Content Menu

● Aluminum Extruder Definition

● The Aluminum Extrusion Process

>> 1. Die Preparation

>> 2. Billet Preheating

>> 3. Extrusion Process

>> 4. Cooling and Quenching

>> 5. Stretching and Cutting

● Types of Aluminum Extrusion Processes

>> Hot Extrusion

>> Cold Extrusion

● Applications of Aluminum Extrusions

● Benefits of Aluminum Extrusions

● Challenges in Aluminum Extrusion

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQs

>> 1. What materials can be extruded besides aluminum?

>> 2. How does temperature affect the extrusion process?

>> 3. What are common defects in extruded products?

>> 4. Can I customize my aluminum extrusion design?

>> 5. How do I choose between hot and cold extrusion?

● Citations:

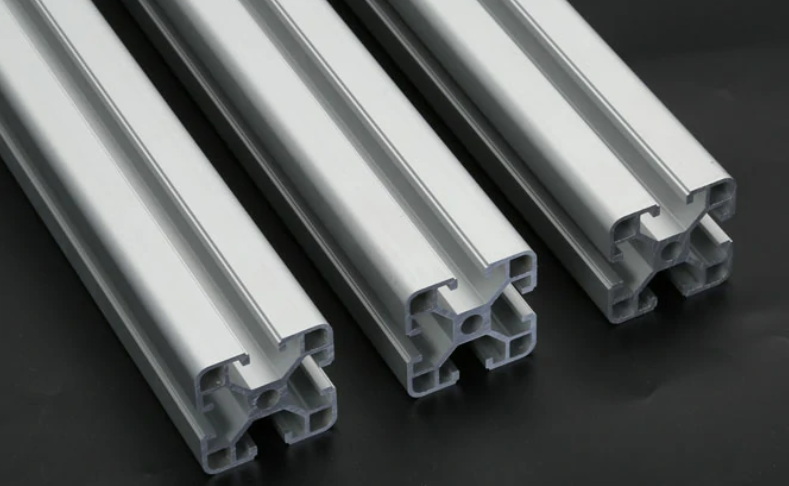

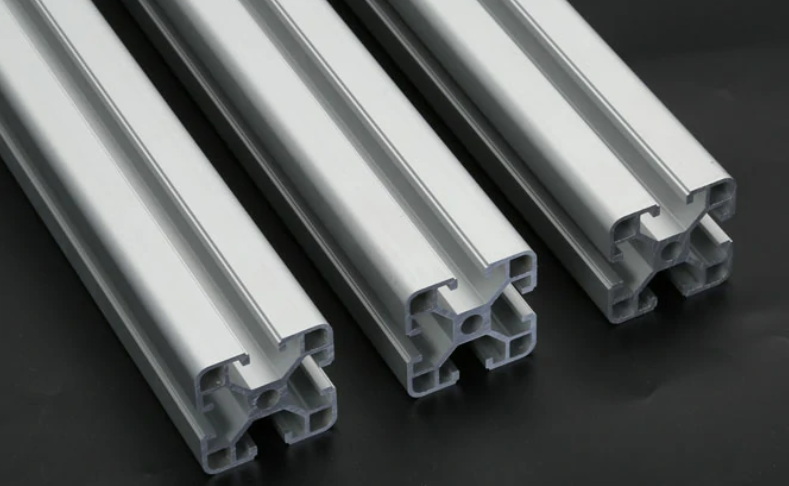

Aluminum extrusion is a manufacturing process that shapes aluminum into specific forms by forcing it through a die. This technique is widely used in various industries due to aluminum's unique properties, such as lightweight, strength, and corrosion resistance. In this article, we will explore the definition of an aluminum extruder, how it works, the processes involved, applications, and much more.

Aluminum Extruder Definition

An aluminum extruder is a machine or system designed to transform aluminum billets (solid blocks of aluminum) into elongated shapes with specific cross-sectional profiles. The process involves heating the aluminum to make it malleable and then using hydraulic pressure to push it through a die, resulting in a continuous length of material that retains the shape of the die opening.

The Aluminum Extrusion Process

The process of aluminum extrusion can be broken down into several key steps:

1. Die Preparation

Before extrusion begins, the die must be meticulously designed and prepared. The die is made from hardened steel and is crafted to create the desired profile of the extruded aluminum. The design can be simple or complex, depending on the end product requirements.

2. Billet Preheating

Aluminum billets are preheated in an oven to temperatures ranging from 400°C to 500°C (750°F to 930°F). This heating process softens the metal, making it easier to extrude. The exact temperature depends on the specific alloy being used.

3. Extrusion Process

Once the billets are heated, they are placed in a container within the extrusion press. A hydraulic ram applies significant force (up to 15,000 tons) to push the softened aluminum through the die. As pressure builds up, the aluminum flows through the die opening and emerges as a continuous profile.

4. Cooling and Quenching

After exiting the die, the extruded aluminum is guided along a runout table where it is cooled rapidly—often by water or air quenching—to set its shape and prevent deformation.

5. Stretching and Cutting

Once cooled, the extrusions may undergo stretching to eliminate any distortions that occurred during the extrusion process. They are then cut into specified lengths for further processing or shipping.

Types of Aluminum Extrusion Processes

There are two primary methods for aluminum extrusion: hot extrusion and cold extrusion.

Hot Extrusion

In hot extrusion, the aluminum is heated before being forced through the die. This method allows for easier shaping of complex profiles and is typically used for larger sections or more intricate designs.

