Content Menu

● Understanding Aluminum Extrusions

>> Advantages of Aluminum Extrusions

● Getting Started with Fusion 360

>> Setting Up Your Workspace

● Designing the Aluminum Extrusion Profile

>> Step 1: Create a New Sketch

>> Step 2: Draw the Profile

>> Step 3: Dimensioning Your Sketch

>> Step 4: Extrude the Profile

● Adding Features to Your Extrusion

>> Step 5: Creating Holes

>> Step 6: Applying Fillets and Chamfers

● Assembling Multiple Extrusions

>> Step 7: Importing Existing Models

>> Step 8: Aligning Components

● Finalizing Your Design

● Exporting Your Design

● Tips for Effective Design in Fusion 360

● Advanced Techniques in Aluminum Extrusion Design

>> Creating Complex Profiles with Multi-Sketches

>> Simulation and Stress Testing

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion?

>> 2. Can I import existing aluminum extrusion profiles into Fusion 360?

>> 3. How do I create complex shapes using aluminum extrusions in Fusion 360?

>> 4. What are some common applications of aluminum extrusions?

>> 5. Is there a way to automate repetitive tasks when designing extrusions?

● Citations:

Designing aluminum extrusions in Fusion 360 is a powerful way to create custom parts for various applications, from structural frames to intricate components. This article will guide you through the process of designing aluminum extrusions in Fusion 360, covering everything from initial sketches to final assembly. We will also include illustrative images and videos to enhance your understanding.

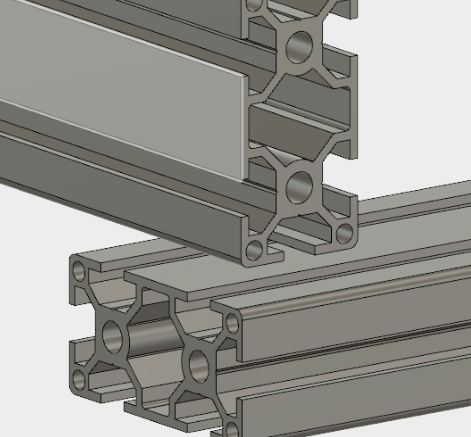

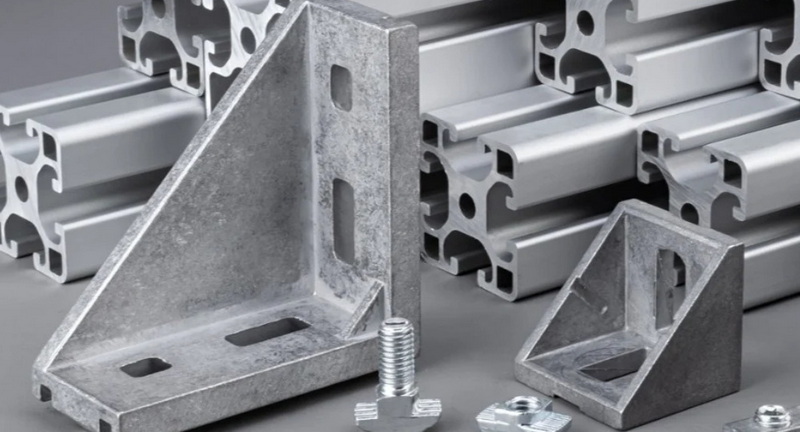

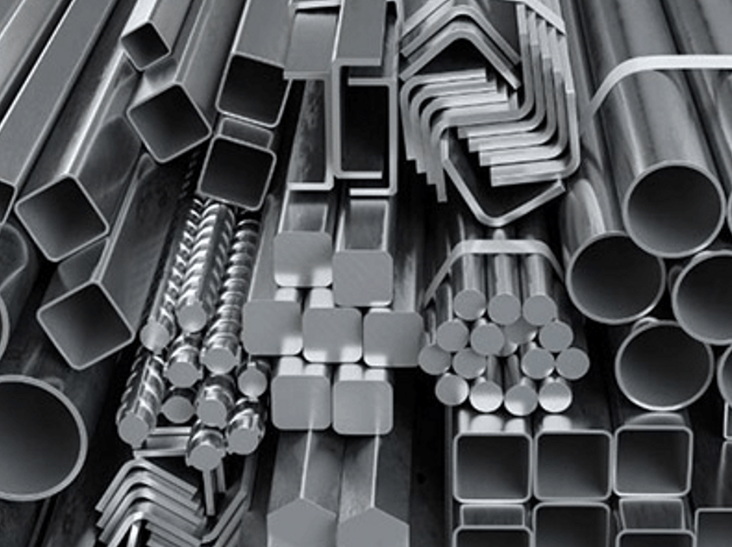

Understanding Aluminum Extrusions

Aluminum extrusions are created by forcing aluminum alloy through a die to create long shapes with a consistent cross-section. These shapes can be used in various applications, including construction, automotive, and aerospace industries. The benefits of using aluminum extrusions include their lightweight nature, strength, and resistance to corrosion.

