Content Menu

● Understanding Aluminum Extrusion

● The Aluminum Extrusion Process

● Types of Aluminum Extrusion

● Benefits of Aluminum Extrusion

● Applications of Aluminum Extrusion

● Innovations in Aluminum Extrusion

● Challenges in Aluminum Extrusion

● Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of aluminum extrusion?

>> 2. How does aluminum extrusion compare to other manufacturing processes?

>> 3. What industries use aluminum extrusion?

>> 4. Can aluminum extrusions be recycled?

>> 5. What factors influence the quality of aluminum extrusions?

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that transforms aluminum alloy into specific shapes and profiles. This technique is widely used in various industries due to its versatility, efficiency, and the unique properties of aluminum. In this article, we will explore the aluminum extrusion process in detail, its applications, benefits, and the technology behind it.

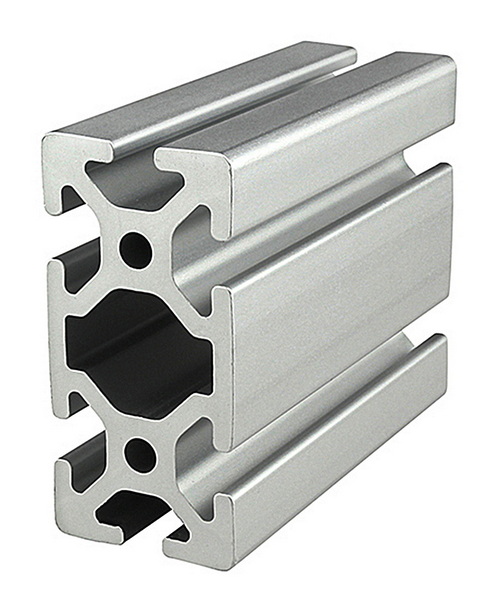

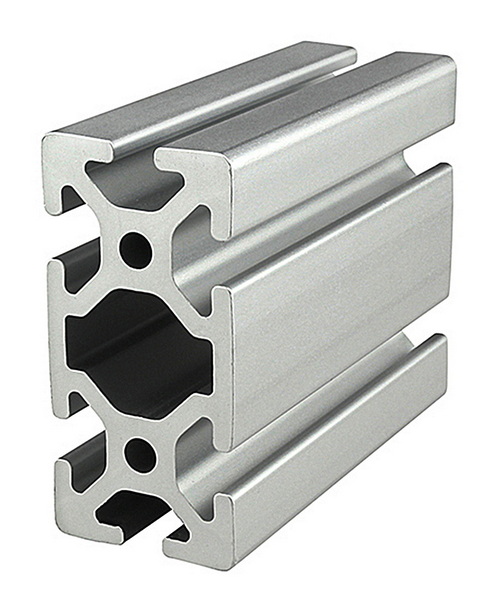

Aluminum extrusion involves forcing aluminum alloy through a die to create a continuous profile with a specific cross-sectional shape. The process begins with a solid aluminum billet, which is heated to a malleable state. Once the aluminum reaches the desired temperature, it is placed in a press, where it is pushed through a die. The die determines the final shape of the extruded aluminum.

The Aluminum Extrusion Process

1. Billet Preparation: The process starts with the selection of an aluminum alloy, which is then cut into billets. These billets are typically around 20 feet long and can weigh several hundred pounds.

2. Heating: The billets are heated in a furnace to a temperature between 800°F and 1,000°F (427°C to 538°C). This heating process makes the aluminum more malleable, allowing it to be easily shaped.

3. Extrusion: Once heated, the billet is placed in the extrusion press. A ram pushes the aluminum through the die, which shapes it into the desired profile. The extrusion can be either direct or indirect:

- Direct Extrusion: The billet is pushed directly through the die.

- Indirect Extrusion: The die moves towards the billet, which remains stationary.

4. Cooling: After exiting the die, the extruded aluminum is cooled, usually by air or water. This cooling process solidifies the aluminum and helps maintain its shape.