- Advantages:

- Lower pressure required

- Ability to create complex shapes

- Faster production rates

- Disadvantages:

- Surface finish may not be as smooth as cold-extruded products

Cold Extrusion

Cold extrusion involves shaping aluminum at room temperature or slightly elevated temperatures. This method produces stronger parts with superior surface finishes but requires higher pressures.

- Advantages:

- Higher strength due to work hardening

- Better surface finish

- More precise tolerances

- Disadvantages:

- Limited to simpler shapes

- Higher energy costs due to increased pressure requirements

Applications of Aluminum Extrusions

Aluminum extrusions have a wide range of applications across various industries:

- Construction: Used for window frames, doors, curtain walls, and structural components.

- Automotive: Lightweight components such as chassis parts and heat exchangers improve fuel efficiency.

- Aerospace: Components like fuselage frames and wing structures take advantage of aluminum's strength-to-weight ratio.

- Consumer Products: Items like furniture frames, appliances, and sporting goods utilize extruded aluminum for durability and aesthetics.

- Electronics: Heat sinks and enclosures benefit from aluminum's thermal conductivity and lightweight properties.

Benefits of Aluminum Extrusions

Aluminum extrusions offer numerous advantages:

- Lightweight yet Strong: Aluminum has a high strength-to-weight ratio, making it ideal for applications where weight savings are critical.

- Corrosion Resistance: The natural oxide layer that forms on aluminum protects it from corrosion without additional coatings.

- Versatile Design Options: The extrusion process allows for complex shapes that can be tailored to specific applications.

- Recyclability: Aluminum is highly recyclable without loss of properties, making it an environmentally friendly choice.

Challenges in Aluminum Extrusion

While there are many benefits to using aluminum extrusions, there are also challenges:

- Cost of Tooling: Designing and manufacturing dies can be expensive, especially for custom profiles.

- Temperature Control: Maintaining consistent temperatures during preheating is crucial for achieving desired mechanical properties.

- Quality Control: Ensuring uniformity in thickness and profile can be challenging during large-scale production runs.

Future Trends in Aluminum Extrusion

The future of aluminum extrusion looks promising with advancements in technology:

- Automation: Increased automation in extrusion processes enhances efficiency and reduces labor costs.

- Sustainability Practices: Manufacturers are focusing on reducing waste and energy consumption throughout the extrusion process.

- Innovative Alloys: Development of new aluminum alloys with enhanced properties opens up new possibilities for applications.

Conclusion

Aluminum extruders play a crucial role in transforming raw materials into functional components used across various industries. Understanding how these machines work helps manufacturers optimize their processes and create high-quality products that meet customer demands. With ongoing advancements in technology and growing emphasis on sustainability, the future of aluminum extrusion holds significant potential for innovation.

FAQs

1. What materials can be extruded besides aluminum?

While this article focuses on aluminum extrusions, other materials such as copper, magnesium, and plastics can also be extruded using similar processes.

2. How does temperature affect the extrusion process?

Temperature significantly influences material flow; higher temperatures make metals more malleable but may affect surface finish quality.

3. What are common defects in extruded products?

Common defects include surface imperfections like scratches or dents, dimensional inaccuracies, and internal voids or cracks due to improper processing conditions.

4. Can I customize my aluminum extrusion design?

Yes! Custom dies can be created based on specific design requirements to achieve unique profiles tailored for particular applications.

5. How do I choose between hot and cold extrusion?

The choice between hot and cold extrusion depends on factors such as desired strength, complexity of shape, production volume, and cost considerations.

Citations:

[1] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[2] https://www.kloecknermetals.com/blog/what-are-aluminum-extrusions/

[3] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[4] https://orangealuminum.com/blog/aluminum-extrusion-glossary-terms-and-definitions/

[5] https://aec.org/aluminum-extrusion-process

[6] https://cncpartsxtj.com/cnc-machining/cnc-machine-tools/what-is-aluminum-extrusion/

[7] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[8] https://eagle-aluminum.com/what-is-extruded-aluminum/

[9] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[10] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[11] https://www.howardprecision.com/what-is-an-aluminum-extrusion-and-what-are-aluminum-extrusions-used-for/

[12] https://en.wikipedia.org/wiki/Extrusion

[13] https://www.ccmfg.net/what-is-aluminum-extrusion/

[14] https://www.chiefdelphi.com/t/definition-of-aluminum-extrusion/29159

[15] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[16] https://waykenrm.com/blogs/aluminum-extrusion/

[17] https://www.kloecknermetals.com/blog/what-are-aluminum-extrusions/

[18] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

[19] https://aec.org/features-benefits

[20] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[21] https://www.gabrian.com/6-key-reasons-to-choose-aluminum-extrusions-for-your-project/

[22] https://aec.org/industries

[23] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[24] https://aec.org/auto-industry

[25] https://taberextrusions.com/why-engineers-prefer-aluminum-extrusion/

[26] https://www.youtube.com/watch?v=lWWlLIW9tgA

[27] https://aec.org/aluminum-extrusion-process

[28] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[29] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[30] https://almag.com/education/all-about-extrusion/

[31] https://hackaday.com/2020/08/13/under-pressure-how-aluminum-extrusions-are-made/

[32] https://www.youtube.com/watch?v=ELgtjeJyFw8

[33] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[34] https://profileprecisionextrusions.com/benefits/

[35] https://www.odmetals.com/blog/6-applications-for-aluminum-extrusionsv

[36] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[37] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[38] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[39] https://amcaluminum.ph/common-applications-of-aluminum-extrusion/

[40] https://haluminium.com/Product/aluminum-extrusion-molding/