Content Menu

● Introduction to Aluminum Extrusion

● Understanding Aluminum Extrusion

● Benefits of Aluminum Extrusion

● Types of Aluminum Extrusions

>> Standard Shapes

>> Custom Profiles

>> Structural Framing Systems

● Where to Buy Cheap Aluminum Extrusion

>> 1. Online Aluminum Extrusion Retailers

>> 2. Industrial Aluminum Extrusion Distributors

>> 3. Direct from Manufacturers

>> 4. Wholesale Suppliers

>> 5. Local Metal Suppliers

>> 6. Surplus and Liquidation Sales

● Factors to Consider When Buying Cheap Aluminum Extrusion

>> 1. Quality and Specifications

>> 2. Quantity and Minimum Order Requirements

>> 3. Lead Times and Availability

>> 4. Additional Services

>> 5. Shipping and Handling

>> 6. Supplier Reputation and Customer Service

● Tips for Getting the Best Deals on Aluminum Extrusions

● The Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> Q1: What is the difference between standard and custom aluminum extrusions?

>> Q2: How can I determine the right aluminum alloy for my extrusion needs?

>> Q3: Are there any disadvantages to buying cheap aluminum extrusions?

>> Q4: How much can I save by buying aluminum extrusions in bulk?

>> Q5: What should I look for in a reliable aluminum extrusion supplier?

Introduction to Aluminum Extrusion

Aluminum extrusion is a versatile and widely used manufacturing process that produces a variety of shapes and profiles for countless applications across industries. From construction and automotive to aerospace and consumer goods, aluminum extrusions play a crucial role in modern manufacturing. For businesses and individuals looking to source these materials, finding Affordable Aluminum Extrusion Suppliers is often a top priority.

Understanding Aluminum Extrusion

Before diving into where to buy cheap aluminum extrusion, it's essential to understand what it is and how it's made. Aluminum extrusion is a process where aluminum alloy material is forced through a die with a specific cross-sectional profile. The result is a long, straight piece of aluminum with a consistent cross-section that matches the die's shape.

This process allows for the creation of complex shapes that would be difficult or impossible to produce using other manufacturing methods. The versatility of aluminum extrusion makes it an ideal choice for various applications, from structural components to decorative elements.

Benefits of Aluminum Extrusion

Understanding the advantages of aluminum extrusion can help you appreciate why it's such a popular choice in many industries:

1. Lightweight yet strong

2. Corrosion-resistant

3. Excellent thermal and electrical conductivity

4. Easily machined and finished

5. Recyclable and environmentally friendly

6. Cost-effective for both small and large production runs

These benefits make aluminum extrusion an attractive option for many projects, driving the demand for Quality Aluminum Extrusion Products across various sectors.

Types of Aluminum Extrusions

When searching for Bulk Aluminum Profiles Wholesale, you'll encounter various types of extrusions. Here are some common categories:

Standard Shapes

- Angles

- Channels

- Tubes

- Bars

Custom Profiles

Custom Aluminum Extrusion Manufacturers can create unique profiles tailored to specific project requirements. These may include:

- Complex cross-sections

- Multi-void extrusions

- Thin-walled profiles

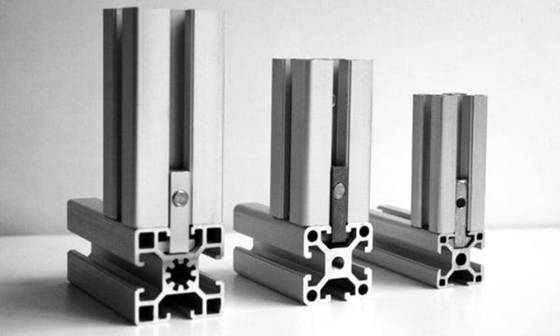

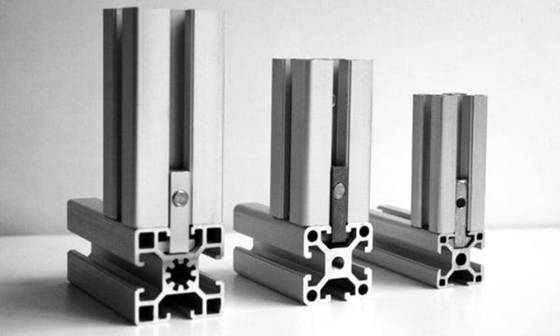

Structural Framing Systems

Extruded Aluminum T-Slot Framing is popular in many industrial applications, offering modular and flexible construction options.