5. Cutting and Finishing: The extruded aluminum is then cut to the required lengths. Additional finishing processes, such as anodizing or painting, may be applied to enhance the appearance and corrosion resistance of the aluminum.

Types of Aluminum Extrusion

Aluminum extrusion can be categorized into several types based on the method used and the final product's characteristics:

- Solid Profiles: These are simple shapes like bars and rods, often used in structural applications.

- Hollow Profiles: These include tubes and channels, which are commonly used in construction and manufacturing.

- Complex Shapes: Custom shapes designed for specific applications, such as automotive parts or architectural elements.

Benefits of Aluminum Extrusion

Aluminum extrusion offers numerous advantages, making it a preferred choice in various industries:

- Versatility: The process can create a wide range of shapes and sizes, allowing for customization to meet specific design requirements.

- Lightweight: Aluminum is significantly lighter than other metals, making it ideal for applications where weight is a concern, such as in the aerospace and automotive industries.

- Strength: Despite its lightweight nature, aluminum has a high strength-to-weight ratio, providing durability and structural integrity.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

- Recyclability: Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice.

Applications of Aluminum Extrusion

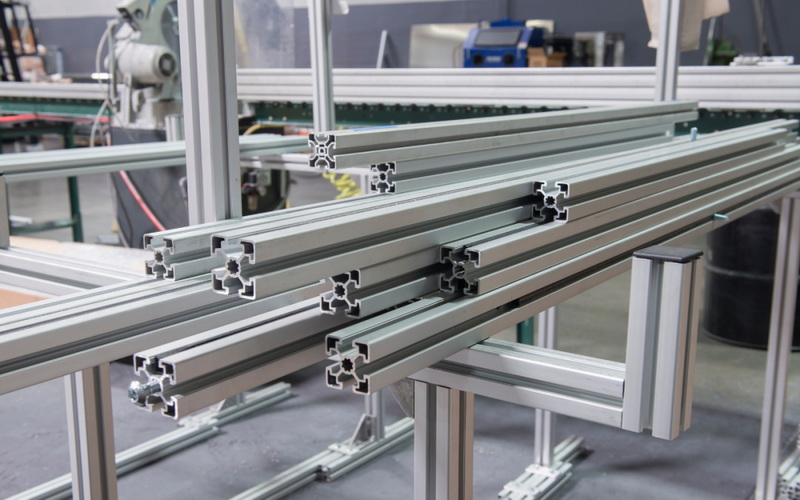

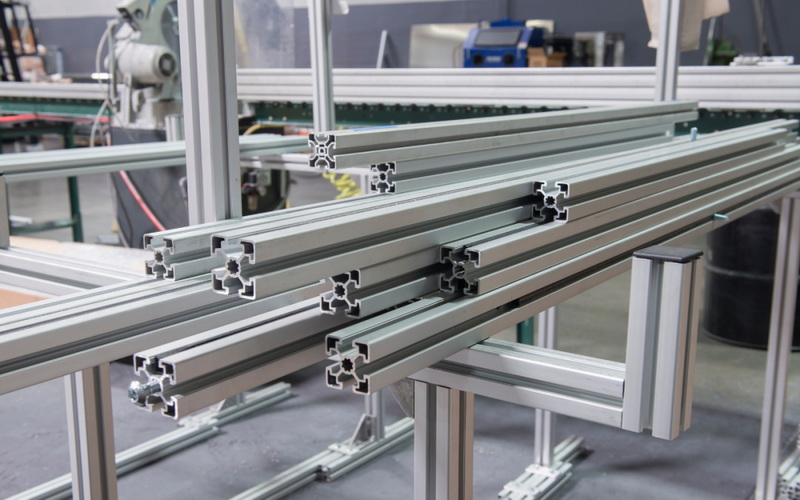

Aluminum extrusion is used in a wide range of applications across various industries:

- Construction: Aluminum extrusions are commonly used in window frames, doors, and structural components due to their strength and lightweight properties. The ability to create custom shapes allows architects and builders to design innovative structures that are both functional and aesthetically pleasing.