Advantages of Aluminum Extrusions

- Lightweight: Aluminum is much lighter than steel, making it ideal for applications where weight is a concern.

- Strength: Despite being lightweight, aluminum has a high strength-to-weight ratio, which allows for strong structures without excessive weight.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that helps resist corrosion, making it suitable for outdoor applications.

- Versatility: Aluminum extrusions can be easily shaped into complex profiles, allowing for creative designs that meet specific needs.

Getting Started with Fusion 360

Before diving into the design process, ensure you have Autodesk Fusion 360 installed on your computer. This CAD software is versatile and user-friendly, making it ideal for both beginners and experienced designers.

Setting Up Your Workspace

1. Open Fusion 360: Launch the application and create a new project.

2. Create a New Design: Click on "File" > "New Design" to start a fresh workspace.

3. Familiarize Yourself with the Interface: Take a moment to explore the toolbar and navigation tools.

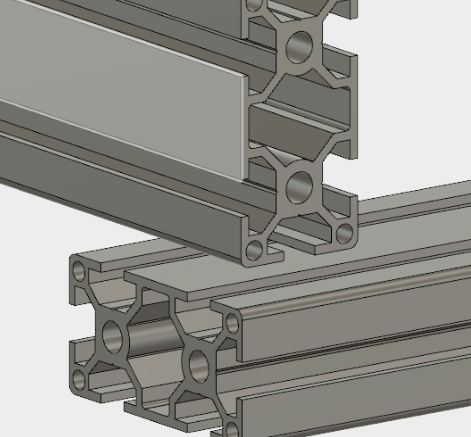

Designing the Aluminum Extrusion Profile

To design an aluminum extrusion in Fusion 360, follow these steps:

Step 1: Create a New Sketch

- Select the plane where you want to create your extrusion profile (e.g., the front plane).

- Click on "Create Sketch" from the toolbar.

Step 2: Draw the Profile

- Use the Rectangle Tool or Line Tool to draw the outline of your extrusion profile.

- For example, if you are designing a simple rectangular profile, you might draw a rectangle with dimensions of 20 mm x 40 mm.

Step 3: Dimensioning Your Sketch

- Use the Dimension Tool (shortcut 'D') to specify exact measurements for your profile.

- Ensure that all dimensions are constrained properly for accurate modeling.

Step 4: Extrude the Profile

- Finish your sketch by clicking on "Finish Sketch."

- Select the profile you just created and click on "Create" > "Extrude."

- Enter the desired length for your extrusion (e.g., 100 mm) and click OK.

Adding Features to Your Extrusion

Once you have your basic extrusion shape, you can add features such as holes, slots, or fillets.

Step 5: Creating Holes

1. Create a New Sketch on one of the faces of your extrusion.

2. Use the Circle Tool to place holes where needed.

3. Dimension these holes appropriately.

4. Finish the sketch and use the Extrude Tool again, selecting "Cut" to remove material for the holes.

Step 6: Applying Fillets and Chamfers

- To smooth out edges or create beveled edges, use the Fillet or Chamfer tools found under "Modify."

- Select edges and specify the radius or angle for your fillet or chamfer.

Assembling Multiple Extrusions

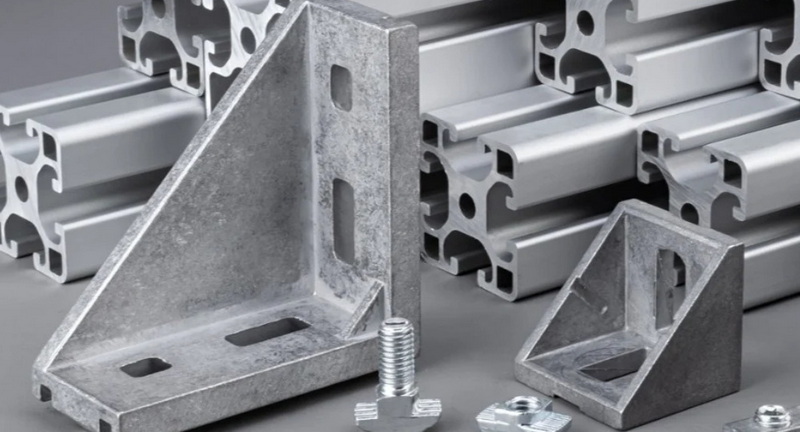

For complex designs, you may need to assemble multiple extrusions together.

