Content Menu

● Introduction to Extrusion Granulator Machinery

>> Plastic Extrusion Granulator Machinery

>> Fertilizer Extrusion Granulator Machinery

● Working Principle of Extrusion Granulator Machinery

>> Plastic Recycling Extrusion Granulation

>> Fertilizer Extrusion Granulation

● Types of Extrusion Granulator Machinery

>> 1. Double Roller Extrusion Granulator

>> 2. Plastic Extrusion Granulator

>> 3. Basket Granulator

● Applications of Extrusion Granulator Machinery

>> Advantages in Plastics Recycling

>> Benefits in Fertilizer Production

>> Role in Pharmaceuticals

● Technical Considerations for Extrusion Granulator Machinery

>> Material Selection

>> Energy Efficiency

>> Maintenance Practices

● Future Developments in Extrusion Granulator Technology

>> Sustainable Materials

>> Automation and AI Integration

>> Energy Harvesting Technologies

● Conclusion

● FAQ

>> 1. What is the primary function of an extrusion granulator in the plastics industry?

>> 2. How does a double roller fertilizer granulator work?

>> 3. What are the advantages of using a basket granulator in pharmaceutical applications?

>> 4. How does the heating and cooling system contribute to the efficiency of plastic extrusion granulators?

>> 5. What maintenance practices can extend the lifespan of a double roller fertilizer granulator?

Extrusion granulator machinery is a crucial piece of equipment in various industries, including plastics, fertilizers, and pharmaceuticals. It plays a vital role in transforming raw materials into uniform granules or pellets, which are essential for further processing or direct application. This article delves into the working principles, types, and applications of extrusion granulator machinery, providing insights into its significance across different sectors.

Introduction to Extrusion Granulator Machinery

Extrusion granulator machinery is designed to process materials by applying pressure and heat, depending on the type of material being processed. In the plastics industry, it is used to recycle plastic waste into reusable granules. For fertilizers, it compacts powders into pellets, enhancing their handling and application efficiency. In pharmaceuticals, it helps in creating uniform drug pellets for controlled release formulations.

Plastic Extrusion Granulator Machinery

In the plastics sector, extrusion granulators are primarily used for recycling. They transform plastic waste into granules that can be reused in manufacturing new plastic products. The process involves melting the plastic, extruding it into strands, and then cutting these strands into granules.

Key Components of Plastic Extrusion Granulator Machinery:

1. Extruder System: This includes the screw, barrel, hopper, die head, and mold. The screw and barrel work together to melt and plasticize the plastic material.

- Screw: Made from high-strength alloy steel, it is crucial for the efficiency of the granulator.

- Barrel: Typically made from alloy steel, it provides heat resistance and compressive strength.

- Hopper: Feeds plastic into the system with a cutting device for material flow regulation.

- Die Head and Mold: Converts the melt into a linear flow and shapes it into strands.

2. Transmission System: Powers the extruder.

3. Heating and Cooling System: Maintains optimal temperatures for plasticization.

4. Control System: Ensures precise control over temperature, pressure, and speed.

Fertilizer Extrusion Granulator Machinery

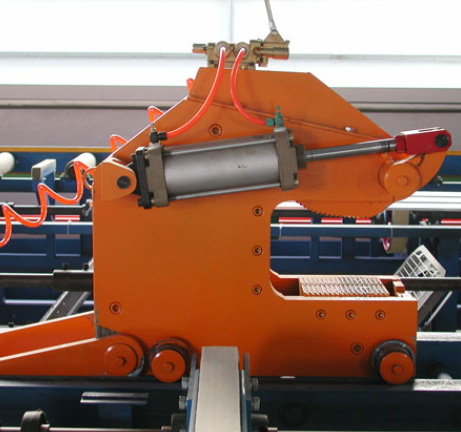

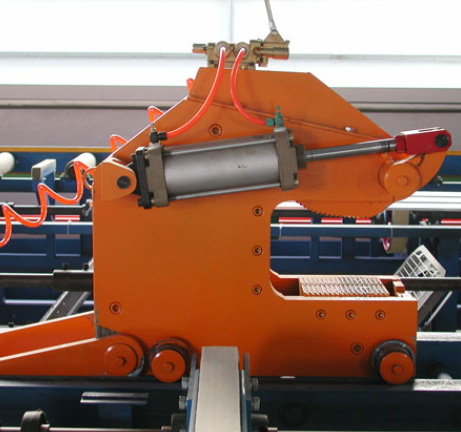

Fertilizer extrusion granulators are used to compact powders into pellets, enhancing their storage and application efficiency. The most common type is the double roller extrusion granulator.

