Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Using 1/2 Inch Aluminum Extrusion

● Innovative Uses of 1/2 Inch Aluminum Extrusion

>> Structural Frameworks

>> Custom Furniture

>> Automotive Applications

>> DIY Projects

>> Greenhouse Structures

>> Signage and Displays

>> Industrial Applications

>> Lighting Fixtures

>> Aerospace Applications

>> Art and Sculpture

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using 1/2 inch aluminum extrusion?

>> 3. Can I use aluminum extrusion for DIY projects?

>> 4. Is aluminum extrusion suitable for outdoor use?

>> 5. What industries commonly use aluminum extrusion?

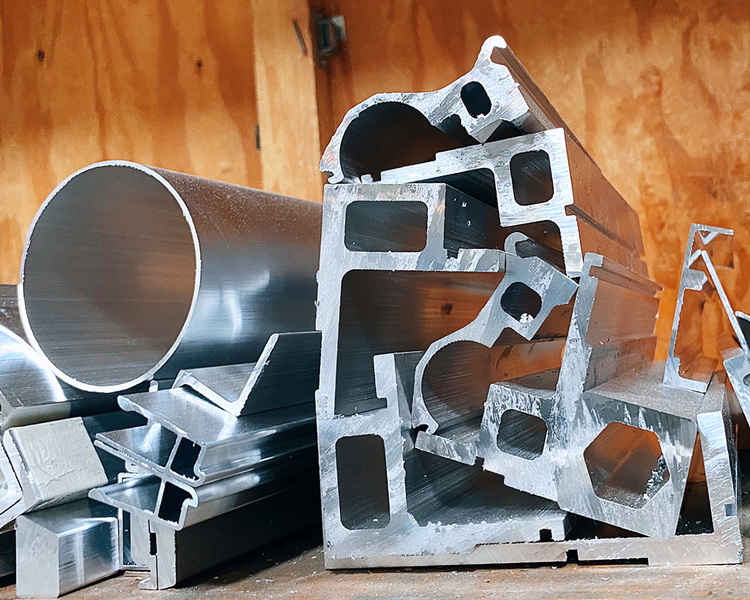

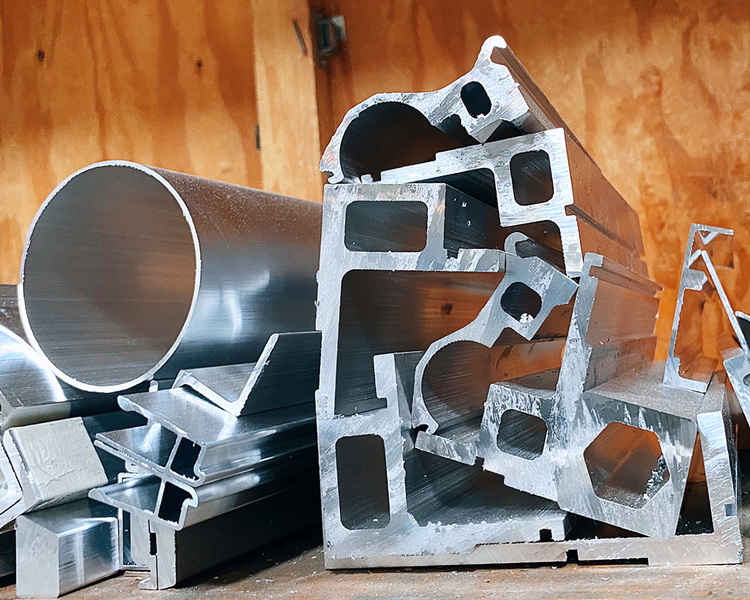

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, lightweight nature, and strength. Among the different sizes available, 1/2 inch aluminum extrusion is particularly popular for a range of innovative applications. In this article, we will explore the various uses of 1/2 inch aluminum extrusion, showcasing its benefits and providing insights into how it can be utilized in creative and practical ways.

