Content Menu

● Understanding Aluminum Extrusion

● Design Guidelines for Aluminum Extrusions

>> 1. Shape Configuration

>> 2. Wall Thickness

>> 3. Rounded Corners and Smooth Transitions

>> 4. Tolerances and Dimensions

>> 5. Material Selection

● Impact on Product Performance

>> 1. Structural Integrity

>> 2. Manufacturing Efficiency

>> 3. Cost-effectiveness

● Visualizing Aluminum Extrusion

● Case Studies on Aluminum Extrusion Design Guidelines

>> Case Study 1: Automotive Industry

>> Case Study 2: Architectural Applications

● Conclusion

● FAQ

>> 1. What are aluminum extrusion design guidelines?

>> 2. How does wall thickness affect aluminum extrusions?

>> 3. Why are rounded corners important in extrusion design?

>> 4. What alloys are commonly used in aluminum extrusion?

>> 5. How do design guidelines influence manufacturing efficiency?

Aluminum extrusion is a widely utilized manufacturing process that involves shaping aluminum alloy by forcing it through a die to create specific cross-sectional profiles. This method is favored for its versatility, lightweight properties, and strength, making it suitable for various applications, from automotive to architectural components. However, the performance of aluminum extrusions is heavily influenced by the design guidelines followed during the extrusion process. This article explores how these guidelines affect product performance, focusing on key design considerations, best practices, and their implications on functionality and cost.

Understanding Aluminum Extrusion

Aluminum extrusion involves several stages, including heating the aluminum billet, applying pressure to push it through a die, and cooling the extruded shape. The resulting product can be customized in terms of size, shape, and mechanical properties based on the alloy used and the design parameters set during the process.

Key Benefits of Aluminum Extrusion:

- Versatility: Allows for complex shapes and designs.

- Strength-to-weight ratio: Lightweight yet strong.

- Corrosion resistance: Naturally resistant to corrosion.

- Customization: Easily tailored to specific applications.

Design Guidelines for Aluminum Extrusions

To maximize the performance of aluminum extrusions, designers must adhere to specific guidelines that influence both the manufacturing process and the final product's functionality.

1. Shape Configuration

The first step in designing an aluminum extrusion is determining its shape. Designers should aim for profiles that meet functional requirements while allowing for efficient manufacturing. The three main categories of extruded shapes are:

- Solid shapes: Simple geometries that provide strength.

- Hollow shapes: Useful for reducing weight while maintaining structural integrity.

- Semi-hollow shapes: Combine features of both solid and hollow designs.

Design Tip: Keep shapes symmetrical to reduce stress concentrations and improve die longevity.

Example Applications:

- Solid Shapes: Used in structural beams where strength is paramount.

- Hollow Shapes: Commonly found in window frames and railings where weight reduction is essential without sacrificing strength.

2. Wall Thickness

Choosing the appropriate wall thickness is crucial for balancing strength requirements with cost efficiency. Uniform wall thicknesses are easier to produce but may not always meet strength needs.

Considerations:

- The choice of alloy influences how thin or thick walls can be without compromising strength.

- Variations in wall thickness should be minimized to avoid cooling issues during production.

Impact on Performance:

A thicker wall may enhance load-bearing capacity but can also increase material costs. Conversely, thinner walls reduce weight but might compromise structural integrity under load.

3. Rounded Corners and Smooth Transitions

Sharp corners can lead to weaknesses in extruded profiles due to stress concentrations. Designers should incorporate rounded corners with a radius of at least 0.5 mm to enhance strength and ease of extrusion.

Benefits:

- Reduces the likelihood of cracking or breaking during processing.

- Improves material flow through the die.

