Content Menu

● Overview of Aluminum Extrusion

● Key Components of Aluminum Extrusion

● The Aluminum Extrusion Process Steps

>> 1. Die Preparation

>> 2. Billet Preheating

>> 3. Loading the Billet into the Press

>> 4. Extrusion Process

>> 5. Cooling (Quenching)

>> 6. Shearing

>> 7. Further Processing

● Types of Aluminum Extrusion

● Applications of Aluminum Extrusions

● Advantages of Aluminum Extrusion

● Emerging Trends in Aluminum Extrusion

● Challenges in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. What are the main steps in aluminum extrusion?

>> 3. What types of dies are used in aluminum extrusion?

>> 4. How does temperature affect aluminum extrusion?

>> 5. What industries benefit from aluminum extrusions?

● Citations:

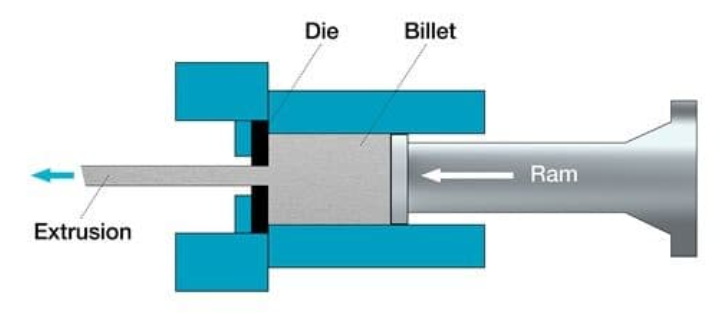

Aluminum extrusion is a manufacturing process that transforms aluminum alloy into specific shapes by forcing it through a die. This process is widely used in various industries, including automotive, construction, and consumer goods. Understanding the aluminum extrusion process in a press machine involves examining the steps involved, the machinery used, and the applications of the finished products.

Overview of Aluminum Extrusion

Aluminum extrusion is akin to squeezing toothpaste from a tube; the aluminum is pushed through a shaped opening (die) to create long profiles with uniform cross-sections. The process allows for a wide range of shapes and sizes, making it versatile for numerous applications.

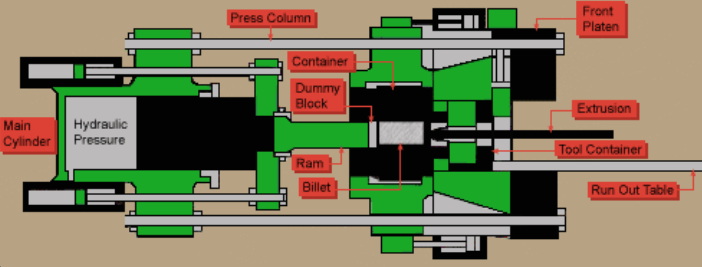

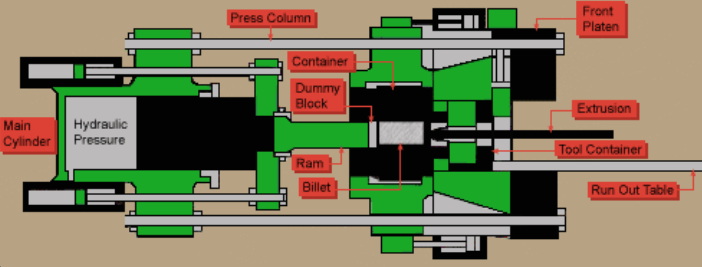

Key Components of Aluminum Extrusion

- Aluminum Billet: A solid cylindrical block of aluminum alloy that serves as the raw material for extrusion.

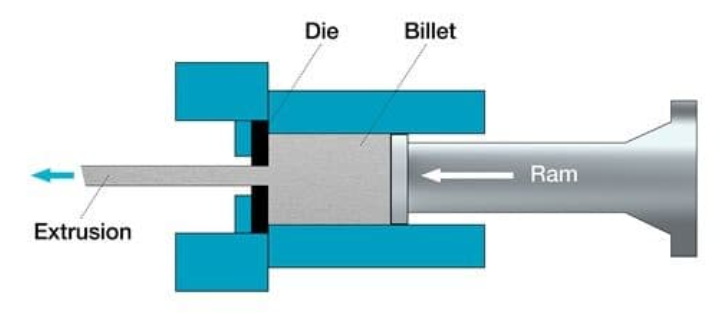

- Extrusion Die: A specially designed tool that shapes the aluminum as it is forced through. The die can have various profiles depending on the desired shape of the extruded product.