Understanding Aluminum Extrusion

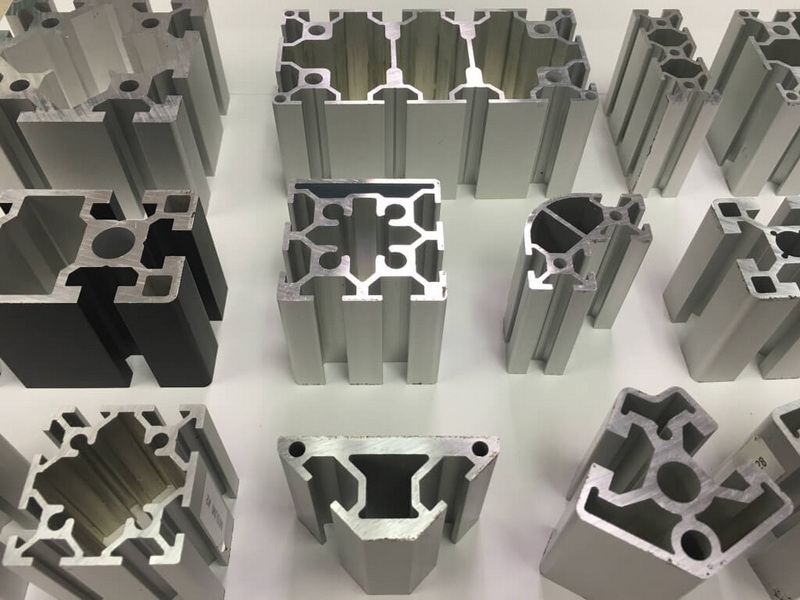

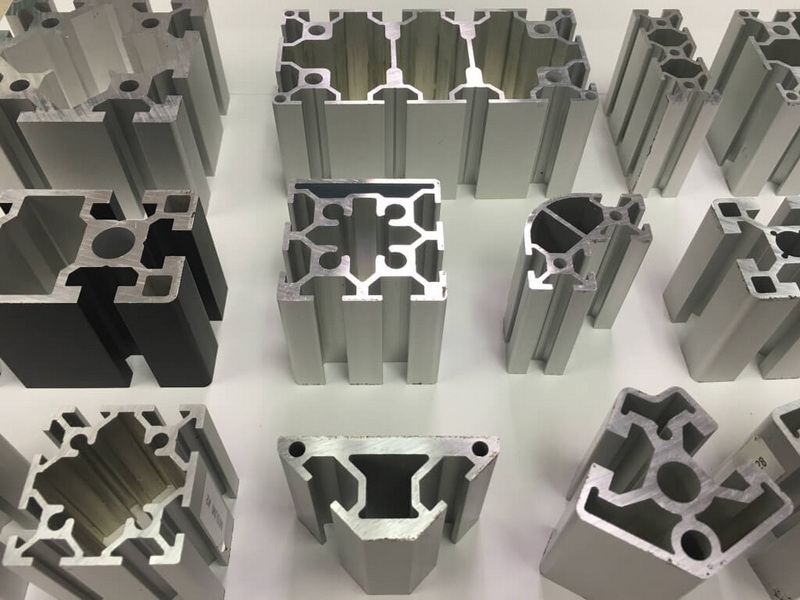

Before diving into the innovative uses of 1/2 inch aluminum extrusion, it's essential to understand what aluminum extrusion is and how it works. The process involves heating aluminum billets until they become malleable and then forcing them through a die to create a specific shape. This method allows for the production of complex profiles that can be used in various applications, from construction to consumer products.

Benefits of Using 1/2 Inch Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion, making it ideal for outdoor applications.

3. Strength: Despite its lightweight nature, aluminum is strong and can withstand significant loads, especially when designed correctly.

4. Versatility: The extrusion process allows for a wide range of shapes and sizes, making it suitable for various applications.

5. Recyclability: Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice.

Innovative Uses of 1/2 Inch Aluminum Extrusion

Structural Frameworks

One of the most common uses of 1/2 inch aluminum extrusion is in the construction of structural frameworks. These frameworks can be used in various applications, including:

- Shelving Units: Aluminum extrusions can be used to create lightweight yet sturdy shelving units for warehouses, garages, or retail spaces. The modular nature of aluminum extrusions allows for easy customization and expansion, making it a popular choice for businesses that require flexible storage solutions.

- Display Stands: Retailers often use aluminum extrusions to build display stands that are both functional and aesthetically pleasing. The sleek design of aluminum can enhance the visual appeal of products while providing a robust structure to support them.

Custom Furniture

The modern design trend leans towards minimalism and functionality, making aluminum extrusion an excellent choice for custom furniture. Designers can create unique pieces such as:

- Tables and Desks: Using 1/2 inch aluminum extrusion, designers can craft sleek and modern tables that are both durable and stylish. The ability to create custom shapes and sizes allows for personalized designs that fit specific spaces and needs.

- Chairs: Aluminum frames can be used to create lightweight chairs that are easy to move and rearrange. This is particularly beneficial in environments where flexibility is essential, such as cafes or co-working spaces.

Automotive Applications

In the automotive industry, weight reduction is crucial for improving fuel efficiency. 1/2 inch aluminum extrusion can be used in various components, including:

- Chassis Components: Aluminum extrusions can replace heavier steel parts, reducing the overall weight of the vehicle. This weight reduction can lead to improved performance and fuel economy, making aluminum a preferred material in modern automotive design.