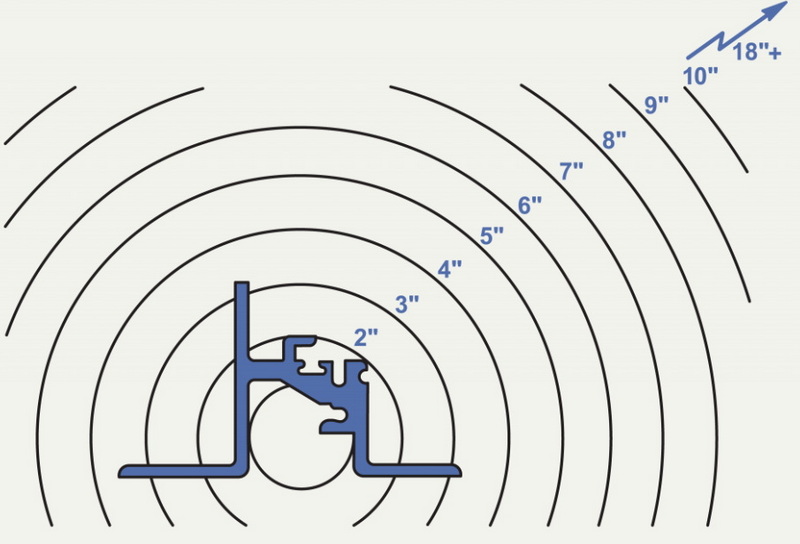

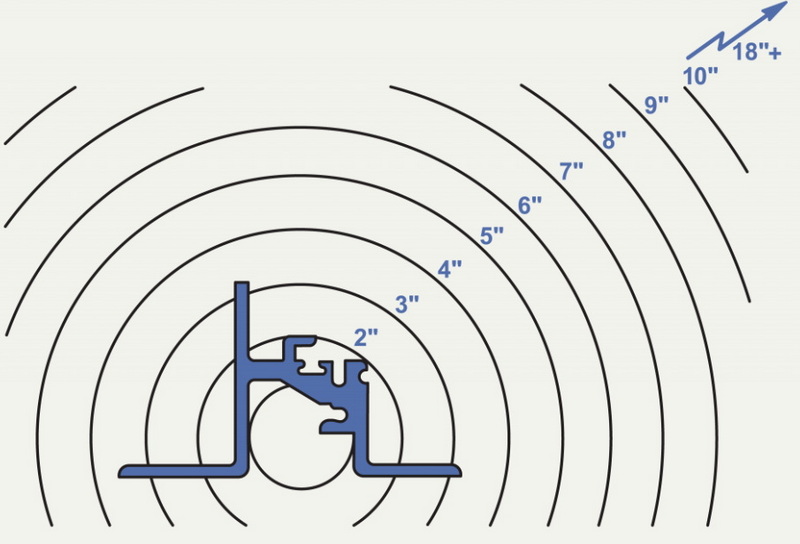

Visual Representation:

*Figure 1: Comparison of sharp vs. rounded corners in aluminum extrusions.*

4. Tolerances and Dimensions

Setting appropriate tolerances is essential for ensuring that extruded parts fit together correctly in their final application. Designers should avoid overly tight tolerances that can complicate manufacturing and increase costs.

Best Practices:

- Use corporate standards for tolerances when possible.

- Clearly dimension critical areas while allowing flexibility in less critical zones.

Example Tolerances:

Typical tolerances for aluminum extrusions might range from ±0.5 mm for large sections to ±0.1 mm for smaller, more intricate designs.

5. Material Selection

The choice of aluminum alloy significantly affects product performance. Different alloys exhibit varying mechanical properties, corrosion resistance, and thermal characteristics.

Common Alloys:

- 6061: Known for its excellent corrosion resistance and weldability; often used in structural applications.

- 6063: Frequently used for architectural applications due to its aesthetic finish and good flow characteristics during extrusion.

- 7075: A high-strength alloy suitable for aerospace applications where weight savings are critical.

Considerations in Alloy Selection:

Selecting an appropriate alloy involves balancing factors such as mechanical properties, cost, availability, and intended application environment (e.g., exposure to moisture or chemicals).

Impact on Product Performance

Adhering to aluminum extrusion design guidelines directly impacts product performance in several ways:

1. Structural Integrity

Proper design ensures that extruded products can withstand applied loads without failure. Factors such as wall thickness, corner radii, and overall shape contribute to the structural integrity of the final product.

Example Case Study:

A manufacturer producing a series of lightweight bicycle frames found that by optimizing wall thickness according to guidelines, they reduced weight by 15% while maintaining strength standards required by safety regulations.

2. Manufacturing Efficiency

Following design guidelines helps streamline the manufacturing process, reducing waste and production time. Efficient designs minimize unnecessary complexities that can lead to defects or increased costs.

Process Optimization Techniques:

Implementing simulation software during the design phase can predict potential issues in extrusion processes before actual production begins, allowing adjustments to be made early on.

3. Cost-effectiveness

By optimizing designs according to extrusion guidelines, manufacturers can reduce material costs while maintaining quality. This balance is crucial in competitive markets where cost pressures are significant.

