Content Menu

● What is Aluminum Extrusion?

● Step 1: Material Preparation

● Step 2: Heating the Billet

● Step 3: Extrusion

● Step 4: Cooling

● Step 5: Stretching

● Step 6: Cutting

● Step 7: Surface Treatment

● Step 8: Quality Control

● Benefits of Aluminum Extrusion

● Applications of Aluminum Extrusion

● The Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between direct and indirect aluminum extrusion?

>> 2. What are the most common aluminum alloys used in extrusion?

>> 3. How does the cooling process affect the properties of extruded aluminum?

>> 4. What surface treatments can be applied to extruded aluminum?

>> 5. What industries commonly use aluminum extrusion?

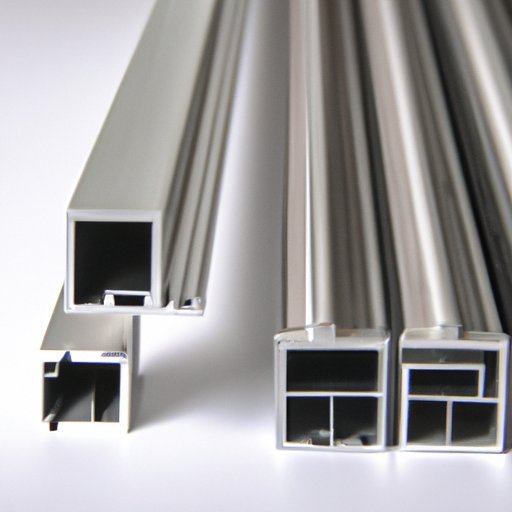

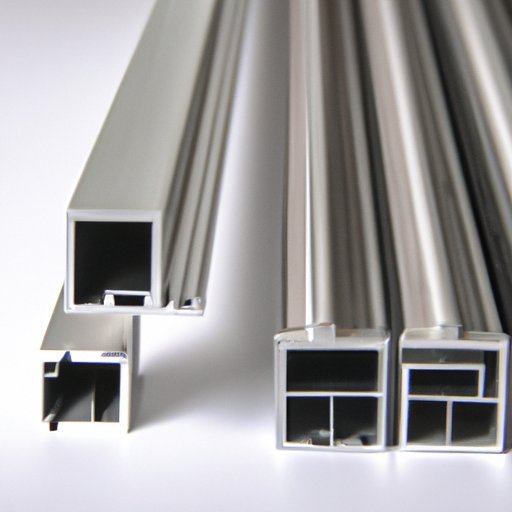

What is Aluminum Extrusion?

Aluminum extrusion involves forcing aluminum alloy through a die to create a continuous profile with a specific cross-sectional shape. The process can produce a wide range of products, from simple shapes like rods and tubes to complex designs used in architectural applications. The primary advantage of aluminum extrusion is its ability to create lightweight yet strong components, making it an ideal choice for many applications.

Step 1: Material Preparation

The first step in the aluminum extrusion process is preparing the aluminum alloy. The most commonly used alloys for extrusion are 6061 and 6063, known for their excellent mechanical properties and corrosion resistance. The aluminum is typically supplied in the form of billets, which are cylindrical bars of aluminum that are heated to a specific temperature before extrusion.

Step 2: Heating the Billet

Once the aluminum billets are prepared, they are heated in a furnace to a temperature between 400°F and 900°F (204°C to 482°C). This heating process softens the aluminum, making it easier to extrude. The exact temperature depends on the specific alloy being used and the desired properties of the final product.

Step 3: Extrusion

After the billets are heated, they are placed in an extrusion press. The press consists of a container that holds the heated billet and a ram that pushes the aluminum through the die. The die is a specially designed tool that shapes the aluminum into the desired profile.

As the ram pushes the aluminum through the die, it takes on the shape of the die opening. This process can be done using two main methods: direct extrusion and indirect extrusion. In direct extrusion, the ram pushes the billet directly through the die, while in indirect extrusion, the die is moved towards the billet.