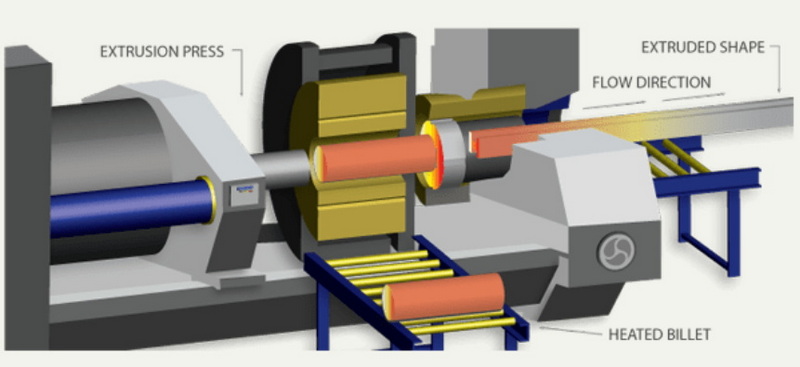

- Extrusion Press: The machine that applies pressure to the aluminum billet to force it through the die. It typically uses hydraulic systems to generate significant force.

The Aluminum Extrusion Process Steps

The aluminum extrusion process can be broken down into several key steps:

1. Die Preparation

Before starting the extrusion process, the die must be prepared. This involves machining a round-shaped die from hardened steel and preheating it to approximately 450-500°C (842-932°F). Preheating ensures even metal flow and maximizes die lifespan.

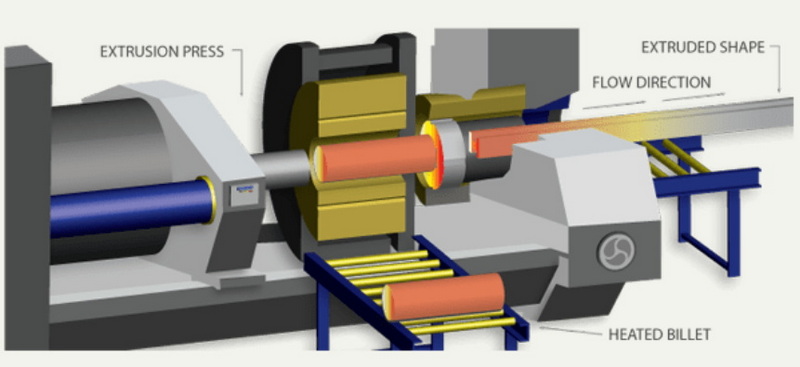

2. Billet Preheating

The aluminum billet is cut from a larger log and preheated in an industrial oven to about 400-500°C (752-932°F). This heating makes the billet malleable enough for extrusion without melting it.

3. Loading the Billet into the Press

Once preheated, the billet is transferred mechanically into the extrusion press. A lubricant or release agent is applied to prevent sticking between the billet and the ram.

4. Extrusion Process

The hydraulic ram applies pressure—often up to 15,000 tons—to push the heated billet into the container of the press. As pressure builds, the aluminum expands to fill the container walls and is pressed against the die. The material then flows through the die opening, emerging as a fully formed profile.

5. Cooling (Quenching)

After exiting the die, the extruded profile is cooled quickly using air or water—a process known as quenching. This rapid cooling helps set the material's shape and properties.

6. Shearing

Once cooled, the extruded profile is cut to length using a hot saw. This step separates it from any remaining material in the press.

7. Further Processing

After shearing, extrusions may undergo additional processes such as stretching (to correct any distortions), aging (to enhance mechanical properties), machining (for precise dimensions), and surface treatment (such as anodizing).

Types of Aluminum Extrusion

There are primarily two types of aluminum extrusion processes:

- Direct Extrusion: The most common method where both the ram and billet move in one direction through a stationary die.

- Indirect Extrusion: In this method, the die moves towards a stationary billet, allowing for better control over temperature and material properties.

Applications of Aluminum Extrusions

Aluminum extrusions are used in various industries due to their lightweight and strong characteristics:

- Automotive: Used for frames, chassis components, and heat exchangers.

- Construction: Employed in window frames, roofing systems, and structural components.

- Consumer Products: Found in furniture, appliances, and packaging materials.

Advantages of Aluminum Extrusion

- Versatility: Can produce complex shapes with high precision.

- Efficiency: The process allows for continuous production of long lengths.

- Sustainability: Aluminum can be recycled without losing its properties.

Emerging Trends in Aluminum Extrusion

The aluminum extrusion industry is evolving rapidly due to technological advancements and changing market demands:

- Digitalization: Manufacturers are adopting digital solutions for real-time monitoring and predictive maintenance to enhance efficiency.

- Sustainability Initiatives: There is a growing focus on reducing carbon emissions throughout production processes by utilizing recycled materials and renewable energy sources.