- Interior Frames: Lightweight aluminum frames can be used in car interiors, providing strength without adding excess weight. This is particularly important in luxury vehicles, where both performance and comfort are prioritized.

DIY Projects

For DIY enthusiasts, 1/2 inch aluminum extrusion offers endless possibilities. Some popular projects include:

- Robotics: Many hobbyists use aluminum extrusions to build robot frames due to their lightweight and customizable nature. The modular design allows for easy adjustments and modifications, making it ideal for experimental projects.

- Home Automation: Aluminum can be used to create frames for home automation systems, such as automated curtains or smart shelving. The ability to design custom solutions can enhance the functionality and aesthetics of home automation projects.

Greenhouse Structures

Aluminum extrusion is an excellent material for building greenhouse structures. Its lightweight nature allows for easy assembly, and its corrosion resistance ensures longevity. Key benefits include:

- Durability: Aluminum can withstand harsh weather conditions, making it ideal for outdoor use. This durability ensures that greenhouse structures remain intact and functional for many years.

- Customizability: Growers can design their greenhouses to fit specific needs, using 1/2 inch aluminum extrusion for frames and supports. This flexibility allows for the creation of unique growing environments tailored to different plants and climates.

Signage and Displays

Aluminum extrusion is widely used in the signage industry due to its lightweight and durable properties. Applications include:

- Directional Signs: 1/2 inch aluminum extrusion can be used to create sturdy directional signs for businesses and public spaces. The ability to customize shapes and sizes allows for clear and effective communication in various environments.

- Display Frames: Retailers often use aluminum frames to hold promotional materials, ensuring they are both secure and visually appealing. The sleek design of aluminum enhances the overall presentation of products and advertisements.

Industrial Applications

In industrial settings, 1/2 inch aluminum extrusion is used for various applications, including:

- Machine Guards: Aluminum extrusions can be used to create protective barriers around machinery, ensuring safety in the workplace. These guards can be designed to fit specific machines, providing tailored protection for workers.

- Workstations: Custom workstations can be built using aluminum extrusion, providing a flexible and durable solution for industrial environments. The modular nature of aluminum allows for easy reconfiguration as needs change.

Lighting Fixtures

Aluminum extrusion is also popular in the lighting industry. Its lightweight and heat-dissipating properties make it ideal for:

- LED Light Fixtures: Designers can create custom LED light fixtures using 1/2 inch aluminum extrusion, ensuring efficient heat management. This is crucial for maintaining the longevity and performance of LED lights.

- Track Lighting: Aluminum tracks can be used for adjustable lighting solutions in homes and commercial spaces. The ability to reposition lights easily allows for versatile lighting arrangements.

Aerospace Applications

In the aerospace industry, weight is a critical factor. 1/2 inch aluminum extrusion is used in various components, including:

- Aircraft Frames: Aluminum extrusions can be used to create lightweight frames for aircraft, improving fuel efficiency. The strength-to-weight ratio of aluminum makes it an ideal choice for aerospace applications.

- Interior Components: Lightweight aluminum can be used for interior fittings, reducing overall weight without compromising strength. This is essential for enhancing the performance and efficiency of aircraft.

Art and Sculpture

Artists and sculptors are increasingly using aluminum extrusion to create modern art pieces. The material allows for:

- Unique Sculptures: Artists can manipulate aluminum extrusions to create intricate and modern sculptures. The versatility of aluminum enables the creation of complex shapes and designs that capture the imagination.

- Functional Art: Designers can create functional pieces that serve as both art and utility, such as benches or decorative screens. This fusion of art and functionality is becoming increasingly popular in contemporary design.

Conclusion

1/2 inch aluminum extrusion is a versatile material that can be used in a wide range of innovative applications. From structural frameworks to custom furniture, automotive parts, and even art, the possibilities are endless. Its lightweight, durable, and corrosion-resistant properties make it an ideal choice for various industries and DIY projects. As technology advances and design trends evolve, we can expect to see even more creative uses for aluminum extrusion in the future.

Frequently Asked Questions

1. What is aluminum extrusion?

- Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile by forcing it through a die.

2. What are the benefits of using 1/2 inch aluminum extrusion?

- The benefits include lightweight, corrosion resistance, strength, versatility, and recyclability.

3. Can I use aluminum extrusion for DIY projects?

- Yes, aluminum extrusion is popular among DIY enthusiasts for building projects like robotics, furniture, and home automation systems.

4. Is aluminum extrusion suitable for outdoor use?

- Yes, aluminum is naturally corrosion-resistant, making it an excellent choice for outdoor applications.

5. What industries commonly use aluminum extrusion?

- Industries such as construction, automotive, aerospace, signage, and furniture design commonly use aluminum extrusion.