Step 7: Importing Existing Models

You can import existing aluminum extrusion profiles from libraries like GrabCAD or other sources:

1. Download a STEP file of an extrusion profile.

2. In Fusion 360, go to "Insert" > "Insert CAD File" and select your downloaded file.

3. Position it in your workspace as needed.

Step 8: Aligning Components

To align multiple components:

1. Use the Move Tool (shortcut 'M') to position components accurately.

2. Utilize the Align Tool under "Assemble" to ensure parts fit together correctly.

Finalizing Your Design

After assembling all components:

1. Review your design for any necessary adjustments.

2. Use the Inspect Tool to check clearances and fit between parts.

3. Save your project frequently to avoid losing work.

Exporting Your Design

Once satisfied with your design:

1. Go to "File" > "Export."

2. Choose your preferred file format (e.g., STL for 3D printing).

3. Specify export settings and save it.

Tips for Effective Design in Fusion 360

To enhance your design experience in Fusion 360 when working on aluminum extrusions:

- Utilize Parameters: Set up parameters for dimensions that may change frequently. This allows you to adjust sizes without redrawing everything.

- Use Components Wisely: Organize different parts of your design into components. This makes it easier to manage complex assemblies.

- Leverage Patterns: If you need multiple identical features (like holes), use pattern tools instead of creating each one individually.

- Explore Add-ins: Consider using add-ins available in Fusion 360 that can help streamline processes specific to aluminum extrusion design.

Advanced Techniques in Aluminum Extrusion Design

For users looking to take their designs further, consider implementing some advanced techniques:

Creating Complex Profiles with Multi-Sketches

You can create more intricate profiles by utilizing multiple sketches:

1. Create several sketches on different planes or faces of your extrusion.

2. Use these sketches as reference points when adding features like ribs or cutouts.

Simulation and Stress Testing

Fusion 360 offers simulation capabilities that allow you to test how your design will perform under real-world conditions:

1. Use the Simulation workspace within Fusion 360.

2. Apply loads and constraints similar to those expected in actual use cases.

3. Analyze results to identify potential weaknesses in your design before manufacturing.

Conclusion

Designing aluminum extrusions in Fusion 360 opens up endless possibilities for creating custom components tailored to specific needs. By following these steps—sketching profiles, adding features, assembling parts—you can efficiently produce intricate designs ready for manufacturing or prototyping. The versatility of Fusion 360 combined with aluminum's advantageous properties makes this process not only effective but also enjoyable.

FAQ

1. What is an aluminum extrusion?

An aluminum extrusion is a process where aluminum alloy is forced through a die to create long shapes with a consistent cross-section used in various applications.

2. Can I import existing aluminum extrusion profiles into Fusion 360?

Yes, you can import existing profiles from libraries like GrabCAD or other sources by downloading them as STEP files and inserting them into your design.

3. How do I create complex shapes using aluminum extrusions in Fusion 360?

You can create complex shapes by sketching multiple profiles, extruding them separately, and then assembling them together using alignment tools.

4. What are some common applications of aluminum extrusions?

Common applications include structural frames for buildings, automotive parts, furniture manufacturing, and components for machinery like CNC routers.

5. Is there a way to automate repetitive tasks when designing extrusions?

Yes! You can create templates for common profiles in Fusion 360 that allow you to reuse designs without redrawing them each time.

Citations:

[1] https://www.instructables.com/Design-Self-made-CNC-in-Fusion-360/

[2] https://forums.autodesk.com/t5/fusion-design-validate-document/fusion-360-design-for-aluminium-profile-systems-such-as-ips/td-p/7264440

[3] https://www.youtube.com/watch?v=GqL-qvoCMcg

[4] https://www.youtube.com/watch?v=NTzOsFlU_00

[5] https://prod.cloudfront.making.unsw.edu.au/documents/2101555-GD-ENUS-1.pdf

[6] http://www.inventortales.com/2017/08/Custom-Extrusion-Templates.html