4. How can I ensure my aluminum billets are of high quality?

Select billets that are free from impurities, properly cast, and have good deformation properties.

5. What inspection methods can be used to detect defects?

Advanced inspection techniques such as ultrasonic testing can help identify internal defects that may not be visible on the surface.