Key Features of Double Roller Fertilizer Granulator:

1. No Drying Process: Works at normal temperatures without drying.

2. Low Energy Consumption: Saves energy and reduces costs.

3. Compact Structure: Easy to operate and maintain.

4. Corrosion-Resistant Rollers: Made from durable materials for longevity.

Working Principle of Extrusion Granulator Machinery

The working principle of extrusion granulator machinery varies depending on the application:

Plastic Recycling Extrusion Granulation

1. Melting and Extrusion: Plastic waste is melted and extruded into strands.

2. Cutting: The strands are then cut into granules using a cutting system.

3. Cooling and Drying: Granules are cooled and dried for packaging.

Fertilizer Extrusion Granulation

1. Material Mixing: Fertilizer powders are mixed in a specific ratio.

2. Extrusion: Mixed material is fed into the granulator and compacted into pellets.

3. Screening: Pellets are screened to ensure uniform size.

Types of Extrusion Granulator Machinery

1. Double Roller Extrusion Granulator

- Application: Fertilizers, pharmaceuticals, and chemicals.

- Features: No drying process, low energy consumption, compact structure.

2. Plastic Extrusion Granulator

- Application: Plastic recycling.

- Features: High efficiency, precise temperature control, robust construction.

3. Basket Granulator

- Application: Pharmaceutical and chemical industries.

- Features: Uniform granulation, easy operation, GMP compliance.

Applications of Extrusion Granulator Machinery

Extrusion granulator machinery is versatile and finds applications across various sectors:

- Plastics Recycling: Converts plastic waste into reusable granules.

- Fertilizer Production: Compacts powders into pellets for efficient application.

- Pharmaceuticals: Creates uniform drug pellets for controlled release formulations.

Advantages in Plastics Recycling

1. Environmental Benefits: Reduces plastic waste by recycling it into usable materials.

2. Cost Savings: Recycled granules are cheaper than virgin materials.

3. Consistency: Ensures uniformity in the quality of recycled plastic products.

Benefits in Fertilizer Production

1. Improved Handling: Pellets are easier to store and transport compared to powders.

2. Efficient Application: Uniform pellets ensure consistent fertilizer distribution.

3. Reduced Waste: Minimizes dust and waste during application.

Role in Pharmaceuticals

1. Uniformity: Ensures consistent drug release profiles.

2. Controlled Release: Allows for tailored drug delivery systems.

3. Compliance: Meets stringent pharmaceutical manufacturing standards.

Technical Considerations for Extrusion Granulator Machinery

When selecting or operating extrusion granulator machinery, several technical considerations must be taken into account:

Material Selection

The choice of material for the granulator components is critical. For instance, in fertilizer production, corrosion-resistant materials are essential to prevent chemical reactions with the fertilizers.

Energy Efficiency

Optimizing energy consumption is vital for cost-effective operation. Modern granulators often incorporate energy-saving technologies to reduce operational costs.

Maintenance Practices

Regular maintenance is crucial for extending the lifespan of the machinery. This includes cleaning, lubricating moving parts, and ensuring proper alignment of rollers.

Future Developments in Extrusion Granulator Technology

As technology advances, extrusion granulator machinery is expected to become more efficient and environmentally friendly. Innovations in materials science and automation will play a significant role in enhancing the performance and sustainability of these machines.

Sustainable Materials

The use of sustainable materials in granulator construction can reduce environmental impact. This includes using recycled metals and designing components for recyclability.

Automation and AI Integration

Integrating automation and AI can optimize production processes, improve product quality, and reduce labor costs. Predictive maintenance enabled by AI can also minimize downtime.

Energy Harvesting Technologies

Incorporating energy-harvesting technologies, such as solar panels or kinetic energy recovery systems, can further reduce the carbon footprint of extrusion granulator operations.

Conclusion

Extrusion granulator machinery is a vital tool in transforming raw materials into usable granules or pellets. Its applications span plastics recycling, fertilizer production, and pharmaceutical manufacturing. Understanding the working principles and types of extrusion granulators can help industries optimize their production processes and improve product quality.

FAQ

1. What is the primary function of an extrusion granulator in the plastics industry?

The primary function of an extrusion granulator in the plastics industry is to recycle plastic waste by transforming it into reusable granules. This process involves melting the plastic, extruding it into strands, and then cutting these strands into granules.

2. How does a double roller fertilizer granulator work?

A double roller fertilizer granulator works by compacting mixed fertilizer powders into pellets. It uses two counter-rotating rollers to apply pressure, eliminating the need for a drying process. This results in pellets with improved handling and application efficiency.

3. What are the advantages of using a basket granulator in pharmaceutical applications?

Basket granulators offer uniform granulation, easy operation, and compliance with GMP standards. They are suitable for processing wet materials and can produce granules with a controlled diameter, making them ideal for pharmaceutical applications.

4. How does the heating and cooling system contribute to the efficiency of plastic extrusion granulators?

The heating and cooling system in plastic extrusion granulators ensures that the plastic material is melted and plasticized efficiently. Accurate temperature control is crucial for maintaining the quality of the granules produced.

5. What maintenance practices can extend the lifespan of a double roller fertilizer granulator?

Regular cleaning and maintenance of the rollers can extend the lifespan of a double roller fertilizer granulator. Ensuring proper alignment and lubrication of moving parts also helps in preventing wear and tear.