- Automotive: The automotive industry utilizes aluminum extrusions for components such as chassis, bumpers, and heat exchangers to reduce weight and improve fuel efficiency. The lightweight nature of aluminum helps manufacturers meet stringent fuel economy standards while maintaining safety and performance.

- Aerospace: In aerospace applications, aluminum extrusions are used for aircraft frames, wings, and other structural components, where weight reduction is critical. The high strength-to-weight ratio of aluminum makes it an ideal material for aircraft, contributing to improved fuel efficiency and performance.

- Electronics: Aluminum extrusions are used in the manufacturing of heat sinks and enclosures for electronic devices, providing effective heat dissipation. The thermal conductivity of aluminum helps manage heat in electronic components, enhancing their performance and longevity.

- Furniture: The furniture industry employs aluminum extrusions for creating lightweight and modern designs in tables, chairs, and shelving units. The versatility of aluminum allows designers to create innovative and functional furniture pieces that are both stylish and durable.

Innovations in Aluminum Extrusion

The aluminum extrusion industry is continuously evolving, with advancements in technology and processes. Some notable innovations include:

- 3D Printing and Extrusion: Combining 3D printing with aluminum extrusion allows for the creation of complex shapes and designs that were previously difficult to achieve. This technology enables manufacturers to produce customized components quickly and efficiently.

- Automated Processes: Automation in the extrusion process enhances efficiency, reduces labor costs, and improves product consistency. Automated systems can monitor and control various parameters during extrusion, ensuring high-quality output.

- Advanced Alloys: The development of new aluminum alloys with enhanced properties, such as increased strength and improved corrosion resistance, expands the range of applications for aluminum extrusions. These advanced alloys can be tailored to meet specific performance requirements in demanding environments.

Challenges in Aluminum Extrusion

While aluminum extrusion offers many benefits, there are also challenges to consider:

- Die Design: The design of the die is critical to the success of the extrusion process. A poorly designed die can lead to defects in the final product, such as uneven thickness or surface imperfections. Engineers must carefully consider the geometry and material of the die to ensure optimal performance.

- Material Costs: The cost of aluminum can fluctuate, impacting the overall cost of production. Manufacturers must stay informed about market trends and pricing to manage their budgets effectively.

- Quality Control: Ensuring consistent quality in extruded products requires rigorous quality control measures throughout the manufacturing process. This includes monitoring the extrusion parameters, inspecting the final product, and conducting tests to verify material properties.

Future of Aluminum Extrusion

The future of aluminum extrusion looks promising, with ongoing research and development aimed at improving processes and expanding applications. As industries continue to prioritize sustainability, the demand for recyclable materials like aluminum is expected to grow. Innovations in extrusion technology, such as the integration of artificial intelligence and machine learning, may further enhance efficiency and product quality.

Additionally, the trend towards lightweight materials in transportation and construction will likely drive the continued adoption of aluminum extrusion. As manufacturers seek to reduce weight and improve energy efficiency, aluminum's unique properties will make it an increasingly popular choice.

Conclusion

Aluminum extrusion is a vital manufacturing process that plays a significant role in various industries. Its ability to create lightweight, strong, and corrosion-resistant products makes it an ideal choice for applications ranging from construction to aerospace. As technology continues to advance, the aluminum extrusion process will likely see further innovations, enhancing its efficiency and expanding its applications.

Frequently Asked Questions

1. What is the main advantage of aluminum extrusion?

The main advantage of aluminum extrusion is its versatility, allowing for the creation of a wide range of shapes and sizes tailored to specific applications.

2. How does aluminum extrusion compare to other manufacturing processes?

Aluminum extrusion is often more efficient than other processes, such as machining, because it produces less waste and can create complex shapes in a single step.

3. What industries use aluminum extrusion?

Aluminum extrusion is used in various industries, including construction, automotive, aerospace, electronics, and furniture.

4. Can aluminum extrusions be recycled?

Yes, aluminum is 100% recyclable, and recycling does not compromise its properties, making it an environmentally friendly material.

5. What factors influence the quality of aluminum extrusions?

Factors such as die design, billet quality, extrusion temperature, and cooling methods can significantly impact the quality of the final product.