Content Menu

● Understanding Extrusion

>> Types of Extrusion

● Advantages of Custom Extrusion Production Lines

>> 1. Tailored Solutions for Unique Requirements

>> 2. Enhanced Material Efficiency

>> 3. Increased Production Speed

>> 4. Versatility in Product Design

>> 5. Cost-Effectiveness

● Key Components of an Extrusion Production Line

● The Customization Process

● Innovations in Extrusion Technology

>> Co-extrusion Technology

>> Smart Manufacturing Integration

>> Advanced Cooling Techniques

● Case Studies of Successful Custom Extrusions

● Environmental Considerations

● Conclusion

● FAQ

>> 1. What industries benefit most from custom extrusion?

>> 2. How does custom extrusion improve sustainability?

>> 3. Can I get prototypes before full-scale production?

>> 4. What materials can be used in custom extrusion?

>> 5. How long does it take to set up a custom extrusion line?

● Citations:

In today's manufacturing landscape, the demand for customized solutions is on the rise. Industries are increasingly seeking tailored production processes that meet their specific requirements. One of the most effective ways to achieve this is through custom extrusion production lines. This article explores the benefits of choosing a custom extrusion production line factory, the technology involved, and how it can enhance your manufacturing capabilities.

Understanding Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die. This method is commonly used for metals, plastics, and even food products. The versatility of extrusion allows manufacturers to produce complex shapes that would be difficult or impossible to achieve through other methods.

Types of Extrusion

- Direct Extrusion: The most common form where the material is pushed through the die.

- Indirect Extrusion: In this method, the die is stationary while the material and container move.

- Co-extrusion: Multiple materials are extruded simultaneously to create multi-layered products.

Advantages of Custom Extrusion Production Lines

Choosing a custom extrusion production line factory offers numerous advantages that can significantly impact your business's efficiency and product quality.

1. Tailored Solutions for Unique Requirements

Every industry has unique needs, and a custom extrusion line can be designed to meet these specific requirements. Whether it's for automotive parts, construction materials, or consumer goods, a custom line ensures that the products are manufactured to precise specifications.

2. Enhanced Material Efficiency

Custom extrusion processes can optimize material usage, reducing waste significantly. By producing only what is needed and minimizing off-cuts, manufacturers can achieve sustainability goals while also saving costs.

3. Increased Production Speed

Modern custom extrusion lines are equipped with advanced technology that allows for faster production cycles. Automation features reduce manual labor and human error, leading to quicker turnaround times without compromising quality.

4. Versatility in Product Design

Custom extrusion allows for endless design possibilities. Manufacturers can create complex shapes and profiles that cater to specific applications, enhancing product functionality and aesthetics.

5. Cost-Effectiveness

While the initial investment in a custom extrusion line may be higher than standard options, the long-term savings from reduced material waste, lower labor costs, and increased efficiency often outweigh these costs. Additionally, custom solutions can lead to higher-quality products that command better market prices.