- Advanced Alloys: Research into new aluminum alloys continues to improve strength, corrosion resistance, and thermal conductivity.

Challenges in Aluminum Extrusion

Despite its advantages, aluminum extrusion faces several challenges:

- Raw Material Costs: Fluctuations in raw material prices can significantly impact production costs.

- Energy Efficiency: The need for energy-efficient technologies is becoming increasingly important as sustainability concerns rise.

- Quality Control: Maintaining consistent product quality amidst variations in alloy composition and processing conditions requires rigorous quality control measures.

Conclusion

The aluminum extrusion process in a press machine is a critical manufacturing technique that produces a wide variety of products used across multiple industries. By understanding each step—from preparation to cooling—manufacturers can optimize production efficiency and product quality. As technology advances, particularly in areas such as automation and sustainability practices, aluminum extrusion will continue to play an essential role in modern manufacturing.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that involves forcing heated aluminum alloy through a shaped die to create specific profiles or shapes.

2. What are the main steps in aluminum extrusion?

The main steps include die preparation, billet preheating, loading into the press, extrusion, cooling (quenching), shearing, and further processing.

3. What types of dies are used in aluminum extrusion?

There are various types of dies used depending on the desired shape—solid dies for simple shapes and hollow dies for complex profiles with voids.

4. How does temperature affect aluminum extrusion?

Temperature plays a crucial role; if too low, it can lead to poor flow; if too high, it may compromise material properties during cooling.

5. What industries benefit from aluminum extrusions?

Industries such as automotive, construction, aerospace, and consumer goods utilize aluminum extrusions due to their lightweight yet strong properties.

Citations:

[1] https://aec.org/aluminum-extrusion-process

[2] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-using-an-aluminum-extrusion-press-in-manufacturing.html

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://www.techbriefs.com/component/content/article/45505-improving-extrusion-press-performance-with-hydraulics-upgrade

[5] https://www.lightmetalage.com/news/industry-news/extrusion/aluminum-extrusion-epds-and-the-push-for-decarbonization/

[6] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[7] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[8] https://kmcaluminium.com/5-machines-essential-for-aluminium-extrusion-production/

[9] https://www.linkedin.com/pulse/nine-main-points-aluminum-extrusion-press-machine-maintenance-

[10] https://www.lightmetalage.com/news/industry-news/extrusion/supporting-extruders-in-navigating-the-environmental-landscape/

[11] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[12] https://asaluminum.com/blog/exploring-the-art-of-aluminum-extrusion-methods-advantages-and-applications/

[13] https://waykenrm.com/blogs/aluminum-extrusion/

[14] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[15] https://www.retop-industry.com/news/aluminum-profile.html

[16] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[17] https://aj-racks.com/blog/uses-and-applications-for-aluminum-extrusions/

[18] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[19] https://www.otalum.com/common-faults-and-solutions-in-the-work-of-aluminum-extruder.html

[20] https://aec.org/extrusion-epdslca

[21] https://rpmindinc.com/step-step-process-making-aluminum-extrusions/

[22] https://inquivixtech.com/aluminum-extrusion-process/

[23] https://extal.com/en/the-evolution-of-aluminum-extrusion-techniques-with-extal/

[24] https://ikin-fluid.com/how-to-maintain-and-manage-extrusion-press-hydraulic-system/

[25] https://www.yjing-extrusion.com/what-are-the-environmental-benefits-of-using-an-aluminum-extrusion-press.html

[26] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[27] https://www.aluminiumalca.com/blog/exploring-the-advantages-and-applications-of-aluminum-extrusion/1/

[28] https://extruderpress.com/aluminum-extrusion-press/

[29] https://gloriaaluminium.com/blog/aluminium-extrusion-demand-challenges-in-2023/

[30] https://aluminiumtoday.com/news/aec-releases-updated-aluminum-extrusion-epds

[31] https://www.youtube.com/watch?v=ELgtjeJyFw8

[32] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[33] https://www.chanjeou.com/product/back-loading-aluminium-extrusion-press-machine

[34] https://www.academia.edu/67204627/A_Case_Study_on_Aluminium_Extrusion_Press_Problems_Identified_and_Probable_Alternative_Solution_for_its_Problem_Related_to_Guideways

[35] https://www.goldapple-alu.com/environmental-practices-of-aluminium-extrusion-suppliers.html

[36] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[37] https://extruderpress.com/aluminum-extrusion-machines/

[38] https://www.linkedin.com/pulse/how-solve-common-faults-aluminum-extrusion-press-wonsten

[39] https://www.researchgate.net/publication/357468251_Reducing_the_environmental_impacts_of_aluminum_extrusion

[40] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/