Content Menu

● Understanding Drying Extrusion Granulation

>> Key Components of a Drying Extrusion Granulation Production Line

● Advantages of Drying Extrusion Granulation

● Applications of Drying Extrusion Granulation

● Finding a Drying Extrusion Granulation Production Line

● Challenges in Drying Extrusion Granulation

● Future Trends in Drying Extrusion Granulation

● Conclusion

● FAQ

>> 1. What is dry granulation?

>> 2. What are the benefits of using a drying extrusion granulation production line?

>> 3. What types of products can be produced using this method?

>> 4. How does the drying process work in this production line?

>> 5. Where can I purchase a drying extrusion granulation production line?

Drying extrusion granulation is a crucial process in various industries, particularly in the production of fertilizers, pharmaceuticals, and food products. This article will explore the intricacies of drying extrusion granulation production lines, including their components, processes, and applications. We will also discuss where to find these production lines and provide visual aids to enhance understanding.

Understanding Drying Extrusion Granulation

Drying extrusion granulation is a method that combines the processes of extrusion and drying to produce granules from powdered materials. This technique is particularly advantageous for materials sensitive to moisture or heat, as it does not require the addition of water or binders during the granulation process. The process can be broken down into several key stages, each contributing to the final product's quality and characteristics.

Key Components of a Drying Extrusion Granulation Production Line

1. Raw Material Preparation:

- The initial step involves preparing raw materials that typically contain crystal water or have a moisture content of around 5%. The particle size should ideally be between 80 mesh to 300 mesh for optimal granulation. Proper preparation ensures uniformity in the final product.

2. Extrusion Process:

- In this stage, materials are fed into an extruder, where they are subjected to high pressure by counter-rotating rollers. This pressure compacts the materials into large tablets or pellets. The extruder's design can vary based on the material properties and desired output size.

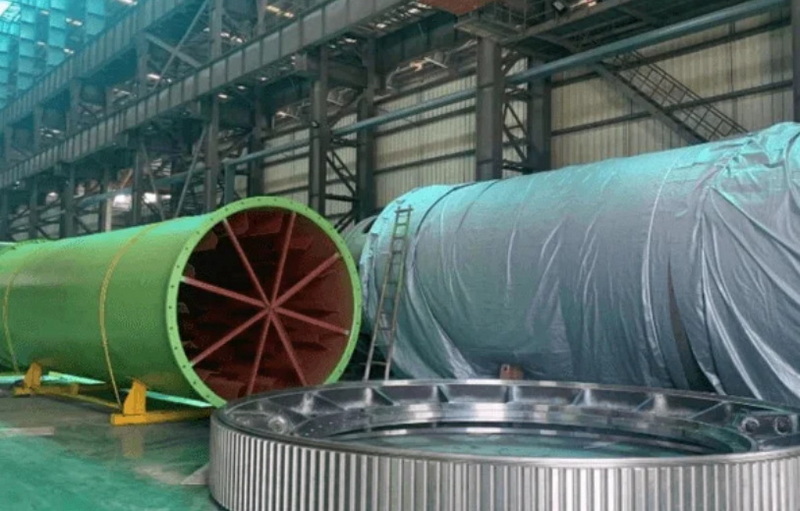

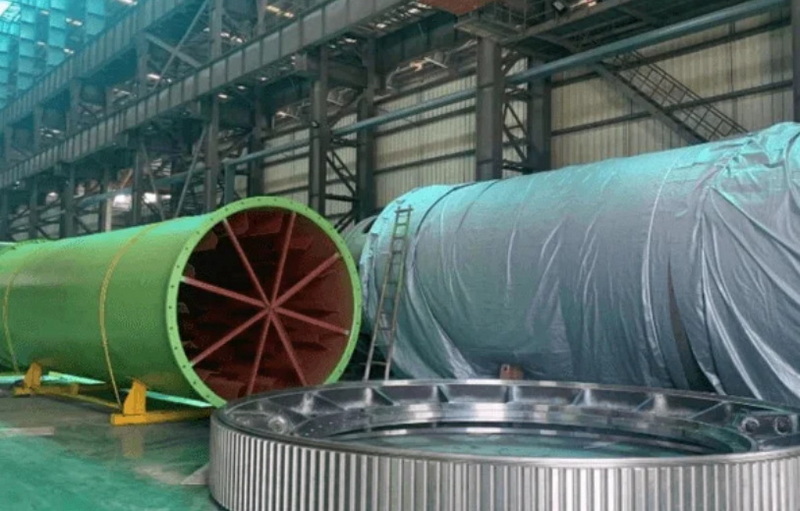

3. Drying Stage:

- After extrusion, the formed pellets are dried using hot air. The drying process is crucial as it removes excess moisture without overheating the pellets, ensuring their structural integrity. Different drying methods can be employed, such as fluidized bed dryers or rotary dryers, depending on the production scale and specific requirements.