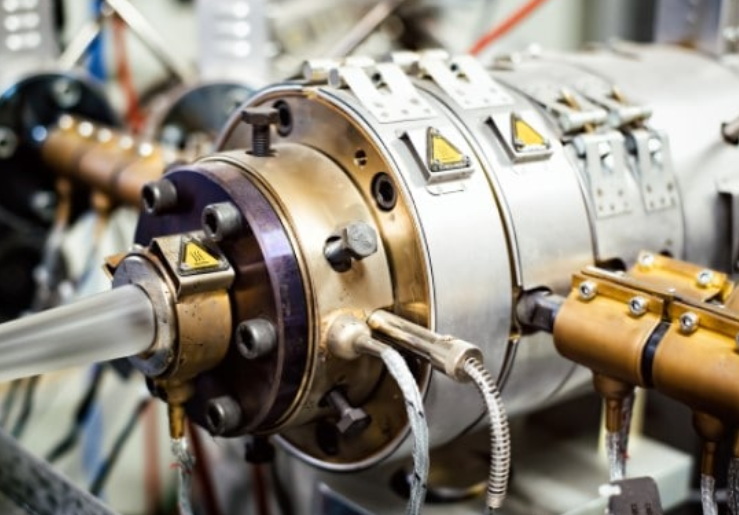

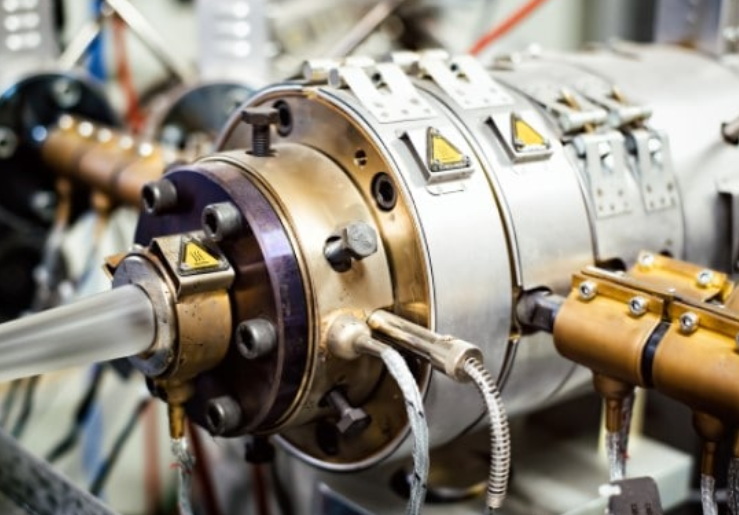

Key Components of an Extrusion Production Line

A typical custom extrusion production line consists of several key components that work together seamlessly:

- Extruder: The heart of the operation where raw materials are melted and shaped.

- Die: Shapes the molten material into the desired profile.

- Calibration Unit: Ensures that the extruded product maintains its dimensions as it cools.

- Cooling Tanks: Cool the extruded material to solidify its shape.

- Haul-off Unit: Pulls the extruded product through the line at a controlled speed.

- Cutter: Cuts the finished product into specified lengths.

The Customization Process

When working with a custom extrusion production line factory, understanding the customization process is crucial:

1. Design Phase: Collaborate with engineers to create a design that meets your specifications using CAD software.

2. Die Preparation: A die is created based on the finalized design. This die will shape the extruded material into its final form.

3. Material Selection: Choose suitable materials based on your product's requirements (e.g., aluminum, PVC).

4. Production Setup: The factory sets up the machinery according to your specifications and prepares for production.

5. Testing and Quality Control: Before full-scale production begins, samples are tested for quality assurance.

6. Full Production Run: Once everything is approved, mass production commences.

Innovations in Extrusion Technology

The field of extrusion technology has seen significant advancements in recent years, making it more efficient and versatile:

Co-extrusion Technology

Co-extrusion allows manufacturers to produce multi-layered products using different materials simultaneously. This technique enhances properties such as barrier resistance and aesthetic appeal while reducing material costs[1][5].

Smart Manufacturing Integration

With Industry 4.0 technologies being integrated into extrusion processes, manufacturers can now utilize IoT devices for real-time monitoring and control of production parameters[15]. This leads to improved efficiency and reduced downtime due to predictive maintenance capabilities enabled by AI-driven analytics[18].

Advanced Cooling Techniques

Modern cooling techniques ensure that products maintain their shape and quality during production. These innovations help reduce defects and improve overall product consistency[11].

Case Studies of Successful Custom Extrusions

To illustrate the effectiveness of custom extrusion production lines, consider these examples:

- Automotive Industry: A manufacturer needed specific aluminum profiles for vehicle frames. By investing in a custom extrusion line, they were able to produce lightweight yet strong components that improved fuel efficiency while meeting safety standards[14].

- Construction Sector: A construction company required unique window frames with integrated insulation features. A tailored extrusion line allowed them to produce these frames efficiently while maintaining high thermal performance standards[3].

- Healthcare Applications: In healthcare settings, companies have developed specialized extrusions for medical devices that require precise tolerances and high durability[16]. These custom solutions not only enhance patient safety but also streamline manufacturing processes.