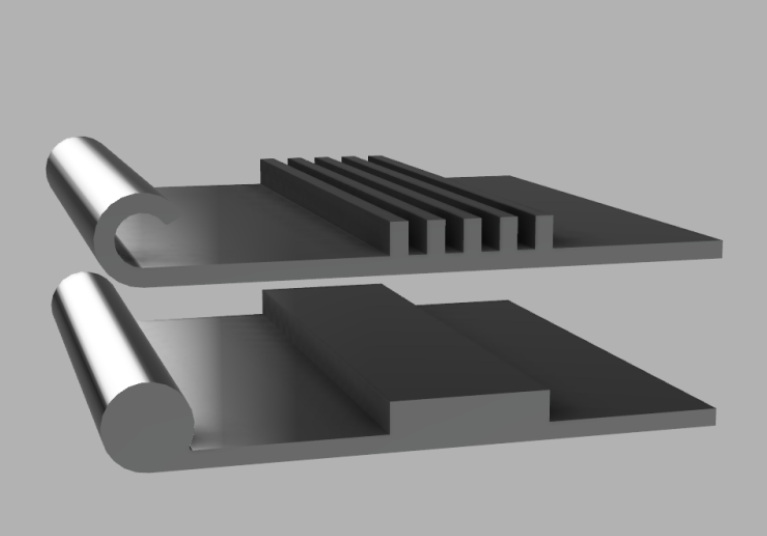

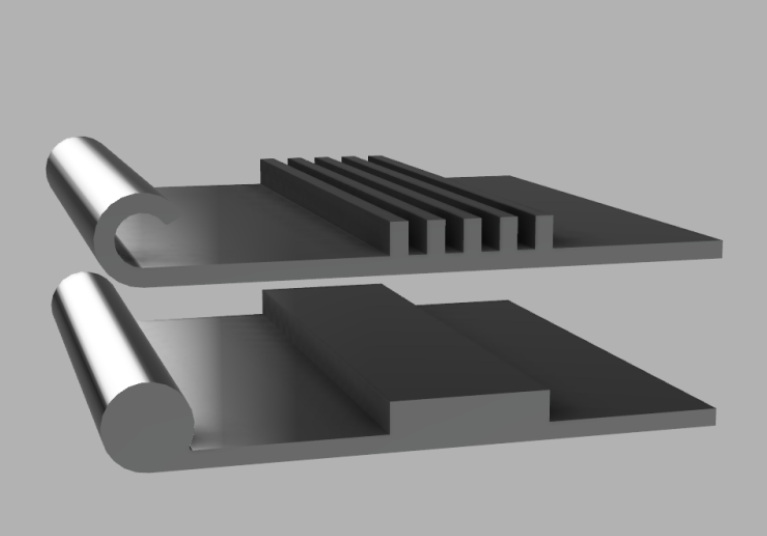

Visualizing Aluminum Extrusion

To better understand the aluminum extrusion process and its design implications, consider these visual aids:

*Figure 2: Overview of the aluminum extrusion process.*

*Figure 3: Various shapes produced through aluminum extrusion.*

Case Studies on Aluminum Extrusion Design Guidelines

To illustrate how adherence to design guidelines can impact performance positively, several case studies highlight successful implementations:

Case Study 1: Automotive Industry

An automotive manufacturer redesigned an engine component using optimized extrusion profiles that adhered closely to established guidelines. The result was a part that was not only lighter but also demonstrated improved thermal efficiency due to better heat dissipation characteristics from its enhanced surface area.

Case Study 2: Architectural Applications

In a recent project involving curtain wall systems for a skyscraper, designers utilized hollow extrusions with rounded corners as per guidelines. This choice not only met aesthetic requirements but also provided significant savings on materials while ensuring compliance with building codes regarding wind load resistance.

Conclusion

Aluminum extrusion design guidelines play a vital role in determining product performance across various applications. By focusing on shape configuration, wall thickness, corner radii, tolerances, and material selection, designers can create efficient profiles that meet functional requirements while optimizing manufacturing processes. The right design choices not only enhance structural integrity but also contribute to cost savings and improved product quality.

FAQ

1. What are aluminum extrusion design guidelines?

Aluminum extrusion design guidelines are principles that help engineers create effective profiles by considering factors like shape symmetry, wall thickness, corner radii, tolerances, and material selection.

2. How does wall thickness affect aluminum extrusions?

Wall thickness impacts both the strength and weight of an extruded profile; thicker walls generally provide greater strength but may increase weight and production costs.

3. Why are rounded corners important in extrusion design?

Rounded corners reduce stress concentrations that can lead to cracking or breaking during processing, thereby enhancing overall product durability.

4. What alloys are commonly used in aluminum extrusion?

Commonly used alloys include 6061 for general purposes, 6063 for architectural applications due to its finish, and 7075 for high-strength needs in aerospace applications.

5. How do design guidelines influence manufacturing efficiency?

Adhering to design guidelines streamlines production by minimizing waste and defects while ensuring that parts fit together correctly, ultimately leading to cost savings.