4. Cooling Process:

- Once dried, the pellets are cooled to room temperature to prevent deformation or softening due to residual heat. Cooling can be achieved through air cooling or water cooling systems.

5. Screening and Packaging:

- The final stage involves screening the granules for size uniformity and packaging them for distribution. Proper packaging is essential to maintain product quality during storage and transportation.

Advantages of Drying Extrusion Granulation

- No Need for Binders: This method eliminates the need for additional binders, which can affect the purity of the final product. This is particularly important in pharmaceutical applications where product integrity is critical.

- Energy Efficiency: The drying process requires lower temperatures compared to traditional methods, leading to energy savings. This efficiency not only reduces operational costs but also minimizes environmental impact.

- High Production Efficiency: Continuous operation capabilities allow for higher throughput and reduced processing times. This efficiency is vital for meeting market demands without compromising quality.

- Improved Product Quality: The controlled environment during extrusion and drying ensures that the final granules have consistent size and shape, which is crucial for applications requiring precise dosing or mixing.

Applications of Drying Extrusion Granulation

- Fertilizer Production: Used extensively in producing various types of fertilizers due to its ability to handle different raw materials effectively. Granulated fertilizers offer better flowability and ease of application compared to powdered forms.

- Pharmaceuticals: Ideal for producing granules from moisture-sensitive drugs without compromising their efficacy. The uniformity in size also aids in achieving consistent dosing in tablet formulations.

- Food Industry: Employed in creating uniform granules for food additives and supplements. For instance, flavorings and nutritional supplements can benefit from this method as it enhances solubility and dispersibility in food products.

- Chemical Industry: Used for producing granular chemicals that require specific particle sizes for effective application in various chemical processes.

Finding a Drying Extrusion Granulation Production Line

When searching for a drying extrusion granulation production line, consider the following options:

- Manufacturers and Suppliers: Companies specializing in industrial machinery often offer customized solutions tailored to specific production needs. Notable manufacturers include Zhengzhou Shunxin Engineering Equipment Co., Ltd., which provides various models of dry granulators suited for different scales of production.

- Trade Shows and Expos: Attending industry-specific trade shows can provide insights into the latest technologies and equipment available in the market. These events often feature live demonstrations that allow potential buyers to evaluate machinery performance firsthand.

- Online Marketplaces: Websites like Alibaba and Made-in-China feature numerous suppliers offering drying extrusion granulation systems. These platforms allow buyers to compare prices, specifications, and customer reviews before making a purchase decision.

Challenges in Drying Extrusion Granulation

While drying extrusion granulation offers numerous advantages, there are also challenges that manufacturers must address:

- Material Variability: Different raw materials may behave differently during extrusion and drying processes. Manufacturers need to conduct thorough testing to determine optimal conditions for each material type.

- Equipment Maintenance: Regular maintenance is essential to ensure smooth operation and prevent downtime caused by equipment failures. This includes routine checks on extruders, dryers, and cooling systems.

- Energy Consumption: Although energy-efficient compared to other methods, optimizing energy use remains a priority for manufacturers looking to reduce operational costs further.

- Regulatory Compliance: In industries like pharmaceuticals and food production, compliance with regulatory standards is critical. Manufacturers must ensure that their processes meet safety and quality regulations set by authorities such as the FDA or EMA.

Future Trends in Drying Extrusion Granulation

The future of drying extrusion granulation looks promising with advancements in technology:

- Automation: Increased automation in production lines will enhance efficiency by minimizing human intervention while ensuring consistent quality control throughout the process.

- Smart Technologies: Incorporating IoT (Internet of Things) devices will allow manufacturers to monitor equipment performance in real-time, enabling predictive maintenance strategies that reduce downtime.

- Sustainability Practices: As industries strive towards sustainability, innovations aimed at reducing waste generation during production processes will become more prevalent.

Conclusion

The drying extrusion granulation production line is an essential system in modern manufacturing processes across various industries. Its ability to produce high-quality granules efficiently makes it a preferred choice for many manufacturers. By understanding its components and processes, businesses can optimize their production lines for better efficiency and product quality while addressing challenges through innovation and technology advancements.

FAQ

1. What is dry granulation?

Dry granulation is a process that compacts powdered materials into granules without using liquid binders or water. It typically involves mechanical compression through devices like roller compactors.

2. What are the benefits of using a drying extrusion granulation production line?

The benefits include energy efficiency, elimination of binders, high production rates, improved product quality, and suitability for moisture-sensitive materials.

3. What types of products can be produced using this method?

Products include fertilizers, pharmaceuticals, food additives, granular chemicals, and other materials that require uniformity in size and shape.

4. How does the drying process work in this production line?

The drying process uses hot air to remove moisture from extruded pellets while controlling temperature and airflow to prevent overheating.

5. Where can I purchase a drying extrusion granulation production line?

You can purchase these systems from specialized manufacturers, online marketplaces like Alibaba or Made-in-China, or through industry trade shows that showcase machinery suppliers.