Environmental Considerations

The push towards sustainability has made custom extrusion an attractive option for many industries:

- Material Recycling: Many modern extrusion factories incorporate recycling processes that allow manufacturers to reuse scrap materials in new productions[6]. This reduces waste and lowers overall material costs.

- Energy Efficiency: Newer machines are designed with energy-efficient technologies that minimize power consumption during production[11]. This not only helps reduce operational costs but also aligns with corporate sustainability goals.

Conclusion

In conclusion, choosing a custom extrusion production line factory can provide significant advantages in terms of efficiency, cost-effectiveness, and product quality. With tailored solutions designed to meet specific industry needs, businesses can enhance their manufacturing capabilities and stay competitive in today's fast-paced market.

FAQ

1. What industries benefit most from custom extrusion?

Custom extrusion benefits various industries including automotive, construction, electronics, and consumer goods by providing tailored solutions that meet specific application needs.

2. How does custom extrusion improve sustainability?

By optimizing material usage and reducing waste during production processes, custom extrusion contributes to sustainability goals while also lowering costs associated with excess material disposal.

3. Can I get prototypes before full-scale production?

Yes, most custom extrusion factories offer prototyping services to test designs before committing to full-scale production runs.

4. What materials can be used in custom extrusion?

Common materials include various aluminum alloys, plastics like PVC and HDPE, as well as specialty materials depending on application requirements.

5. How long does it take to set up a custom extrusion line?

The setup time varies based on complexity but typically ranges from several weeks to a few months depending on design finalization and die preparation processes.

Citations:

[1] https://paramountextrusions.com/blogs/why-choose-custom-aluminum-extrusions

[2] https://www.exelliq.com/en/company/technology-innovation

[3] https://www.liveline.tech/case-studies

[4] https://paulmurphyplastics.com/industry-news-blog/maximizing-efficiency-the-benefits-of-custom-plastic-extrusions-for-industrial-applications/

[5] https://www.seagateplastics.com/shaping-the-future-innovations-in-plastic-extrusion-techniques/

[6] https://hitechextrusions.com/case-studies/

[7] https://paulmurphyplastics.com/industry-news-blog/what-is-custom-extrusion-and-why-you-should-consider-this-in-purchasing-products/

[8] https://plasticextrusiontech.net/shaping-the-future-of-plastic-extrusion-technology/

[9] https://www.iotone.com/case-study/enhancing-aluminum-extrusion-manufacturing-with-iot-a-case-study-of-apel-extrusions-limited/c7655

[10] https://www.custom-profile.com/blog/the-benefits-and-process-of-creating-solar-custom-plastic-extrusions-for-sustainable-energy/

[11] https://www.yjing-extrusion.com/why-invest-in-a-pipe-extrusion-production-line-for-your-manufacturing.html

[12] https://www.luigibandera.com/unveiling-techno-flex-po5-revolutionizing-extrusion-technology-for-diverse-packaging-solutions/

[13] https://bdcustommfg.com/case-studies/plastic-strips/

[14] https://rpmindinc.com/how-custom-aluminum-extrusions-benefit-the-manufacturing-process/

[15] https://www.bausano.com/en/press-and-news/smart-manufactoring-pipe-extrusion

[16] https://www.sfrindustries.com/case_studies/

[17] http://scaluminum.com/2020/01/custom-aluminum-extrusion-the-benefits-of-aluminum-products/

[18] https://www.plasticsmachinerymanufacturing.com/extrusion/article/55089954/ai-process-monitoring-improve-quality-for-extruders

[19] https://www.cyframe.com/category/resource/case-studies/

[20] https://www.custom-profile.com/blog/custom-extruded-plastic-tubing-manufacturing-process-applications-and-benefits/

[21] https://bdcustommfg.com/case-studies/

[22] https://www.globenewswire.com/news-release/2025/01/02/3003332/0/en/U-S-Plastic-Extrusion-Machine-Market-to-Hit-Valuation-of-US-1-548-99-Million-By-2033-Rapid-Innovation-and-Growing-Collaboration-Fueling-Market-Growth-Says-Astute-Analytica.html

[23] https://www.10in6.com/case-studies/aluminum-extrusion-plant-case-study/