Where to Buy Cheap Aluminum Extrusion

Now that we understand the basics of aluminum extrusion, let's explore various options for sourcing these materials at competitive prices.

1. Online Aluminum Extrusion Retailers

The internet has made it easier than ever to find and compare prices for aluminum extrusions. Many Online Aluminum Extrusion Retailers offer a wide selection of standard and custom profiles, often at competitive prices due to lower overhead costs. When shopping online, consider factors such as:

- Product range and customization options

- Minimum order quantities

- Shipping costs and delivery times

- Customer reviews and ratings

Some popular online retailers include McMaster-Carr, Online Metals, and Amazon Industrial & Scientific.

2. Industrial Aluminum Extrusion Distributors

Working with Industrial Aluminum Extrusion Distributors can be an excellent option for businesses requiring larger quantities or specialized profiles. These distributors often have established relationships with manufacturers, allowing them to offer competitive pricing and access to a wide range of products. Benefits of working with distributors include:

- Expert advice on material selection

- Access to multiple manufacturers

- Potential for volume discounts

- Value-added services such as cutting and finishing

Examples of well-known distributors include Ryerson, ThyssenKrupp Materials, and Alro Metals.

3. Direct from Manufacturers

For projects requiring large volumes or highly customized profiles, buying directly from Custom Aluminum Extrusion Manufacturers can be the most cost-effective option. This approach allows for:

- Direct communication with the manufacturer

- Potential for significant cost savings on large orders

- Customization of alloys, tempers, and finishes

- Quality control and traceability

Some reputable aluminum extrusion manufacturers include Hydro Extrusion, Sapa Extrusions, and Kaiser Aluminum.

4. Wholesale Suppliers

Wholesale Aluminum Extrusion Materials suppliers can offer significant savings for those able to purchase in bulk. These suppliers often cater to businesses and may have minimum order requirements. Benefits of buying wholesale include:

- Lower per-unit costs

- Access to a wide range of standard profiles

- Potential for consistent supply for ongoing projects

When considering wholesale options, be sure to factor in storage costs and inventory management.

5. Local Metal Suppliers

Don't overlook local metal suppliers when searching for Discount Aluminum Structural Shapes. These businesses may offer:

- Competitive pricing on standard profiles

- Quick turnaround times

- Reduced shipping costs

- Opportunity to inspect materials before purchase

Local suppliers can be particularly beneficial for small to medium-sized projects or when you need materials quickly.

6. Surplus and Liquidation Sales

For those willing to put in some extra effort, surplus and liquidation sales can be a goldmine for Low-Cost Aluminum Extrusion Services. These sales may occur when:

- Companies overstock materials

- Projects are cancelled or scaled back

- Businesses close or restructure

While the selection may be limited, and materials may not always be in perfect condition, significant savings can be found through these channels.

Factors to Consider When Buying Cheap Aluminum Extrusion

While price is a crucial factor, it shouldn't be the only consideration when sourcing aluminum extrusions. Here are some important aspects to keep in mind:

1. Quality and Specifications

Ensure that the materials meet your project's requirements in terms of:

- Alloy composition

- Temper

- Dimensional tolerances

- Surface finish

2. Quantity and Minimum Order Requirements

Consider your project needs and storage capabilities when deciding on order quantities. Some suppliers may offer better pricing for larger orders but require minimum purchase amounts.