Step 4: Cooling

Once the aluminum has been extruded, it needs to be cooled to solidify the shape. This is typically done using air or water cooling methods. The cooling process is crucial as it affects the mechanical properties of the aluminum. Rapid cooling can lead to increased strength, while slower cooling can enhance ductility.

Step 5: Stretching

After cooling, the extruded aluminum may be slightly warped or distorted. To correct this, the extruded profile is stretched. Stretching involves pulling the aluminum through a series of rollers to ensure it is straight and to improve its mechanical properties. This step is essential for achieving precise dimensions and tolerances.

Step 6: Cutting

Once the aluminum has been stretched, it is cut into specific lengths based on the requirements of the final product. This cutting can be done using saws or shears, depending on the thickness and type of the extruded profile.

Step 7: Surface Treatment

To enhance the appearance and durability of the extruded aluminum, various surface treatments can be applied. Common treatments include anodizing, painting, and powder coating. Anodizing involves creating a protective oxide layer on the surface, while painting and powder coating provide color and additional protection against corrosion.

Step 8: Quality Control

Before the extruded aluminum products are shipped to customers, they undergo rigorous quality control checks. This includes measuring dimensions, checking for surface defects, and testing mechanical properties. Quality control ensures that the final products meet industry standards and customer specifications.

Benefits of Aluminum Extrusion

Aluminum extrusion offers numerous advantages, making it a popular choice in various industries:

1. Versatility: The extrusion process can create a wide range of shapes and sizes, allowing for customization to meet specific design requirements.

2. Lightweight: Aluminum is significantly lighter than other metals, making it ideal for applications where weight is a concern, such as in the automotive and aerospace industries.

3. Strength: Despite its lightweight nature, aluminum is strong and durable, providing excellent structural integrity.

4. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

5. Cost-Effective: The extrusion process is efficient and can produce large quantities of products at a lower cost compared to other manufacturing methods.

Applications of Aluminum Extrusion

Aluminum extrusion is used in a wide variety of applications, including:

- Construction: Aluminum extrusions are commonly used in window frames, doors, and structural components in buildings.

- Automotive: Lightweight aluminum extrusions are used in vehicle frames, bumpers, and other components to improve fuel efficiency.

- Aerospace: The aerospace industry utilizes aluminum extrusions for aircraft structures, components, and interior fittings due to their strength-to-weight ratio.

- Consumer Products: Many everyday items, such as furniture, appliances, and electronics, incorporate aluminum extrusions in their design.

The Future of Aluminum Extrusion

As industries continue to evolve, the demand for aluminum extrusion is expected to grow. Innovations in technology and manufacturing processes are leading to more efficient and sustainable practices. For instance, advancements in recycling methods are allowing manufacturers to use recycled aluminum in the extrusion process, reducing waste and energy consumption.

Additionally, the development of new aluminum alloys and composite materials is expanding the possibilities for aluminum extrusion. These innovations enable the production of even lighter and stronger components, further enhancing the versatility of aluminum in various applications.

Conclusion

The aluminum extrusion process is a highly efficient and versatile manufacturing method that transforms aluminum alloy into a wide range of shapes and profiles. By understanding the step-by-step process, from material preparation to quality control, we can appreciate the complexity and benefits of aluminum extrusion. This process not only provides lightweight and strong components but also allows for customization to meet specific design needs.

Frequently Asked Questions

1. What is the difference between direct and indirect aluminum extrusion?

- Direct extrusion involves pushing the billet directly through the die, while indirect extrusion involves moving the die towards the billet.

2. What are the most common aluminum alloys used in extrusion?

- The most common alloys are 6061 and 6063, known for their excellent mechanical properties and corrosion resistance.

3. How does the cooling process affect the properties of extruded aluminum?

- Rapid cooling can increase strength, while slower cooling can enhance ductility.

4. What surface treatments can be applied to extruded aluminum?

- Common treatments include anodizing, painting, and powder coating.

5. What industries commonly use aluminum extrusion?

- Aluminum extrusion is widely used in construction, automotive, aerospace, and consumer products.