3. Lead Times and Availability

Factor in production and shipping times, especially for custom or large orders. Some suppliers may offer quick turnaround times for standard profiles, while others may require longer lead times for specialized extrusions.

4. Additional Services

Consider whether you need any value-added services such as:

- Cutting to length

- Machining or fabrication

- Surface treatments or anodizing

- Assembly or kitting

Some suppliers may offer these services in-house, potentially saving you time and money compared to outsourcing these processes separately.

5. Shipping and Handling

Don't forget to factor in shipping costs, especially for bulky or heavy extrusions. Some suppliers may offer free shipping above a certain order value, while others may have significant shipping charges that can impact the overall cost.

6. Supplier Reputation and Customer Service

Research potential suppliers thoroughly, looking at:

- Customer reviews and testimonials

- Industry certifications and accreditations

- Technical support and customer service quality

- Financial stability and longevity in the market

Tips for Getting the Best Deals on Aluminum Extrusions

To maximize your savings when sourcing aluminum extrusions, consider the following strategies:

1. Compare quotes from multiple suppliers

2. Consider buying in larger quantities for better pricing

3. Look for seasonal promotions or clearance sales

4. Negotiate prices, especially for large or recurring orders

5. Join industry associations for access to member discounts

6. Consider alternative alloys or profiles that may be more cost-effective

7. Optimize your designs to reduce material usage

8. Explore the possibility of using standard profiles instead of custom extrusions

The Future of Aluminum Extrusion

As technology advances and sustainability becomes increasingly important, the aluminum extrusion industry continues to evolve. Some trends to watch include:

1. Increased use of recycled aluminum in extrusions

2. Development of stronger and lighter alloys

3. Advancements in extrusion technology for more complex profiles

4. Growing demand in emerging markets and industries

5. Integration of smart manufacturing and Industry 4.0 principles

Staying informed about these trends can help you make better decisions when sourcing aluminum extrusions for your projects.

Conclusion

Finding and buying cheap aluminum extrusion requires a balance of research, planning, and consideration of various factors beyond just price. By understanding the different types of suppliers, considering important factors, and implementing smart buying strategies, you can source high-quality aluminum extrusions at competitive prices for your projects.

Remember that the cheapest option isn't always the best in the long run. Consider the total cost of ownership, including factors like quality, lead times, and additional services, to make the most informed decision for your aluminum extrusion needs.

Frequently Asked Questions

Q1: What is the difference between standard and custom aluminum extrusions?

A1: Standard aluminum extrusions are pre-designed profiles that are readily available and often more cost-effective for common applications. Custom aluminum extrusions are specially designed and manufactured to meet specific project requirements, offering unique shapes and features but typically at a higher cost and with longer lead times.

Q2: How can I determine the right aluminum alloy for my extrusion needs?

A2: Choosing the right aluminum alloy depends on factors such as strength requirements, corrosion resistance, machinability, and cost. Common alloys for extrusions include 6061, 6063, and 7075. Consult with a materials expert or extrusion manufacturer to determine the best alloy for your specific application.

Q3: Are there any disadvantages to buying cheap aluminum extrusions?

A3: While cost savings are attractive, extremely cheap aluminum extrusions may come with drawbacks such as lower quality, inconsistent dimensions, poor surface finish, or use of recycled materials that may not meet your specifications. It's important to balance cost with quality and ensure that the extrusions meet your project requirements.

Q4: How much can I save by buying aluminum extrusions in bulk?

A4: Bulk purchases can often lead to significant savings, with discounts typically ranging from 10% to 30% or more, depending on the quantity and supplier. However, the exact savings will vary based on factors such as the specific profile, alloy, and market conditions.

Q5: What should I look for in a reliable aluminum extrusion supplier?

A5: A reliable aluminum extrusion supplier should have a track record of quality products, on-time delivery, competitive pricing, and excellent customer service. Look for suppliers with industry certifications, a wide range of capabilities, transparent pricing, and positive customer reviews. Additionally, consider their technical support, ability to handle custom orders, and willingness to work with you on your specific project needs.